Factory Service Repair Manuals Set For Hitachi Zaxis 40U-2, 50U-2 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1208

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi 40u-2, 50u-2

Contents

1.Technical Manual

2.Circuits

3.Workshop manual

4.Training Text(Operational Principle)

5.Training Text(Performance Check & Troubleshooting)

1.Technical Manual

INTRODUCTION

SAFETY

-GENERAL

–SPECIFICATION

Specifications

Working Ranges

–COMPONENT LAYOUT

Main Components

Electrical Component Layout (Overview)

Electrical System (Controllers and Relays)

Electrical System (Monitor and Switches)

Engine

Swing Device

Travel Device

Control Valve

2-Unit Solenoid Valve

Revolution Sensing Valve / Pilot Filter

Auxiliary Flow Selector Valve (Optional)

–COMPONENT SPECIFICATIONS

Engine

Engine Accessories

Hydraulic Component

Filter

Electrical Component

-SYSTEM

–CONTROL SYSTEM

Outline

Engine Control

Pump Control

Other Control

–HYDRAULIC SYSTEM

Outline

Pilot Circuit

Main Circuit

–ELECTRICAL SYSTEM

Outline

Electric Power Circuit (key Switch : OFF)

Electric Power Circuit (Key Switch : ON)

Preheat Circuit (Key Switch : HEAT)

Starting Circuit (Key Switch : START)

Charging Circuit (Key Switch : ON)

Engine Stop Circuit (Key Switch : OFF)

-COMPONENT OPERATION

–PUMP DEVICE

Outline

Main Pump P1

Power Control

Flow Rate Control

PS Valve

–REVOLUTION SENSING VALVE

Outline

Operation

–SWING DEVICE

Outline

Swing Motor

Parking Brake

Valve Unit

Swing Reduction Gear

–CONTROL VALVE

Outline

Hydraulic Circuit

Main Relief Valve

Overload Relief Valve

Make-Up Valve

Boom Anti-Drift Valve

Unload Valve

Differential Reducing Valve

Pressure Compensator

–PILOT VALVE

Outline

Operation

Shockless Function (Only for Travel Pilot Valve)

Shuttle Valve (Only for Travel Pilot Valve)

–TRAVEL DEVICE

Outline

Travel Reduction Gear

Travel Motor

Travel Brake Valve

Parking Brake

–OTHERS (UPPERSTRUCTURE)

2-Unit Solenoid Valve

Pilot Relief Valve

Back Pressure Valve

Auxiliary Flow Selector Valve (Optional)

–OTHERS (UNDERCARRIAGE)

Swing Bearing

Center Joint

Track Adjuster

-OPERATIONAL PERFORMANCE TEST

–INTRODUCTION

Operational Performance Test

Preparation for Performance Tests

–STANDARD

Operational Performance Standard

Main Pump P-Q Diagram

–ENGINE TEST

Engine Speed

Engine Compression Pressure

Valve Clearance

Nozzle Check

Injection Timing

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Motor Leakage

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift

Control Lever Operating Force

Control Lever Stroke

Combined Boom Raise/Swing Function Check

–COMPONENT TEST

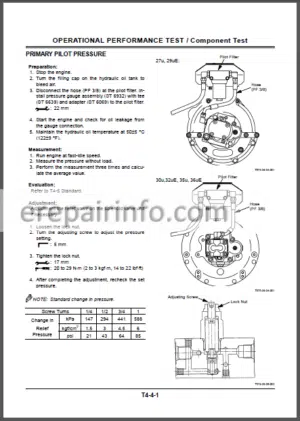

Primary Pilot Pressure

Secondary Pilot Pressure

Main Relief Valve Set Pressure

Overload Relief Valve Set Pressure

Swing Motor Drainage

Travel Motor Drainage

Revolution Sensing Valve Output Pressure

Pump Delivery Pressure

Pump Driving Torque

Auxiliary Flow Selector Valve Pressure (Optional)

–ADJUSTMENT

Governor Adjustment

2.Circuits(T1M9-E-01 circuit)

ZAXIS40U-2/50U-2 HYDRAULIC CIRCUIT DIAGRAM

ZAXIS30U-2/35U-2/40U-2/50U-2 ELECTRICAL CIRCUIT DIAGRAM

ZAXIS30U-2/35U-2/40U-2/50U-2 FLOOR HAR-NESS

ZAXIS30U-2/35U-2/40U-2/50U-2 AIR CONDI-TIONER HARNESS (FLOOR) (Cab Version Only)

ZAXIS40U-2/50U-2 MAIN HARNESS

ZAXIS40U-2/50U-2 ENGINE HARNESS

ZAXIS40U-2/50U-2 BATTERY HARNESS (1), (2)

ZAXIS40U-2/50U-2 BOOM LIGHT HARNESSZAXIS30U-2/35U-2/40U-2/50U-2 CANOPY LIGHT HARNESS

ZAXIS30U-2/35U-2/40U-2/50U-2 AUTO-IDLE PRESSURE SENSOR HARNESS

ZAXIS30U-2/35U-2/40U-2/50U-2 IMMOBILIZER HARNESS (Optional)

ZAXIS30U-2/35U-2/40U-2/50U-2 TRAVEL ALARM HARNESS (FLOOR) (Optional)

ZAXIS40U-2/50U-2 TRAVEL ALARM HARNESS (ALARM) (Optional)

ZAXIS30U-2/35U-2/40U-2/50U-2 AIR CONDI-TIONER HARNESS (SOLENOID VALVE) (Cab Version Only)

ZAXIS30U-2/35U-2/40U-2/50U-2 AIR CONDI-TIONER HARNESS (COMPRESSOR) (Cab Ver-sion Only)

ZAXIS30U-2/35U-2/40U-2/50U-2 AUXILIARY FLOW SELECTOR VALVE (SWITCH) (Optional)

ZAXIS30U-2/35U-2/40U-2/50U-2 AUXILIARY FLOW SELECTOR VALVE (SOLENOID VALVE) (Optional)

2.Workshop Manual

INTRODUCTION

SAFETY

-GENERAL INFORMATION

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

Maintenance Standard Terminology

–TIGHTENING

Tightening Torque Specifications

Torque Chart

Piping Joint

Periodic Replacement of Parts

–PAINTING

Painting

–BLEEDING AIR

Bleed Air from Hydraulic Oil Tank

–FLOOR-TILTING DEVICE

Floor-Tilting Device Operetion Procedure

Procedure for Floor Tilting up

Procedure for Floor Tilting down

-UPPERSTRUCTURE

–CANOPY

Remove and Install Canopy

–COUNTERWEIGHT

Remove and Install Counterweight

–PUMP DEVICE

Remove and Install Pump Device

Disassemble Pump Device

Assemble Pump Device

Maintenance Standard

–CONTROL VALVE

Remove and Install Control Valve

Disassemble And Assemble Control Valve

Remove and Install Relief Valve and Make-up Valve

Disassemble and Assemble Body

Disassemble Unload Section

Assemble Unload Section

Disassemble and Assemble Spool

Disassemble and Assemble Boom Anti-Drift Valve

Disassemble and Assemble Shuttle Valve and Pressure Compensation Valve

–SWING DEVICE

Remove and Install Swing Device

Disassemble Swing Device

Assemble Swing Device

Disassemble Swing Motor

Assemble Swing Motor

Maintenance Standards

–PILOT VALVE

Remove and Install Front Pilot Valve

Remove and Install Travel Pilot Valve

Remove and Install Blade Pilot Valve

Remove and Install Boom Swing Pilot Valve

Disassemble Front Pilot Valve

Assemble Front Pilot Valve

Disassemble Travel Pilot Valve

Assemble Travel Pilot Valve

Disassemble Pilot Valves for Boom Swing, Blade and Auxiliary

Assemble Pilot Valves for Boom Swing, Blade and Auxiliary

–SOLENOID VALVE

Remove and Install 2-Unit Solenoid Valve

Disassemble 2-Unit Solenoid Valve

Assemble 2-Unit Solenoid Valve

Remove and Install 1-Unit Solenoid Valve

Structure of 1-Unit Solenoid Valve

–REVOLUTION SENSING VALVE

Remove and Install

Revolution Sensing Valve

Disassemble Revolution Sensing Valve

Assemble Revolution Sensing Valve

–AUXILIRY FLOW SELECTOR VALV< (OPTIONAL)

Remove and Install Auxiliary Flow Selector Valve

Disassemble Auxiliary Flow Selector Valve

Assemble Auxiliary Flow Selector Valve

-UNDERCARRIAGE

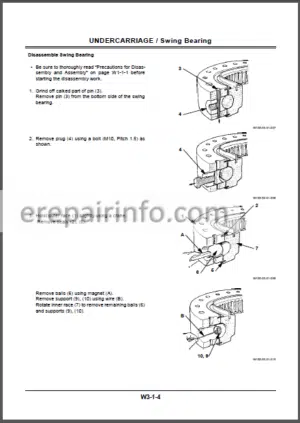

--SWING BEARING

Remove and Install Swing Bearing

--TRAVEL DEVICE

Remove and Install Travel Device

Disassemble Travel Device

Assemble Travel Device

Disassemble and Assemble Brake Valve

Maintenance Standard

--CENTER JOINT

Remove and Install Center Joint

Disassemble Center Joint

Assemble Center Joint

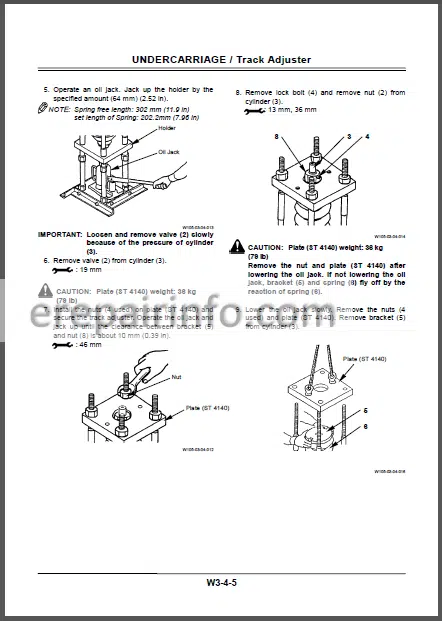

--TRACK ADJUSTER

Remove and Install Track Adjuster

Disassemble Track Adjuster

Disassemble Track Adjuster

--FRONT IDLER

Remove and Install Front Idler

Disassemble and Assemble Front Idler

Maintenance Standard

--UPPER AND LOWER ROLLER

Remove and Install Upper Roller

Remove and Install Lower Roller

Disassemble and Assemble Lower Roller

Maintenance Standard

--TRACK

Remove and Install Rubber Track

Maintenance Standard

-FRONT ATTACHMENT

--FRONT ATTACHMENT

Remove and Install Front Attachment

Maintenance Standards

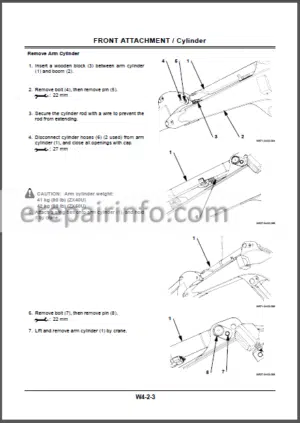

--CYLINDER

Remove and Install Cylinders

Disassemble Boom Cylinder

Assemble Boom Cylinder

Disassemble Arm Cylinder

Assemble Arm Cylinder

Disassemble Bucket Cylinder

Assemble Bucket Cylinder

Disassemble Boom Swing Cylinder

Assemble Boom Swing Cylinder

Disassemble Blade Cylinder

Assemble Blade Cylinder

Maintenance Standards

--ENGINE AND ACCESSORY

--GENERAL

Engine Nomenclature

Specifications

Fuel Oil, Lubricating Oil and Cooling Water

Engine External Views

Structural Description

Exhaust Gas Emission Regulation

--INSPECTION AND ADJUSTMENT

Periodic Maintenance Schedule

Periodic Inspection and Maintenance Procedure

Adjusting the No-load Maximum or Minimum Speed

Sensor Inspection

Water Leak Check in Cooling Water System

Radiator Cap Inspection

Thermostat Inspection

Adjusting Operation

Long Storage

--TROUBLESHOOTING

Preparation before Troubleshooting

Quick Reference Table for Troubleshooting

Troubleshooting by Measuring Compression Pressure

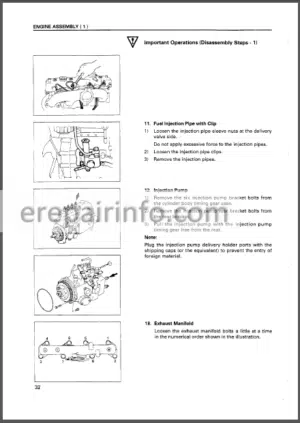

--DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES

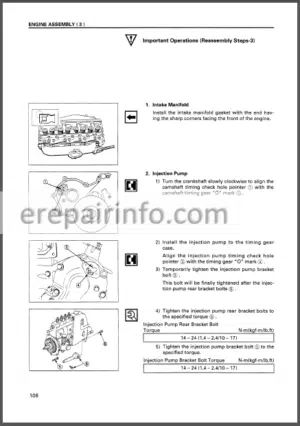

Complete Disassembly and Reassembly

Cylinder Head: Disassembly, Inspection and Reassembly

Gear Train and Camshaft

Cylinder Block

--LUBRICATION SYSTEM

Lubrication System Diagram

Trochoid Pump Components

Disassembly (Reverse the Procedure below for Assembly)

Servicing Points

Parts Inspection and Measurement

--COOLING SYSTEM

Cooling Water System

Cooling Water Pump Components

Disassembly (Reverse the Procedure below for Assembly)

Servicing Points

Fuel Injection Pump / Governor Introduction

Fuel Injection Pump

--TURBOCHARGER: DISASSEMBLY, INSPECTION AND REASSEMBLY

Structure and Functions

Service Standards and Tightening Torque

Periodic Inspection Procedure

Disassembly Procedure

Washing and Inspection Procedure

Reassembly Procedure

Handling after Disassembly and Reassembly

Troubleshooting

--STARTING MOTOR

For 4TNV94L/ 98

For 4TNV106 (T)

--ALTERNATOR

The 40A Alternator for 3TNV84 and Other Models

--ELECTRIC WIRING

Electric Wiring Diagram

Precaution on Electric Wiring

--SERVICE STANDARDS

Engine Tuning

Engine Body

Lubricating Oil System (Trochoid Pump)

--TIGHTENING TORQUE FOR BOLTS AND NUTS

Tightening Torques for Main Bolts and Nuts

Tightening Torques for Standard Bolts and Nuts

4.Training Text(Operational Principle)

-GENERAL

--SPECIFICATION

Specifications

Working Ranges

--COMPONENT Layout

Main Components

Electrical Component Layout (Overview)

Electrical System (Controllers and Relays)

Electrical System (Monitor and Switches)

Engine

Swing Device

Travel Device

Control Valve

2-Unit Solenoid Valve

Revolution Sensing Valve / Pilot Filter

Auxiliary Flow Selector Valve (Optional)

--COMPONENT SPECIFICATIONS

Engine

Engine Accessories

Hydraulic Component

Filter

Electrical Component

-SYSTEM

--CONTROL SYSTEM

Outline

Engine Control

Pump Control

Other Control

--HYDRAULIC SYSTEM

Outline

Pilot Circuit

Main Circuit

--ELECTRICAL SYSTEM

Outline

Electric Power Circuit (key Switch : OFF)

Electric Power Circuit (Key Switch : ON)

Preheat Circuit (Key Switch : HEAT)

Starting Circuit (Key Switch : START)

Charging Circuit (Key Switch : ON)

Engine Stop Circuit (Key Switch : OFF)

-COMPONENT OPERATION

--PUMP DEVICE

Outline

Main Pump P1

Power Control

Flow Rate Control

PS Valve

--REVOLUTION SENSING VALVE

Outline

Operation

--SWING DEVICE

Outline

Swing Motor

Parking Brake

Valve Unit

Swing Reduction Gear

--CONTROL VALVE

Outline

Hydraulic Circuit

Main Relief Valve

Overload Relief Valve

Make-Up Valve

Boom Anti-Drift Valve

Unload Valve

Differential Reducing Valve

Pressure Compensator

--PILOT VALVE

Outline

Operation

Shockless Function (Only for Travel Pilot Valve)

Shuttle Valve (Only for Travel Pilot Valve)

--TRAVEL DEVICE

Outline

Travel Reduction Gear

Travel Motor

Travel Brake Valve

Parking Brake

--OTHERS (UPPERSTRUCTURE)

2-Unit Solenoid Valve

Pilot Relief Valve

Back Pressure Valve

Auxiliary Flow Selector Valve (Optional)

--OTHERS (UNDERCARRIAGE)

Swing Bearing

Center Joint

Track Adjuster

5.Training Text(Performance Check & Troubleshooting)

-OPERATIONAL PERFORMANCE TEST

--INTRODUCTION

Operational Performance Test

Preparation for Performance Tests

--STANDARD

Operational Performance Standard

Main Pump P-Q Diagram

--ENGINE TEST

Engine Speed

Engine Compression Pressure

Valve Clearance

Nozzle Check

Injection Timing

--EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Motor Leakage

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift

Control Lever Operating Force

Control Lever Stroke

Combined Boom Raise/Swing Function Check

--COMPONENT TEST

Primary Pilot Pressure

Secondary Pilot Pressure

Main Relief Valve Set Pressure

Overload Relief Valve Set Pressure

Swing Motor Drainage

Travel Motor Drainage

Revolution Sensing Valve Output Pressure

Pump Delivery Pressure

Pump Driving Torque

Auxiliary Flow Selector Valve Pressure (Optional)

--ADJUSTMENT

Governor Adjustment

-TROUBLESHOOTING

--DIAGNOSING PROCEDURE

Introduction

Diagnosing Procedure

--TROUBLESHOOTING A

Troubleshooting A Procedure

Error Indication List

Wire Breakage and Short Circuit of Engine Control Dial (System Failure Indicator: Flickering Every 1 Sec)

Motor Sensor Breakage and Short Circuit (System Failure Indicator: Flickering Every 05 Sec)

Abnormal Motor (System Failure Indicator: Lit)

--TROUBLESHOOTING B

Troubleshooting B Procedure

Engine System Troubleshooting

Actuator Operating System Troubleshooting

Front Attachment System Troubleshooting

Swing System Troubleshooting

Travel System Troubleshooting

Blade System Troubleshooting

Boom Swing System Troubleshooting

How to Lower Boom when Engine Stops

How to Prevent Hom Blowing at Key Switch Position of OFF

--TROUBLESHOOTING C

Troubleshooting C Procedure

Malfunction of Coolant Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Preheat Indicator

Malfunction of Alternator Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Overheat Indicator

Malfunction of Fuel Level Indicator

Malfunction of Monitor Buzzer

Malfunction of Liquid Crystal Display (LCD)

Malfunction of Hour Meter

Malfunction of Auto-Idle Indicator

--ELECTRICAL SYSTEM INSPECTION

Precautions for Inspection and Maintenance

Fuse Continuity Test

Battery Voltage Check

Voltage Check

Continuity Check

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet