John Deere 9400 9500 9600 Repair Manual

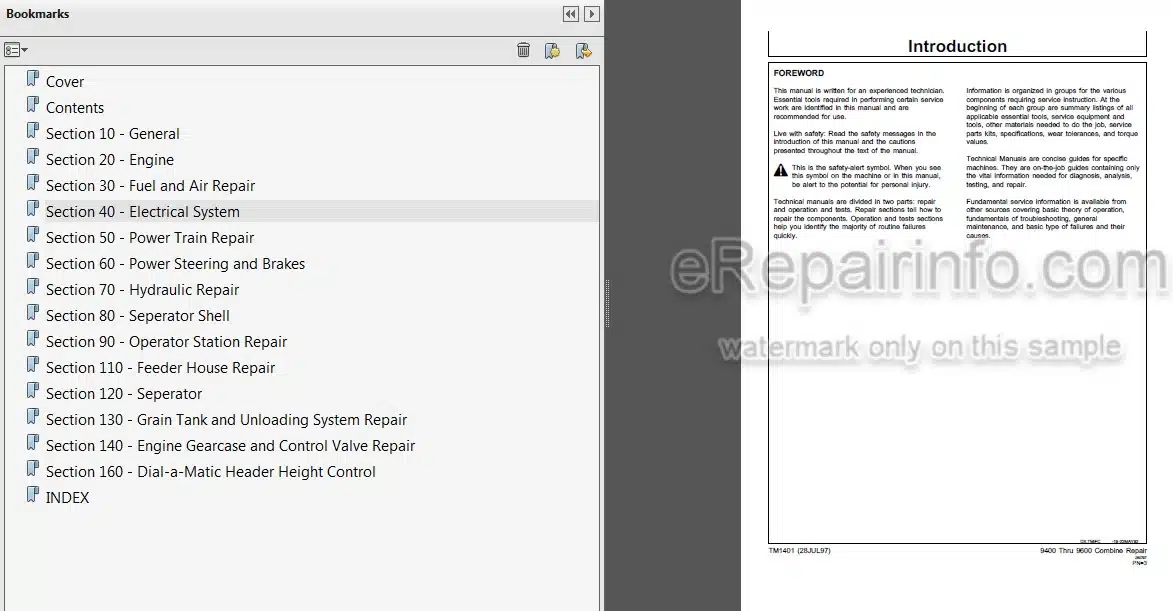

The John Deere 9400 9500 9600 Repair Manual (TM1401) is an essential resource for owners, operators, and technicians responsible for maintaining and repairing John Deere 9400, 9500, and 9600 combines. This factory repair manual, formatted as a searchable PDF with convenient bookmarks, spans 1235 pages and is available in English. It includes extensive illustrations, instructions, and diagrams to facilitate step-by-step procedures for removal, installation, assembly, disassembly, service, inspection, repair, troubleshooting, and tune-ups.

Format and Accessibility

- Format: PDF

- Language: English

- Pages: 1235

- Bookmarks: Yes

- Searchable: Yes

- Number: TM1401

Models Covered

This repair manual covers the following John Deere combine models:

- 9400

- 9500

- 9600

Contents Overview

The manual is meticulously organized into various sections, each dedicated to specific systems and components of the combines. Here’s a brief overview of the contents:

General

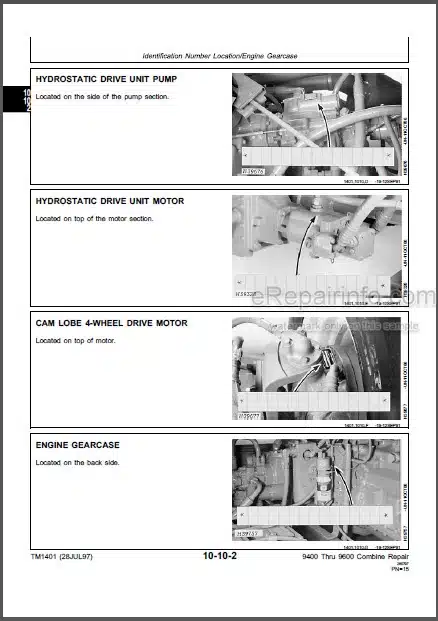

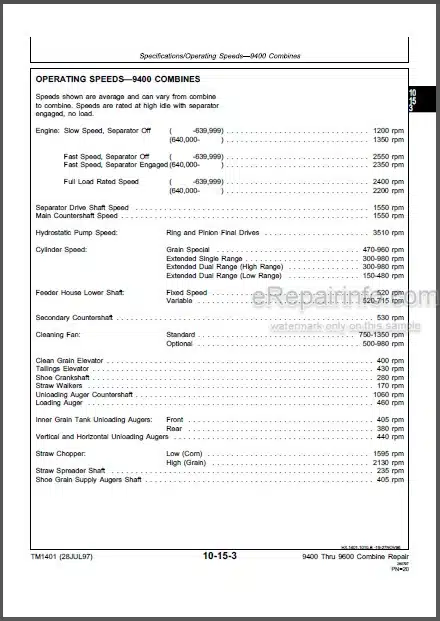

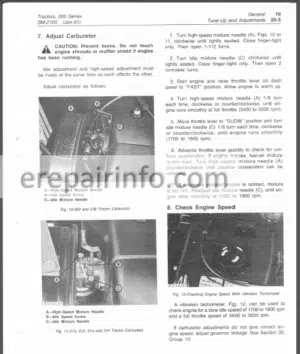

- Safety guidelines, identification number locations, specifications, tune-up and adjustment procedures, and information on fuels and lubricants.

Engine

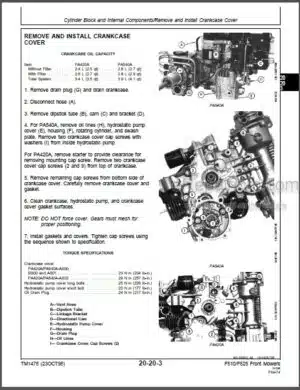

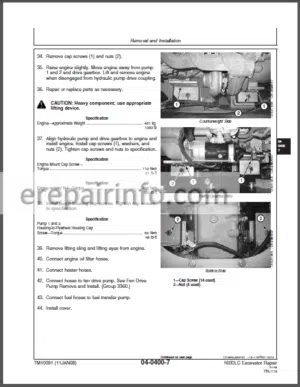

- Detailed procedures for engine removal and installation, cooling system maintenance, and lower engine repair.

Fuel and Air Repair

- Comprehensive guide for the air intake system and diesel fuel system maintenance and repair.

Electrical System

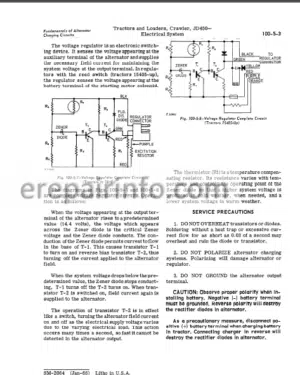

- Instructions for repairing and maintaining electrical components, including bulbs, switches, batteries, harnesses, connectors, gauges, monitors, wipers, radios, alternators, starting motors, and electrical engine control.

Power Train Repair

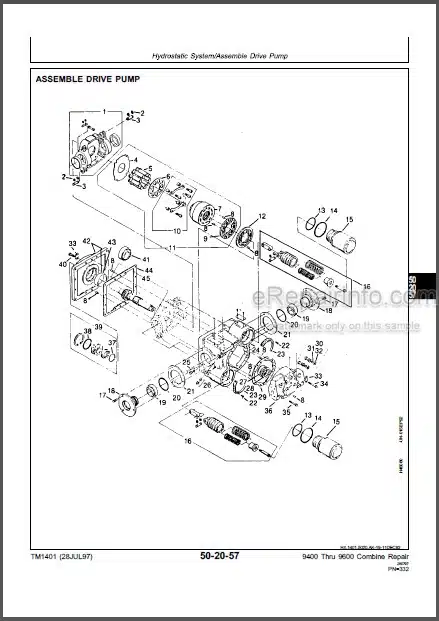

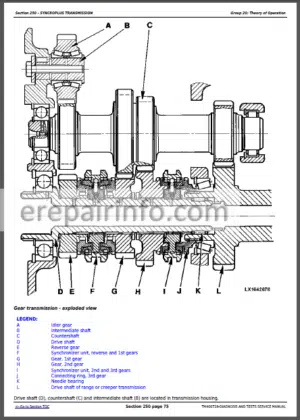

- Detailed maintenance and repair procedures for the transmission, differential, ring and pinion, final drive, hydrostatic system, cam lobe motor, tires, and wheels.

Power Steering and Brakes

- Comprehensive guide for steering and brake system maintenance and repair.

Hydraulic Repair

- Instructions for servicing the hydraulic reservoir, pumps, valves, cylinders, motors, accumulator, and reel/belt pickup pump drive.

Separator Shell

- Maintenance and repair procedures for the gull wing doors.

Operator Station Repair

- Detailed instructions for maintaining and repairing the air conditioning system (both R-12 and R134A types), system components, and the cab.

Feeder House Repair

- Comprehensive guide for feeder house and conveyor maintenance, including the feeder house conveyor drum, conveyor shaft and slip clutch, feeder house drives and reverser gear case, contour master platform driveshafts, tilt cylinder, tilt frame, and feeder house.

Separator

- Instructions for separator repair, including cylinder drives, straw walkers and crankshafts, straw chopper, straw spreader, chaff spreader, shoe supply augers, cleaning fan, chaffer, sieve frame, tailings elevator, augers, primary countershaft gearcase, and header electromagnetic clutch.

Grain Tank and Unloading System Repair

- Detailed procedures for grain tank cross augers, unloading auger system drives, vertical unloading auger and lower gearcase, horizontal unloading auger and gearcase, upper clean grain elevator, grain tank and extensions, clean grain elevator, and loading auger gear case.

Engine Gearcase and Control Valve Repair

- Maintenance and repair instructions for the engine gearcase and control valve.

Dial-A-Matic Header Height Control

- Detailed instructions for the Dial-A-Matic header height control system.

Conclusion

In conclusion, the John Deere 9400 9500 9600 Repair Manual (TM1401) is an invaluable tool for anyone involved in the maintenance and repair of these combines. Its comprehensive coverage, detailed instructions, and user-friendly format make it an essential resource for ensuring that John Deere 9400, 9500, and 9600 combines remain in optimal working condition. Whether performing routine maintenance or extensive repairs, this manual provides all the necessary information to keep your combine running smoothly and efficiently.

Anonymous (verified owner) –

great manual