Factory Service And Operators Manual For JCB Backhoe Loader. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. So It Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 3619

Number: 9813-0250-07; 9831-0400 (march 2015)

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

JCB Backhoe Loader

3CX T4F Serial No. from 02254521 to 02274521

4CX T4F Serial No. from 02254521 to 02274521

Contents

-GENERAL INFORMATION

Introduction

Safety

Use

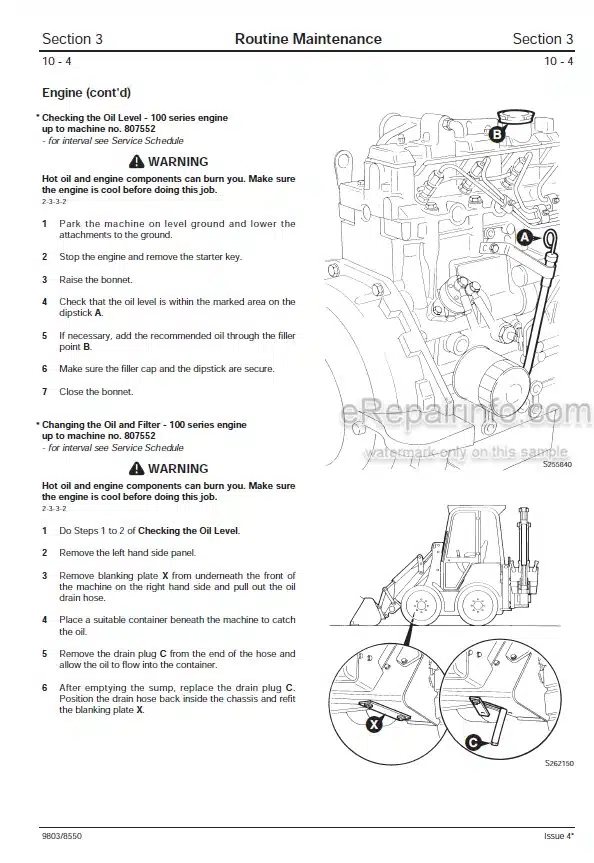

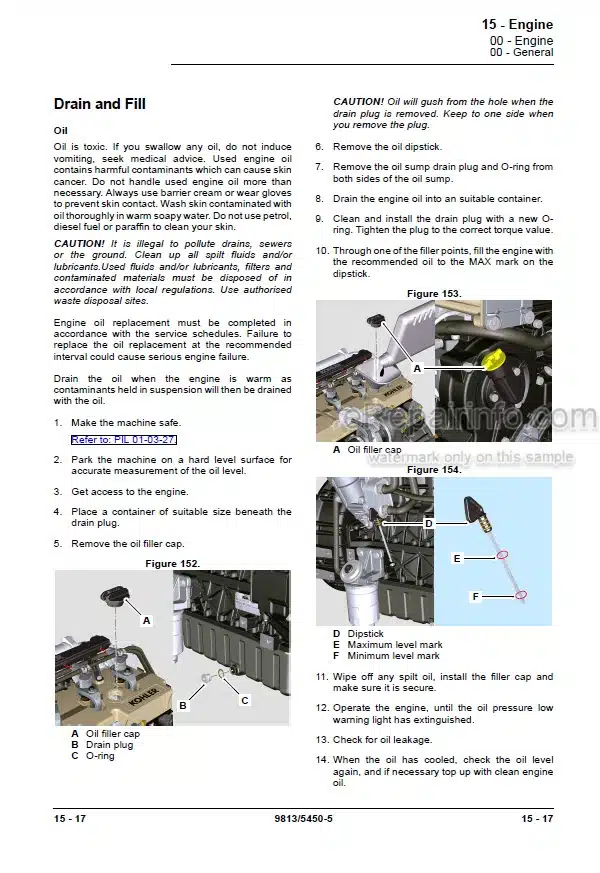

Routine Maintenance

General Procedures

Service Consumables

Torque Settings

Stall Speed Combinations

Service Tools

-OPERATOR MANUAL

Introduction

About The Product

Operation

Attachments

Preservation and Storage

Maintenance

Technical Data

-ATTACHMENTS

Applications

Hi-Flow Bi-Direction Auxiliary Circuit

Hi-Flow Hammer Circuit

Hydraulic Tool Circuit (HTC)

Excavator Hydraulic Quickhitch

Automatic Excavator Quickhitch System

Hydraulic Thumb (Excavator)

-BODY AND FRAMEWORK

Applications

Cab Air Conditioning System

Overload Warning System

Stabiliser Leg Alarm System

Air Conditioning Condenser

Cab HVAC Unit

Binary Switch

Air Conditioning Compressor

Heater Valve

Stabiliser Legs – Sideshift

Stabiliser Legs – Centremount

Boom

Dipper

Inner Dipper

Kingpost

Carriage

Hydraclamps

Power Sideshift

Loader Arms

Boom Lock Cable

Shovel Reset

Cab

Hydraulic Tank

Fuel Tank

Engine Cover

Front Grille Housing

Engine Cover Support Frame

Front Bumper / Counterweight

Chassis Panels

Inner Dipper Wear Pads

Cold Climate Heating System

Auto Boom Lock

Routine Maintenance Procedures

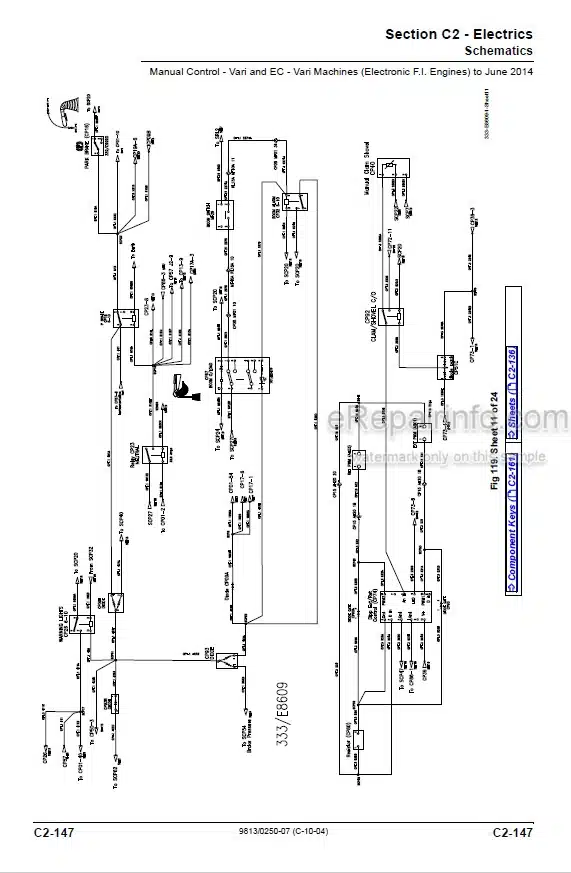

-ELECTRICS

Applications

Fuses and Relays

Schematics

Electrical Harness System

Alternator (C-04-01)

Alternator (C-04-02)

Battery

Routine Maintenance Procedures

-HYDRAULICS

Applications

Systems and Schematics

Manual Controls Hydraulic System

Manual Controls – Vari Hydraulic System

Easycontrol Hydraulic System

Easycontrol – Vari Hydraulic System

Advanced Easy Control Hydraulic System

Advanced EasyControl Plus Hydraulic System

Smooth Ride System (SRS)

Auto Smooth Ride System (SRS)

Ram Creep Tests

Excavator Valve – Parallel Type

Excavator Valve – Closed Centre Type

Loader Valve – Parallel Type

Loader Valve – Closed Centre Type

Pilot Pressure Supply Valve

Pilot Changeover Valves

Hydraclamp Valve

Shovel Reset Valve

HPCO Manifold

Hose Burst Check Valves (HBCV)

Main Pump – Gear Type (P1/P2)

Main Pump – Gear Type (Pump 3)

Main Pump – Variflow Type

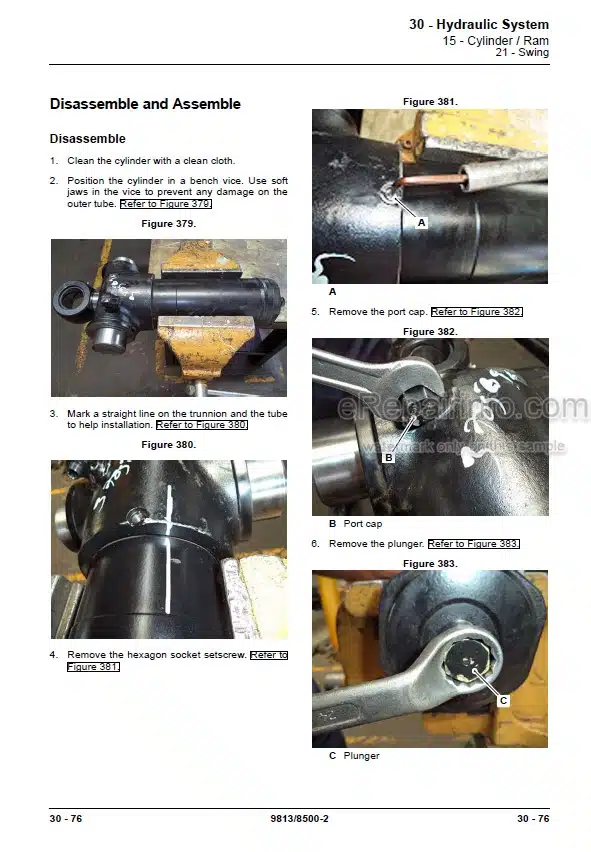

Rams

Excavator Control Levers

Loader Control Levers

Joystick Controllers

Stabilisers Controller

Auxiliary Foot Pedal Control

Oil Cooler Matrix

Routine Maintenance Procedures

-TRANSMISSION

Application

Wheels And Tyres

Front Axle

Rear Axle

SS700 Gearbox System

SS750 Gearbox System

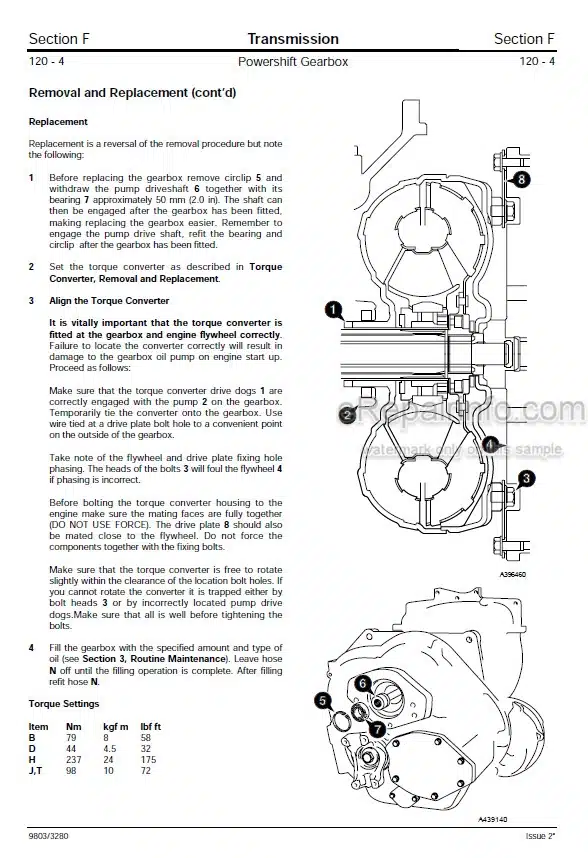

PS764 Gearbox System

PS766 Gearbox System

Torque Converter Lock Up System

Gearbox Systems Fault Finding

Torque Converter Stall Tests

Flushing the Transmission Oil

Shiftmaster ECU

SS700 Gearbox

SS750 Gearbox

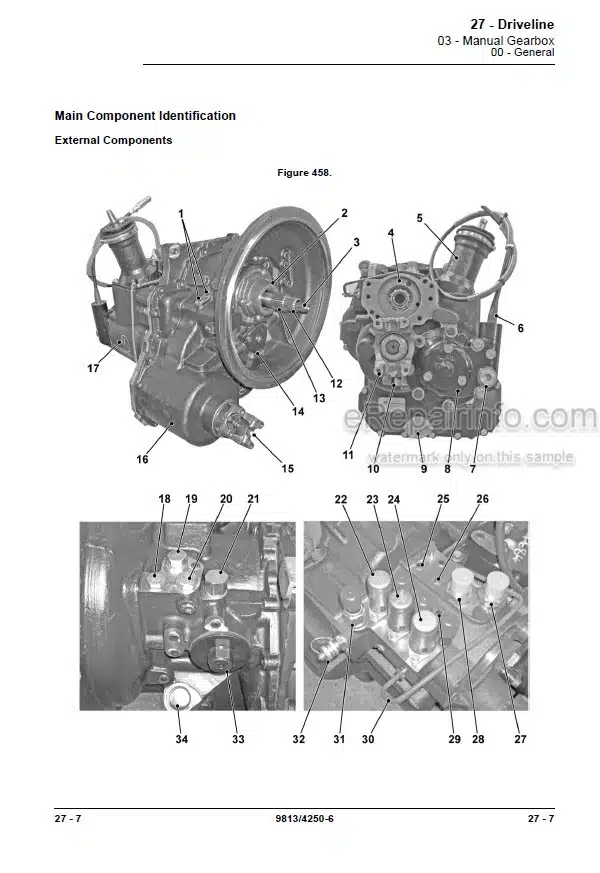

PS760 Gearbox

Torque Converter

Oil Cooler Matrix

Propshafts

Speed Sensors

Speedometer

Gearbox Mountings

Routine Maintenance Procedures

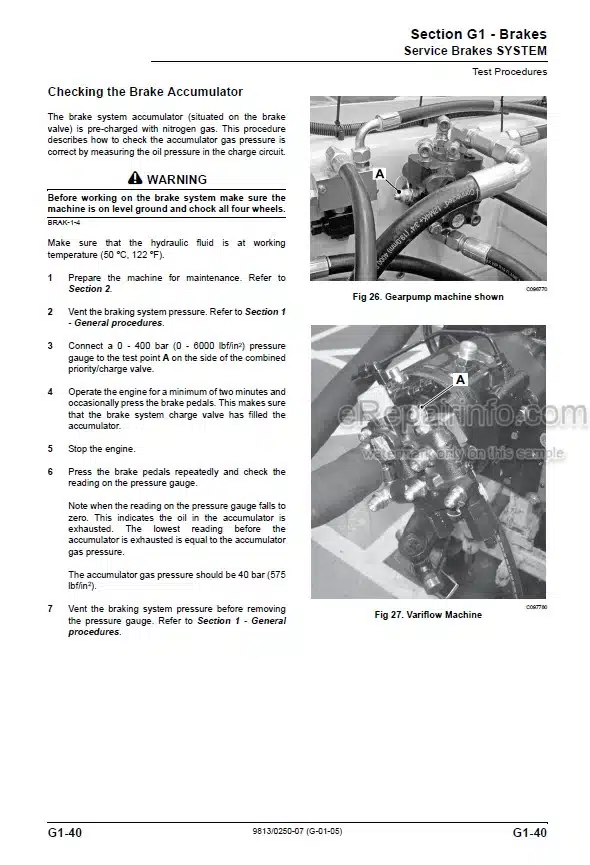

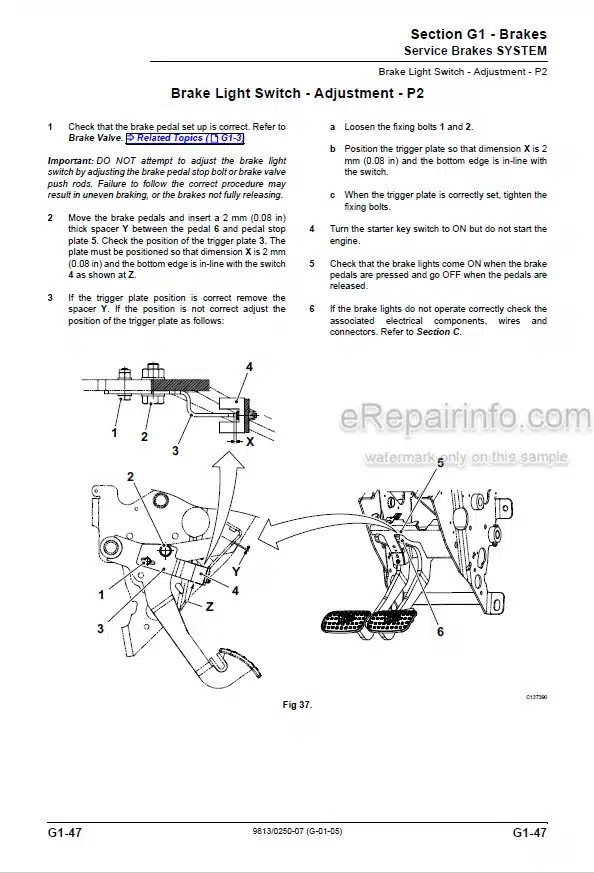

-BRAKES

Applications

Service Brake System

Internal Park Brake System

External Park Brake System

Brake Valve

Combined Priority/Charge Valve

Park Brake Calliper

Park Brake Disc

Park Brake Switch

Routine Maintenance Procedures

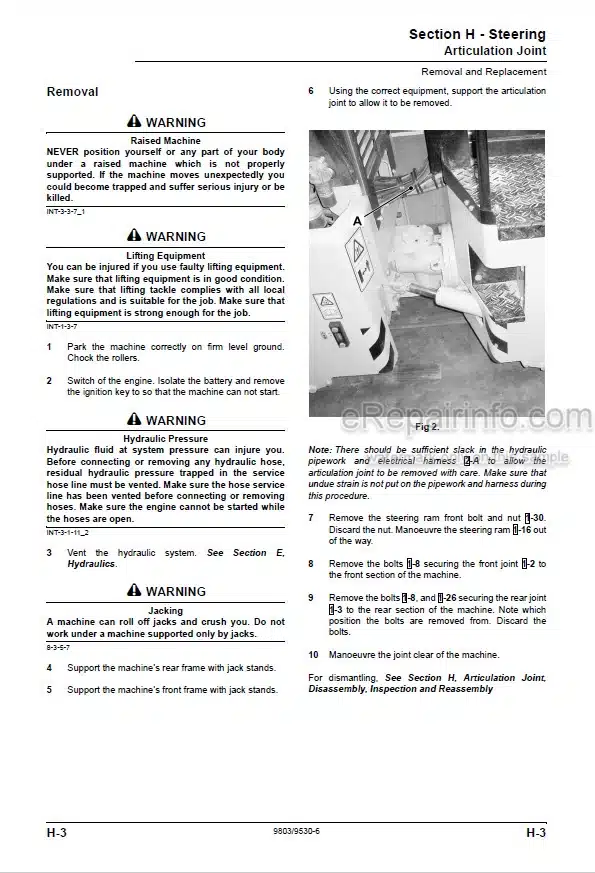

-STEERING

Application

Steering System

Hydraulic Steer Unit

Priority Valve

Power Track Rod

Steering Column

Auto Steer Mode Valve

Steer Mode ECU

Steer Mode Select Switch

-ENGINE

Application

Start And Stop System (Mechanical F.I. Engines)

Inlet Manifold Heater System

Starter Motor

Coolant Expansion Tank

Cooling Pack

Cooling Fan Viscous Coupling

Fuel Cooler

Throttle Cable

JCB Dieselmax and Ecomax

Air Filter Housing and Ducts

Air Filter Vacuum Switch

Silencer – Mechanical F.I. Engines

Silencer – Electronic F.I. Engines

Electronic F.I. Engine – Machine Devices

SCR Systems

Routine Maintenance Procedures

-ELECTRONIC CONTROL SYSTEMS

Application

CANbus System

RH Instrument Cluster

Immobiliser Devices

Automate Systems

Fault Code System

Servicemaster System

Servicemaster Tools Set

Shiftmaster 2.3 Diagnostics Tool

Immobiliser Setup Tool (M-05-15)

Immobiliser Diagnostics Tool (M-05-17)

RH Instrument Cluster Setup Tool

Pulse Width Modulation Theory

Electronic Control Unit Theory

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet