Repair Manual For Ford New Holland 8670A, 8770A, 8870A, 8970A Tractors. Illustrations, instructions, diagrams, step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 2105

Bookmarks: Yes

Searchable: Yes

Number:

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Ford New Holland

8670A, 8770A, 8870A, 8970A

Contents

- – General Information

Contents

Foreword

Precautionary Statements

Safety Precautions

Health And Safety Precautions

Tractor Identification

Service Techniques

Sealer Specifications

Hardware Torque Values

Lubrication

Recommended Lubricants And Coolants - – Engine

Specifications

Torque Values

Grease And Sealants

Special Tools

Description Of Operation

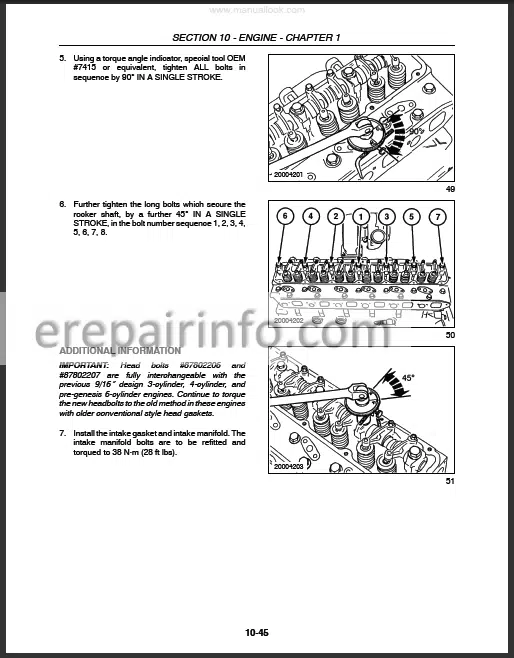

Cylinder Head Assembly

Camshaft Assembly

Crankshaft Assembly

Connecting Rods

Pistons

Manifolds

Cylinder Block Assembly

Timing Gears

Engine Lubrication

Troubleshooting

Disassembly And Repair

Cylinder Head

Cylinder Head Reassembly

Additional Information

Crankcase Front Cassette Seal

Parts Affected

Additional Information

Removal Of Old Style Seal And Installation Of The New Cassette Seal

Front Cassette Seal Removal

Engine Front Cover And Timing Gear

Connecting Rods, Bearings, Pistons And Rings

Cylinder Block Overhaul

Piston Assembly Installation

Main Bearings, Flywheel And Crankshaft

Rear Cover Plate

Oil Pump

Oil Filter Support Assembly

Crankshaft

Camshaft

Engine Timing Gears

Engine Compression Test

Test Procedure

Test Reading

Test Conclusion

Cooling System

Troubleshooting

Disassembly And Repair

Radiator

Thermostat

Temperature Warning Sender

Fan Blade

Viscous Clutch Assembly

Fan Belt Tensioner

Idler Pulley

Waterpump

Turbocharger

Intercooler

Troubleshooting

Intercooler Leak Test

Disassembly And Repair

Air Cleaner

Turbocharger

Intercooler

Fuel System Torque Chart

Special Tools

Description Of Operation

Testing And Diagnosis

Low-Pressure Fuel System

Fuel Tank Valve(S)

Filter Inlet And Outlet Pressure Tests

High-Pressure Fuel System

Injection Timing Check

Fuel Injector Nozzle Check, Engine Running

Injector Assembly Bench Testing

Preliminary Setup Procedure

Perform Opening Pressure Test

Perform Nozzle Seat Leakage Test

Perform Chatter And Spray Pattern Test

Surging

Fuel Shutoff Diagnosis

Shutoff Solenoid Specifications

Preliminary Checks

Checking Electrical Feed

Adjustments

Bleeding The Fuel System

Adjustment Of Foot And Hand Throttle Cables

Adjustment Of High Idle Speed

Adjustment Of Low Idle And Antisurge

Removal And Installation

Fuel Lift Pump

Fuel Shutoff Solenoid

Fuel Injection Pump

Fuel Injection Lines

Low-Pressure Fuel Injection Lines

High-Pressure Fuel Lines

Injector Leak-Off Line

Fuel Filter

Fuel Filter Manifold

Injection Nozzles

Lower Tank Removal

Lower Tank Installation

Top Tank Removal

Top Tank Installation - – Transmission

Powershift Transmission

Gearratios

Ground Speed

Electrical System

Description Of Operation

Transmission Housing

Powershift Transmission Controls

Digital Display

Inching Pedal

Starting The Engine And Moving Forward

Starting The Engine And Moving In Reverse

Shuttle Operations

Speed Matching

Auto Shift

Creeper Gears (Optional)

Programmable Upshift – Downshift

Transmission Components

Clutches

Speed Clutches

Directional Clutches

Clutch Engagement

Troubleshooting And Diagnosis

Disassembly And Repair

Engine And Side Rail Separation From The Transmission

Four-Wheel Drive Shaft Removal (If Equipped)

Engine And Side Rail Reassembly

Rear Housing And Directional Clutches – Removal

Front Housing And Speed Clutches – Removal

Main Input Gear Assembly – Removal

Speed Clutches – Disassembly

Speed Clutches – Inspection

Directional Clutches – Disassembly

Directional Clutches – Inspection And Overhaul

Speed Clutches And Directional Clutches – Reassembly

Main Input Gear And Oil Seal – Disassembly Inspection, Overhaul And Reassemble

Two Gear Clusters In Front And Rear Housing -Disassembly, Inspection And Reassembly

Front And Rear Housings And Center Section -Inspection And Overhaul

Torque Limiting Clutch And Sprung Damper Hub Drive Assembly – Removal, Inspection And Replacement

Reassembly

Speed Clutches And Front Housing

Directional Clutches And Rear Housing

Transmission Shimming

Front Housing Shimming

Rear Housing Shimming

Shimming The Output Shaft

Creeper Gear

Creeper Gear Repair

Specifications

Low-Pressure Hydraulic System

Special Tools

Description Of Operation

Regulator Valve Operation

Clutch Valve Operation

Modulator Valve Operation

Electro-Hydraulic Pilot Line

Troubleshooting And Diagnosis

70/70A Series Transmission Test Sheet

Electrical7Electronic System Checks

70/70A Series Transmission Test Sheet Hydraulic System Checks

Clutch Apply Pressure Chart

Pressure Testing And Adjustments

Clutch Apply Circuit Pressure Testing

Transmission Pressure Checklist

Transmission Programming

Programming The Programmable Upshift, Downshift

Programming Reverse Gear Ratios

Transmission Calibration

Check Powershift Transmission Clutch Calibration

Calibration Review

Calibrate Directional Clutch

Calibrate Reverse Directional Clutch

Calibration Mode

Calibration Of Shift Constant

Disassembly And Repair

Removal And Disassembly

Removal Of The Complete Valve Assembly From The Tractor

Disassembly

Solenoid And Valve Assembly

Speed And Directional Clutch Circuit Valves

Modulator Valves

Regulator Valve

Lubrication And Cooling Circuit Relief Valve

Electrical System

Description Of Operation

Clutch Apply Circuits

Modulation Solenoids

Shift Control Lever

Inching Pedal

Speed Sensors

Display Module

Troubleshooting And Diagnosis

Transmission Solenoid And Pressure Testing

Disassembly And Repair

Control Valve Solenoids

Speed Sensors

Chassis Control Module (Ccm)

Inching Pedal Switches

Transmission Shift Control - – Drive Lines

70 Series Fwd Electric Control Operation

70A Series Fwd Electric Control Operation

Engaging And Disengaging Four Whee Drive

Fwd Operating Precautions - – Front Mechanical Drive

Wheel ToeIn

Fwd Steering Stop

Hub Bearing Preload Adjustment

Check For Correct Pinion To Ring Gear Tooth Contact

Wrong Tooth Contact Pattern

Swivel Pin Bearing Adjustment

Fwd Ratios

Fwd Tire Vs Gear Ratios

Four Wheel Drive Lead Factor

Front Axle Serviceability

Lubrication

Disassembly And Repair

Front Axle

Steering Cylinders

Planetary Reduction

Hub

Swivel Housing

Center Housing Swivel Bearing

Drive Shaft

Outer Yoke

Differential

Crown Wheel To Backlash Adjustment - – Rear Drive Axle

Differential Carrier

Final Reduction Drive

Differential Lock Mechanical Operation

Differential Lock Control System Operation

Differential Lock Electrical Circuit Operation

Differential Lock Hydraulic Circuit Operation

Front Axle Differential Line

Troubleshooting

Adjustments

Disassembly And Repair

Axle Assembly

Axle Housing

Planetary Overhaul

Axle Seal

Top Cover

Pinion Assembly

Differential Lock Solenoid

Pressure Testing

Circuit Pressure Test - – Power Take-Off

Power Flow All Models

Engaging And Disengaging The Pto

Troubleshooting And Diagnosis

Disassembly And Repair

Pto Assembly Removal And Installation

Upper Pto Input Shaft Removal And Installation

Pto Output Shaft And Driven Gear Overhaul

Pto Clutch Assembly Overhaul - – Brakes And Controls

Boosters

Master Cylinders

Rear Axle Brake Assemblies

Four Wheel Braking

Troubleshooting

Bleeding The Brakes

Brake Pedal Adjustment

Brake Switch Adjustment

Disassembly And Repair

Power Brake ValveOverhaul

Installation Of The Brake Lube Kit

Rear Axle BrakesOverhaul

Hydraulic Trailer Brake - – Hydraulic Systems

Closed Center Load Sensing (Ccls) Pump And Remote Valve System

Standard Flow Hydraulic System

Megaflow Hydraulic System

Variable Displacement Pump

Priority Flow Divider

Remote Control Valves

Standard Flow Tractors

Megaflow Tractor

LowPressure Return Circuit - – Steering

Steering System Control Valve

Steering Control Valve Types

Steering Cylinders

Troubleshooting

Removal And Disassembly

Steering Control Valve

Parts Inspection

Assembling The Steering Control Unit

Installing The Steering Control Valve - – Two-Wheel Drive Axle And Wheels

Front Wheel Track Spacing

Axle Adjustment

Front Wheel Position

Front Wheel Toein

Disassembly and Repair

Axle Removal

Axle Installation

Axle Center Beam Bushing Replacement

Axle Extension Installation

Spindle Removal and Disassembly

Axle Extention/Spindle Bushing Replacement

Spindle Reassembly

Front Wheel Bearing

Steering Cylinder

Center Steering Arm

Steering Rod - – Climate Control

Tightening Torques

Description Of Operation

Air Conditioning System Components

Troubleshooting And Servicing Air Conditioning System

Primary Troubleshooting And Testing

Diagnosis Chart

A/C System Performance Test And Diagnosis Chart

Component Removal And Installation - – Electrical Systems

Main Distribution Panel

Service Diagnostics

Electronic Instrument Cluster (Eic)

Central Lcds

Tractor Performance Monitor

Automatic Engine Shutdown

Series Indicator, Warning Lamps And Audible Alarm

Air Filter Restriction

Differential Lock

Cold Start Assist

Coolant Level Low

Alternator Charge Indicator

Intercooler Overheated

Transmission Pressure Low

Transmission, Rear Axle/Hydraulic Oil Temperature

Hydraulic/Transmission Filters Restricted

Pto Engaged

Programmable Up Shift

Programmable Down Shift

Fwd On

Fwd Auto

Four Wheel Drive (Fwd) Switch (If Equipped)

Headlight High Beam

System Status

Parking Brake

Bar Graph Displays (Lcd)

Stop And Audible Alarm Conditions

Central Display (Lcd)

Lower Selectable Display

Electronic Instrument ClusterTractor Performance Monitor (Tpm)

Automatic Display Information

Selectable Display Information

Eic Lighting Display

Troubleshooting And Diagnostics

Eic Harness Tool

Operator Calibrations

View Stored Fault Codes

All Module Input Parameters

Eic Output Diagnostics

Rhc Output Diagnostics

Edc Output Diagnostics

Etc Output Diagnostics

Eic Full Display Test

Hardware/Software Revision Level

Transmission Calibration Review And Programming

Point Hitch And Edc Calibration

Tractor Features Configuration

Steering Angle Sensor Operation/Calibration (A Series) - – Platform, Cab, And Bodywork

Headliner

Cab Trim

Seat

Door Removal

Rear Window

Instrument Cluster

Steering Column

RightHand Console

Procedures For RightHand Console Upgrade

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Supert.