Factory Service Manual For Gehl And Mustang Compact Track Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 353

Number: 50950457 (july 2019)

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Gehl And Mustang Compact Track Loader

GEHL RT105

MUSTANG 1050RT

Contents

Introduction

Contents And Use Of This Manual

Machine Orientation

Machine Controls And Operation

Component Identification

Machine Model And Serial Number Locations

Indicator And Operation Symbols

Safety

Safety Symbol And Signal Words

Mandatory Safety Shutdown Procedure

Before Starting

During Operation

Applications With Load-Handling Devices

Parking The Machine

Electrical Energy

Maintenance And Service Safety Practices

Battery Hazards

Fire Hazards

Additional Safety Equipment

Crystalline Silica Exposure

Transporting The Machine

Lifting The Machine With A Crane

Loading And Transporting The Machine

Safety Decals And Locations

Lifting The Machine Using A Crane

Loading And Transporting The Machine On A Transport Vehicle

Lubrication

Types Of Lubricants

Lubricant Capacities

Lubrication Points

Lubrication Schedule Intervals

Filter Table

General Information

Hydraulic Oil Reservoir

Crankcase Oil

Grease Fitting Locations

Engine Cooling System

Maintenance

Maintenance Schedule

Engine Maintenance

Engine Access Cover

Engine Oil

Dpf Exhaust System Service

Fuel System Maintenance

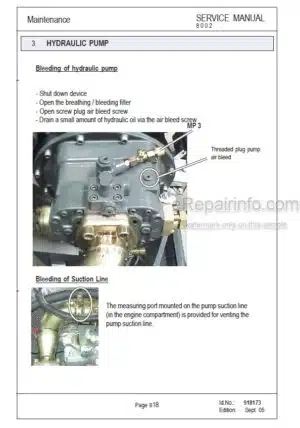

Hydraulic System Maintenance

Hydraulic Hose Maintenance

Travel Motor Maintenance

Tracks

Electrical System

Windshield Washer Reservoir

Long-Tenn Storage

Final Shutdown / Decommissioning

Engine

General Information

Engine Access

Engine Maintenance

Engine Components

Adjustments

Engine Removal Installation

Radiator/Cooler Removal Installation

Air Filter Housing Removal/Lnstallation

Fan Shroud Removal Installation

Engine Fan Removalinstallation

Starter Removal Installation

Battery Removal/Lnstallation

Troubleshooting Guide

Engine Error Codes

Hydrostatic System

Introduction General Infoimation

General Hydraulic Service Notes

Hydraulic Oil Analysis

Theory Of Operation How It Works

Hydrostatic System Components

Hydrostatic Pump Removal/Installation

Hydrostatic Pump Drive Coupler Removal Installation

Bogie Wheels Removal/Installation

Track Removal Installation

Track Tension Cylinder Removal Installation

Sprocket Removal Installation

Front Idler Wheel Removal Installation

Travel Drive Motors

Tracks

Troubleshooting

Hydraulic System

Introduction General Information

General Hydraulic Service Notes

Hydraulic Oil Analysis

Hydraulic System Components

Main Pressure Test And Adjustment

Gear Pump Removal Installation

Control Valve Removal Installation

Lift Solenoid Valve Removal Installation

Solenoid Valve Test

Tilt Solenoid Valve Removal Installation

Brake Solenoid Valve Removal Installation

Tilt Cylinder Test

Lift Cylinder Removal Installation

Self-Leveling Valve Test

Self-Leveling Valve Removal Installation

Troubleshooting

Hydrostatic /Hydraulic Schematic

Chassis Electrical Schematic (1 Of 2) (Some Overlap With 2 Of 2 Drawing)

Chassis Electrical Schematic (2 Of 2) (Some Overlap With 1 Of 2 Drawing)

Rops Fops Electrical Schematic (1 Of 2) (Some Overlap With 2 Of 2 Drawing)

Rops Fops Electrical Schematic (2 Of 2) (Some Overlap With 1 Of 2 Drawing)

Stall Box Jumper Electrical Schematic

Chassis Hamess Wiling Diagram – Dpf Models

Rops/Fops Wiling Hamess Diagram – Dpf Models

Door Harness Wiring Diagram

Rear Wiper Hamess Diagram

Rops/Fops Wiling Hamess Diagram – Non-Dpf Models

Chassis Hamess Wiling Diagram – Non-Dpf Models

Rear Lights Hamess

Electrical Controls System

Electrical Control System General Infoimation

Control Modules

Can System Service/Computer Connection

Operation Controller Area Network (Can) Functional Organization

Can/Control System Troubleshooting

Indicator Lamp Troubleshooting

Electrical System

Battery

Introduction

Components

Power Distribution

Control Modules And Connectors

Component Tests

Light Bulb Replacement

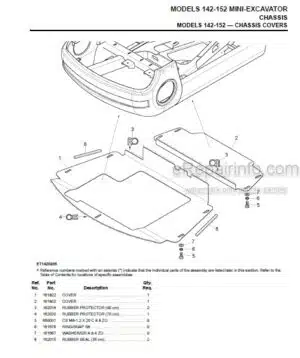

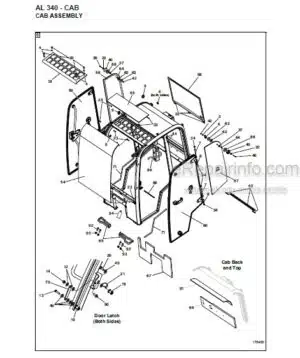

Cab

Control Locations

Components

Control Adjustments

Rops Tops Cab

Tilt Rops/Fops

Ropstops/Cab Removal

Ropstops Installation

Restraint Bar Removal Installation

Hitch Removal/Lnstallation

Floor Plate Removal/Lnstallation

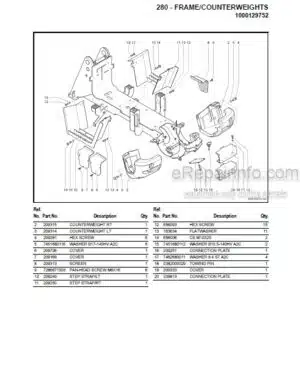

Crossmember Removal Installation

Pivot Tube Assembly Removal Installation

Pivot Tube Assembly Installation

Lift Tilt Control Removalinstallation

Electronic Foot Throttle Removal Installation

Seat Removal/Lnstallation

Control Handle Removal Installation

Heater Removal Installation

Programmed Display Removal Installation

Operator Presence Switch Removal Installation

Restraint Bar Switch Removal Installation

Lift Arm

Introduction

Notes

Lift Ann Components

Lift Ann Adjustments

Lift Aim Support

Lift Aim Removal

Lift Aim Installation

Specifications

Fluids Lubricants Types And Capacities

Dimensions

Payloads Capacities

Weights

Coolant Compound Table

Track Drive

Engine

Hydraulic System

Sound Power Pressure Levels

Vibration Levels

Torque Specifications

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet