Factory Operator Safety And Maintenance Manual For JLG Boom Lift. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF (ZIP File)

Language: ITA; ENG; CHI; FRA; GER; ESP; NED; SWE; DEN; NOR; RUS; POL; SLO; FIN; JPN

Quantity of Manuals: 15

Pages: 224; 216; 212; 226; 232; 228; 230; 220; 218; 212; 242; 226; 216; 216; 214

Number: MUX26JP011602 (issued 2016); MUX26JP021602 (issued 2016); MUX26JP021817 (issued 2016); MUX26JP031602 (issued 2016); MUX26JP041602 (issued 2016); MUX26JP051602 (issued 2016); MUX26JP061602 (issued 2016); MUX26JP071602 (issued 2016); MUX26JP091602 (issued 2016); MUX26JP101602 (issued 2016); MUX26JP111602 (issued 2016); MUX26JP121602 (issued 2016); MUX26JP131602 (issued 2016); MUX26JP141602 (issued 2016); MUX26JP161602 (issued 2016)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

JLG Boom Lift

X26J PLUS

Contents

-PREFACE

Attention – Danger

Warning

Note

HOW TO USE THE MANUAL

NORMATIVE REFERENCE

WARRANTY

LIABILITY

EC DECLARATION CONFORMITY

-TECHNICAL INFORMATION

Description Of The Machine

Machine Identification Plate

Overall Dimensions Of The Machine

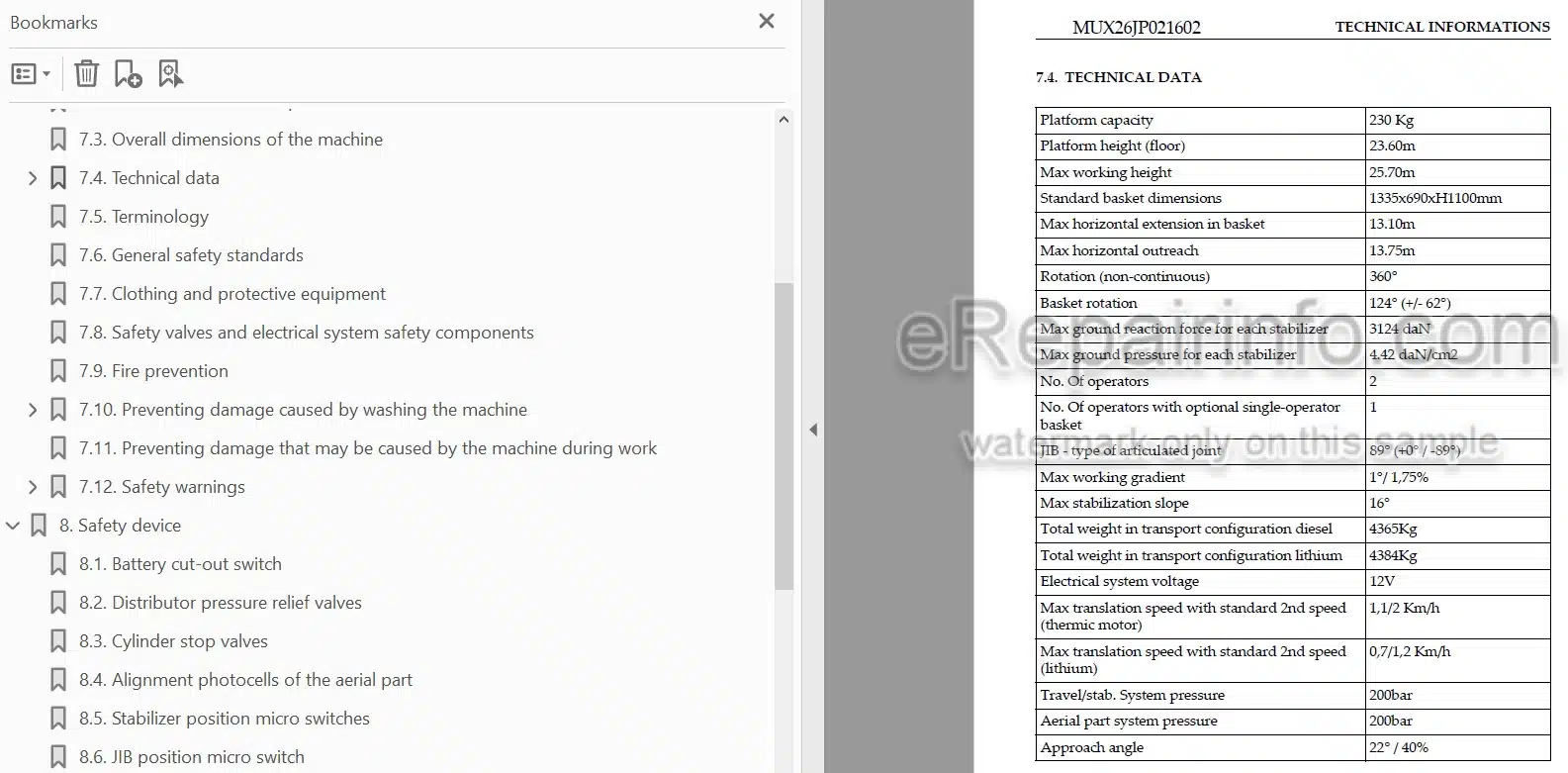

Technical Data

Terminology

General Safety Standards

Clothing And Protective Equipment

Safety Valves And Electrical System Safety Components

Fire Prevention

Preventing Damage Caused By Washing The Machine

Preventing Damage That May Be Caused By The Machine During Work

Safety Warnings

-SAFETY DEVICE

Battery Cut-Out Switch

Distributor Pressure Relief Valves

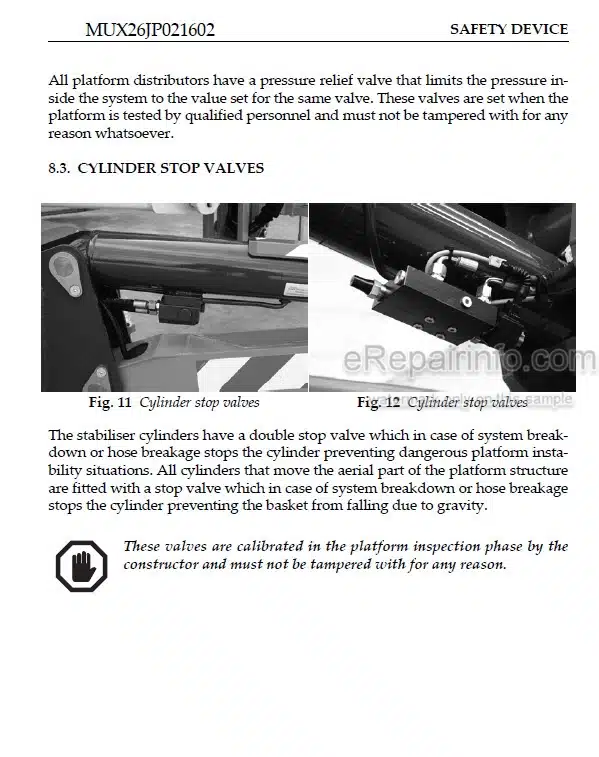

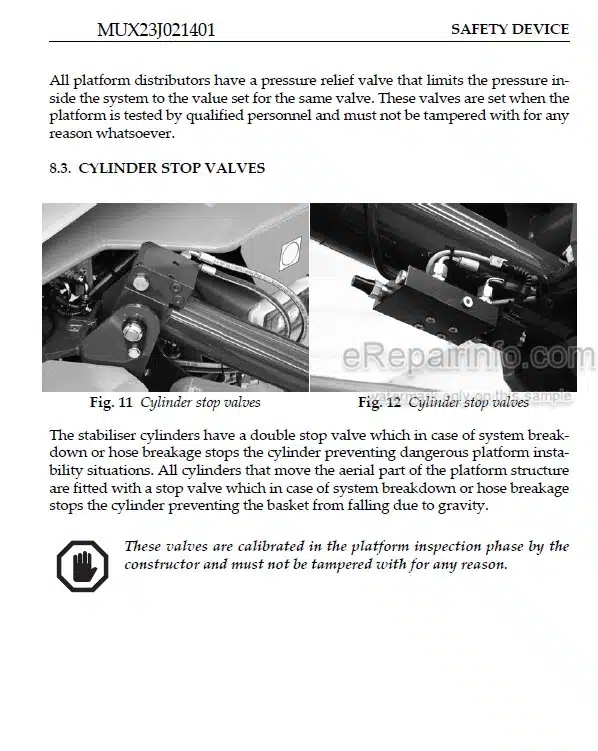

Cylinder Stop Valves

Alignment Photocells Of The Aerial Part

Stabilizer Position Micro Switches

Jib Position Micro Switch

Ropes Integrity Micro Switch

Basket Load Sensor

Control Protection

Spirit And Electronic Level

Pin Locking Bolts And Nuts

Safety Device Electronic Control Board

Booms Position Sensors

Outrigger Joint Lock Pins

External Temperature Sensor (Optional)

-INSTRUMENTS AND CONTROLS

Remote Control

Foot Switch (Optional)

Control Position

Remote Control MOVE (Optional)

Sky-Guard System (Optional)

-EMERGENCY DEVICE

Emergency Stop Button

Hand Pump

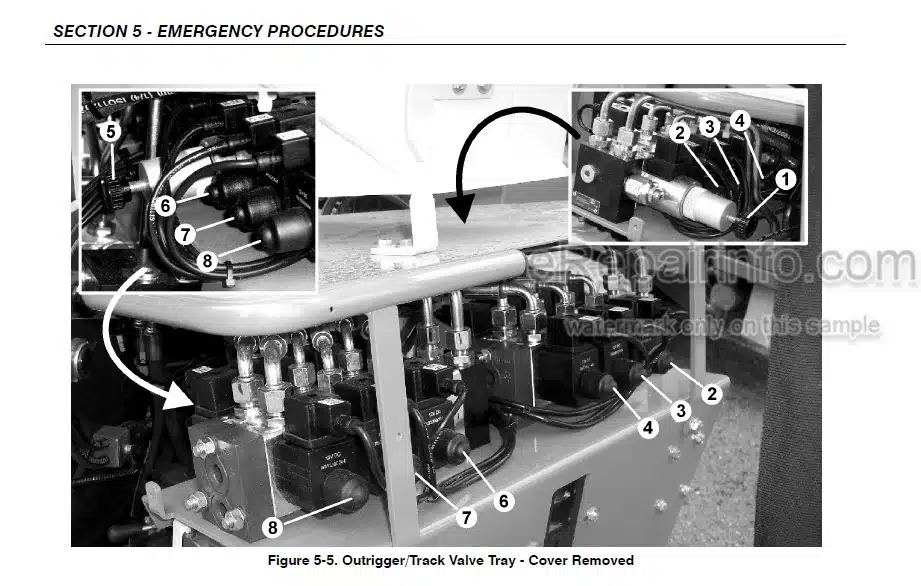

Solenoid Valves For Emergency Descent

Safety Device Bypass Key

Emergency Position Controls

-USING THE MACHINE

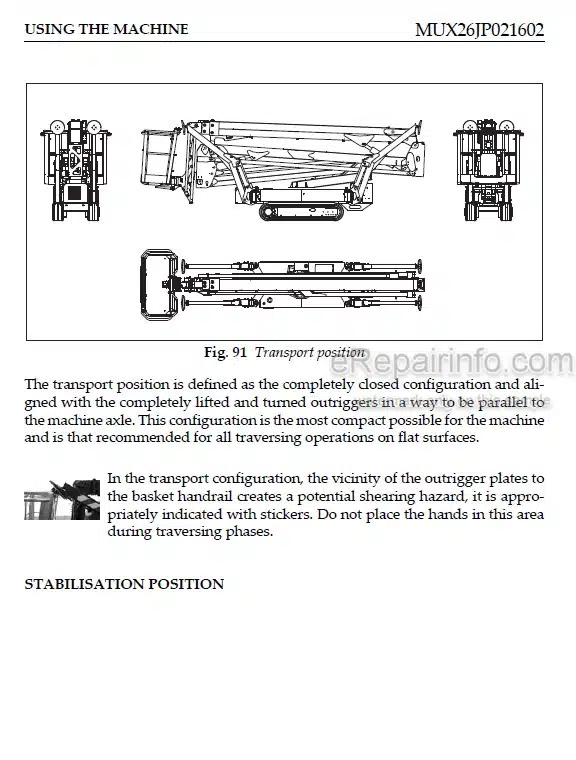

Safety Standards To Adopt Before Using The Platform

Procedures For Correct Use

Working Area

Use Of The Elevating Work Platform (MEWP)

Aerial Part Emergency Manoeuvres

Electrical Connection Of Remote Control

Recharging The Battery

Main Intended Uses Of The Platform

-MAINTENANCE

Safety Instructions Tor Greasing And Lubrication

Safety Instructions For Maintenance Operations

Maintenance Control Position With Remote Control From The Ground

Periodical Maintenance Intervals

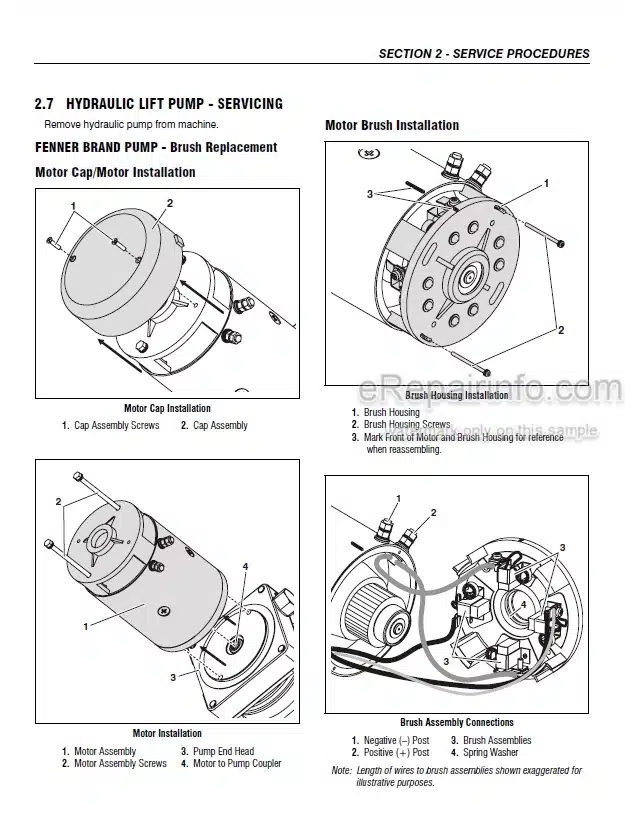

Electric Motor Maintenance

Inspection And Maintenance Intervals

General Periodical Checks

Maintenance On Rubber Tracks

Checking Tightness Of Nuts And Bolts

Hydraulic Oil Level Check

Checking For Leaks In The Hydraulic System

Checking The Condition Of The Filter Cartridge

Checking That All The Plates Are Present On The Machine And Intact

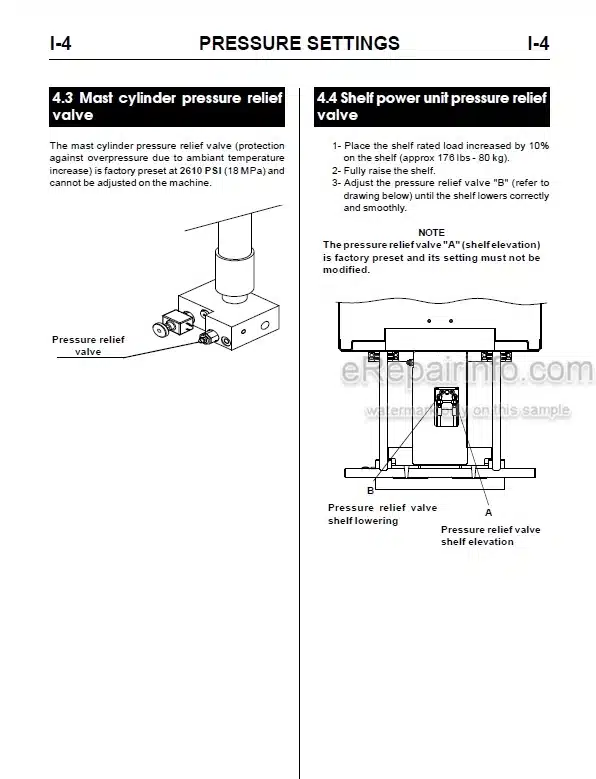

Checking The Operating Pressures In The Hydraulic System

Checking Extension Ropes

Checking Wear Of The Telescopic Arm Slide Blocks

Battery Petrol/Diesel Engine: Maintenance – Replacement – Disposal

Battery Pack Maintenance Operating Specifications

Servicing The Engine Thermic Version

Start-Up Of The Machine After Maintenance

-SAFETY STANDARDS FOR TRANSPORT

Removing The Basket

Loading And Unloading The Machine On Transport Vehicles Using Ramps

Lifting The Machine

Transporting The Machine

-SERVICE MENU ON THE REMOTE CONTROL

Input Menu

Language Menu

Errors Menu

Working Hours Menu

Joystick Menu

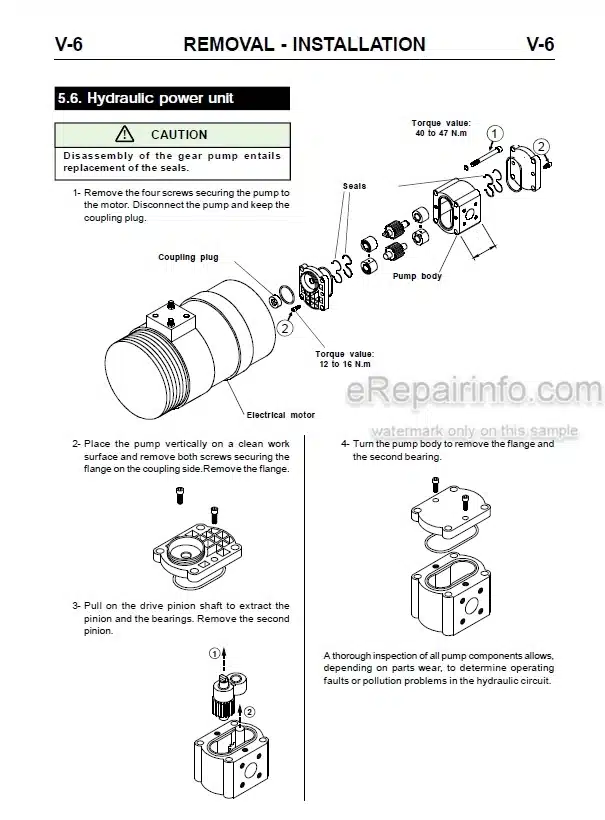

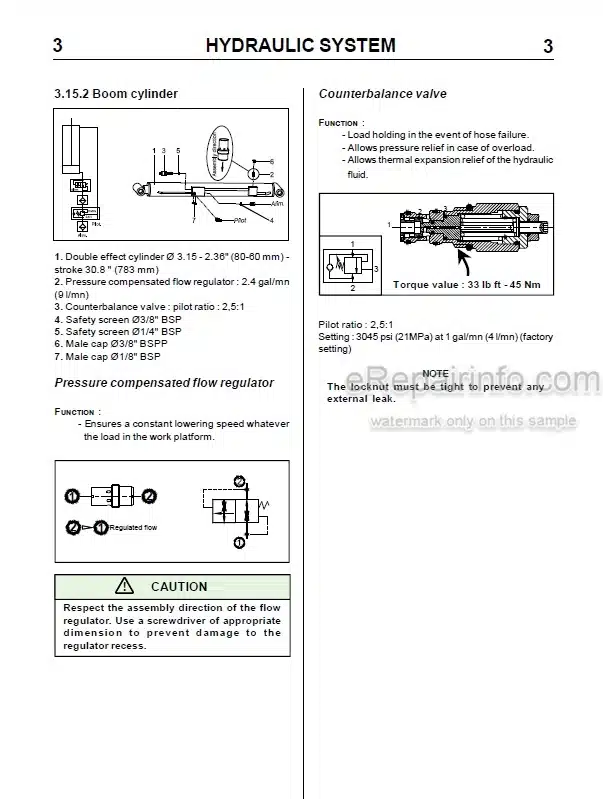

HYDRAULIC SYSTEM

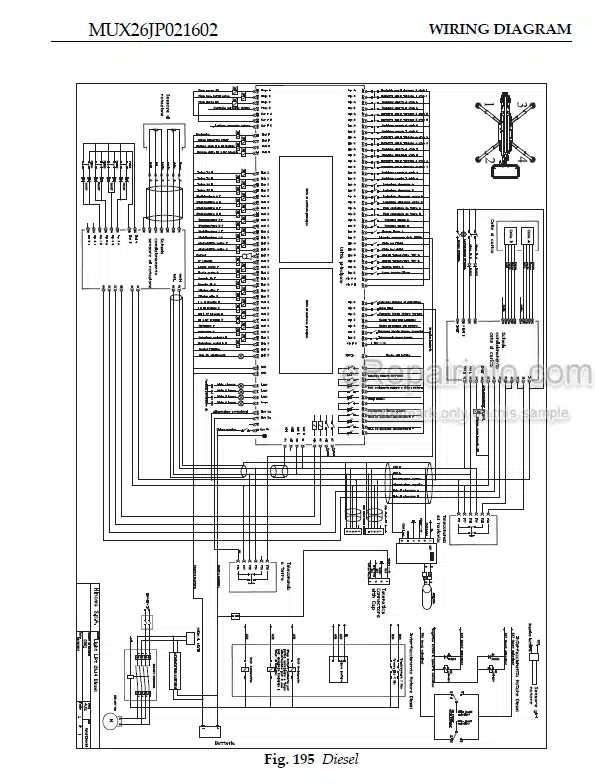

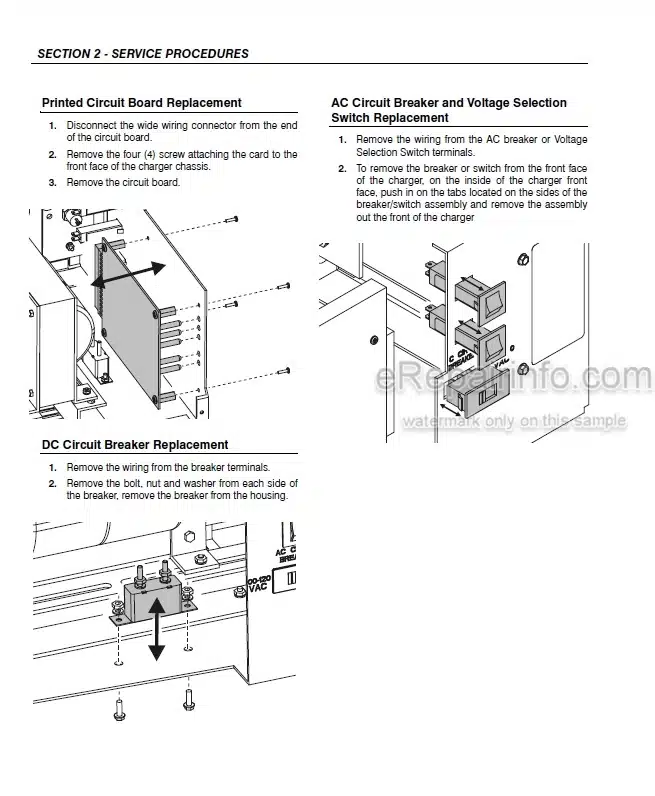

WIRING DIAGRAM

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet