Factory Operation & Maintenance Manual For Kawasaki Wheel Loader. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 401

Number: 93107-00711 (february 2015)

Bookmarks: Yes

Searchable: Yes

Model

Kawasaki Wheel Loader

62Z7

67Z7

67TM7

Serial No. 62J1-5001 and up

Serial No. 65J5-5001 and up

Contents

FOREWORD

CONTENTS

ENGINE EMISSION CONTROL LABEL

MACHINE NUMBERS

SAFETY

SAFETY LABELS

COMPONENTS NAME

GETTING ON/OFF THE MACHINE

-OPERATOR’S STATION

Exhaust Filter

Diesel Particulate Filter

Description of DPF functions

Automatic regeneration

Cab Features

Monitor Panel

Switches, Steering Wheel and Pedals

Right Console / Switches

Cigar Lighter (24 VDC Electrical Outlet)

Ash Tray

Auto Air Conditioner

Adjusting Operator’s Seat (Air Suspension Type Seat)

Rear Tray

Electric Power Output (Option)

Fuse Box

Hot/Cool Box

Tray and Drink Holder

ROPS Cab

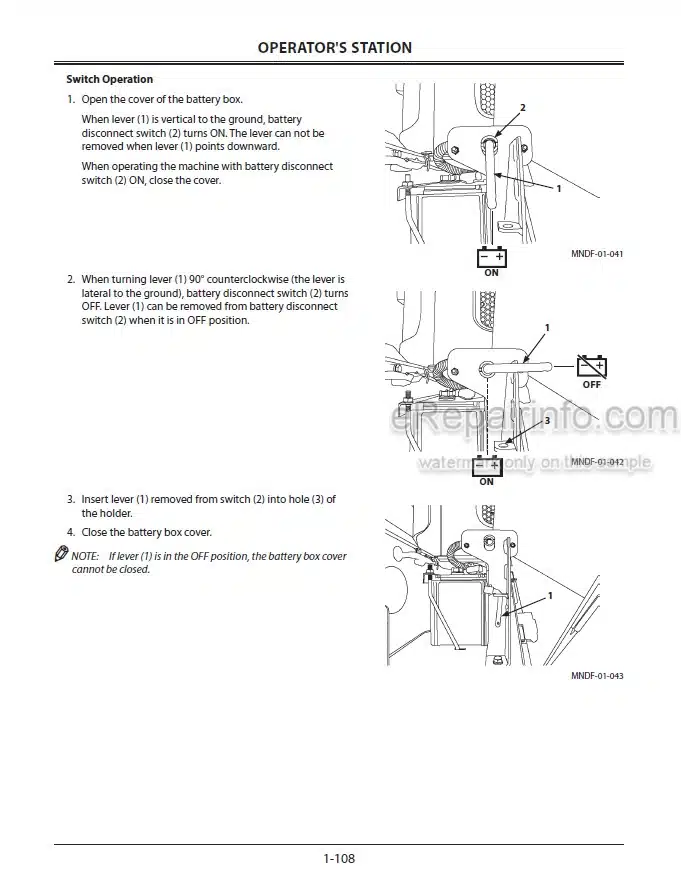

Battery Disconnect Switch

Articulation Lock Bar

Towing Pin

Inspection/Maintenance Side Access Cover

Steps

Tool Box

Vandal-Resistant Devices

Seat Belt

-BREAK-IN

Break-in Period for New Machine

-OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Check Before Starting

Starting Engine

Starting in Cold Weather

Check After Starting

Using Booster Batteries

Warm Up

Cold Weather Warm Up

Stopping Engine

-MOVING THE MACHINE

Driving the Machine

Starting to Move

Parking Brake Switch

Drive Speed Change

Changing Forward/Reverse Drive Direction

Steering Wheel

Secondary Steering (Option)

Emergency Stop and Restart of Operation

Precautions for Driving on Slopes

Precautions for Driving Speeds

Precautions to be Taken if Machine Failure Occurs

Stop the Machine

Parking

Emergency Stopping

-OPERATING THE MACHINE

Control Lever

Control Lever Lock Switch

Ride Control Switch (Option)

Lift Arm Height Kickout (62Z7, 67Z7)

Adjustment of Loader Front

Adjustment of Dual Lift Arm Auto Leveler (67TM7)

Adjustment of Bucket Auto Leveler

Auto Idling Stop

Before Operation

Precautions for Operation

Ensure Safety When Operating on Road Shoulders

Avoid Overloading

Avoid Rapid Steering Changes and/or Sudden Braking

Avoid Operation with Loads on Only One Side Excavation

Grading

Loading

Dozing

Stock Piling

Removing Snow

Lifting Wheel Loader

Precautions for After Operation

-TRANSPORTING

Transporting by Road

Selecting a Trailer

Loading I Unloading on Trailer

Fastening Machine for Transporting

Transporting Wheel Loader (Urgent Situation)

Towing Method

Lifting Machine

-MAINTENANCE

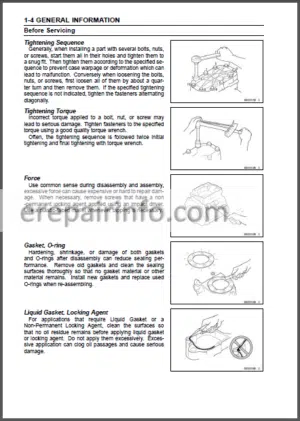

Correct Maintenance and Inspection Procedures

Check the Hour Meter Regularly

Layout 62Z7, 67Z7

Layout 67TM7

Preparations for Inspection and Maintenance

Articulation Lock

Inspection/Maintenance Access Side Cover

Periodic Replacement of Parts

Inspection and Maintenance Table

Kind of Oils

Greasing

Engine

Power Train

Hydraulic System

Fuel System

Air Cleaner

Cooling System

Electrical System

Brake System

Tire

Air Conditioner

Miscellaneous

Exhaust Filter

-MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

Maintenance Under Special Environmental Conditions

Precautions for Maintenance During Cold Weather Season

-STORAGE

Storing the Machine

-TROUBLESHOOTING

Troubleshooting

-SPECIFICATIONS

Specifications

Specifications

Sound Level Results (2000/14/EC)

Vibration Level

-OPTIONAL ATTACHMENTS

Hydraulic Type Quick Coupler Operation 62Z7, 67Z7

Hydraulic Type Quick Coupler Operation 67TM7

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet