Factory Shop Manual For Komatsu Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 806

Number: YEBM200101 (april 2004)

Bookmarks: Yes

Model

Komatsu Diesel Engine

102-1 Series

102-2 Series

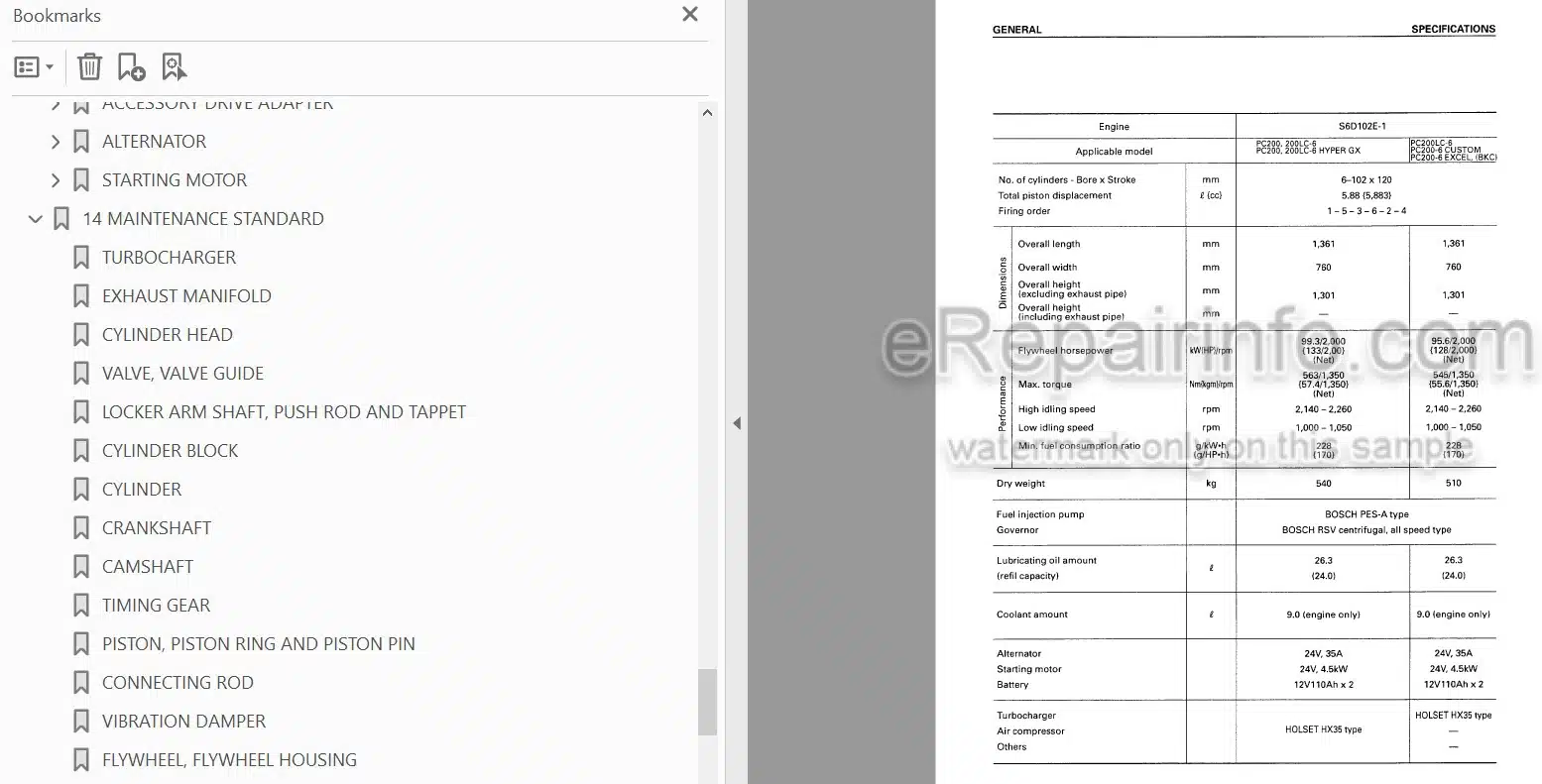

S6D102E-1

SA6D102E-1

SAA6D102E-2

Contents

-SAFETY

Safety Notice

-FOREWORD

General

How To Read The Shop Manual

Hoisting Instructions

Method Of Disassembling, Connecting Push-Pull Type Coupler

Coating Materials

Standard Tightening Torque

Electric Wire Code

Units

Capscrew Markings And Torque Values

Pipe Plug Torque Values

Symbols

Illustrations

-GENERAL

Applicable Machine

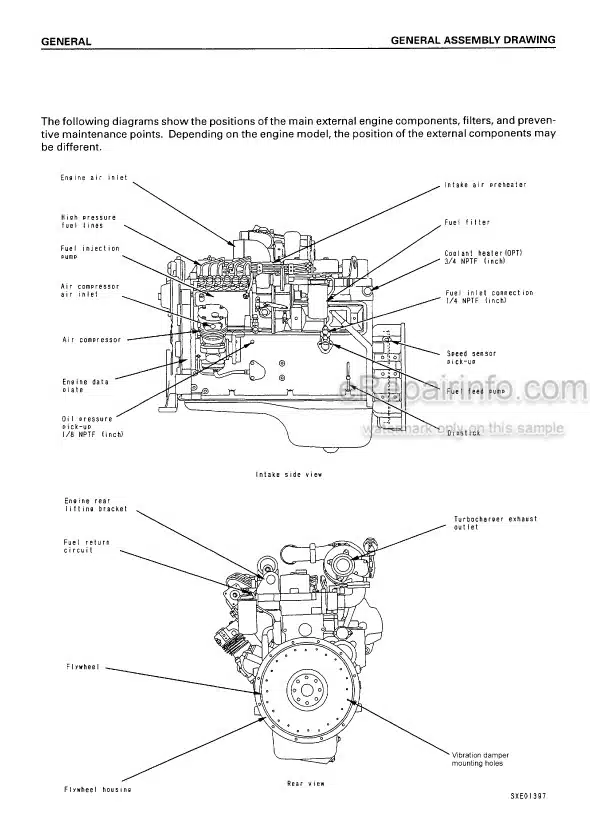

General Assembly Drawing

Engine Performance Curve

Weight Table

-STRUCTURE AND FUNCTION

Outline Of Air Intake And Exhaust Systems

Intake And Exhaust Devices

Air Cleaner

Turbocharger

Cylinder Head

Cylinder Block

Main Moving Parts

Timing Gear Portion

Front Gear Cover

Camshaft Timing Pin

Valve Mechanism

Flywheel, Flywheel Housing

Lubrication System Diagram

Oil Pump

Oil Filter, Oil Cooler

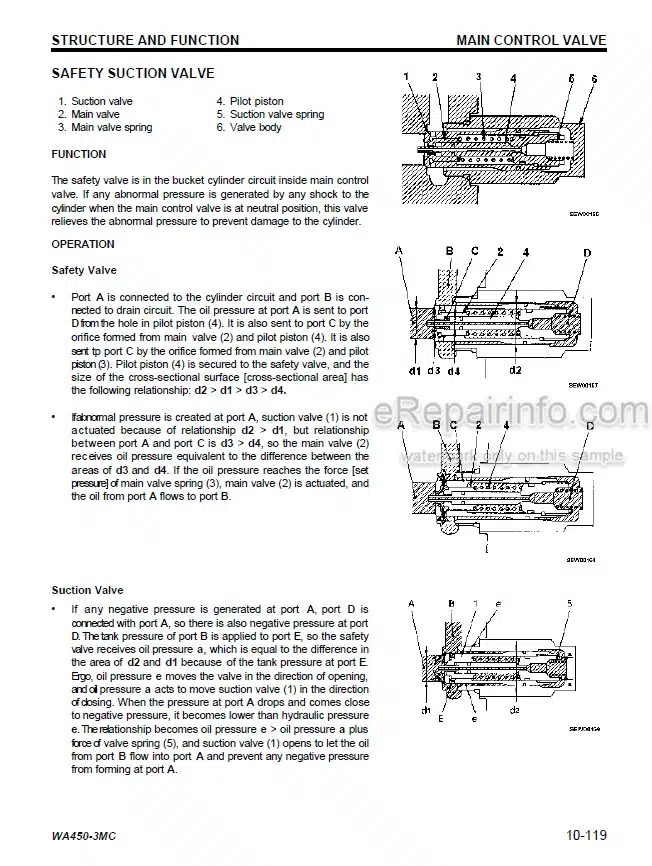

Regulator Valve, Safety Valve

Fuel System Diagram

Fuel Injection Pump

Timing Lock Pin For Fuel Injection Pump

Fuel Filter

Fuel Injection Nozzle

Fuel Cut Solenoid

Cooling System Diagram

Water Pump

Thermostat

Fan Drive

Air Compressor

Flow Diagrams-Compressed Air System

Alternator

Alternator (Optional)

Starting Motor

Starting Motor

Starting Motor(Optional)

Starting Aid

-TEATING AND ADJUSTING

Special Tool List

Troubleshooting Defective Actuation Of Intake And Exhaust System

Measuring Play Of Turbocharger Rotor In Axial And Radial Direction(Engine With Turbocharger)

Testing Turbocharger Westgate Valve(Engine With Turbocharger)

Testing Turbocharger Westgate Capsule (Engine With Turbocharger)

Testing Actuation Of Turbocharger Westgate (Engine With Turbocharger)

Replacing Turbocharger Westgate Actuator Boost Capsule(Engine With Turbocharger)

Adjusting Turbocharger Westgate Actuator(Engine With Turbocharger)

Measuring Exhaust Resistance

Replacing Turbocharger(Engine With Turbocharger)

Troubleshooting Defective Actuation Of Engine

Adjusting Valve Clearance

Troubleshooting Defective Actuation Of Lubricating System

Fuel Injection Pump Calibration Data

Running In Standard

Performance Test Criteria

Troubleshooting Defective Actuation Of Feed Pump(Diaphragm Type)

Troubleshooting Defective Actuation Of Feed Pump(Piston Type)

Testing Air Inside Fuel System

Testing Water Separator Fuel Filter

Troubleshooting Failure Of Fuel Injection Pump(Bosch VV, Lucas CAV)

Testing High-Pressure Fuel Piping

Testing Fuel Injection Nozzle

Testing Fuel Drain Piping

Bleeding Air From Fuel System

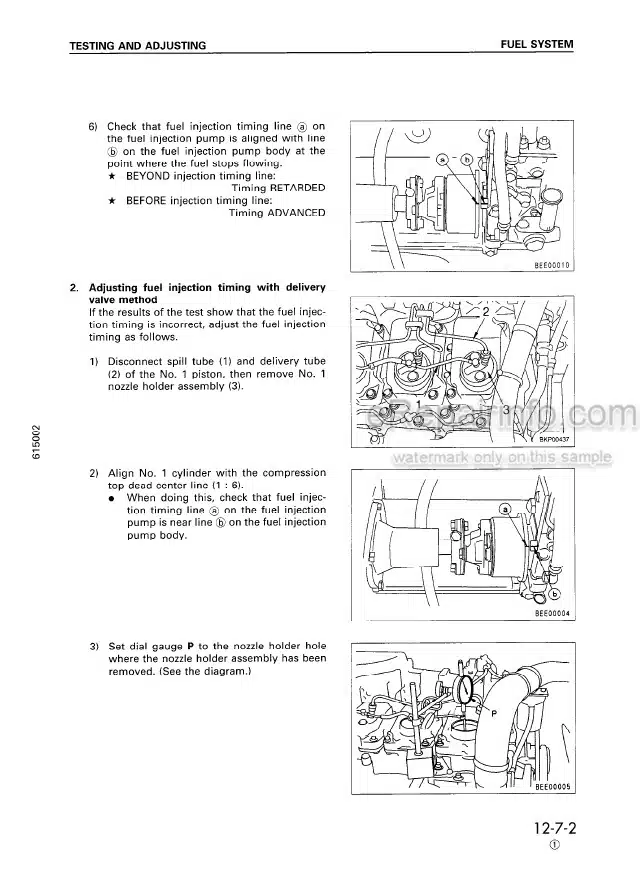

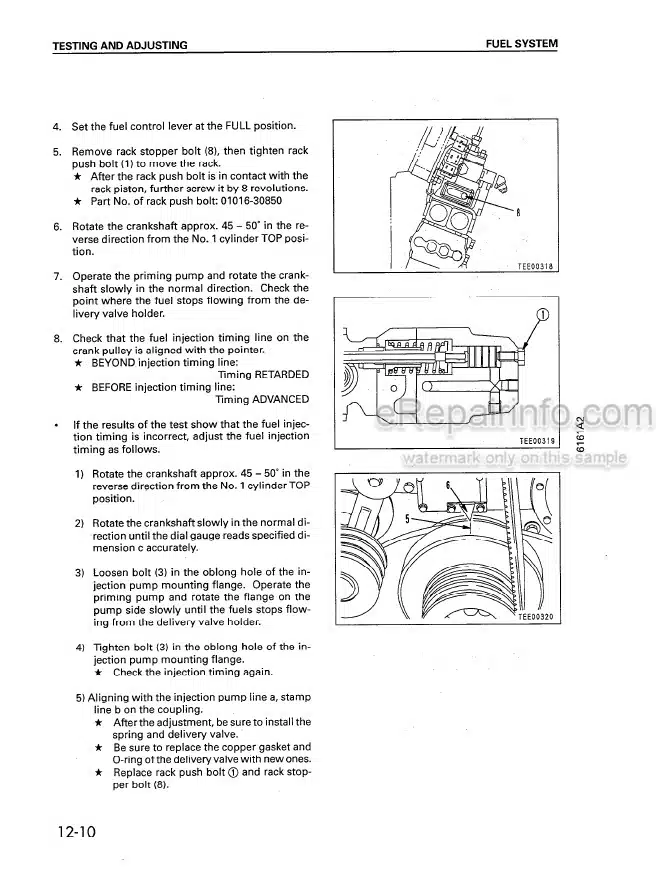

Adjusting Fuel Injection Timing

Adjusting Low Idling Speed (Bosch Ve, Lucas Cav)

Replacing Fuel Injection Nozzle

Troubleshooting Defective Actuation Of Cooling System

Testing Carbon Deposit In Air Compressor

Testing Air Leakage From Air Compressor

Testing Air Governor, Unloader Valve

Testing Air Governor

Testing Battery

Testing Battery Terminal Connections

Testing Starting Circuit

Testing Alternator

Testing Oil Pressure Switch And Water Temperature Sensor

Testing White Smoke

Testing Intake Heater

Side View Of Engine

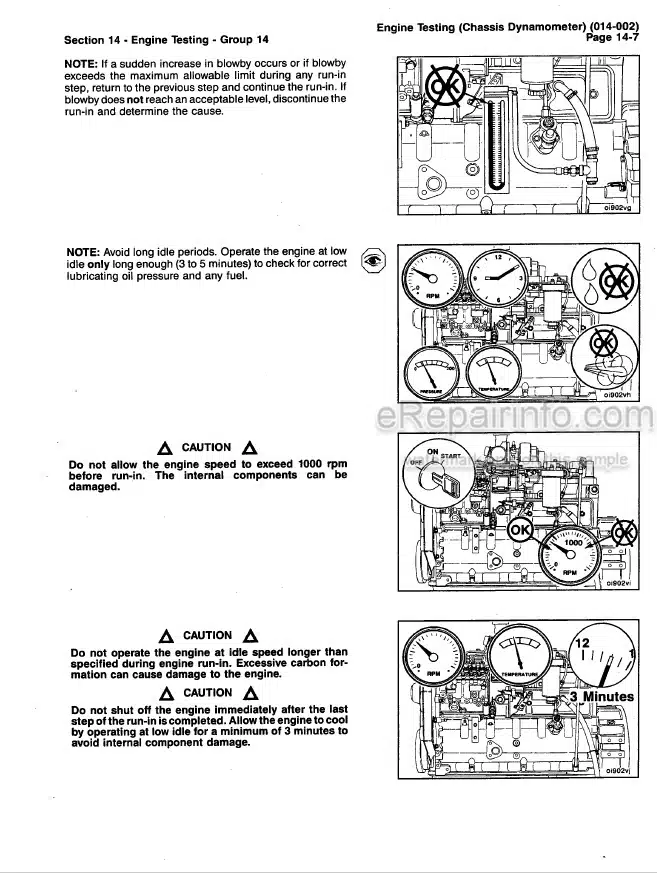

Outline Of Engine Performance Test

Blow-By Measurement And Replacement Table

Engine Dynamometer

Engine Paintwork

Troubleshooting

-DISASSEMBLY AND ASSEMBLY

Special Tool List

Outline Of Disassembly And Assembly Of Engine

Disassembly Of Engine

Assembly Of Engine

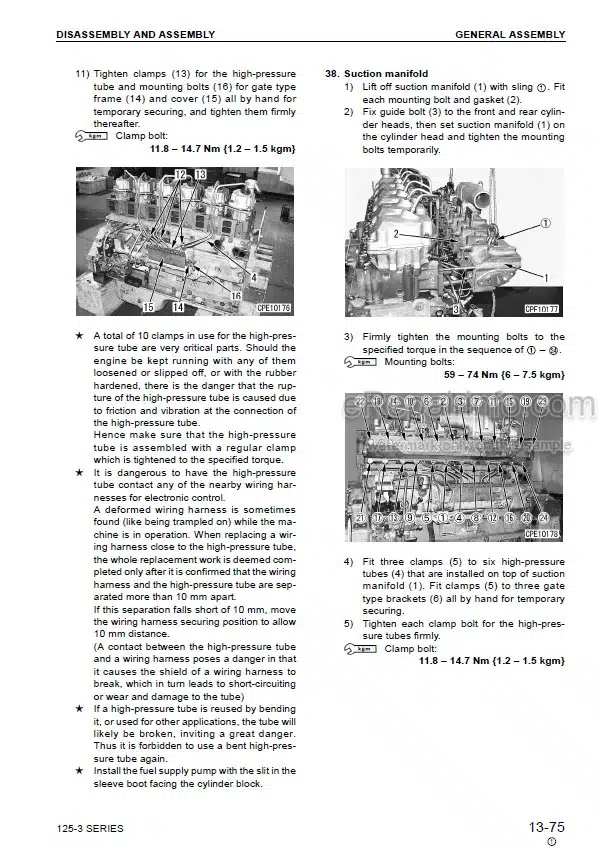

Intake Group

Replacement Of Turbocharger(Engine With Turbocharger)

Replacement Of Aftercooler, Gasket(Engine With Aftercooler)

Replacement Of Intake Connector

Air Connector

Replacement Of Intake Manifold Cover, Gasket

Air Crossover Tube

Exhaust Group

Replacement Of Exhaust Manifold. Gasket

Replacement Of Turbocharger

Turbocharger Mounting Stud(Engine With Turbocharger)

Cylinder Block Group

Cylinder Block

Crankshaft

Replacement Of Timing Pin

Replacement Of Gear Housing, Gasket

Replacement Of Vibration Damper, Crankshaft Pulley

Piston, Pin, Connecting Rod

Balancer

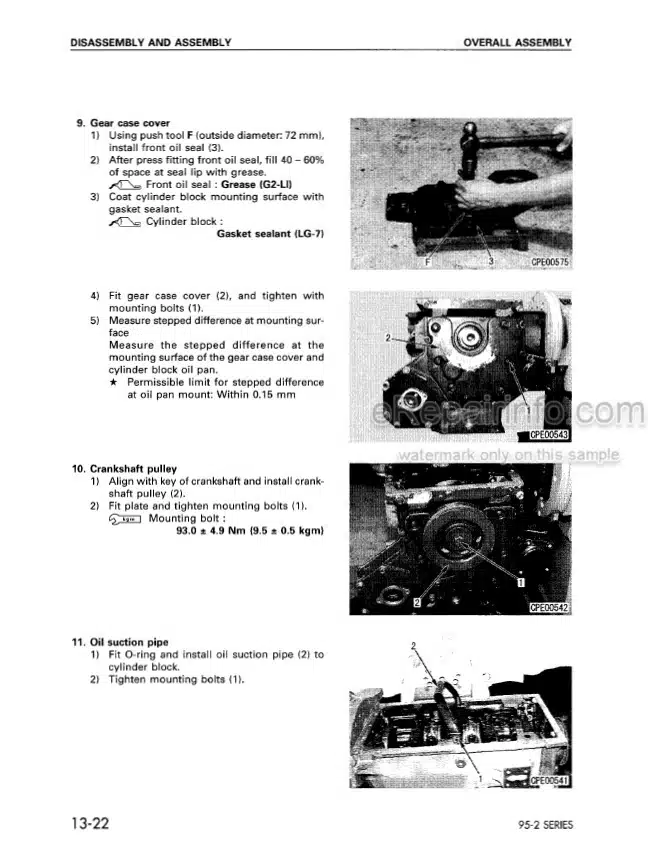

Gear Cover

Cylinder Head

Rocker Lever

Tappets And Push Rods

Engine Mount Group

Flywheel. Ring Gear

Flywheel Housing

Front Support

Removal Of Engine

Inspection Of Engine Mount

Installation Of Engine

Oil Pan And Suction Tube

Regulator Valve

Oil Filter Bypass Valve

Oil Cooler

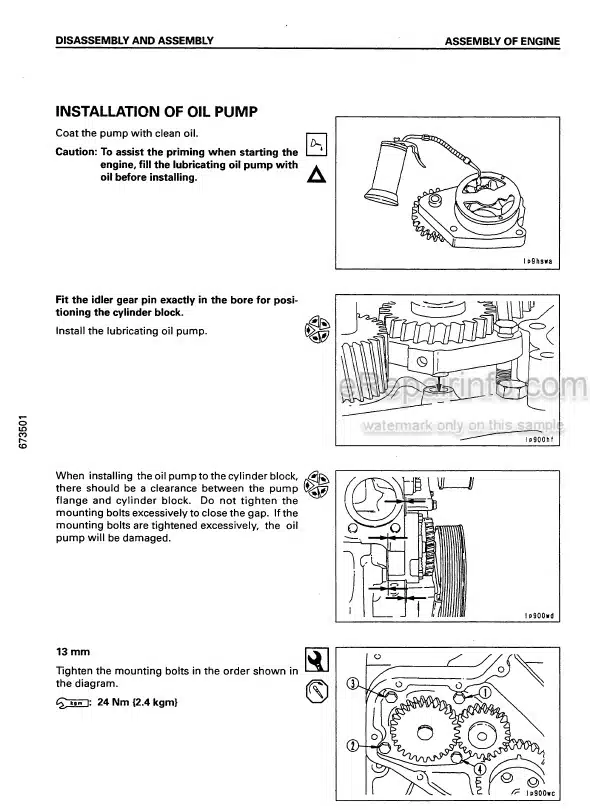

Oil Pump

Fuel Injection Pump Group

Fuel Injection Nozzle Group

Feed Pump(Cylinder Block Mount Type)

Replacement Of Fuel Filter

Fuel Piping

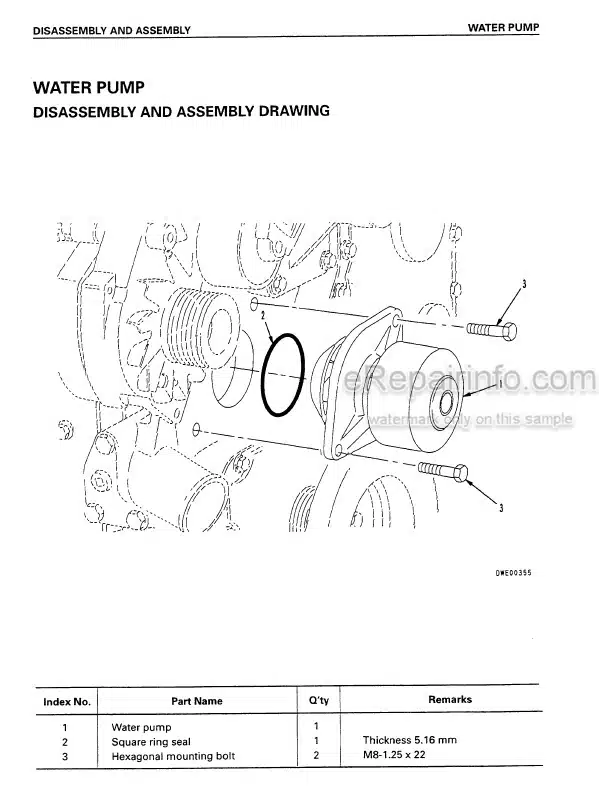

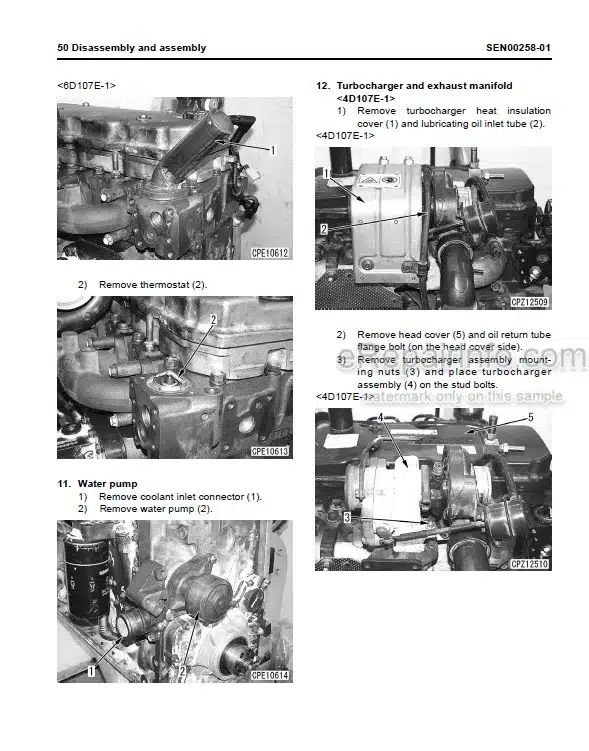

Water Pump

Fan Hub

Belt Tensioner

Thermostat

Fan

Coolant

Accessory Drive Adapter

Alternator

Starting Motor

-MAINTENANCE STANDARD

Turbocharger

Exhaust Manifold

Cylinder Head

Valve, Valve Guide

Locker Arm Shaft, Push Rod And Tappet

Cylinder Block

Cylinder

Crankshaft

Camshaft

Timing Gear

Piston, Piston Ring And Piston Pin

Connecting Rod

Vibration Damper

Flywheel, Flywheel Housing

Fan Hub

Oil Pump

Water Pump, Thermostat

Fuel Injection Pump

Fuel Injection Nozzle

-REPAIR AND REPLACEMENT OF PARTS

Outline

Repair Methods For Screws Using Coil Thread Insert

Method For Using Taper Thread Plugs To Seal Pockets And Small Holes In Castings

Method For Repairing Taper Thread Plug Holes Worn By Large Size Copper Plated Plugs

Method Of Using Filler Metal In Emergency Repairs

Procedure And Tools For Repairing Cylinder Block

Inspection And Grinding To Repair Combustion Deck

Inspection And Installation Of Valve Guide

Procedure 1 For Building Up Using Service Valve Guide

Procedure 2 For Building Up Using Service Valve Guide

Outline Of Valve Seat Repair

Calculating Grinding Depth Of Valve Seat

Method Of Grinding Valve Seat

Method Of Installing Valve Seat

Machining Exhaust Valve Insert Pocket

Method Of Grinding Valve

Assembly Of Cylinder Head

Procedure For Repairing Cylinder Block

Procedure For Repairing Crankshaft

Procedure For Repairing Connecting Rod

Packing Style Of Cylinder Head And How To Install Plugs

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet