Factory Technical Manual and Workshop Manual For Hitachi ZX17U-2 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Searchable: Yes

Number: W1MS-E-01

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi ZX17U-2

Contents

1. Technical Manual

INTRODUCTION

SAFETY

-GENERAL

–SPECIFICATION

Specifications

Working Ranges and Machine Dimensions for Transportation

–COMPONENT LAYOUT

Main Component Layout

Electrical Component Layout (Overview)

Electrical System (Relays)

Electrical System (Monitor and Switches)

Engine

Swing Device

Control Valve

Travel Device

2-Spool Solenoid Valve

–COMPONENT SPECIFICATIONS

Engine

Engine Accessories

Hydraulic Component

Filter

Electrical Component

-SYSTEM

–HYDRAULIC SYSTEM

Outline

Pilot Circuit

Main Circuit

–ELECTRICAL SYSTEM

Outline

Main Circuit

Electrical Power Circuit (key Switch: OFF)

Electrical Power Circuit (Key Switch: ON)

Preheating Circuit (Key Switch: HEAT)

Starting Circuit (Key Switch: START)

Charging Circuit (Key Switch: ON)

Engine Stop Circuit (Key Switch: OFF)

Monitor Circuit

Indicator Circuit

Work Light/ Internal Illumination Circuit

Gauge Circuit

Travel Alarm Circuit

-COMPONENT OPERATION

–PUMP DEVICE

Outline

Main Pump P1, P2

Main Pump P3, Pilot Pump P4

Horse Power Control Operation

–SWING DEVICE

Outline

Swing Motor

Parking Brake

Valve Unit

–CONTROL VALVE

Outline

Hydraulic Circuit

Arm Regenerative Valve

Flow Combiner Valve

Main Relief Valve

Overload Relief Valve

Make-Up Valve

–PILOT VALVE

Outline

Operation

Shockless Function (Only for Travel Pilot Valve)

–TRAVEL DEVICE

Outline

Travel Motor

Parking Brake

Travel Brake Valve

Travel Reduction Gear’

–OTHERS (UPPERSTRUCTURE)

2-Spool Solenoid Valve

Pilot Relief Valve

–OTHERS (UNDERCARRIAGE)

Swing Bearing

Center Joint

Track Adjuster

–OPERATIONAL PERFORMANCE TEST

–INTRODUCTION

Operational Performance Test

Preparation for Performance Tests

–STANDARD

Operational Performance Standard

Main Pump P-Q Diagram

–ENGINE TEST

Engine Speed

Engine Compression Pressure

Valve Clearance

Nozzle Check

Injection Timing

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Motor Leakage

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift

Control Lever Operating Force

Control Lever Stroke

Combined Boom Raise/Swing Function Check

–COMPONENT TEST

Primary Pilot Pressure

Secondary Pilot Pressure

Main Relief Valve Set Pressure

Overload Relief Valve Set Pressure

Pump Driving Torque

Swing Motor Drainage

Travel Motor Drainage

–ADJUSTMENT

Fuel Lever Adjustment

-TROUBLESHOOTING

–DIAGNOSING PROCEDURE

Introduction

Diagnosing Procedure

–TROUBLESHOOTING B

Troubleshooting B Procedure

Engine System Troubleshooting

Actuator System Troubleshooting

Front Attachment System Troubleshooting

Swing System Troubleshooting

Travel System Troubleshooting

Boom Swing System Troubleshooting

Blade System Troubleshooting

Side Frame Extend / Retract System Troubleshooting

How to Lower Boom In Case of Emergency and when Engine Stops

–TROUBLESHOOTING C

Troubleshooting C Procedure

Malfunction of Coolant Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Preheat Indicator

Malfunction of Alternator Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Overheat Indicator

Malfunction of Fuel Level Indicator

Malfunction of Monitor Buzzer

Malfunction of Hour Meter

–ELECTRICAL SYSTEM INSPECTION

Precautions for Inspection and Maintenance

Fuse Continuity Test

Battery Voltage Check

Voltage Check

Continuity Check

2.Workshop Manual

INTRODUCTION

SAFETY

-GENERAL

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

–TIGHTENING

Tightening Torque

Tightening Bolts and Nuts

Piping Joint

Periodic Replacement Parts

–PAINTING

Painting

–BLEEDING AIR FROM HYDRAULIC OIL TANK

Bleeding Air from Hydraulic Oil Tank (Canopy Spec)

Bleeding Air from Hydraulic Oil Tank (Cab Spec)

-UPPERSTRUCTURE

–CANOPY AND CAB

Removal and Installation of Canopy (2-Pillar)

Removal and Installation of Canopy (3-Pillar)

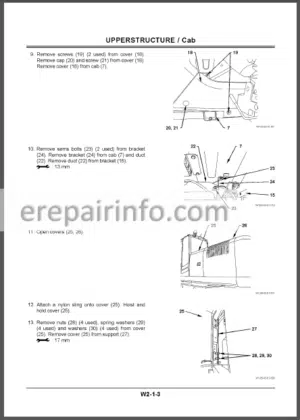

Removal and Installation of Cab

Dimensions of Cab Glass

–COUNTERWEIGHT

Removal and Installation of Counterweight (Canopy Spec Machine)

Removal and Installaton of Counterweight (Cab Spec Machine)

–MAIN FRAME

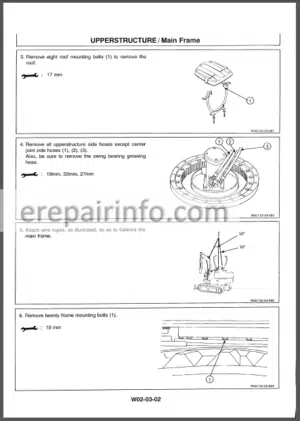

Removal and Installation of Main Frame

–PUMP DEVICE

Removal and Installation of Pump Device

Disassembly of Pump Device

Assembly of Pump Device

Maintenance Standard

–CONTROL VALVE

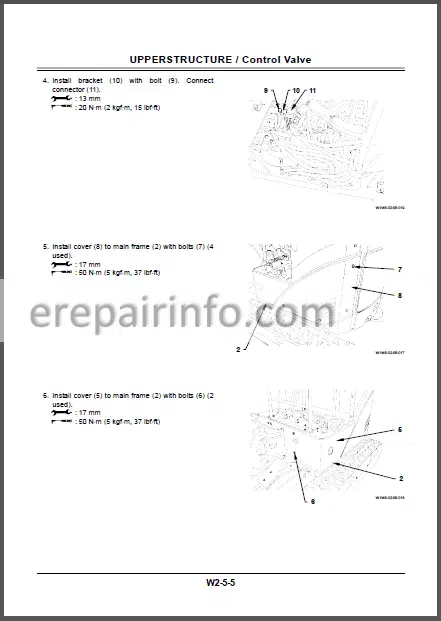

Removal and Installation of Control Valve

Disassembly and Assembly of Control Valve

Disassembly of Body

Assembly of Body

Disassembly of Spool

Assembly of Spool

Disassembly and Assembly of Check Valve

–SWING DEVICE

Removal and Installation of Swing Device

Disassembly of Swing Device

Assembly of Swing Device

–PILOT VALVE

Removal and Installation of Left Pilot Valve

Removal and Installation of Right Pilot Valve

Removal and Installation of Travel Pilot Valve

Removal and Installation of Blade Pilot Valve

Removal and Installation of Boom Swing Pilot Valve

Disassembly of Left and Right Pilot Valves

Assembly of Left and Right Pilot Valves

Disassembly of Travel Pilot Valve

Assembly of Travel Pilot Valve

Disassembly of Pilot Valves for Boom Swing, Blade, and Auxiliary

Assembly of Pilot Valves for Boom Swing, Blade, and Auxiliary

–SOLENOID VALVE

Removal and Installaiton of Solenoid Valve

Disassembly of 2-Spool Solenoid Valve

Assembly of 2-Spool Solenoid Valve

-UNDERCARRIAGE

–SWING BEARING

Removal and Installation of Swing Bearing

–TRAVEL DEVICE

Removal and Installation of Travel Device

Disassembly of Travel Device

Assembly of Travel Device

Disassembly of Travel Motor

Assembly of Travel Motor

Disassembly of Brake Valve

Assembly of Brake Valve

Maintenance Standard

–CENTER JOINT

Removal and Installation of Center Joint

Disassembly of Center Joint

Assembly of Center Joint

–TRACK ADJUSTER

Removal and Installation of Track Adjuster

Disassembly of Track Adjuster

Assembly of Track Adjuster

–FRONT IDLER

Removal and Installation of Front Idler

Disassembly of Front Idler

Assembly of Front Idler

Maintenance Standard

–UPPER AND LOWER ROLLER

Removal and Installation of Lower Roller

Structure of Lower Roller

Maintenance Standard

–TRACK

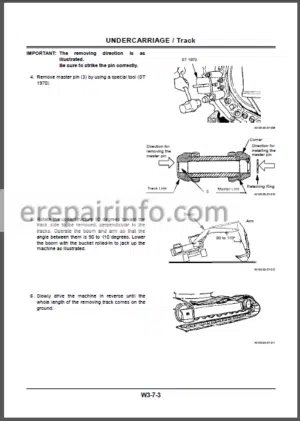

Removal and Installation of Track

Maintenance Standard

-FRONT ATTACHMENT

–FRONT ATTACHMENT

Hydraulic Circuit Pressure Release Procedure

Removal and Installation of Front Attachment

Maintenance Standard

Standard Dimensions for Arm and Bucket Connection

–CYLINDER

Hydraulic Circuit Pressure Release Procedure

Removal and Installation of Cylinder

Disassembly of Boom Cylinder

Disassembly of Arm, Bucket, Blade, Boom Swing, and Side Frame Extend/Retract Cylinders

Assembly of Boom Cylinder

Assembly of Arm, Bucket, Blade, Boom Swing, and Side Frame Extend/Retract Cylinders

Maintenance Standard

-ENGINE

–INTRODUCTION

–YANMAR WARRANTIES

Yanmar Limited Warranty

Emission System Warranty

Yanmar Co, Ltd Limited Emission Control System Warranty – USA Only

–SAFETY

Safety Statements

Safety Precautions

–GENERAL SERVICE INFORMATION

Component Identification

Location of Labels

EPA / ARB Emission Control

Regulations – USA Only

Emission Control Labels

The 97/68/EC Directive Certified Engines

Engine Family

Function of Major Engine Components

Function of Cooling System Components

Diesel Fuel

Engine Oil

Engine Coolant

Specifications

Principal Engine Specifications

Engine Service Information

Tightening Torques for Standard

Bolts and Nuts

Abbreviations and Symbols

Unit Conversions

–PERIODIC MAINTENANCE

Introduction

Precautions

Periodic Maintenance Schedule

Periodic Maintenance Procedures

–ENGINE

Before You Begin Servicing

Introduction

Cylinder Head Specifications

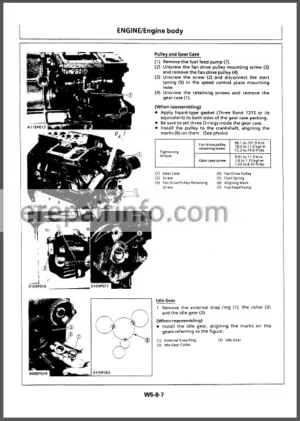

Camshaft and Timing Gear Train Specifications

Crankshaft and Pistons Specifications

Cylinder Block Specifications

Special Torque Chart

Special Service Tools

Measuring Instruments

Cylinder Head

Cylinder Block

–Fuel System

Before You Begin Servicing

Introduction

Fuel System Specifications

Special Service Tools

Measuring Instruments

Fuel System Diagram

Fuel System Components

Fuel Injection Lines

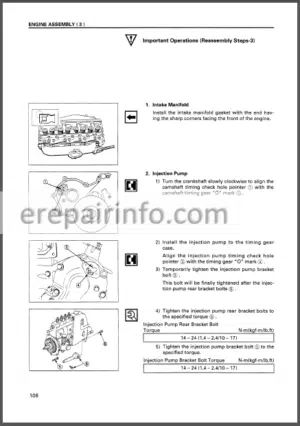

Fuel Injection Pump

Checking and Adjusting Fuel Injection Timing

Fuel Injectors

Disassembly and Inspection of Fuel Injectors

Adjusting Fuel Injector Pressure

Reassembly of Fuel Injectors

Installation of the Fuel Injectors

–Cooling System

Before You Begin Servicing

Introduction

Cooling System Diagram

Engine Coolant Pump Components

Engine Coolant System Check

Engine Coolant Pump

–Lubrication System

Before You Begin Servicing

Introduction

Oil Pump Service Information

Lubrication System Diagram

Checking Engine Oil Pressure

Trochoid Oil Pump

–STARTER MOTOR

Before You Begin Servicing

Introduction

Starter Motor Information

Starter Motor Specifications

Starter Motor Troubleshooting Starter Motor Components

Starter Motor

–ALTERNATOR

Before You Begin Servicing

Introduction

Standard and Optional Dynamo Information

Standard and Optional Alternator Information

Alternator Specifications

Dynamo Specifications

Alternator Troubleshooting

Alternator Components

Alternator Wiring Diagram

Alternator Standard Output

Alternator

Dynamo Component Location

Dynamo Wiring Diagram

Operation of Dynamo

Dynamo Standard Output

Testing of Dynamo

Dynamo

–ELECTRIC WIRING

Electric Wiring Precautions

Electric Wire Resistance

Battery Cable Resistance

Electrical Wire Sizes – Voltage Drop

Conversion of AWG to European Standards

–TROUBLESHOOTING

Special Service Tools

Troubleshooting By Measuring Compression Pressure

Quick Reference Table For Troubleshooting Troubleshooting Charts

Electric Wiring

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet