Factory Service Repair Manual For Hitachi EX400-3 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 914

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi EX400-3

Contents

Workshop Manual

- SAFETY

- -GENERAL INFORMATION

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

–TIGHTENING TORQUE

Tightening Torque Specification

Torque Chart - -UPPERSTRUCTURE

–CAB

Remove and Install Cab

Dimensions of the Cab Glass

–COUNTERWEIGHT

Remove and Install Counterweight

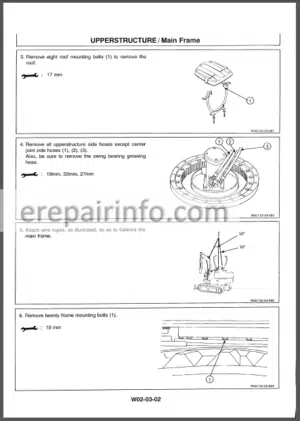

–MAIN FRAME

Remove and Install Main Frame

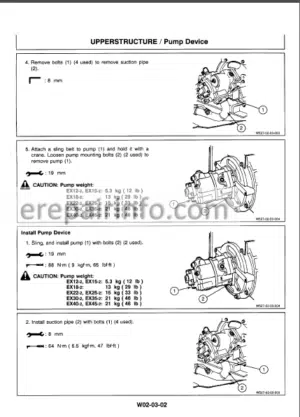

–PUMP DEVICE

Remove and Install

Pump Device

Disassemble Pump Transmission

Assemble Pump Transmission

Disassemble Main Pump

Assemble Main Pump

Maintenance Standard

–CONTROL VALVE

Remove and Install

Control Valve

Disassemble Control Valve

Assemble Control Valve

–SWING DEVICE

Remove and Install Swing Device

Disassemble Swing Reduction Gears

Assemble SwingReduction Gears

Disassemble Swing Motor

Assemble Swing Motor

Maintenance Standard

–PILOT VALVE

Remove and Install Left Pilot Valve

Remove and Install Right Pilot Valve

Disassemble Right and Left Pilot Valve

Assemble Right and Left Pilot Valve

Remove and Install Travel Pilot Valve

Disassemble Travel Pilot Valve Assemble Travel Pilot Valve

–PILOT SHUT-OFF VALVE

Remove and Install

Pilot Shut-off Valve

Disassemble Pilot Shut-off Valve

Assemble Pitot Shut-off Valve

–SHOCKLESS VALVE

Remove and Install Shockless Vatve (for Digging/Swing)

Disassemble and Assemble Shockless Valve (for Digging/Swing)

Remove and Install Shockless Vatve (for Traveling)

Disassemble and Assemble Shockless Valve (for Traveling)

–ACCUMULATOR

Remove and Install Accumulator

–Solenoid Valve

Remove and Install Solenoid Valve Unit

Disassemble and Assemble Solenoid Valve Unit

–SHUTTLE VALVE

Remove and Install Shuttle Valve

Disassemble and Assemble Shuttle Valve

–SWING DAMPENER VALVE

Remove and Install Swing Dampener Valve

Disassamble Swing Dampener Valve

Assemble Swing Dampener Valve

Disassemble Valve

Assemble Valve - -UNDERCARRIAGE

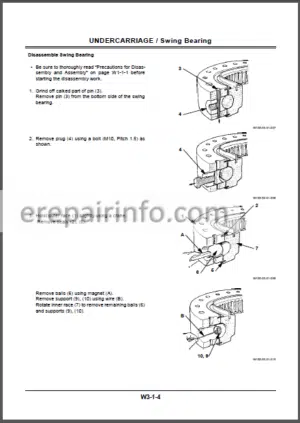

–SWING BEARING

Remove and Install

Swing Bearing

Disassemble Swing Bearing

Assemble Swing Bearing

–TRAVEL DEVICE

Remove and Install Travel Device

Disassemble Travel Device

Assemble Travel Device

Disassemble Travel Motor

Assemble Travel Motor

Disassemble Brake Valve

Assemble Brake Valve

Maintenance Standard

–CENTER JOINT

Remove and Install Center Joint Disassemble Center Joint

Assemble Center Joint

Maintenance Standard

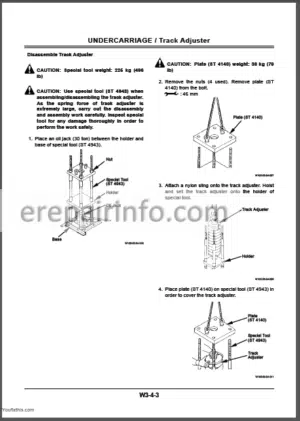

–TRACK ADJUSTER

Remove and Install

Track Adjuster

Disassemble Track Adjuster

Assemble Track Adjuster

–FRONT IDLER

Remove and Install Front Idler

Disassemble Front Idler

Assemble Front Idler

Maintenance Standard

–UPPER AND LOWER ROLLER

Remove and Install Upper Roller

Remove and Install Lower Roller

Disassemble Upper Roller

Assemble Upper Roller

Disassemble Lower Roller

Assemble Lower Roller

Maintenance Standard

–TRACK LINK

Remove and Install Track Link

Maintenance Standard - -FRONT ATTCHMENT

–FRONT ATTACHMENT

Remove and Install Front Attachment

Maintenance Standard

–CYLINDER

Removeand Install Cylinder

Disassembe Cylinder

Assemble Cylinder

Maintenance Standard - -SPECIAL TOOLS

–SPECIAL TOOL LIST

Special Tool List

–GENERAL INFORMATION

General Information

Notes on the Format of Engine Section

Main Data & Specifications

Design Features and General Outline

Tightening Torque Specifications Angular Nut & Bolt Tightening Method

Major Parts Fixing Nuts & Botts Identifications

–MAINTENANCE

Lubricating System

Fuel System

Cooling System

Valve Clearance Adjustment

Injection Timing

Compression Pressure Measurement

Turbocharger Inspection

Engine Repair Kit

Recommended Lubricants

Engine Oil Viscosity Chart

–ENGINE ASSEMBLY I (DISASSEMBLY)

Engine Assembly General Description

Disassembly 1 st Step

2nd Step

3rd Step

Cylinder Head Disassembly Step Piston And Connecting Rod Disassembly Step

Rocker Arm And Shaft Disassembly Step

Camshaft And Gear Disassembly Step

Crankshaft Disassembly Step

–ENGINE ASSEMBLY II (INSPECTION & REPAIR)

Cylinder Head

Valve Guide

Valve And Valve Seal Insert

Valve Spring

Tappet

Push Rod

Rocker Arm Shaft And Rocker Arm

Idler Gear And Idler Gear Shaft Camshaft

Cylinder Body And Liner

Piston And Piston Ring

Piston Pin

Connecting Rod

Crank Shaft And Bearing

Flywheel & Ring Gear

Timing Gear Case Cover

–ENGINE ASSEMBLY III (REASSEMBLY)

Piston And Connecting Rod Reassembly Step

Cylinder Head Reassembly Step Rocker Arm And Rocker Arm Shaft Reassembly Step

Reassembly 1st Step

Reassembly 2nd Step

Reassembly 3rd Step

Reassembly 4th Step

Engine Tuning Operation

–LUBRICATING SYSTEM

General Description

Oil Pump

Main Oil Filter

Oil Cooler

–COOLING SYSTEM

General Description

Water Pump

Thermostat

–FUEL SYSTEM

General Description

Fuel Filter

Injection Nozzle

–TURBO CHARGER

General Description

Identification

Rotor Shaft Play Inspection

–AIR COMPRESSOR (IF EQUIPPED)

General Description

Disassembly Step

Inspection & Repair

Reassembly Step

–ENGINE ELECTRICAL

Starter Motor

Alternator

Intake Heater

–TROUBLESHOOTING

Hard Starting

Unstable Low Idling

Insufficient Power

–SPECIAL TOOL

Special Tod

Technical Manual

- SAFETY

- -SPECIFICATIONS

–GENERAL INFORMATION

Foreword

Specifications

Working Range -Transporting Dimansions

Shoe Types & Applications

–FUELS AND LUBRICANTS

Service Refill Capacities

Fuel

Grease

Engine Oil

Gear Oil

Hydraulic System

Cooling System

–INTERCHANGEABILITY

Interchangeability

Installation of Attachments

–MACHINE NUMBERS

Machine Numbers

–COMPONENT SPECIFICATIONS

Engine

Engine Accessories

Hydraulic Devices

Filters

Electrical Equipment - -UPPERSTRUCTURE

–OUTLINE

Outline

–TANKS

Construction and Function

–PUMP DEVICE

Outline

Pump Transmission

Main Pump

Pump Regulator

Main Pump Control System

Pilot Pump

–SWING DEVICE

Outline

Swing Motor

Brake Valve

Swing Parking Brake

Swing Dampener Valve

Swing Reduction Gear

–CONTROL VALVE

Outline

Construction and Function

Oil Flow

Primary Circuit

Neutral Passages

Return Oil Passages

Parallel Oil Passages

Flow Combining Passages

Main Relief Valve

Pump Control Valve

Overload Relief Valve

Make-up Valve

Holding Valve

Arm Regenerative Valve

Automatic Air Bleeding Circuit

–PILOT VALVE

Outline

Construction

Function

Operation

–OTHERS

Pilot Shut-off Valve

Shockless Valve

Accumulator

Solenoid Valve

Swing Dampener Solenoid Valve Solenoid Valve Assembly

Pump Displacement Solenoid Valve - -UNDERCARRIAGE

–OUTLINE

Outline

–SWING BEARING

Construction and Function

–CENTER JOINT

Outline

–TRAVEL DEVICE

Outline

Travel Device Function

Travel Motor

Parking Brake

Travel Brake Valve

–TRACK ADJUSTER

Construction and Function - -ELECTRICAL SYSTEM

–COMPONENT LOCATION

Component Location

Relays

Monitor and Switch Panel

–CONTROL SYSTEM

Outline

Relationship Between Control Functions

and Input / Output signals

Outline of Engine Control System

Engine Control Motor Circuit

Setting of Engine Mode Speed

Engine Stop System

Functions of Main Electrical Equipment (Excluding Monitor System)

–MONITOR

Outline

Monitor Panel

Monitor Function

Monitor Check Procedure

–CIRCUIT OPERATION

Characteristics of the Electrical System

Power Circuit

Preheat Circuit

Engine Start Circuit

Charging Circuit

Surge Voltage Prevention Circuit

Accessory Circuit

EC Motor Engine Stop Circuit

Engine Stop Motor Circuit

Auto-Idle

–INSPECTION AND MAINTENANCE

Precautions for Inspection and Maintenance

Fuse Continuity Test

Taking apart Connectors

Inspection and Replacement of Fusible Links

Install and Adjustment of the A-Sensor

Positioning the EC Sensor

Installation of the EC Motor - -HYDRAULIC SYSTEM

–GENERAL

General

Hydraulic Circuit

Main Circuit

Pilot Circuit

–CONTROL SYSTEM

Pump Control

Travel Speed Control

–CIRCUIT OPERATION

Single Operation

Combined Operation - -OPERATIONAL PERFORMANCE TEST

–PERFORMANCE TEST

Concept of Performance Test

Conditions Performance Test

–ENGINE TEST

Engine Speed

Engine Compression Pressure

Valve Clearance Adjustment

Nozzle Check

Injection Timing Adjustment

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Parking Function Check

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Swing Bearing Play

Maximum Swingable Slant Angle

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever Stroke

Combined Boom Raise I

Swing Function Check

–HYDRAULIC COMPONENT TEST

Pilot Primary Pressure

Pitot Secondary Pressure

Swing Preference Circuit Control Pressure (MA Pressure)

Main Relief Pressure Changeover Pressure (SA Pressure)

Travel speed Selecting Control Pressure (SB Pressure)

Swing Parking Brake Releasing Pressure (SC Pressure)

Main Relief Pressure (Non Power Boost)

Overload Relief Pressure (Power Boost)

Travel / Swing Relief Pressure

Travel Motor Drainage

Swing Motor Drainage

–STANDARD

Operational Performance

Standard - -TROUBLESHOOTING

–DIAGNOSING PROCEDURE

Introduction

Diagnosing Procedure

DrEX Start-Up Procedure

Self-diagnosing Function

Clearing the Self-Diagnosing Function

Retrial A

Retrial B

DrEX Monitor Function

Check Battery Voltage

Check Fuses

Check Fusible Link

–CONNECTOR

Connector Location

Type of Connector

–Troubleshooting A List of EC-Related Fault Codes

List of PVC-Related Fault Codes T07-03-02 Fault Codes 01,020304 and 06

Fault Code 05

Fault Codes 09 and 10

Fault Code 13

Fault Codes 17,18,19,21 and 22

Fault Code 20

Fault Code 23 and 24

Fault Codes 25,26,33 and 34

Fault Codes 27,28,35 and 36

Fault Codes 29,30,37 and 38 Fault Codes 14 and 15

–TROUBLESHOOTING B

Outline

Effects of Electronic Component Malfunctions Operations

Machine Malfunctions and Possible Causes

Engine Troubleshooting

Actuator Troubleshootings

Front Attachment Troubleshootings

Swing Troubleshooting

Travel Troubleshooting

Other Troubleshooting

–TROUBLESHOOING C

Monitor Panel Switch and Sensor Location

Malfunction of Coolant Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Level Check Switch

Malfunction of Engine Oil Level Indicator

Malfunction of Coolant Level Indicator

Malfunction of Hydraulic Oil Level Indicator

Malfunction of Alternator Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Overheat Indicator

Malfunction of Fuel Level Indicator

Malfunction of Air Filter Restriction Indicator

Malfunction of Buzzer

Malfunction of Hour Meter

–HARNESS CHECK

Electical Test Precautions

Continuity Check

Voltage Check

5 Volt Circuit - -EX400-3 ELECTRICAL CIRCUIT

- -EX400-3 ELECTRICAL CIRCUIT (CONNECTOR)

- -EX400-3C ELECTRICAL CIRCUIT

- -EX400-3C ELECTRICAL CIRCUIT (CONNECTOR)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet