Factory Service Repair Manuals For Hitachi Zaxis 180W Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 720 + 413 + 369 + 13

Bookmarks: No

Searchable: Yes

Number: KM-CCBE

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi Zaxis 180W

Contents

1.Principle

2.Wiring Diagrams

3.Troubleshooting

4.Workshop Manual

Workshop Manual

- INTRODUCTION

SAFETY - -GENERAL INFORMATION

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

Maintenance Standard Terminology

–TIGHTENING TORQUE

Tightening Torque Specification

Torque Chart

Piping Joint

Periodic Replacement of Parts

–PAINTING

Painting

–BLEEDING AIR FROM HYDRAULIC OIL TANK

Bleeding Air from Hydraulic Oil tank - -UPPERSTRUCTURE

–CAB

Remove and Install Cab

Dimensions of the Cab Glass

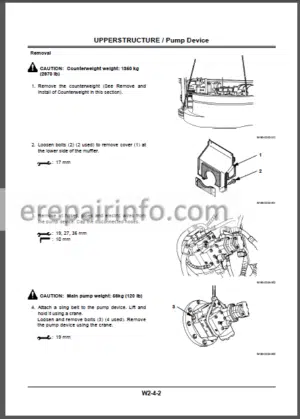

–COUNTERWEIGHT

Remove and Install Counterweight

–MAIN FRAME

Remove and Install Main Frame

–PUMP DEVICE

Remove and Install Pump Device

Disassemble Pump Device

Assemble Pump Device

Disassemble Regulator

Assemble Regulator

Disassemble Solenoid Valve

Assemble Solenoid Valve

Disassemble and Assemble

Pilot Pump

Maintenance Standard

–CONTROL VALVE

Remove and Install Control Valve

Disassemble 4-Spool Control Valve

Disassemble 5-Spool Control Valve

Separate and Combine 4-Spool and 5-Spool Sections

Assemble 4-Spool Control Valve

Assemble 5-Spool Control Valve

Remove and Install Auxiliary Control Valve

Disassemble Auxiliary Control Valve

Assemble Auxiliary Control Valve

–SWING DEVICE

Remove and Install Swing Device

Disassemble Swing Device

Assemble Swing Device

Disassemble Swing Motor

Assemble Swing Motor

Maintenance Standard

–PILOT VALVE

Remove and Install Pilot Valve

Disassemble Front/Swing Pilot Valve

Assemble Front/Swing Pilot Valve

Disassemble Travel,

Positioning/Auxiliary Blade/Stabilizer Pilot Valve

Assemble Travel, Positioning/Auxiliary Blade/Stabilizer Pilot Valve

–PILOT SHUT-OFF VALVE

Remove and Install

Pilot Shut-Off Valve

Disassemble Pilot Shut-Off Valve

Assemble Pilot Shut-Off Valve

–SIGNAL CONTROL VALVE

Remove and Install Signal

Control Valve

–TRAVEL SHOCKLESS VALVE

Remove and Install

Travel Shockless Valve

Construction of

Travel Shockless Valve

–SOLENOID VALVE

Remove and Install 4-Unit Solenoid Valve Unit

Disassemble Proportional Solenoid Valve

Assemble Proportional Solenoid Valve

Remove and Install Solenoid Valve (for Pump Control)

Construction of Solenoid Valve (for Pump Control)

Remove and Install 2-Unit Solenoid Valve (for Blade/Stabilizer)

Construction of 2-Unit Solenoid Valve (for Blade/Stabilizer)

–PILOT RELIEF VALVE

Remove and Install Pilot Relief Valve

Construction of Pilot Relief Valve

–STEERING VALVE

Remove and Install Steering Valve

Disassemble Steering Valve

Assemble Steering Valve

Disassemble and Assemble Check Valve Unit

–BRAKE VALVE

Remove and Install Brake Valve

Disassemble Brake Valve

Assemble Brake Valve

–ACCUMULATOR CHARGING VALVE

Remove and Install Accumulator Charging Valve

Construction of Accumulator Charging Valve

–TRANSMISSION CONTROL VALVE

Remove and Install Transmission Control Valve

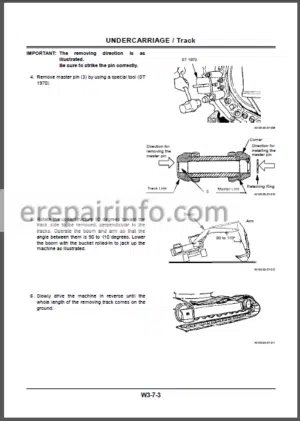

Construction of Transmission Control Valve - -UNDERCARRIAGE

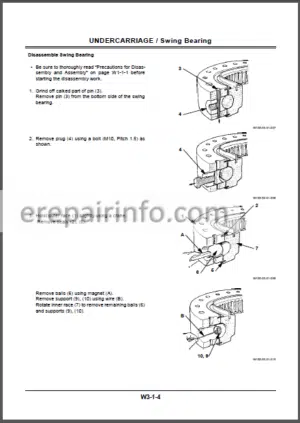

–Swing Bearing

Remove and Install Swing Bearing

Disassemble Swing Bearing

Assemble Swing Bearing

–Travel Motor

Remove and Install Travel Motor

Disassemble Travel Motor

Assemble Travel Motor

Disassemble Brake Valve

Assemble Brake Valve

–Center Joint

Remove and Install Center Joint

Disassemble Center Joint

Assemble Center Joint

Maintenance Standard

–Transmission

Remove and Install Transmission

Disassemble Transmission

Disassemble Final Drive and Differential

Assemble Final Drive and Differential

Assemble Transmission

Adjusting Gear Clearance

–AXLE

Remove and Install Axle

Disassemble Front Axle

Assemble Front Axle

Disassemble Front Differential

Assemble Front Differential

Disassemble Rear Axle

Assemble Rear Axle

Disassemble Rear Differential

Assemble Rear Differential

Disassemble Steering Cylinder

Assemble Steering Cylinder

–AXLE LOCK CYLINDER

Remove and Install Axle Lock Cylinder

Disassemble and Assemble Axle Lock Cylinder

–OPERATE-CHECK VALVE

Remove and Install Operate-Check Valve (for Axle Lock Cylinder)

Construction of Operate-Check Valve (for Axle Lock Cylinder)

–PROPELLER SHAFT

Remove and Install Propeller Shaft - -FRONT ATTACHMENT

–FRONT ATTACHMENT

Hydraulic Circuit Pressure Release Procedure

Remove and Install Monoblock Boom

Front Attachment

Remove and Install 2-Piece Boom Front Attachment

Maintenance Standard

Standard Dimensions for Arm and Bucket Connection

Standard Dimensions for Arm and Boom Connection

–CYLINDER

Remove and Install Cylinder (Monoblock Boom, 2-Piece Boom)….

Disassemble Cylinder (Boom (Monoblock/2-Piece), Positioning and Bucket)

Assemble Cylinder (Boom (Monoblock/2-Piece),Positioning and Bucket

Disassemble Cylinder (Arm)

Assemble Cylinder (Arm

Disassemble Cylinder (Stabilizer, Blade)

Assemble Cylinder (Stabilizer, Blade)

Maintenance Standard

–HOSE-RUPTURE SAFETY VALVE

Remove and Install Hose-Rupture Safety Valve

Construction of Hose-Rupture Safety Valve

–OPERATE-CHECK VALVE

Remove and Install Operate-Check Valve (for Blade/Stabilizer)

Construction of Operate-Check Valve (for Blade/Stabilizer) - -ENGINE AND ACCESSORY

–GENERAL INFORMATION

General Repair Instructions

Notes on the Format of This Manual

Main Data and Specifications

Performance Curve

External View

Tightening Torque Specifications

Angular Nut and Bolt Tightening Method

Major Parts Fixing Nuts and Bolts

Identifications

–MAINTENANCE

Lubricating System

Fuel System

Cooling System

Valve Clearance Adjustment

Injection Timing

Compression Pressure Measurement

Turbocharger Inspection

Engine Repair Kit

Recommended Lubricants

Engine Oil Viscosity Chart

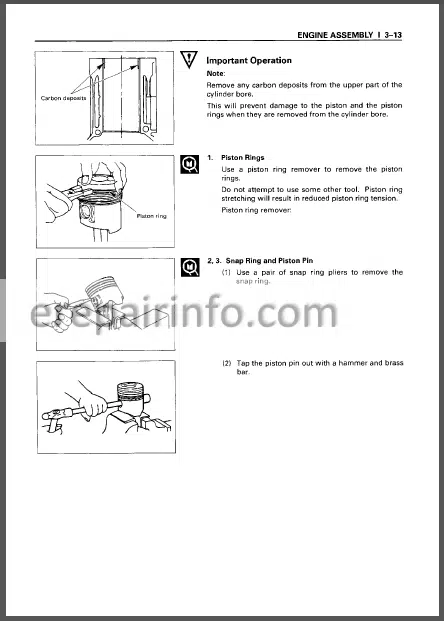

–ENGINE ASSEMBLY 1 (DISASSEMBLY)

External Parts Disassembly Steps

Major Components

Rocker Arm and Rocker Arm Shaft

Disassembly Steps

Cylinder Head Disassembly Steps

Piston and Connecting Rod Disassembly Steps

–ENGINE ASSEMBLY 2 (INSPECTION AND REPAIR)

Cylinder Head

Valve Guide

Valve Spring

Tappet

Push Rod

Rocker Arm Shaft and Rocker Arm

Idler Gear and Idler Gear Shaft

Camshaft

Cylinder Body and Liner

Piston and Piston Ring

Piston Pin

Connecting Rod

Crankshaft

Flywheel

Timing Gear Case Cover

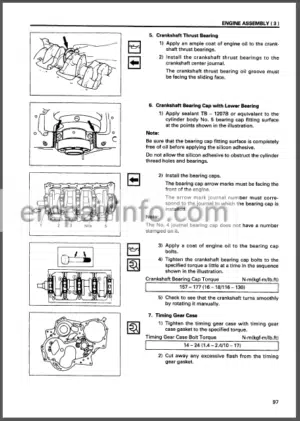

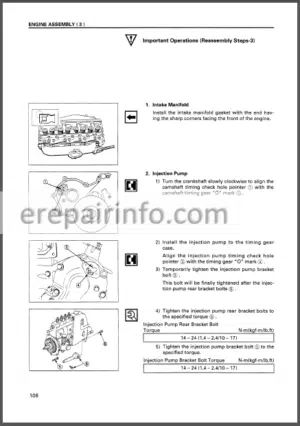

–ENGINE ASSEMBLY 3 (REASSEMBLY)

Piston and Connecting Rod Reassembly Steps

Cylinder Head Reassembly Steps

Rocker Arm and Rocker Arm Shaft

Reassembly Steps

Major Component Reassembly Steps 1

Major Component Reassembly Steps 2

External Parts Reassembly Steps (Left-Hand Side)

External Parts Reassembly Steps (Right-Hand Side)

Engine Tuning Operation

–LUBRICATING SYSTEM

General Description

Oil Pump

Oil Cooler

–COOLING SYSTEM

General Description

Thermostat

–FUEL SYSTEM

General Description

Injection Nozzle

Injection Pump Calibration Data

–TURBOCHARGER

General Description

Turbocharger Identification

Troubleshooting

Inspection and Repair

–ENGINE ELECTRICALS

Starter Identification

Starter Main Data and Specifications

Starter Sectional View

Performance

Disassembly

Inspection and Repair

Reassembly

Adjustment

Performance Test

Alternator Identification

Main Data and Specifications

Alternator Sectional View

Charging Circuit

Structure

Disassembly

Inspections

Reassembly

Bench Test

Current Output Test

Fault Finding

Specifications

–TROUBLESHOOTING

Hard Starting

1)Starter Inoperative

2)Starter Operates but

Engine does not Turn Over

3)Engine Turns Over but does not Start

Fuel is Being Delivered to the Injection Pump

4)Engine Turns Over but does not Start

Unstable Low Idling

Insufficient Power

Excessive Fuel Consumption

Excessive Oil Consumption

Overheating

Whity Exhaust Smoke

Dark Exhaust Smoke

Oil Pressure does not Rise

Abnormal Engine Noise

–SPECIAL TOOL LIST

Special Tool List

–REPAIR STANDARDS

Repair Standards

–CONVERSION TABLE

Length

Area

Volume

Mass

Pressure

Torque

Temperature

Troubleshooting

- INTRODUCTION

SAFETY - -OPERATIONAL PERFORMANCE TEST

–INTRODUCTION

Operational Performance Tests

Preparation for Performance Tests

–STANDARD

Operational Performance Standard Table

Main Pump P-Q Diagram

Injection Pump

DrZX Monitor Indicating Values

Sensor Activating Range

–ENGINE TEST

Engine Speed

Engine Compression Pressure

Valve Clearance Adjustment

Nozzle Check

Injection Timing

Lubricant Consumption

–EXCAVATOR TEST

Travel Speed

Service Brake Function Check

Parking Brake Function Check

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever Stroke

Combined Boom Raise/Swing Function Check

–COMPONENT TEST

Primary Pilot Pressure

Secondary Pilot Pressure

Solenoid Valve Set Pressure

Main Pump Delivery Pressure

Main Relief Valve Set Pressure

Relief Pressure (When relieving Swing)

Relief Pressure (When relieving Travel)

Overload Relief Valve Set Pressure

Main Pump Flow Rate Measurement

Regulator Adjustment

Swing Motor Drainage

Travel Motor Drainage

Steering Valve Relief Valve Set Pressure

Brake Pressure (Front and Rear)

Brake Accumulate Pressure

Brake Warning Set Pressure (Decrease)

Brake Warning Set Pressure (Increase)

–ADJUSTMENT

Engine Speed Adjustment and Engine Learning

Governor Lever and Fuel Cut Lever

Position - -TROUBLESHOOTING

–GENERAL

Introduction

Diagnosing Procedure

Built-In Diagnosing System Operation

Built-In Diagnosing Function

Display List

Dr ZX Operation

Dr ZX Fault Code List (MC)

Dr ZX Monitoring Item List

Dr ZX Special Function

Dr ZX Service Mode

Adjustment Data List

–COMPONENT LAYOUT

Main Component Layout

Electrical Component Layout (Overview)

Electrical System (Relays)

Electrical System(Monitors and Switches)

Ele ctrical System (Column Box)

Pump Device

Swing Device

Signal Control Valve

Control Valve

Auxiliary control Valve

4-Unit Solenoid Valve Unit

3-Unit Solenoid Valve Unit

Travel Shockless Valve / Accumulator Chrging Valve

Transmission Control Valve

Travel Device

Filter

Components in Control Valve

Signal Control Valve Port Location

–TROUBLESHOOTING A

Troubleshooting A Procedure

Fault Code List

Fault Code 01, 02, 03

Fault Code 04

Fault Code 06

Fault Code 07

Fault Code 10, 11

Fault Code 12, 13

Fault Code 14, 15, 16, 18, 23, 24

Fault Code 19

Fault Code 20

Fault Code 22

–TROUBLESHOOTING B

Troubleshooting B Procedure

Relationship between Machine Trouble Symptoms and Related Parts

Correlation between Trouble Symptoms and Part Failures

Engine System Troubleshooting

All Actuator System Troubleshooting

Front Attachment System Troubleshooting

Swing System Troubleshooting

Travel System Troubleshooting

Brake System Troubleshooting

Steering System Troubleshooting

Other System Troubleshooting

Exchange Inspection

Bleeding Air from Transmission

Bleeding Air from Brake (Axle)

Emergency Boom Lowering Procedure (without Hose-Rupture Safety Valve)

Emergency Boom Lowering Procedure (with Hose-Rupture Safety Valve)

–TROUBLESHOOTING C

Troubleshooting C Procedure

Malfunction of Coolant Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Indicator Light Check System

Malfunction of Preheat Indicator

Malfunction of Overheat Indicator

Malfunction of Air Filter Restriction Indicator

Malfunction of Fuel Level Indicator

Malfunction of Alternator Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Hydraulic Oil Filter Indicator (Optional)

–ELECTRICAL SYSTEM INSPECTION

Precautions for Inspection and Maintenance

Instructions for Disconnecting Connectors

Fuse Inspection

Fusible Link Inspection

Battery Voltage Check

How to Troubleshoot Alternator Malfunctions

Continuity Check

Voltage and Current Measurement

Check by False Signal

Test Hamess

–ICX

Outline

ICX Fault Code List

Fault Code 1 to 6

Fault Code 7 to 10

Some Parts of Data in Daily Report, Frequency Distribution, Cumulative Operation Hours are not Recorded

Principle

- INTRODUCTION

- -GENERAL

–SPECIFICATIONS

Specifications

Working Ranges

–COMPONENT LAYOUT

Main Component Layout

Electrical Component Layout (Overview)

Electrical System (Relays)

Electrical System (Monitors and Switches)

Electrical System (Column Box)

Pump Device

Swing Device

Signal Control Valve

Control Valve

Auxiliary control Valve

4-Unit Solenoid Valve Unit

Pump Control Solenoid Valve

Travel Shockless Valve / Accumulator Charging Valve

Transmission Control Valve

Travel Device

Filter

–COMPONENT SPECIFICATIONS

Engine

Engine Accessories

Hydraulic Component

Electrical component - -SYSTEM

–CONTROL SYSTEM

Outline

Engine Control

Pump Control

Valve Control

Other Controls

Electric and Hydraulic

Composite Circuit Control

–HYDRAULIC SYSTEM

Outline

Pilot Circuit

Service Brake Circuit

Steering Circuit

Main Circuit

–ELECTRICAL SYSTEM

Outline

Main Circuit

Electric Power Circuit

Indicator Light Check Circuit

Accessory Circuit

Preheat Circuit

Starting Circuit

Charging Circuit

Parking Brake Circuit

Serge Voltage Prevention Circuit

Engine Stop Circuit - -COMPONENT OPERATION

–PUMP DEVICE

Outline

Main Pump

Regulator

Solenoid Valve

Pilot Pump, Steering Pump

N Sensor (Engine Speed Sensor)

Pump Delivery Pressure Sensor

Pump Control Pressure Sensor

–SWING DEVICE

Outline

Swing Reduction Gear

Swing Motor

Swing Parking Brake

Valve Unit

–CONTROL VALVE

Outline

Hydraulic Circuit

Flow Combiner Valve

Main Relief Valve

Overload Relief Valve

Regenerative Valve

Anti-Drift Valve

Flow Rate Control Valve

Bypass Shut-Out Valve

Auxiliary Flow Combiner Valve

–PILOT VALVE

Outline

Operation

–TRAVEL DEVICE

Outline

Transmission

Front and Rear Propeller Shaft

Front Axle

Steering Cylinder

Differential Gear

Reduction Gear

Rear Axle

Travel Motor

Rotor Section

Regulator

Brake Valve

–SIGNAL CONTROL VALVE

Outline

Pilot Port

Shuttle Valve

Shockless Valve

Pump 1 and Pump 2 Flow Rate

Control Valves

Bucket Flow Rate Control Valve Control Spool, Flow Combiner Valve Control Spool, Swing Parking Brake Release Spool, Arm Flow Rate Control Valve Control Spool

–STEERING VALVE

Outline

Construction

Operation

Relief Valve

Overload Relief Valve

Make-Up Valve

–BRAKE VALVE

Outline

Operation

–TRANSMISSION CONTROL VALVE

Outline

Operation

–OTHERS (UPPERSTRUCTURE)

Pilot Shut-Off Valve

Solenoid Valve Unit

Travel Shockless Valve

Pilot Relief Valve

Accumulator

Accumulator Charging Valve

Hose-Rupture Safety Valve

EC Motor

–OTHERS (UNDERCARRIAGE)

Swing Bearing

Center Joint

Slip Ring

Cylinder

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet