Factory Service And Maintenance Manual For JLG Boom Lift. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 452; 432

Issue: august 2011; may 2008

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

JLG Boom Lift

800A

800AJ

Contents

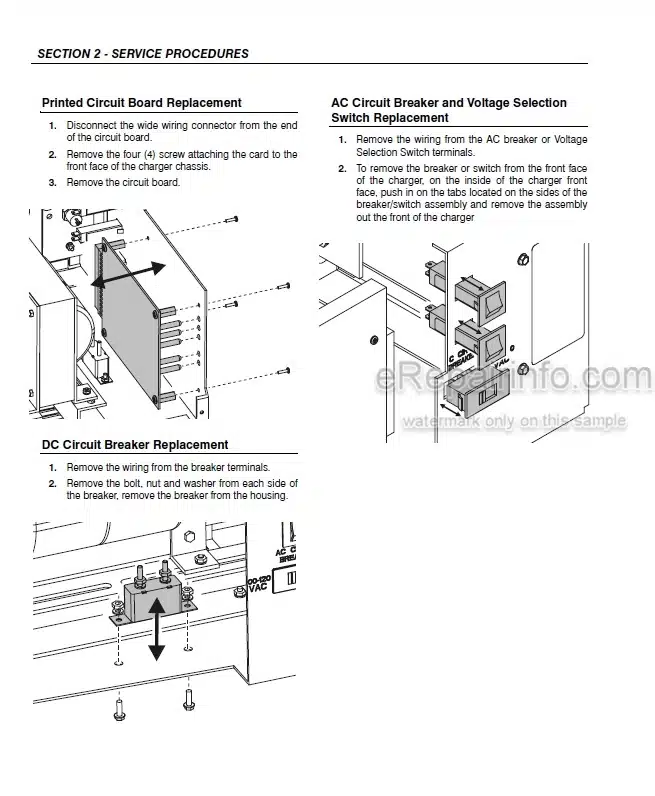

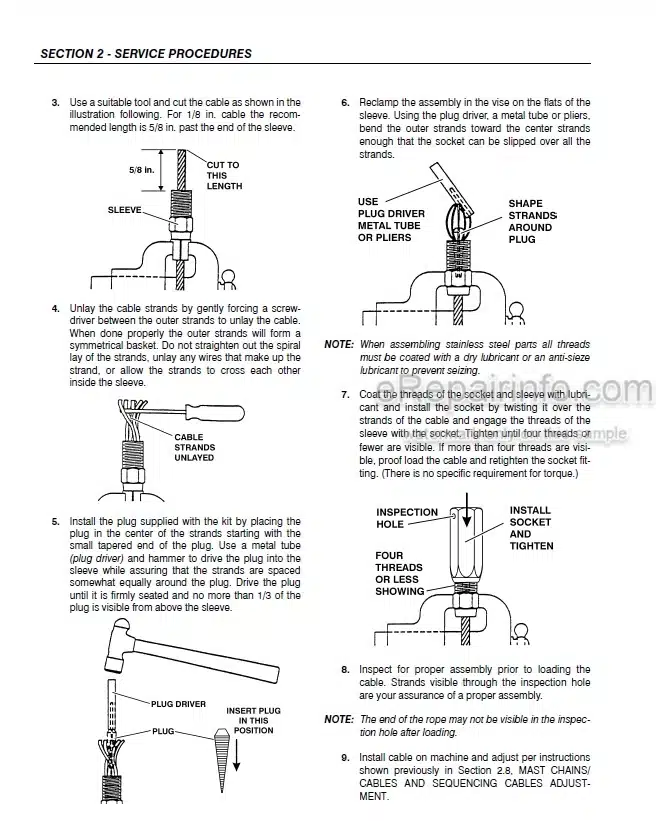

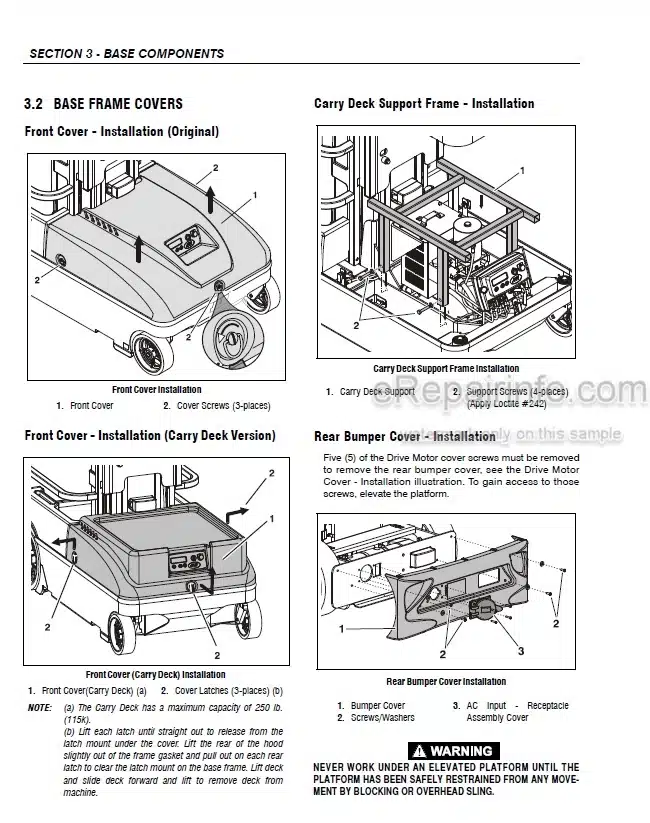

-INTRODUCTION – MAINTENANCE SAFETY PRECAUTIONS

General

Hydraulic System Safety

Maintenance

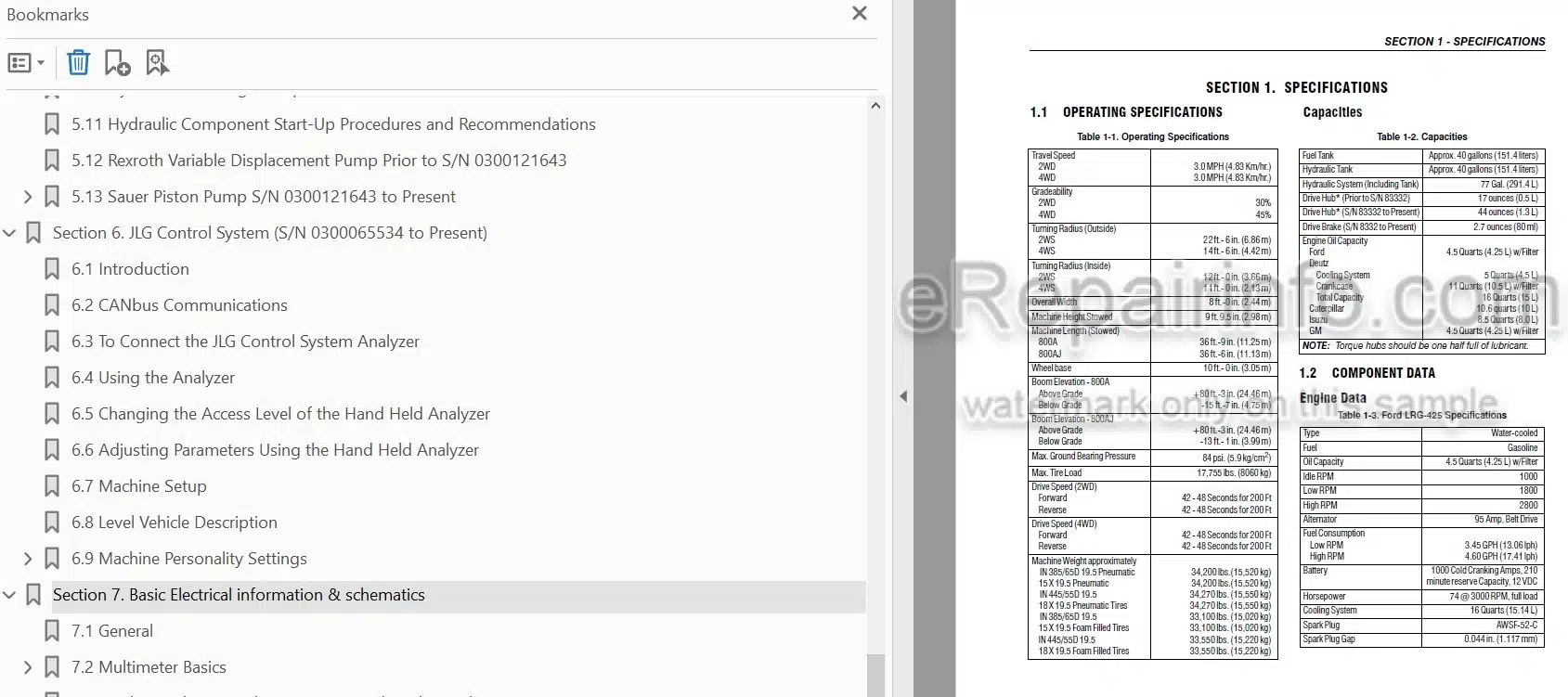

-SPECIFICATIONS

Operating specifications

Component Data

Function Speeds

Torque Requirements

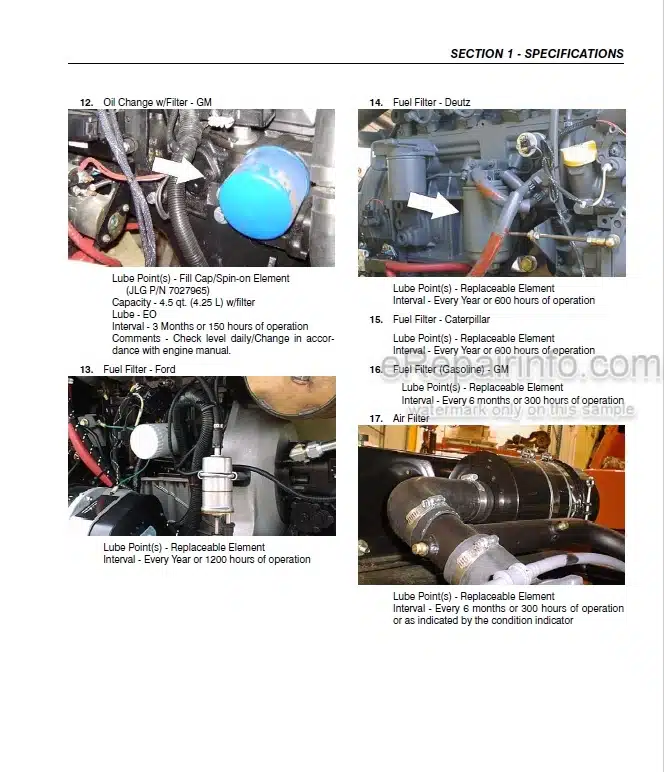

Lubrication

Pressure Settings

Cylinder Specifications

Major Component Weights

Lubrication and Operator Maintenance

-GENERAL

Machine Preparation, Inspection, and Maintenance

Service and Guidelines

Lubrication and Information

Cylinder Drift Test

Pins and Composite Bearing Repair Guidelines

Welding on JLG Equipment

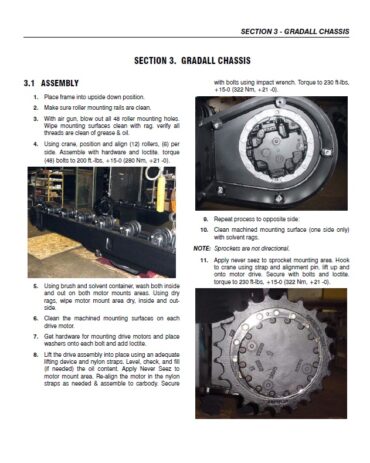

-CHASSIS & TURNTABLE

Tires & Wheels

Oscillating Axle Bleeding Procedure And Lockout Test

Free Wheeling Option

Torque Hub, Drive

Drive Brake – Ausco (Prior to S/N 56875)

Drive Brake – Mico (S/N 56875 to 83332)

Drive Brake (S/N 83332 to Present)

Drive Motor (Prior to S/N 83332)

Drive Motor Adjustment Procedure (Prior to S/N 83332)

Drive Motor (S/N 83332 to Present)

Swing Bearing

Swing Hub installation

Swing Hub (Prior to S/N 0300068040)

Swing Brake – Ausco (Prior to S/N 0300068040)

Swing Motor (Eaton) (Prior to S/N 0300068040)

Swing Hub (S/N 0300068040 to Present)

Swing Brake (S/N 0300068040 to Present)

Swing Motor (S/N 0300068040 to Present)

Rotary Coupling

Tilt Alarm Switch (Prior to S/N 0300065534)

Spark Arrester Cleaning Instructions

Generator

Dual Fuel System

EFI Engine

Ford LPG System (S/N 0300077500 To Present)

Electric Governor Installation And Adjustments – Ford LRG425 Engine (Prior to S/N 0300065534)

Throttle Checks And Adjustments – Deutz Engine (Prior to S/N 0300065534)

Deutz EMR 2 (S/N 85331 to Present)

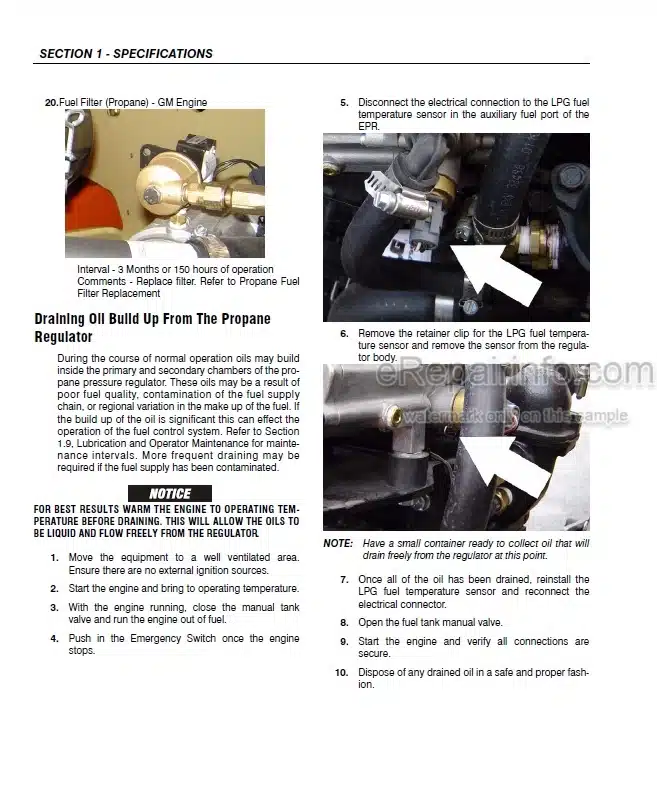

GM Engine General Maintenance

GM Engine Dual Fuel System

GM Engine Fuel System Repair

GM Engine LPG Fuel System Diagnosis

-BOOM & PLATFORM

Platform

Rotator and Slave Cylinder

Upper Boom Powertrack

Upper Boom

Upright

Tower Boom Assembly

Articulating Jib

Sequence For Hose Replacement In The Tower Boom

Limit Switches Adjustment

Boom Valve Adjustment

Wear Pads

Rotator (prior to S/N 0300067538)

Rotator Assembly (S/N 0300067538 to Present)

Drive Card Setup Procedures

Foot Switch Adjustment

Upright Monitoring System

UMS Troubleshooting and Fault Messages – Non-ADE Machines

UMS Troubleshooting and Fault Messages – ADE Machines

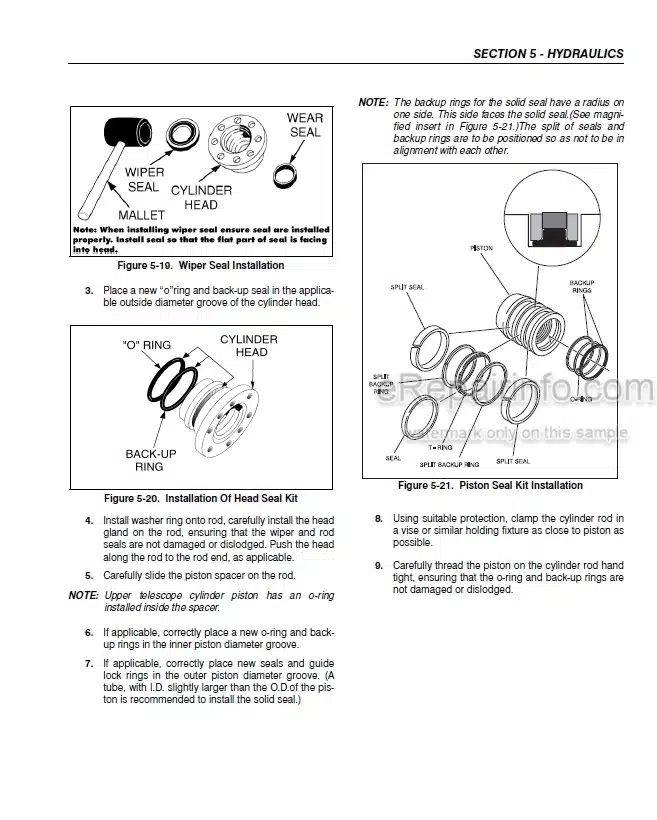

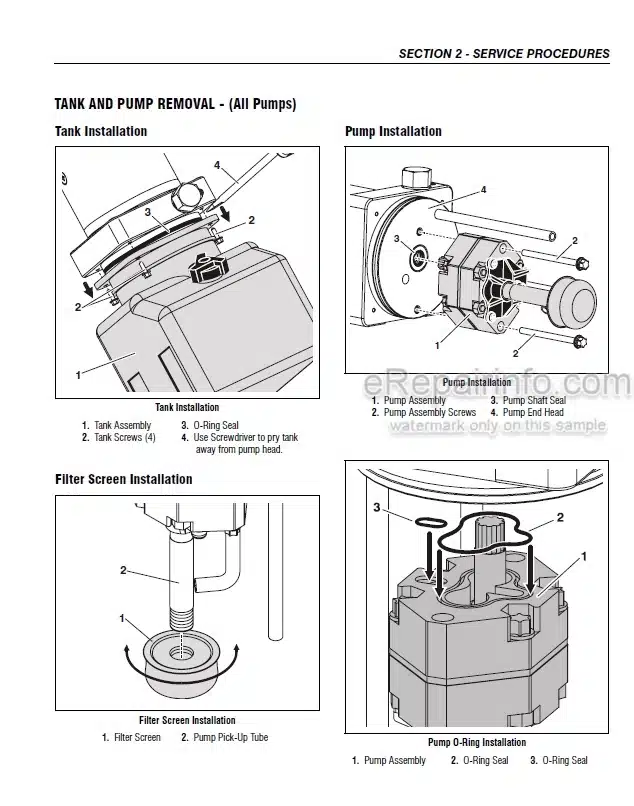

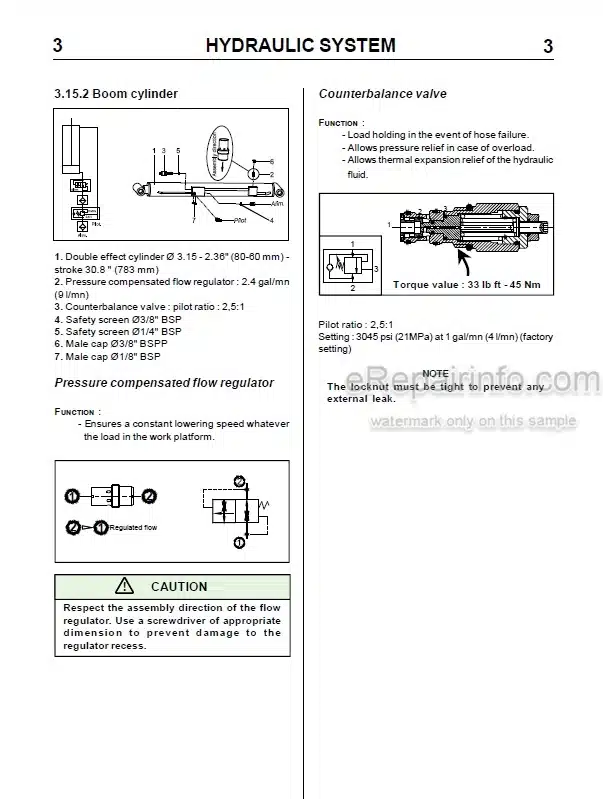

-HYDRAULICS

Lubricating 0-Rings in the Hydraulic System

Valves – Theory Of Operation

Holding Valve Checks

Cylinders – Theory Of Operation

Cylinder Checking Procedure

Cylinder Repair

Cylinder Removal And Installation

Hydraulic Pump W/hayes Pump drive Coupling Lubrication

Pressure Setting Procedures

Hydraulic oil change-out procedure

Hydraulic Component Start-Up Procedures and Recommendations

Rexroth Variable Displacement Pump Prior to S/N 0300121643

Sauer Piston Pump S/N 0300121643 to Present

-JLG CONTROL SYSTEM FS/N 0300065534 TO PRESENT)

Introduction

CANbus Communications

To Connect the JLG Control System Analyzer

Using the Analyzer

Changing the Access Level of the Hand Held Analyzer

Adjusting Parameters Using the Hand Held Analyzer

Machine Setup

Level Vehicle Description

Machine Personality Settings

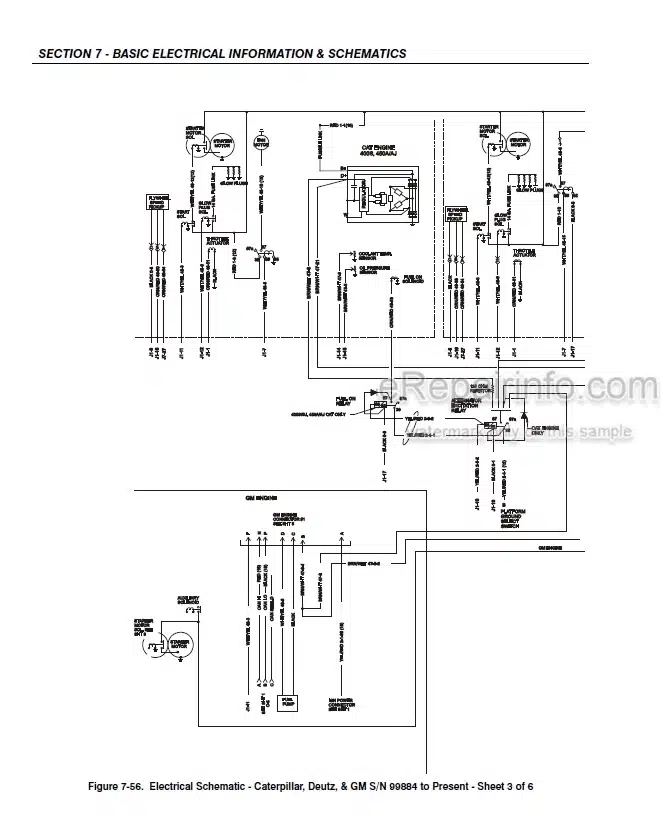

-BASIC ELECTRICAL INFORMATION & SCHEMATICS

General

Multimeter Basics

Applying Silicone Dielectric Compound to Electrical Connections

AMP Connector

Deutsch Connectors

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet