Factory Technical Repair Operation And Test Manual For John Deere Combine. Manual Contains Illustrations, Instructions, Diagrams For Systems Diagnosis, Theory Of Operation, Performance Testing, Tests And Adjustments, Operational Check, Unit Locations, Diagnostic Codes, Schematics And A Lot Of Other Useful Information For Service And Repair Remove And Install, Assembly And Disassembly, Inspection, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1012

Number: TM4545 (december 2000)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

John Deere Combine

2254

2256

2258

2264

2266

Standard

Hillmaster

Contents

-SAFETY

Safety Information

-GENERAL

Lubricants and Coolant

Torques for Hardware

Type Plates

Serial Numbers

-ENGINE

Special Tools

Engines on 2200 Series Combines

Removing and Installing Engine

-FUEL, AIR INTAKE AND COOLING SYSTEMS

Fuel System

Air Intake System

Cooling System

-ELECTRICAL SYSTEM

Connectors

Alternator

Starting Motor

Main Electrical System

Hill master Control

Automatic Header Control (Lateral Tilt)

Low Shaft Speed Monitor System

Harvest Performance Monitor

-POWER TRAIN

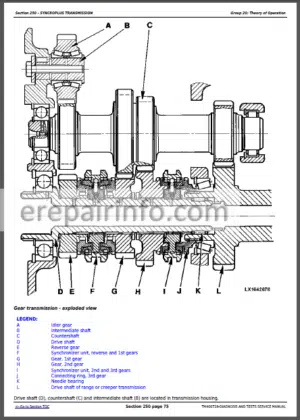

Intermediate Transmission

Transmission and Differential

Planetary Final Drives

Final Drives

Hydrostatic Drive, Variable Pump

Hydrostatic Drive, Fixed-Displacement Motor

Hydrostatic Drive, Oil Change

Cam Lobe Motor

-BRAKES, STEERING, REAR AXLE

Brake Operating Assembly

Brakes

Hydrostatic Steering

Rear Axle

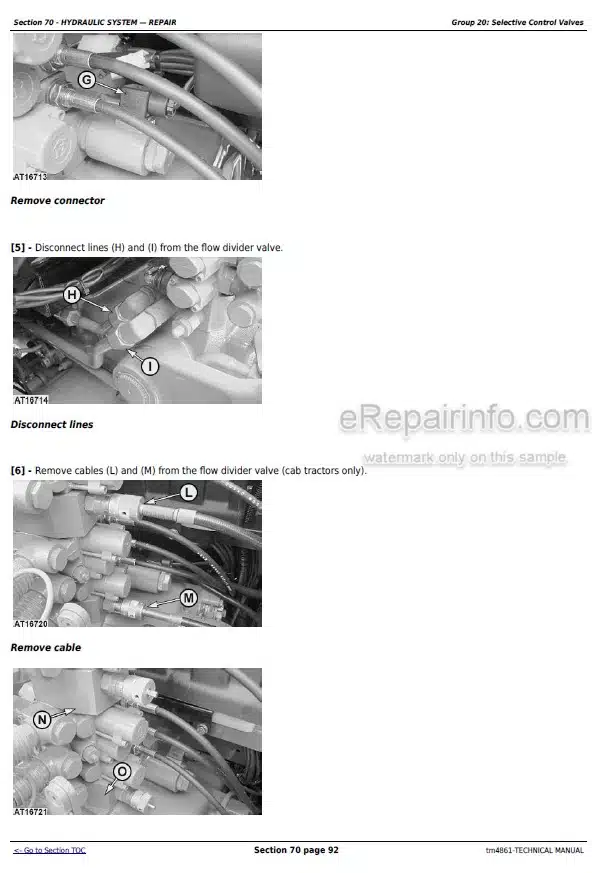

-HYDRAULIC SYSTEM

Hydraulic Reservoir and Lines

Triple Hydraulic Pump

Electro-Magnetic Control Valve

Hydraulic Cylinders

Hillmaster Hydraulic Cylinder

Accumulators

-MISCELLANEOUS

Bearings and Shafts

Drive Belts

Drive Chains

Side Guard

-OPERATOR’S CAB AND AIR CONDITIONING

Air Conditioning System – R134a

Operator’s Cab Heating System

Gear Shift Mechanism

-FEEDER HOUSE

Removing the Feeder House

Bottom Feeder Drum

Upper Feeder Shaft and Slip Clutch

Drives

Reverser

Pivoting Shield

-SEPARATOR AND CLEANING UNIT

Stone Trap

Threshing Cylinder and Concave

Beater/Second Cylinder and Second Concave

Electric Clutch

Countershaft, L.h. Drive Belt Pulley and Belt Guide

Variable Cylinder Drive

Cylinder Drive and Reduction Gear

Countershaft for Straw Walker and Cleaning Shoe Drive

Straw Walkers and Straw Walker Crankshaft

Cleaning Fan and Drive Fan

-GRAIN RECOVERY AND UNLOADING SYSTEM

Tailings Elevator

Clean Grain Elevator

Filling the Grain Tank

Unloading the Grain Tank

Unloading Auger

-SPECIAL EQUIPMENT

Straw Chopper

Chaff Spreader

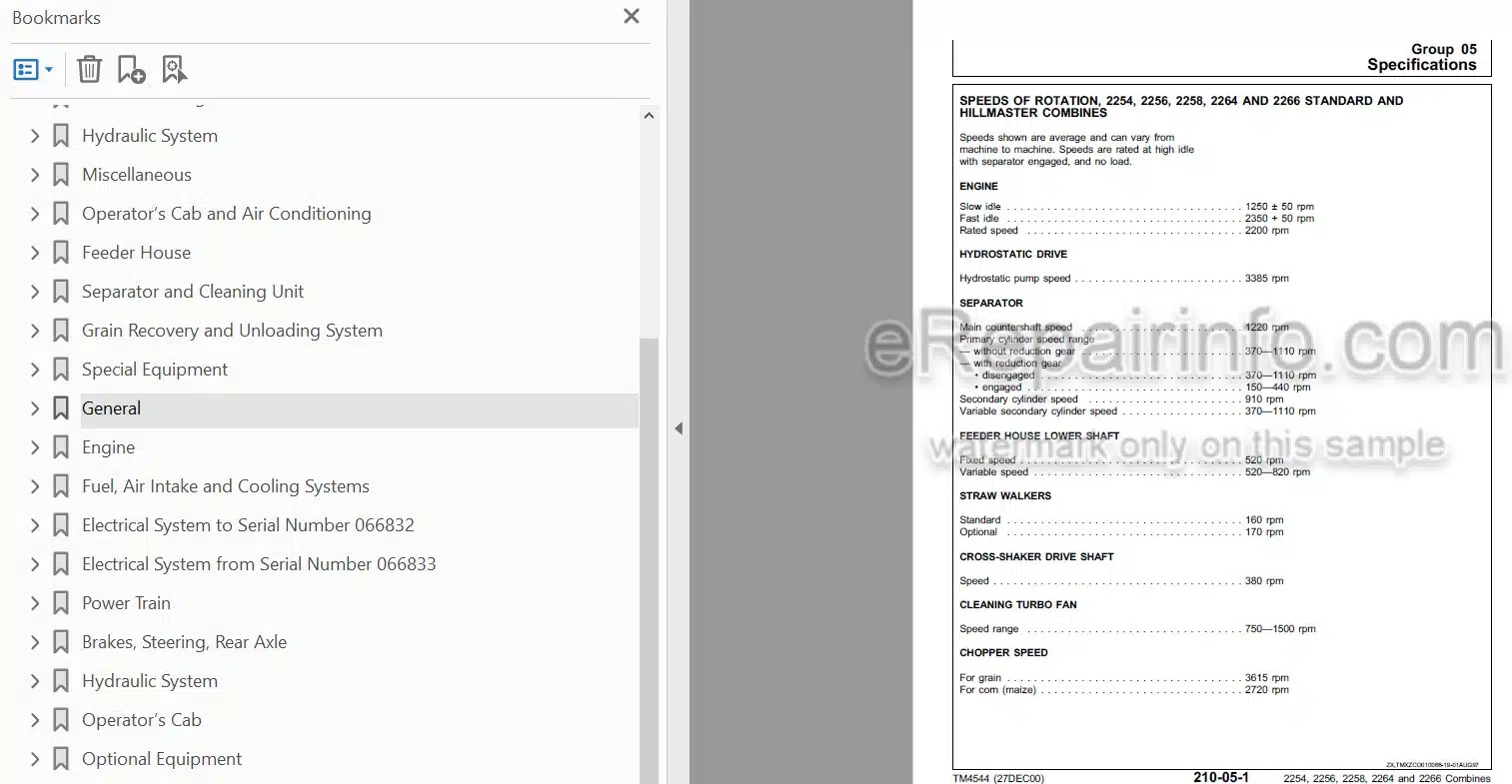

-GENERAL

Specifications

-ENGINE

Specifications

-FUEL, AIR INTAKE AND COOLING SYSTEMS

Fuel System

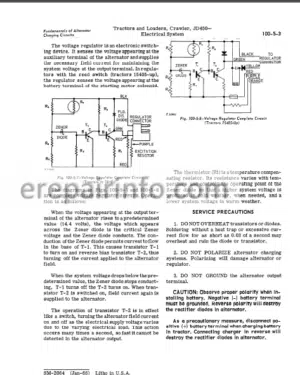

-ELECTRICAL SYSTEM TO SERIAL NUMBER 066832

Test Equipment

Test Equipment

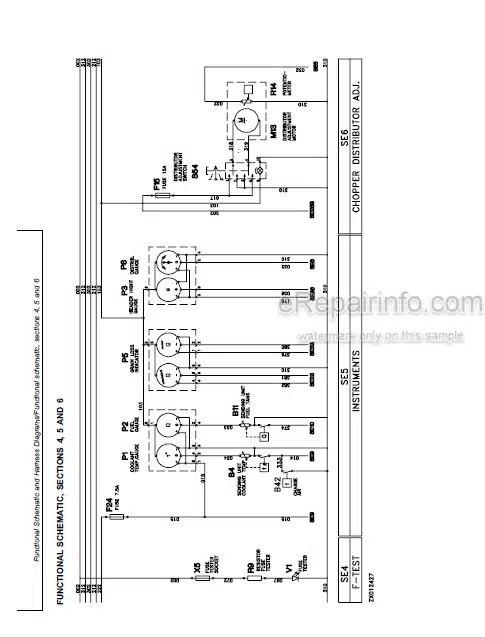

Functional Schematic and Harness Diagrams

Current Supply/Starting Motor

Cold Weather Starting Aid

Engine Shut-Off Device

Instruments

Chopper Distributor Adjustment

Windshield Wiper/Washer System

Radio, Interior Lighting

Cigarette Lighter, Seat Compressor

Lighting System

Flasher Functions

Beacon Lights

Fan, Air Conditioning System

Electrical Mirror Adjustment

Work Lights

Straw Warning Device

Reel Speed Adjustment

Dial-A-Matic

Separator, Header

Infotrak Monitor

Harvest Performance Monitor

Hillmaster Leveling System Separator Adjustment

Separator Adjustment, Combine Data Center

Header Adjustments

Grain Tank Unloading System

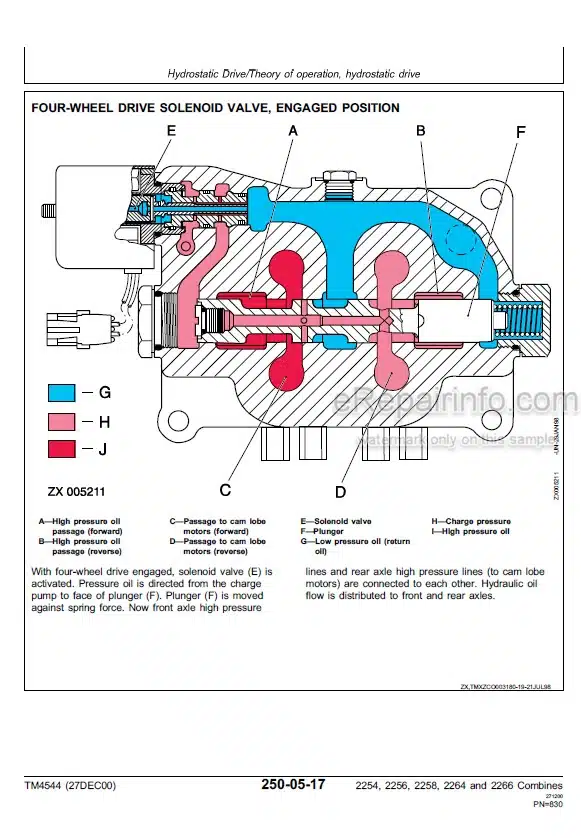

Four-Wheel Drive

Header Lateral Tilt Function

Header Float Control

-ELECTRICAL SYSTEM FROM SERIAL NUMBER 066833

General Information

Test Equipment

Functional Schematics and Harness Diagrams

Radio

Alarm Module, Stop Function

Indicator Lights

Infotrak Monitor, Speed Monitoring System

Separator Adjustment, Combine Data Center

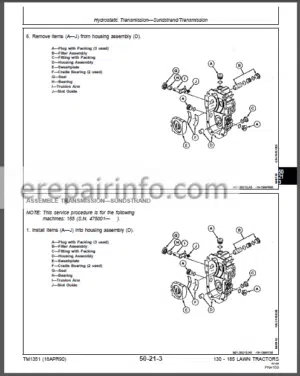

-POWER TRAIN

Hydrostatic Drive

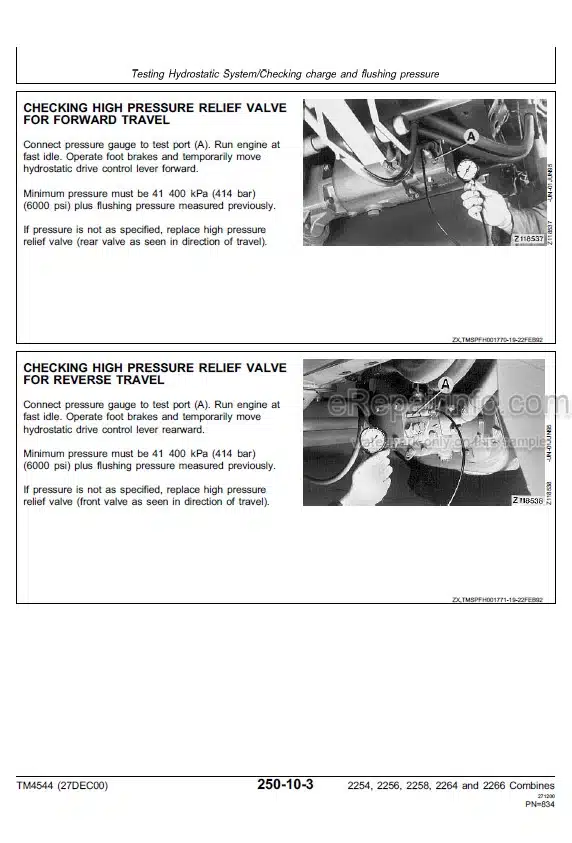

Testing Hydrostatic System

Inspect Parts Subject to Wear

Three-Speed Transmission

-BRAKES, STEERING, REAR AXLE

Brake Operating System

Drum Brakes

-HYDRAULIC SYSTEM

General Information

Solenoid Valves

Hillmaster Leveling System

Hydraulic Tests

-OPERATOR’S CAB

Operator’s Cab and Seat

Air Conditioning and Heating

Troubleshooting Ventilation and Heating Systems

Operational Tests and Troubleshooting

Operation — Air Conditioning System

-OPTIONAL EQUIPMENT

Chaff Spreader

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet