Factory Technical Manual For John Deere Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 421

Number: CTM20 (november 1995)

Model

John Deere Diesel Engine

Series 500

6101

SN -499999

Contents

SAFETY

-GENERAL INFORMATION

Unified Inch Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values

Engine Model Designation

Engine Nameplate Information

6101 Engine Application Chart

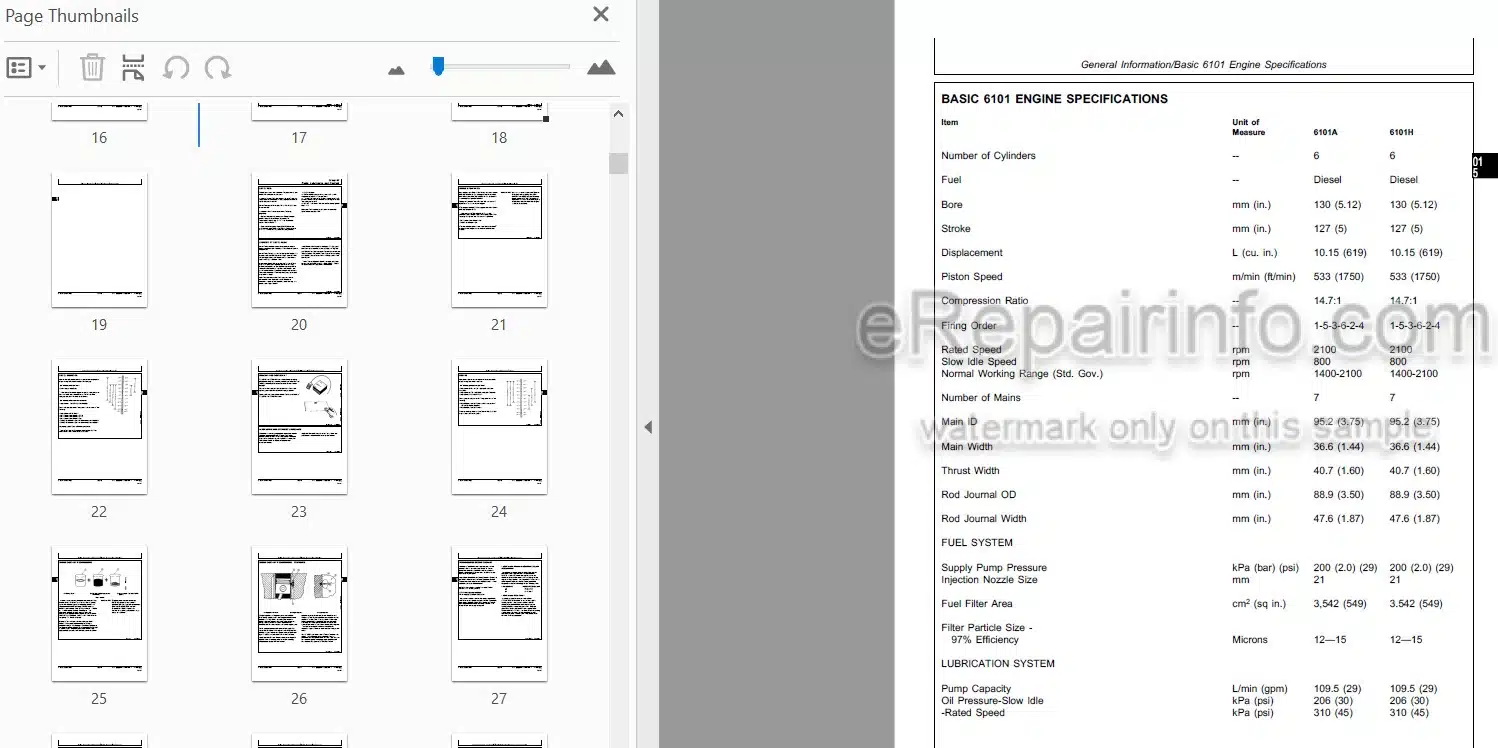

Basic 6101 Engine Specifications

-FUELS, LUBRICANTS, AND COOLANT

Diesel Fuel

Lubricity of Diesel Fuels

Engine Break-In Oil

Diesel Engine Oil

OILSCAN® and COOLSCAN

Alternative and Synthetic Lubricants

Grease

Engine Coolant Requirements

Recommended Engine Coolant

Engine Coolant Specifications

Replenishing Supplemental Coolant Additives

Operating in Tropical Conditions

Flush and Service Cooling System

Disposing of Coolant

-ENGINE MOUNTING

Engine Repair Stand

Safety Precautions

Install 500 Series Adapters on Repair Stand

Engine Lifting Procedure

Clean Engine

Mount Engine on Repair Stand

Disconnect Turbocharger Oil Inlet Line

-ENGINE REBUILD GUIDE

6101 Engine Disassembly Sequence

Sealant Application Guidelines

6101 Engine Assembly Sequence

-CYLINDER HEAD AND VALVES

Special or Essential Tools

Service Equipment and Tools

Other Material

Specifications

Torques

Disconnect Turbocharger Oil Inlet Line

Check and Adjust Valve Clearance

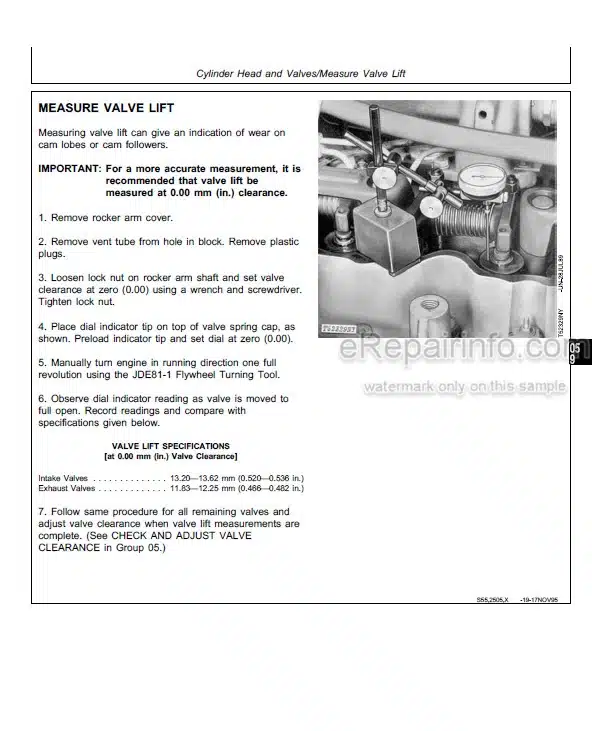

Measure Valve Lift

Remove Cylinder Head and Valves

Check Valve Height in Relation to Cylinder Head

Disassemble and Inspect Rocker Arm Shaft Assembly

Assemble Rocker Arm Shaft Assembly Make Preliminary Valve Checks

Remove Valve Assembly

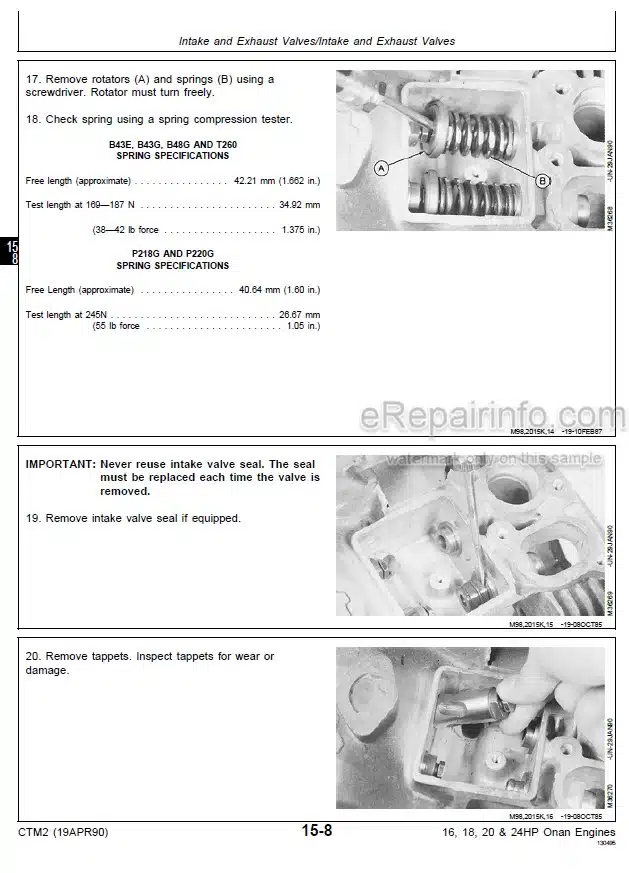

Inspect Valve Springs

Inspect Spring Caps, Wear Caps and Valve Rotators

Clean Valves

Measure Valves

Inspect and Clean Cylinder Head

Check Cylinder Head Combustion Face Flatness

Measure Cylinder Head Thickness

Clean Valve Guides

Measure Valve Guides

Knurl Valve Guides

Replace Valve Guides

Clean and Inspect Valve Seats

Measure Valve Seats

Grind Valve Seats

Replace Valve Seat Inserts

Recheck Valve Height in Relation to Cylinder Head

Install Oversize Valve Seat Inserts

Clean and Inspect Cylinder Head Nozzle Bore

Clean and Inspect Nozzle Seating Surface

Clean and Inspect Push Rods

Clean and Inspect Cylinder Head Cap Screws

Inspect Ventilator Assembly

Inspect and Clean Exhaust Manifold

Clean and Inspect Top Deck of Cylinder Block

Measure Cylinder Liner Height

Install Valve Assembly

Install Cylinder Head

Tighten Cylinder Head Cap Screws

TORCUE-TURN Method for Proper Cylinder Head Torque

Install Rocker Arm Assembly

Complete Final Assembly on Injection Pump Side

Complete Final Assembly on Exhaust Manifold Side

Perform Engine Break-In

-CYLINDER BLOCK, LINERS, PISTONS AND RODS

Special or Essential Tools

Other Material

Service Equipment and Tools

Specifications

Preliminary Liner, Piston, and Rod Checks

Disconnect Turbocharger Oil Inlet Line

Remove Pistons and Connecting Rods

Measure Cylinder Liner Standout (Height Above Block)

Remove Cylinder Liners

Remove Piston Rings

Clean Pistons

Visually Inspect Pistons

Clean Cylinder Liners

Visually Inspect Cylinder Liners

Check Piston Ring Groove Wear

Install Piston Pin in Piston

Measure Piston OD

Determine Piston-to-Liner Clearance

Measure Oil Control Ring Groove

Measure Cylinder Liners

Deglaze Cylinder Liners

Inspect and Measure Connecting Rod Bearings

Inspect Connecting Rod and Cap

Inspect Piston Pins and Bushings

Remove Piston Pin Bushing

Clean and Inspect Piston Pin Bushing Bore

Install Piston Pin Bushing in Rod

Complete Disassembly of Cylinder Block (if required)

Remove and Clean Piston Cooling Orifices

Inspect and Clean Cylinder Block

Clean Cylinder Liner O-Ring Bores in Block

Measure Cylinder Block

Install Piston Cooling Orifices and Galley Plugs

Recheck Cylinder Liner Standout (Height Above Block)

Measure Liner Flange Thickness

Install Liner Shims—If Required

Install Cylinder Liner O-Rings and Packings

Install Cylinder Liners

Install Pistons and Connecting Rods

TORGUE-TURN Connecting Rod Cap Screws

Check Engine Rotation for Excessive Tightness

Complete Final Assembly

-CRANKSHAFT, MAIN BEARINGS AND FLYWHEEL

Special or Essential Tools

Shop Equipment and Tools

Other Material

Specifications

Torques

Crankshaft and Main Bearing Failure

Analysis

Disconnect Turbocharger Oil Inlet Line

Replace Crankshaft Rear Oil Seal and Wear Sleeve

Remove Fan Drive Assembly (If Equipped)

Inspect Vibration Damper

Remove Damper/Pulley Assembly

Remove Crankshaft Front Oil Seal (Timing Gear Cover Installed)

Remove Crankshaft Front Wear Sleeve (Cover Installed/Removed)

Install Crankshaft Front Wear Sleeve (Timing Gear Cover Installed)

Install Crankshaft Front Oil Seal (Timing Gear Cover Installed)

Remove Timing Gear Cover

Check Crankshaft End Play

Check Flywheel Housing Face Runout

Check Flywheel Face Flatness

Remove Flywheel and Flywheel Housing

Inspect and Repair Flywheel

Replace Flywheel Ring Gear

Remove Rear Oil Seal Housing

Remove Rear Oil Seal Housing and Wear Sleeve (Engine Disassembled)

Remove Crankshaft Main Bearings

Check Main Bearing Clearance

Remove Crankshaft

Inspect Crankshaft

Measure Assembled ID of Bearings and OD of Crankshaft Journals

Measure Assembled ID of Main Bearing Caps (Without Bearings)

Crankshaft Grinding Guidelines

Crankshaft Grinding Specifications

Thrust Bearing New Part Specifications Replace Crankshaft Gear

Replace (Crankshaft) Oil Pump Drive Gear

Inspect Thrust Bearings

Remove and Clean Piston Cooling Orifices

Install Main Bearing Inserts in Block

Install Crankshaft

Install Oil Pump and Check Drive Gear-to-Crankshaft Clearance

Install Crankshaft Rear Oil Seal Housing

Check Oil Seal Housing Runout

Crankshaft Rear Oil Seal and Wear Sleeve Handling Precautions

Install Crankshaft Rear Oil Seal and Wear Sleeve Assembly

Install Crankshaft Front Wear Sleeve

Install Timing Gear Cover

Install Crankshaft Front Oil Seal In Timing Gear Cover

Install Damper Pulley Assembly

Install Fan Drive Assembly

Install Flywheel Housing and Flywheel

Complete Final Assembly

-CAMSHAFT AND TIMING GEAR TRAIN

Special or Essential Tools

Specifications

Disconnect Turbocharger Oil Inlet Line

Measure Valve Lift

Remove Fan Drive Assembly (If Equipped)

Remove Damper/Pulley Assembly

Remove Timing Gear Cover

Remove Front Wear Sleeve (Timing Gear Cover Removed)

Remove Front Oil Seal (Timing Gear Cover Removed)

Check Camshaft End Play

Measure Camshaft Drive Gear-to-Crankshaft Gear Minimum Backlash

Remove Camshaft

Remove Camshaft Gear, Spacer, and Thrust Plate

Measure Thrust Plate and Spacer

Inspect Camshaft

Measure Camshaft Journal OD and Bushing ID

Measure Camshaft Lobe Lift

Remove, Inspect, and Measure Camshaft Followers

Assemble Camshaft

Service Camshaft Bushings Using JDE6 Camshaft Bushing Replacement Set

Service Camshaft Bushings Using JDG405 Camshaft Bushing Service Set

Install Camshaft

Install Timing Gear Cover

Install Crankshaft Front Wear Sleeve (Timing Gear Cover Installed)

Install Crankshaft Front Oil Seal (Timing Gear Cover Installed)

Complete Final Assembly

-LUBRICATION SYSTEM

Other Material

Specifications

Diagnosing Lubrication System Malfunctions

Disconnect Turbocharger Oil Inlet Line

Drain Engine Oil, Coolant and Remove Oil Pan

Engine Oil Bypass Valve Housing, Oil Cooler and Oil Filtration System

Remove Oil Bypass Valve Housing and Oil Cooler Assembly

Remove and Inspect Oil Cooler Bypass and Oil Filter Bypass Valves

Assemble Bypass Valve Housing and Oil Cooler Assembly

Install Oil Bypass Valve Housing and Oil Cooler Assembly

Remove, Disassemble, Inspect, and Install Oil Pressure Reg Valve

Check Crankshaft Gear-to-Oil Pump Drive Gear Backlash

Engine Oil Pump Assembly

Remove Engine Oil Pump

Inspect and Clean Oil Pump

Check Drive Shaft End Play

Check Drive Shaft Side Movement

Check Pumping Gear Backlash

Inspect Oil Pump Drive Gear

Adjust Oil Pump Set Screw

Install Engine Oil Pump

Install Oil Pan

-COOLING SYSTEM

Special or Essential Tools

Other Material

Specifications

Service Equipment and Tools

Diagnosing Cooling System Malfunctions

General Cooling System Information

Remove and Install Heavy Duty Fan Drive Assembly

Remove Fan Drive Bearings

Install Fan Drive Bearings

Remove Water Pump—6101AT001 Engines

Remove Water Pump—6101HRW01, 02 Engines

Water Pump Assembly

Disassemble Water Pump

Measure Bearing Bore in Water Pump Housing

Assemble Water Pump

Install Water Pump—6101AT001 Engines

Install Water Pump—6101HRW01, 02 Engines

Remove Water Manifold

Inspect and Clean Water Manifold

Install Water Manifold

Remove Thermostats

Install Thermostats

Remove Coolant Filter Conditioner

Inspect Coolant Filter Conditioner Components

Install Coolant Filter Conditioner

Complete Final Assembly

Check and Adjust V-Belt Tension

Remove Coolant Heater—If Equipped

Install Coolant Heater—If Equipped

-AIR INTAKE AND EXHAUST SYSTEM

Special or Essential Tools

Specifications

Other Material

Extending Turbocharger Life

Remove Turbocharger

Diagnosing Turbocharger Malfunctions

Turbocharger Seven-Step Inspection

A—Compressor Housing Inlet and Compressor Wheel

B—Compressor Housing Outlet

C—Turbine Housing Inlet

D—Turbine Housing Outlet and Turbine Wheel

E—External Center Housing and Joints

F—Internal Center Housing

G—Turbo Bench Test

Perform Radial Bearing Clearance Test (Garret/Ai Research T45)

Perform Axial End Play Bearing Test (Garret/Ai Research T45)

Perform Radial Bearing Clearance Test (Schwitzer S3A)

Perform Axial End Play Bearing Test (Schwitzer S3A)

Disassemble and Inspect Turbocharger (Garrett/Ai Research T45)

Replace Center Housing and Rotating Assembly

Disassemble and Inspect Turbocharger (Schwitzer S3A)

Replace Center Housing and Rotating Assembly

Prelube Turbocharger

Install Turbocharger

Remove Aftercooler Assembly and Intake Manifold (6101A Engines)

Inspect and Repair Aftercooler (6101A Engines)

Inspect and Repair Intake Manifold (6101A Engines)

Install Intake Manifold and Aftercooler Assembly (6101A Engines)

Install Aftercooler Cover (6101A Engines)

Remove, Inspect, and Install Intake Manifold (6101H Engines)

Remove, Inspect, and Install Exhaust Manifold Assembly

-FUEL SYSTEM

Special or Essential Tools

Other Material

Specifications

Relieve System Pressure

Replace Rectangular Final Fuel Filter

Replace Fuel Check Valve Assembly

Remove Fuel Supply Pump

Test Fuel Supply Pump For Leaks

Disassemble Fuel Supply Pump

Inspect and Repair Fuel Supply Pump

Assemble Fuel Supply Pump

Install Fuel Supply Pump

General Information For Aneroid (if Equipped)

Repair Aneroid—Mechanical Governors Only

Remove Hydraulic Aneroid Activator—Mechanical Governor

Disassemble and Clean Hydraulic Aneroid Activator

Assemble and Install Hydraulic Aneroid Activator

Service Injection Pump Overflow Valve

Remove Fuel Injection Pump

Repair Fuel Injection Pump

Install Fuel Injection Pump

Remove Fuel Injection Nozzles

Diagnose Injection Nozzle Malfunction

Test Fuel Injection Nozzles

Perform Opening Pressure Test

Fuel Injection Nozzle Specifications

Perform Leakage Test

Test Nozzle Chatter and Spray Pattern

Disassemble Fuel Injection Nozzle

Clean and Inspect Fuel Injection Nozzle Assembly

Perform Nozzle Slide Test

Clean Spray Orifices

Inspect Nozzle Holder

Inspect Gland Nut

Assemble Fuel Injection Nozzle

Adjust Fuel Injection Nozzles

Inspect and Clean Cylinder Head Nozzle Bore

Inspect and Clean Nozzle Seating Surface

Install Fuel Injection Nozzles

Install Fuel Leak-off and Fuel Delivery Line Assemblies

-ENGINE TUNE-UP AND BREAK-IN

Effects of Altitude and Temperature on Engine Performance

Preliminary Engine Testing

General Tune-Up Recommendations

Dynamometer Test

Engine Break-In Guidelines

Engine Break-In Instructions

Check Crankcase Ventilation System

Check Air Intake System

Check Exhaust System

Check and Service Cooling System

Check Electrical System

-ENGINE SYSTEM OPERATION AND TESTS

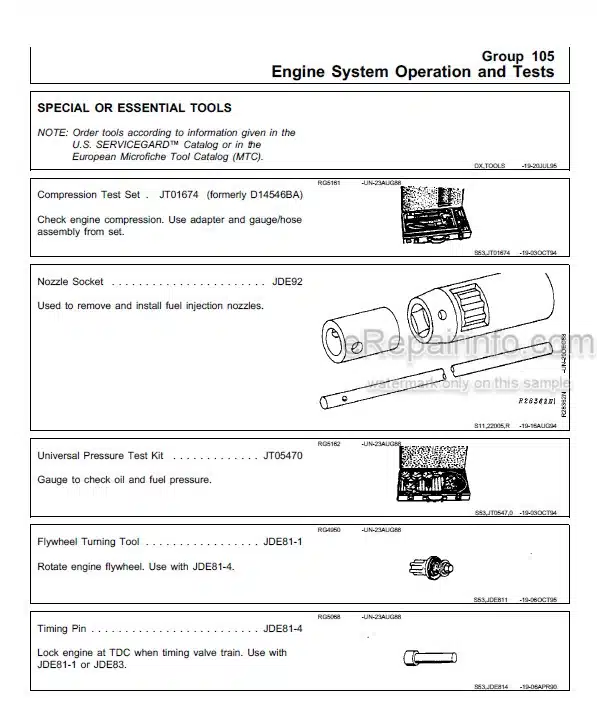

Special or Essential Tools

Engine Test Specifications

General Description

Engine Sectional View

How the Lubrication System Works

Head Gasket Joint Construction and Operation

Diagnosing Head Gasket Joint Failures

Head Gasket Inspection and Repair Sequence

Diagnosing Engine Malfunctions

Test Engine Compression Pressure

Check Engine Oil Pressure

Measure Engine Crankcase Pressure (Blow-By)

Pressure Test Cooling System and Radiator Cap

Inspect Thermostat and Test Opening Temperature

-AIR INTAKE SYSTEM OPERATION AND TESTS

Special or Essential Tools

Air Intake and Exhaust System Test Specifications

Diagnosing Air Intake Malfunctions

How the Air Intake and Exhaust System Works

Air Cleaner Operation

Diagnosing Turbocharger Malfunctions

How the Turbocharger Works

How the Turbocharger is Lubricated

How the Aftercooler Works—6101A

Check Intake Manifold Pressure (Turbo Boost)

Air Filter Restriction Indicator Switch Test

-FUEL SYSTEM OPERATION AND TESTS

Special or Essential Tools

Service Equipment and Tools

Fuel System Test Specifications

Fuel Injection Pump Specifications

Fuel System Operation

Diagnose Fuel System Malfunctions

Supply Pump Operation

Diagnosing Mechanical Fuel Supply Malfunctions

Test Fuel Supply Pump for Leaks

Check Supply Pump Operation

Service Supply Pump

Rectangular Final Filter Operation

Bleed Fuel System

In-Line Fuel Injection Pump Operation

Diagnose In-Line Fuel Injection Pump Malfunctions

Check and Adjust Injection Pump Timing

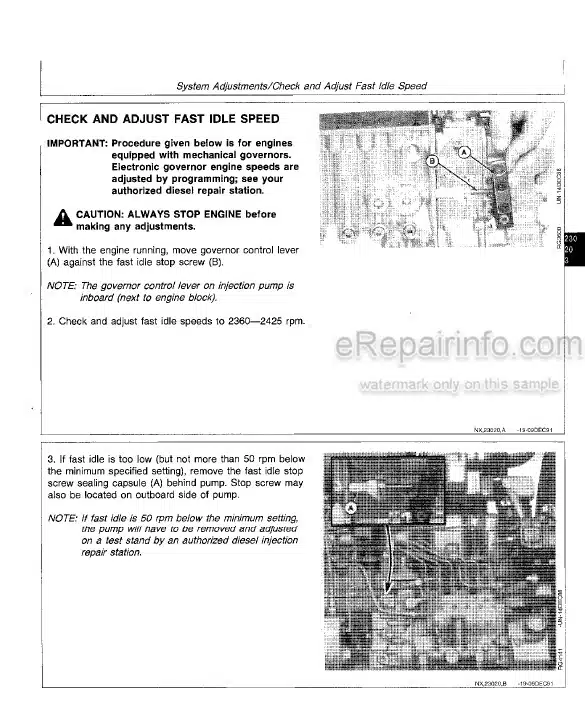

Check Fast Idle Speed

Check and Adjust Engine Slow Idle

How the Aneroid Works—Mechanical Governors Only

Diagnose Aneroid Malfunction

How the Hydraulic Aneroid Activator Works

Diagnose Malfunctions—Hydraulic Aneroid Activator

Fuel Injection Nozzles—General Information

Fuel Injection Nozzle Operation

Diagnose Malfunctions—Fuel Injection Nozzle

Test Fuel Injection Nozzles (Engine Running)

Fuel Drain Back Test Procedure

-DEALER FABRICATED TOOLS

How to Make Tools

Cylinder Liner Holding Fixture

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet