Factory Shop Manual For Komatsu Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 212

Number: SEBM011501 (may 2003)

Bookmarks: Yes

Searchable: Yes

Model

Komatsu 68E And 88E Series Diesel Engine

2D68E

3D68E

3D74E

3D78AE

3D82AE

3D82E

3D84E

3D88E

4D82E

4D84E

4D88E

S3D84E

S4D84E

Contents

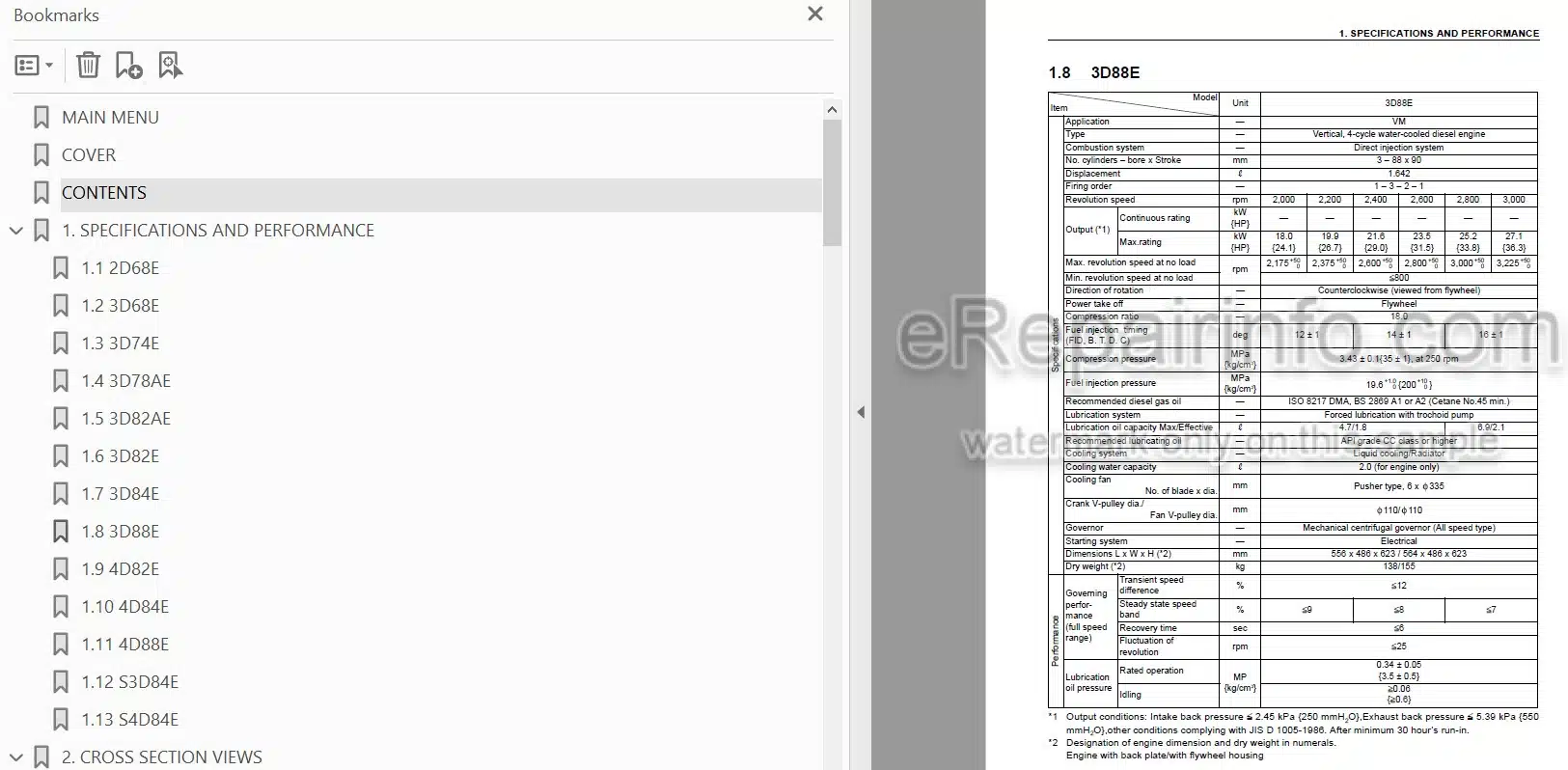

-SPECIFICATIONS AND PERFORMANCE

2D68E

3D68E

3D74E

3D78AE

3D82AE

3D82E

3D84E

3D88E

4D82E

4D84E

4D88E

S3D84E

S4D84E

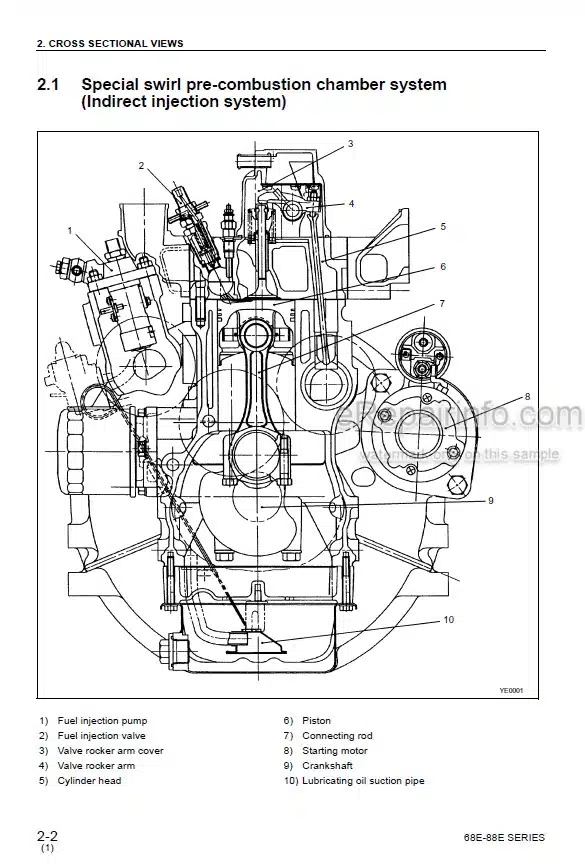

-CROSS SECTION VIEWS

Special Swirl Pre-Combustion Chamber System (Indirect Injection System)

Direct Injection System

-COOLING WATER, LUBRICATING OIL AND FUEL OIL

Cooling Water

Lubricating Oil

Fuel Oil

-TROUBLESHOOTING

Trouble Causes And Remedies

Trouble Diagnosis Through Measurement Of Compression Pressure

-SPECIAL SERVICE TOOLS AND MEASURING INSTRUMENTS

Special Service Tools

Measuring Instruments

-MESUREMENT, INSPECTION AND ADJUSTMENT

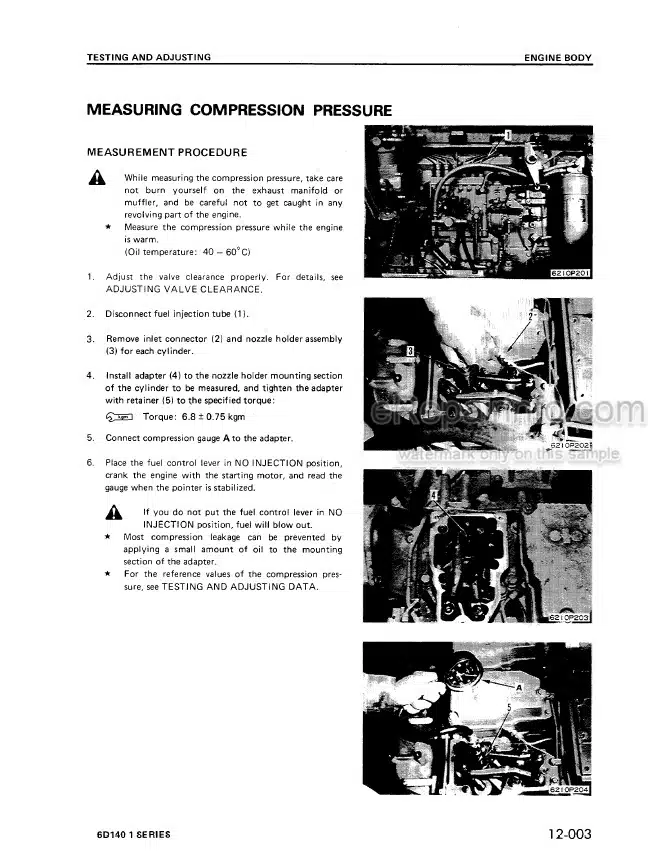

Measuring The Compression Pressure

Adjusting The Valve Head Clearance

Checking The V-Belt Tension

Measuring And Checking The Injection Pressure And Spray Patterns Of The Fuel Injection Valve

Checking And Adjusting The Fuel Injection Timing

Adjusting The No-Load Maximum (Or Minimum) Revolutions

Checking The Cooling Water System And Radiator For Water Leakage

Checking The Battery

Checking The Sensors

Checking The Oil Cooler

Checking The Piston Cooling Nozzle

-MEASURING PROCEDURES, SERVICE DATA AND CORRECTIVE ACTION

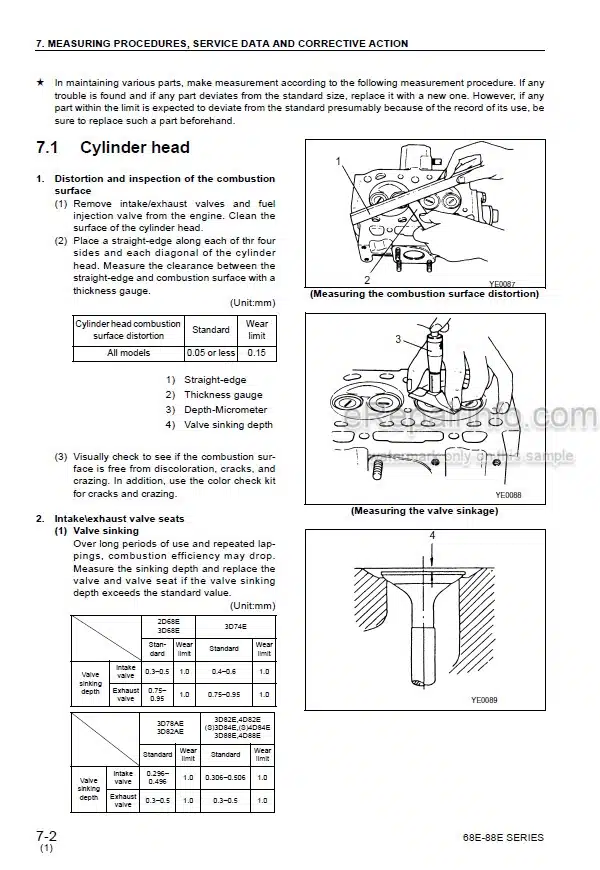

Cylinder Head

Cylinder Block

Valve Rocker Arm

Piston And Piston Ring

Connecting Rod

Camshaft

Crankshaft

Gears

Trochoid Pump

-DISASSEMBLY AND REASSEMBLY

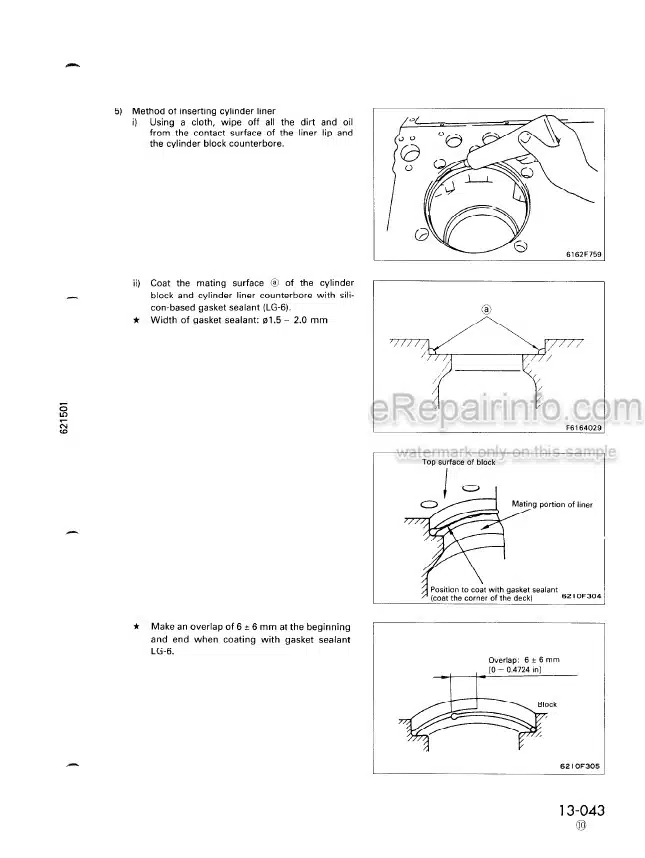

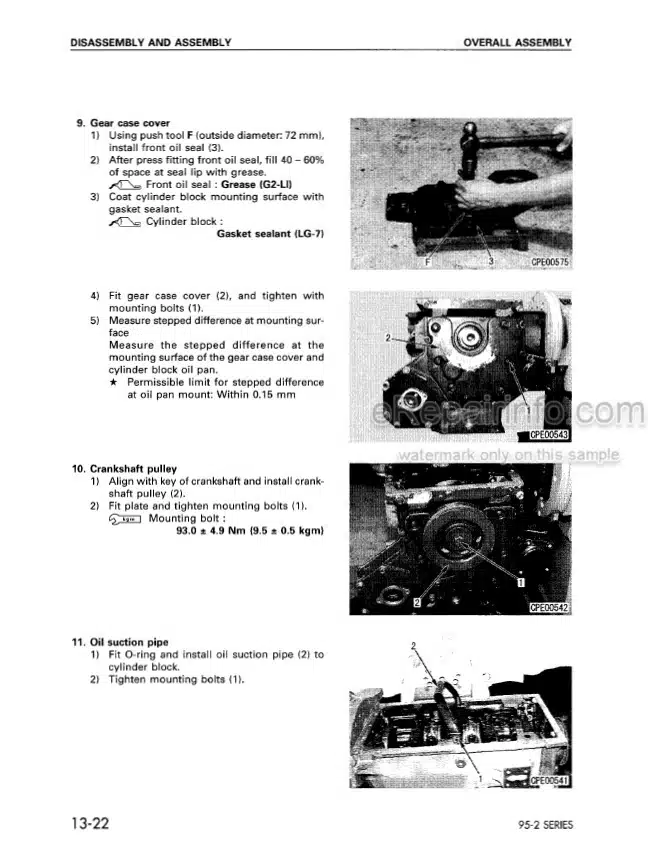

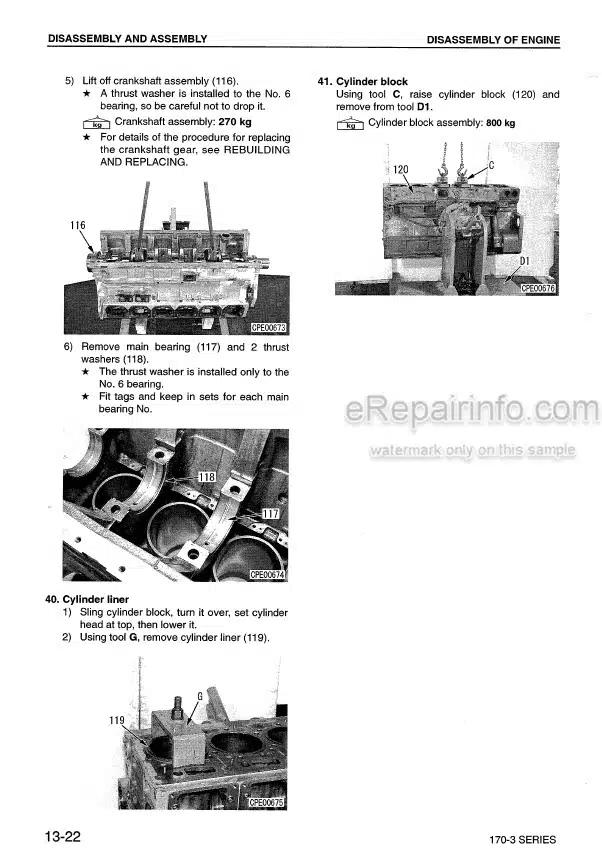

Disassembly

Precautions Before And During Reassembly

-SERVICE DATA

Cylinder Head

Cylinder Block

Valve Rocker Arm

Piston

Piston Ring

Connecting Rod

Camshaft

Crankshaft

Side Gap And Backlash

Others

-TIGHTENING TORQUE

Main Bolt/Nut

Standard Bolt And Nut

-FUEL INJECTION PUMP FOR INDIRECT INJECTION SYSTEM

Exploded View

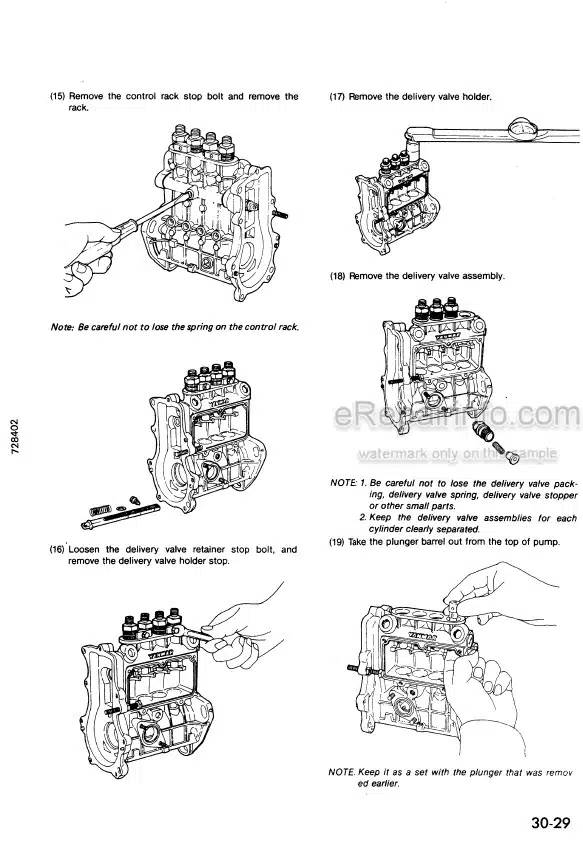

Disassembly

Inspection

Reassembly

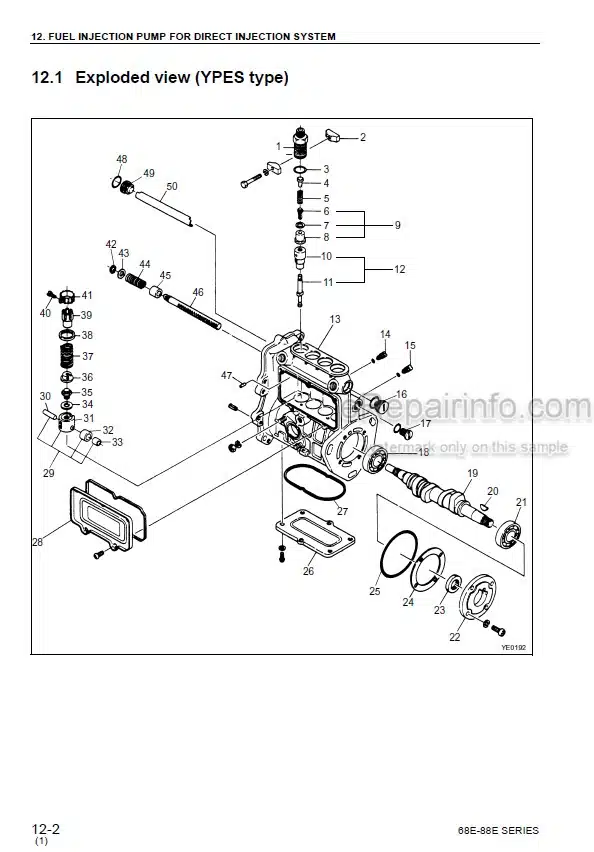

-FUEL INJECTION PUMP FOR DIRECT INJECTION SYSTEM

Exploded View (Ypes Type)

Special Service Tools For Disassembly And Reassembly

Disassembly

Inspection

Reassembly

-GOVERNOR

Exploded Views Of Governor For Indirect Injection System

Exploded Views Of Governor For Direct Injection System Disassembly

Inspection

Reassembly

-TURBOCHARGER

Specifications

Construction

Waste Gate Valve Adjusting Method

Exploded View Of Turbocharger (With Waste Gate)

Tightening Torque

Service Standards

-SERVICE INFORMATION FOR CARB ULG REGULATION

Limiting The High Idle And Low Idle Adjustment Screw

Limiting The Fuel Volume Limiter Screw

-ATTACHED DRAWING

Exploded Views Of Engine Components

-EPA CERTIFIED ENGINE

Applicable Machine, Serial Number (EPA Certified Engine)

EPA Certification Plate Attaching Location

Differences With The Current Production Model

Fuel Injection Timing Adjustment

Specifications

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet