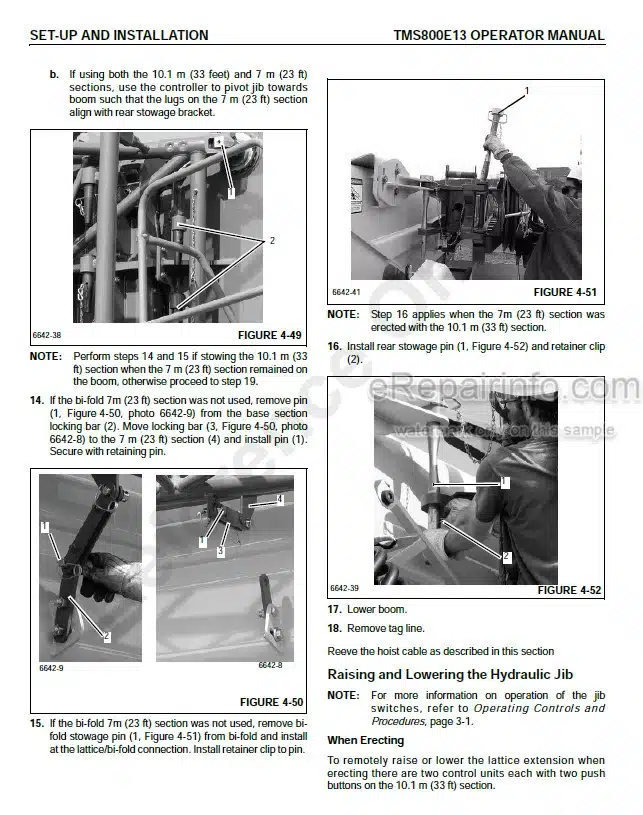

Factory Service Manual For Grove Crane. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG; ESP

Quantity of Manuals: 3

Pages: 390; 412

Number: CTRL649-01 (february 2019); CTRL649-02 (july 2020) ; CTRL649-00 (february 2019)

Bookmarks: Yes

Searchable: Yes

Model

Grove Crane

TMS9000-2

Contents

-GENERAL INSTRUCTIONS

Using the Service Manual

Safety Messages

Manitowoc CraneCare Service Instructions

Definitions of stated directions

Breaking in a New Crane

Safety Rules

Handling Substances which are Harmful to the Environment

Overview of the Operating and Display Elements

Axle Weight Distribution Table

Cleaning

Overview of the Components that are Easily Damaged when Cleaning

Fasteners and Torque Values

Torque Wrenches

Torque Values

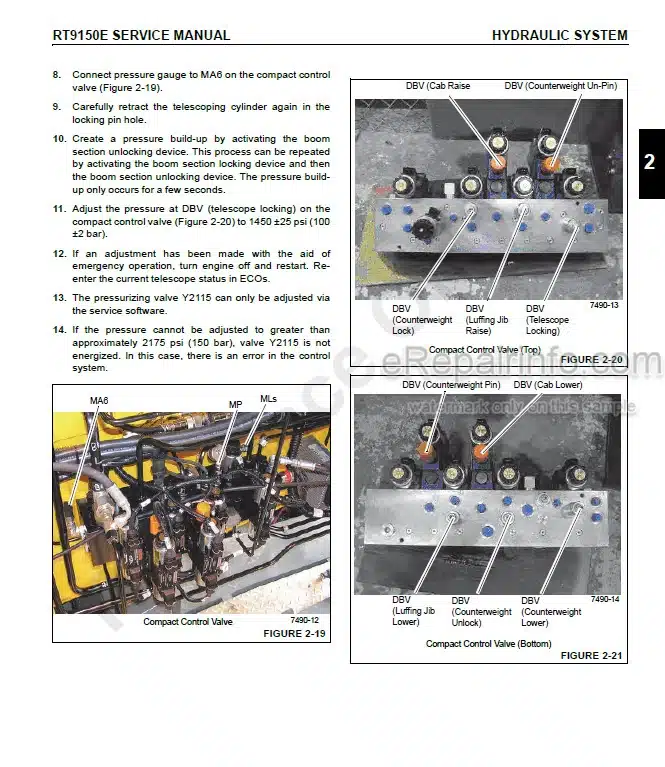

-HYDRAULIC SYSTEM

Description

Supply Pressure and Return Circuit

Maintenance

Return Hydraulic Filter Assembly

Hydraulic Pumps

Carrier Valves

Outrigger Selector-A/C Manifold Valve

Outrigger Control Manifold

Pilot Operated Check Valve

Superstructure Valves

Hydraulic system of the superstructure

Cylinders

Steer Cylinder

Outrigger Extension Cylinder

Outrigger Jack Cylinder

Center Front Jack Cylinder

Lift Cylinder

Counterweight Cylinder

Telescope Cylinder

Pressure Setting Procedures

-ELECTRICAL SYSTEM

Description

Maintenance

Switch Replacement

Windshield Wiper Assembly Replacement

Windshield Washer Assembly Replacement

Remote Controller (Optional)

Jump Starting the Crane

-SUPERSTRUCTURE

Description Of Maintenance Work On The Superstructure

Boom Removal

Boom Installation

Boom Nose Sheaves

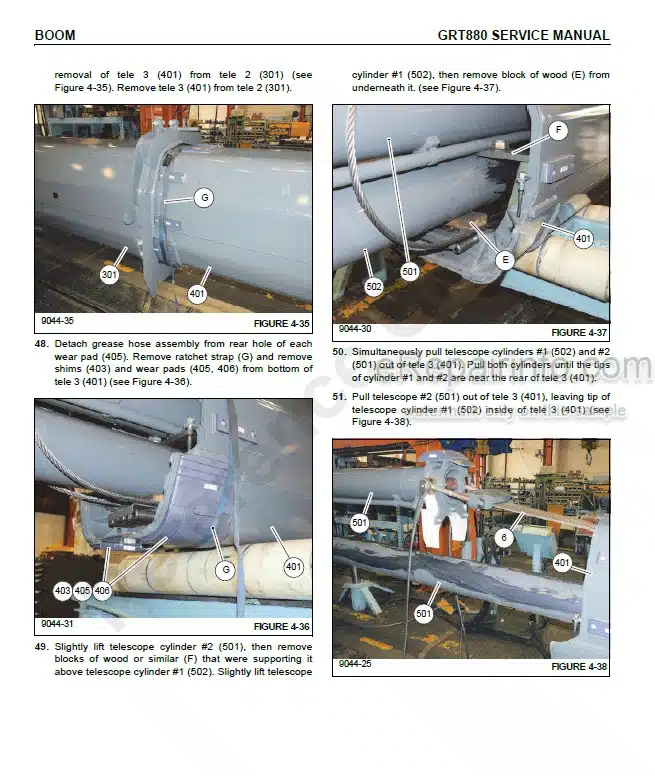

Boom Disassembly

Boom Assembly

Pinning Boom Components

Mechanical Emergency Unlocking And Locking Of The Telescopic Sections

New York House Lock

Bleeding The Telescoping Cylinders

Telescope Slide Pad Adjustment

Check The Locking System

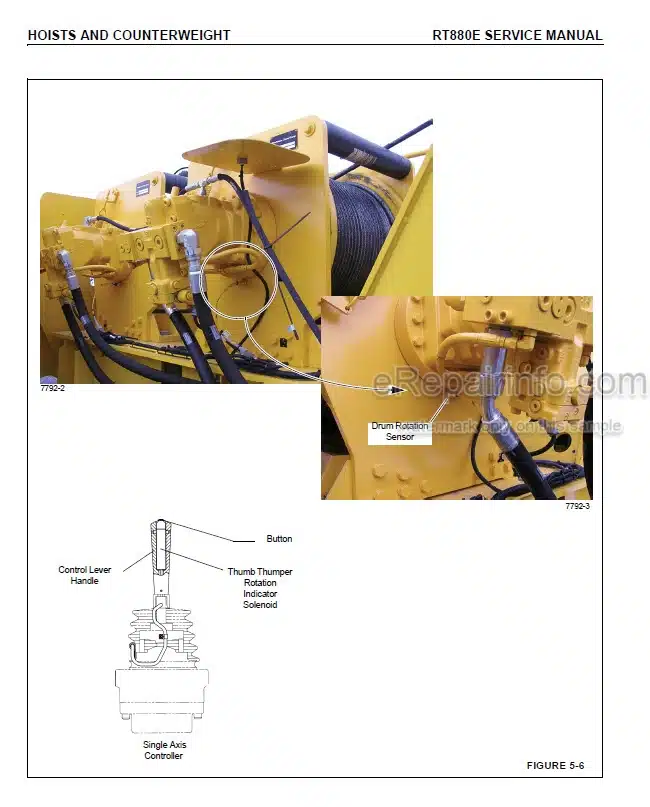

Hoist Ropes

Wire Rope Inspection/Replacement (All Wire Rope)

Rated Capacity Limiter

Superstructure Air Conditioning System (Additional Equipment)

Other Maintenance Work

-SUPERSTRUCTURE MAINTENANCE

Superstructure Maintenance Overview

Maintenance Intervals

Maintenance Plans

Periodic Inspections

Measures Required For Hoist Monitoring

-SWING SYSTEM

Description

Theory of Operation

Maintenance

Swing Box Assemblies

Swing Bearing

Swivels

Swing Lock Pin

360° Swing Lock Control (Positive Lock Type)

-POWER TRAIN

Engine

Maintenance

Engine Control System

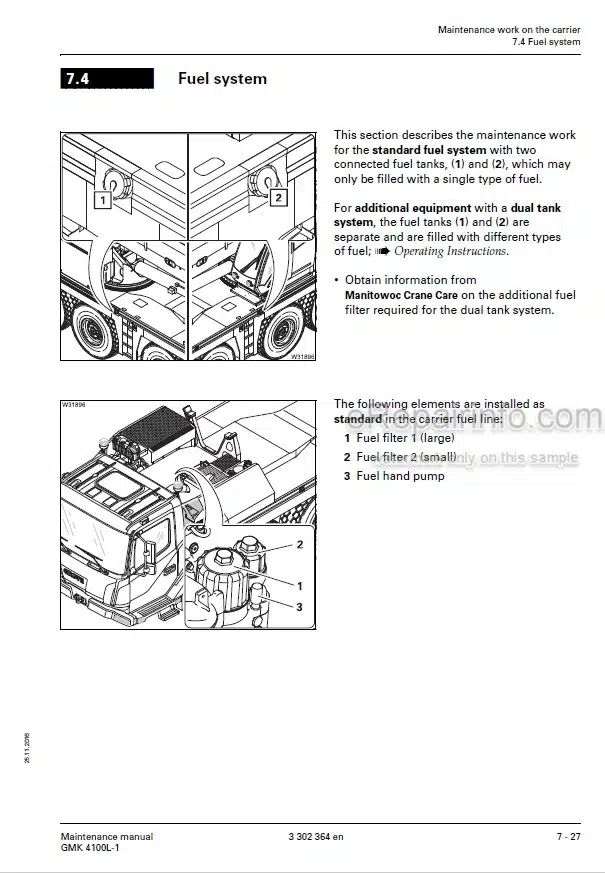

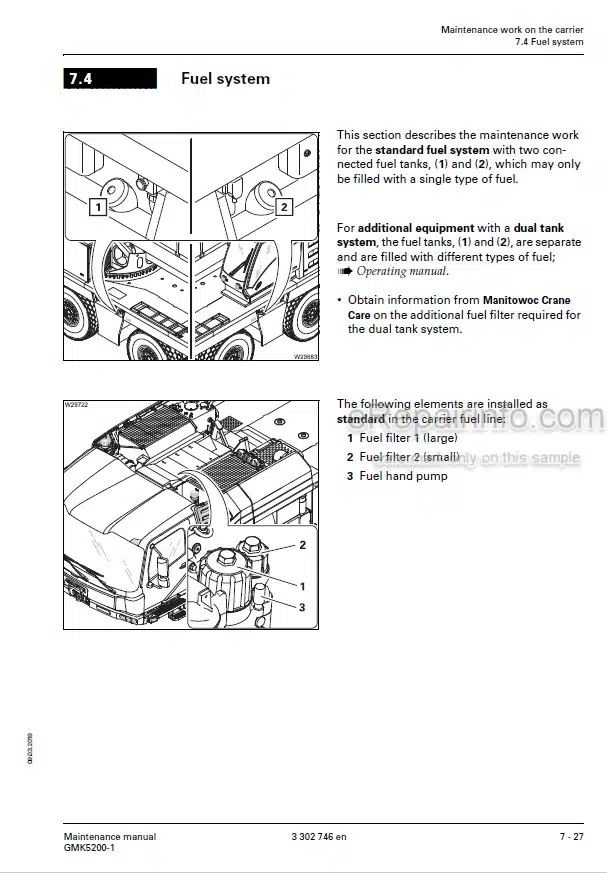

Fuel System

Air Intake System

Exhaust System

Aftertreatment Diesel Exhaust Fluid (DEF)

Water Cooling System

Drive Train

Maintenance

Clutch

Gearshift

Manual Transmission

Transmission Shift Air System

Pump/PTO Assembly

-CARRIER

Front Axle

Maintenance

Steering System

Steering Pump

Steer Cylinder

Wheels and Tires

Rear Axle and Suspension

Wheels and Tires

Maintenance

Air System

Brakes

Non-Asbestos Warning

Front Brakes

Automatic Slack Adjuster

Rear Brakes

Anti-Lock Brake System (ABS)/ Automatic Traction Control (ATC)

Special Tools

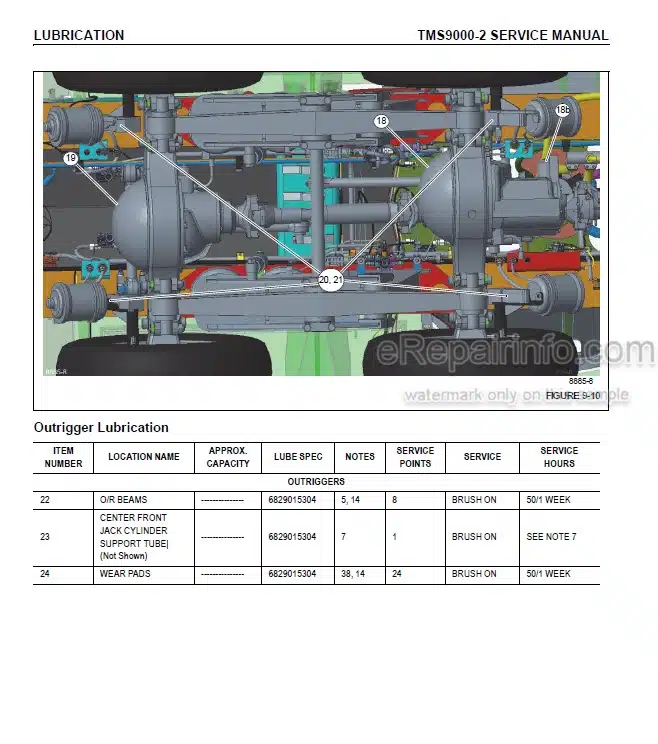

Outriggers

Outrigger Jack Cylinders

Center Front Jack Cylinder

Outrigger Monitoring System (Optional—Standard in North America)

-LUBRICATION

General

Lubrication Points

Carwell Rust Inhibitor

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet