Factory Shop Manual For Kobelco Hydraulic Excavator; Mitsubishi Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1160

Number: 87364097 NA (July 2006)

Bookmarks: Yes

Wiring Diagrams: Yes

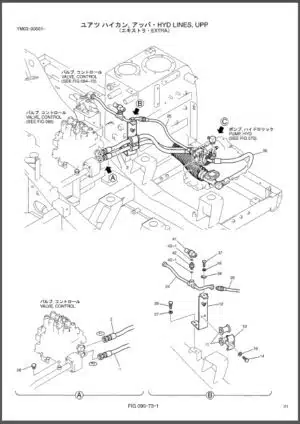

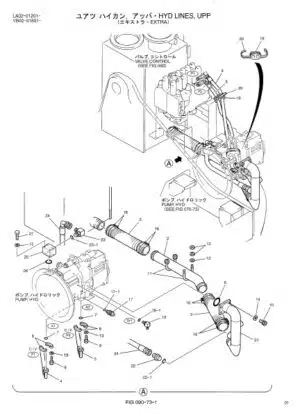

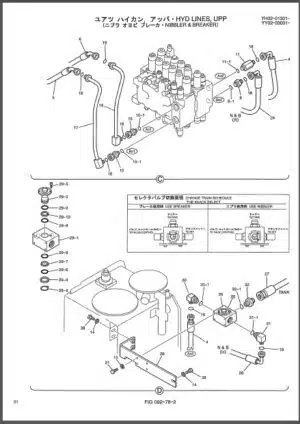

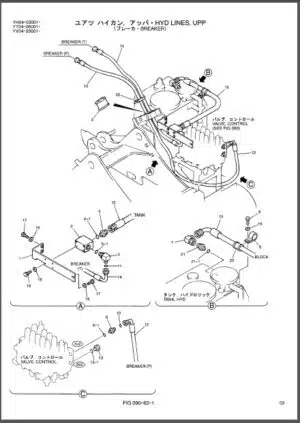

Hydraulic Diagrams: Yes

Model

Kobelco Hydraulic Excavator

SK250LC-6E

Mitsubishi Diesel Engine

6D34-T

Contents

1.KOBELCO SK250LC-6E SHOP MANUAL HYDRAULIC EXCAVATOR.

2.MITSUBISHI 6D34T-SHOP MANUAL DIESEL ENGINE.

1.KOBELCO SK250LC-6E SHOP MANUAL HYDRAULIC EXCAVATOR.

-CYCLE TIMES

Pre-Cycle Time Considerations

Cylinder Cycle Time Tests

Swing Speed Time Test

Travel Speed Time Test

-MAINTENANCE SPECIFICATIONS

Cylinder Drift

Swing Stopping

Swing Drift

Swing Bearing Up-Down (Vertical) Movement

Swing Bearing Side To Side (Horizontal) Movement

Swing Motor Oil Case Drain

Travel Motor Oil Case Drain

Travel Deviation

-HYDRAULIC SCHEMATICS

Symbolsand Components

Hydraulic Control System Logic

Troubleshooting Table

Hydraulic Schematic

-PRESSURE ADJUSTMENTS

Verification Of Engine Rpm

Pilot Circuit

Hydraulic Main Relief

Swing Circuit

Over Load Relief Valves

Measurement Of Additional Circuit Pressure Ports

-MECHATRONICS

Layout of Electric Components

Solenoid/Proportional V alve Block

Construction of Solenoid Valve

Proportional Valve for Control Valve

Pressure Sensors

Components Related to Engine

Left Hand Console

Right Hand Console

Components Related to Cab

Floorplate Wiring Info

Grounding Cable Attaching Position

Main Controller Assembly

Mechatronic Controller Connectors

Mechatronic Controller Assembly

Pin Out of Connectors CN11

Pin Out of Connectors CN12~13

Pin Out of Connectors CN14

Pin Out of Connectors CN15-16

Pin Out of Connectors CN17

Governor Motor (Stepping Motor)

Gauge Cluster

Multi Display Self Diagnostic

Engine Speed Sensor (Sei3)

Potentiometer (For Accel Dial, Se16)

Error Code History Diagnosis

Senice Diagnostic

Adjustment “A & B”

Adjustment ’‘A” – Mechatronic Controller

Procedure “B”

Fine Operating Adjustment Function

-ELECTRICAL SCHEMATICS

Electrical Schematic Symbols

Schematic Nomenclature

Electrical Schematics

-SPECIFICATIONS

Outline

Specification

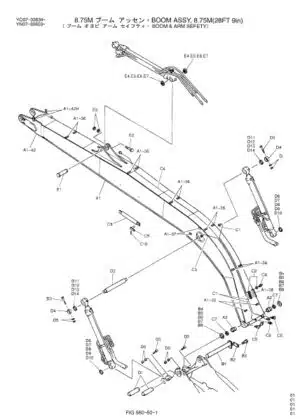

Attachment Dimension

-MAINTENACE

Tools

Standard Maintenance Time Schedule

Maintenance Standard And Test Procedure

-SYSTEM

Mechatro Control System

Hydraulic System

Electrical System

Components System

Air-Conditioner System

-DISASSEMBLY

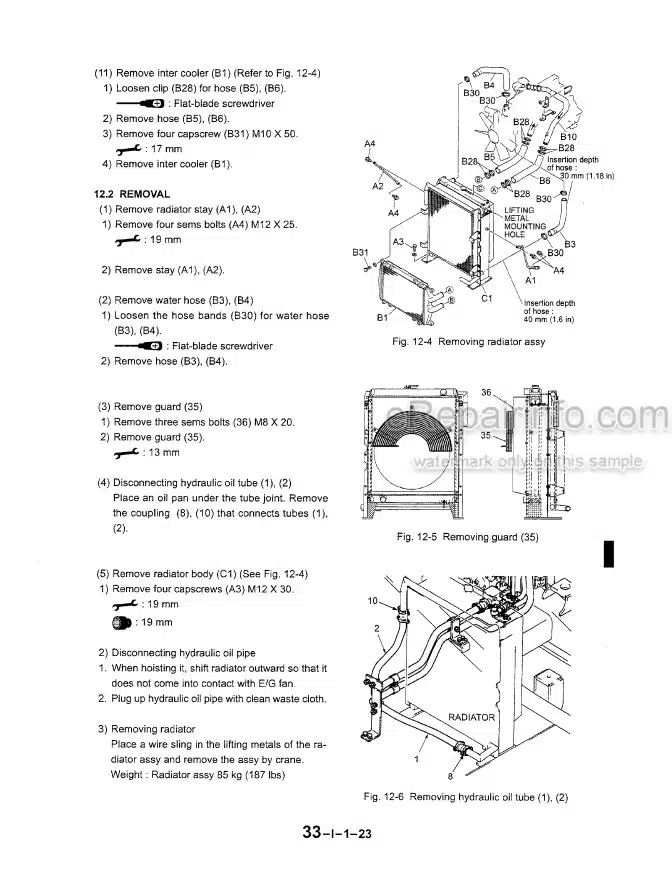

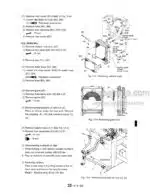

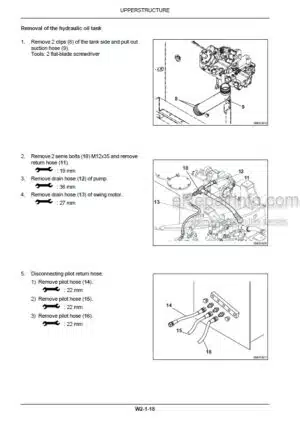

Disassembling And Assembling

Attachment

Upper Structure

Travel System

-TROUBLESHOOTING

Mechatro Control

Hydraulic

Electrical

Engine

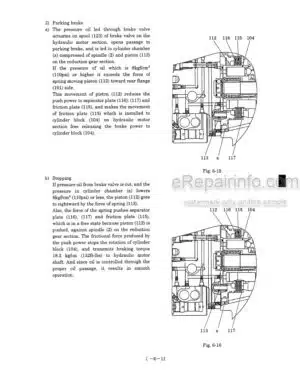

2.MITSUBISHI 6D34T-SHOP MANUAL DIESEL ENGINE.

-GENERAL

General Specifications

Engine Number, Name Plate And Caution Plate

Precautions For Maintenance Operation

Table Of Standard Tightening Torques

-ENGINE

Structure And Operation

Troubleshooting

On-Vehicle Inspection And Adjustment

Cylinder Head And Valve Mechanism

Timing Gears

Camshaft

Pistons, Connecting Rods, And Cylinder Liners

Flywheel

Crankshaft And Crankcase

-LUBRICATION

Specifications

Structure And Operation

Troubleshooting

On-Vehicle Inspection And Adjustment

Oil Pan, Oil Strainer, And Oil Jet

Oil Pump

Oil Cooler And Oil Filter

-FUEL AND ENGINE CONTROL

Specifications

Structure And Operation

Troubleshooting

On-Vehicle Inspection And Adjustment

Fuel Filter

Injection Pump

Injection Nozzle

-COOLING

Specifications

Structure And Operation

Troubleshooting

On-Vehicle Inspection And Adjustment

Cooling Fan, V-Belt, And Water Pump

Thermostat

-INTAKE AND EXHAUST

Specifications

Structure And Operation

Troubleshooting

Turbocharger

Intake Manifold

Exhaust Manifold

Intercooler

-ELECTRICAL SYSTEM

Specifications

Structure And Operation

Troubleshooting

On-Vehicle Inspection And Adjustment

Alternator

Starter

Preheater Circuit

Engine Starter Circuit

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet