Factory Shop Manual For Komatsu Crane. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 974

Number: SMC-150FA (october 2002)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

Komatsu Crane

150A

S.N. -09695 – 10827

150FA

S.N.-09695 – 10827

Contents

-ROSS POWER STEERING GEAR

Torque Sheet

Disassembly

Service To Cam And Actuator Assembly

Service To Lever Shaft And Stud Assembly

Service To Valve Assembly

Reassembly

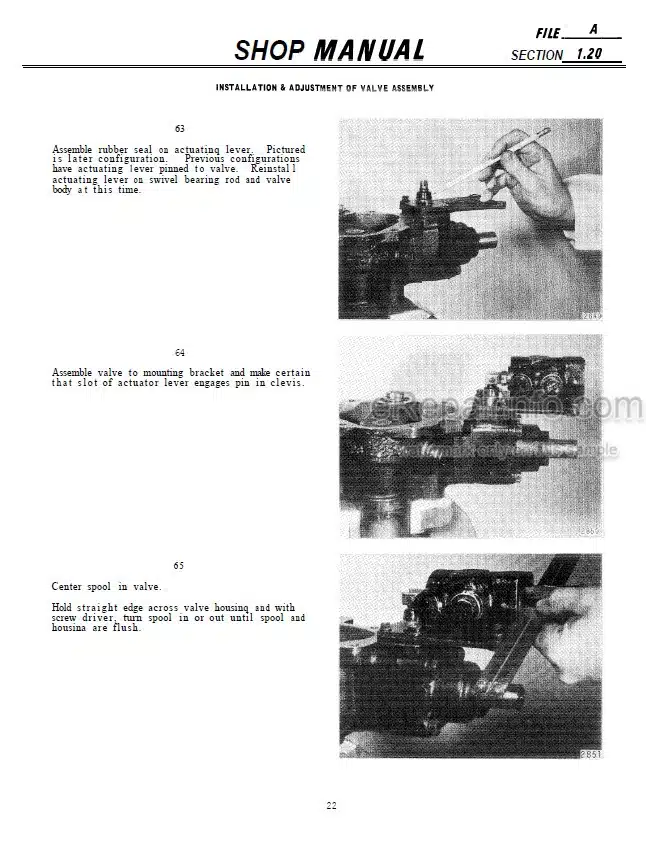

Installation And Adjustment Of Valve Assembly

Lubricant Specifications

Troubleshooting

-TORQUE CONVERTER (MODELS C272 & C273)

Torque Sheets

Special Tools

Disassembly Reassembly

Installation

-TRANSMISSION (MODEL 2420)

Torque Sheet

Special Tools

Transmission Disassembly

Clutch Disassembly

Clutch Reassembly

Control Valve & Oil Circuit Plate Disassembly & Assembly

Transmission Reassembly

Pressure Checks

-ALLISION MODEL TT-2421-1 TRANSMISSION

General Torque Values

Scope Of Manual

Specification, Wear Limits, And Spring Data

Description

Operation

Troubleshooting

Special Tools

Removal From Crane

Disassembly Of Transmission

Inspection And Cleaning

Rebuild Of Sub-Assemblies

Installation In Crane

Servicing Transmission

-PRIMARY MANIFOLD & CONTROLS

Torque Sheet

Disassembly

Reassembly

-PRIMARY MANIFOLD

General Torque Values

System Application

Removal

Disassembly

Cleaning And Inspection

Reassembly

Installation

-SECOND MANIFOLD

Torque Sheet

Removal Of Manifold

Removal Of Individual Valves

Disassembly Of Valve Components

Cleaning And Inspection

Reassembly Of Valve Components

Installation Of Individual Valves

Installation Of Manifold

Testing And Troubleshooting

-HYDRAULIC CRANE CYLINDERS

Torque Sheet

Precautions & Service Notes

Serial Number Ranges By Cylinder

Steering Cylinders

Outrigger Cylinders

Boom Crowd Cylinders

Swing & Hoist Brake Cylinders

Swing & Hoist Brake Checks And Adjustments

-POLYURETHATNE ONE PIECE ROD SEAL USED ON BOOM CYLINDERS

-HYDRAULIC CRANE BOOM LIFT CYLINDER

Torque Sheet

Disassembly

Reassembly

-DUEL CROWD CYLINDER FOUR SECTION POWER BOOM

Torque Sheet

Removal Of Dual Crowd Cylinder From Crane

Disassembly Of Dual Crowd Cylinder

Reassembly Of Dual Crowd Cylinder

Installation Of Dual Crowd Cylinder In Crane

-HYDRAULIC WINCH MOTOR (COMMERCIAL SHEARING)

Torque Sheet

Description & Identification

Troubleshooting

Disassembly

Inspection & Replacement

Cleaning

Special Tools

Reassembly

-SWING DRIVE HYDRAULIC MOTOR (COMMERCIAL SHEARING)

Torque Sheet

Swing Drive Hydraulic Motor Removal

Swing Drive Hydraulic Motor Disassembly

Cleaning

Inspection

Swing Drive Hydraulic Motor Reassembly

Swing Drive Hydraulic Motor Installation

Start-Up Procedure

Special Tools

-TANDEM PUMP (COMMERCIAL SHEARING MODEL 25X)

End Cover Removal

Gear Housing Removal

Drive & Driven Gear Removal

Disassembly Of Shaft End Cover

Disassembly Of Shaft Assembly

Disassembly Of Bearing Carrier

Reassembly

Test Procedure For Rebuilt Pump

Torque Sheet

-SWING COUNTERBALANCE VALVE

Torque Sheet

Introduction

Removal

Disassembly

Cleaning And Inspection

Reassembly

Installation

-HYDRAULIC CRANE TROUBLESHOOTING

Torque Sheet

Hydraulic Pressure & Engine Speed Charts

Hydraulic System Introduction

Troubleshooting The Swing Drive Circuit

Troubleshooting The Boom Lift Cylinder Circuit

Troubleshooting The Crowd Cylinder(S) Circuit

Troubleshooting The Winch Circuit

Troubleshooting The Rear Steering Cylinders

Troubleshooting The Outrigger Circuit

-BOOM WINCH ASSEMBLY

Configuration Changes

Removal Of Winch Assembly From Crane

Disassembly

Inspection & Cleaning

Reassembly

Installing Winch Assembly On Crane

Testing

General Torque Values

-SPRING MOTORS

Torque Sheet

Description

Unloading Retract Mechanism

Service To Old Type Spring Motor

Disassembly

Assembly

Service To New Type Spring Motor

Spring Cartridges

Disassembly

Shaft Bearing S And Cable Drum

Assembly

Reloading Retract Mechanism

Adjustment

Lubrication Of Gleason Reel

-PLANETARY DRIVE AXLE (CLARK SERIES DS-12152)

General Torque Values

Special Tools

Description

Removal Of Axle From Crane

Disassembly

Cleaning And Inspection

Reassembly

Installation Of Axle To Crane

Tooth Contact Sheet

-ROCKWELL AXLE ASSEMBLY

Torque Sheet

Special Tools

Removal Of Axles From Crane

Disassembly

Cleaning And Inspection

Reassembly

Installation

Brake Adjustment, Bleeding & Burnishing

-CLARK AXLE ASSEMBLIES (MODELS DS-13311 ORD1280736, AND DS-13550 OR D12S0840)

Special Tools

Introduction

Troubleshooting

Servicing

Tooth Contact Charts

Steering Adjustment Procedure (Front And Rear Axles)

Brake Shoe Adjustment Procedure (Front And Rear Axles)

Parking Brake Adjustment Procedure (Front Axle)

Brake Bleeding Procedure (Front And Rear Axles)

Burnishing Procedure (Front And Rear Axles)

Rear Steering Indicator Adjustment Procedure (Rear Axle)

-LUBRICATION SPECIFICATIONS

ATF Transmission Fluid

E050 SФУ 50 HВ Engine Oil

EP80 Extreme Pressure SAE 80 Gear Oil

EP90 Extreme Pressure SAE 90 Gear Oil

WBl Worm Gear Lubricant

OGl Open Gear Lubricant (Special Purpose)

SAE80 Straight Mineral SAE 80 Gear Oil

SAE90 Straight Mineral Sae90 Gear Oil

SHC High Temperature Gear Lubricant (Synthesized Hydrocarbon Base Fluid)

C-2 Transmission Fluid

C-3 Transmission Fluid

Ho Hydraulic Oil

Ho Hydraulic Oil

Mpg Multi-Purpose Lithium Base Grease

BF Hydraulic Brake Fluid

10W30 SAE 10W30 Engine Oil

Ho Hydraulic Oil – Low Temperature

80W140 SAE 80W-140

SAE40 SAE 40 Engine Oil

68 Hydraulic Oil – Petroleum Base – Anti-Wear Additives

SAE10W SAE 10W Engine Oil

-WAGNER POWER MASTER CYLINDER USED WITH FOUR WHEEL SERVICE BRAKES

Power Function

Manual Function

Disassembly Of Power Unit

Reassembly Of Power Unit

Disassembly Of Old Style Master Cylinder

Reassembly Of Old Style Master Cylinder

Disassembly Of New Style Master Cylinder

Reassembly Of New Style Master Cylinder Special Tools

-DELCO MORAINE HYDRAULIC MASTER BRAKE CYLINDER

Torque Sheet

Special Tools

Removal

Disassembly

Cleaning And Inspection

Reassembly

Installation

Brake Adjustment And Bleeding

Burnishing

-BENDIX MASTER CYLINDER & POWER BOOSTER

Special Tools

Removal

Disassembly

Cleaning And Inspection

Reassembly

Installation

Bleeding Procedure – 180S And 220S

Brake Adjustment -180S And 220S

Burnishing – 180S And 220S

Brake Adjustment And Bleeding For 150 And 150FA

Burnishing -150 And 150FA

-MINNESOTA BRAKE VALVE

General Torque Values

Removal From Machine

Disassembly Of Reservoir

Reassembly Of Reservoir Section

Disassembly Of Power Assist Section

Reassembly Of Power Assist Section

Installation Of Brake Valve On Machine

Brake Bleeding Procedure

-DELCO MORAINE POWER BOOSTER

Torque Sheet

Introduction

Troubleshooting

Identification

Service Chart

Special Tools

Servicing

-WIRING DIAGRAMS – CRANES

Crane Model 80

Crane Model 90, 100, 110 & 125

Crane Model 125F

Crane Model 90A, 100A, 110A& 125A

Crane Model 125FA

Crane Model 140F

Crane Model 150 & 150Fa

Crane Model 180S

Crane Model 200FA

Crane Model 220A

Crane Model 220S

Crane Model 125P

Crane Model 150P&150T

-TROUBLESHOOTING & REMOVAL OF CRANKING MOTORS

Torque Sheets

Preliminary Checks

Removal

Bench Testing

Installation

Lubrication

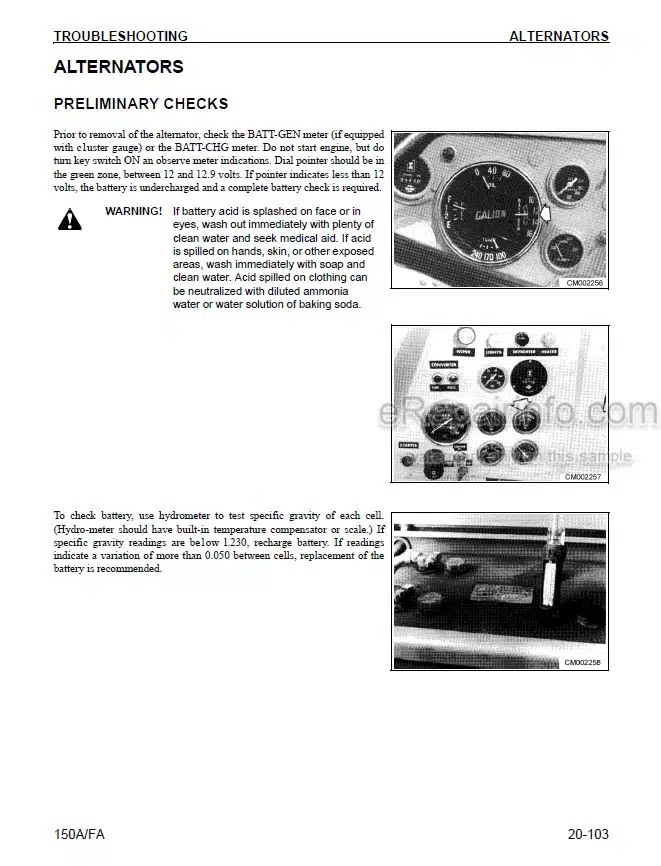

-TROUBLESHOOTING & REMOVAL OF ALTERNATORS

Torques Sheet

Preliminary Checks

Removal

Installation

Lubrication

-PREDELIVERY PROCEDURES (NOT INCLUDED – LISTED FOR REFERENCE ONLY)

-HEAD AND HOOK BLOCK

Torque Sheet

Disassembly

Inspection

Reassembly

Care Of Wire Rope

Wire Rope Replacement

Methods Of Lubrication

-DRESSER HYDRAULIC CRANE – WIRE ROPE SPECIFICATION

Manufacturers Description

Wire Rope

Service And Inspection Of Wire Rope

-GENERAL TORQUE VALUES

Introduction

Torques

Torque Values For Standard Metric Fasteners

Torque Values For Hose Clamps

Torque Values For Split Flange Connections

Torque Values For Hydraulic Tubes And Fittings

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet