Factory Shop Manual For Komatsu Bulldozer. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 723

Number: SEBM01950508 (september 1995)

Bookmarks: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Bulldozer

D355A-5

SN 12622 And Up

Contents

-FOREWORD

How To Read The Shop Manual

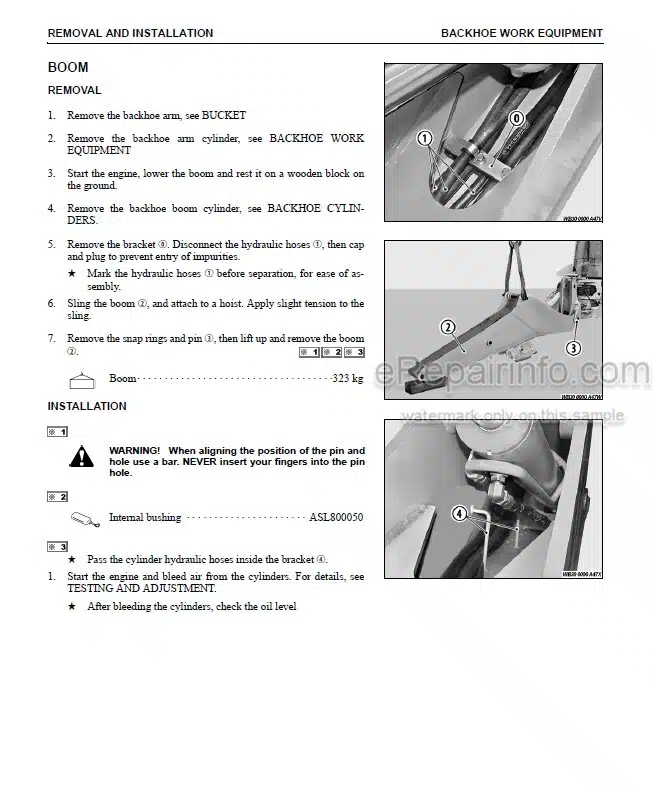

Hoisting Instructions

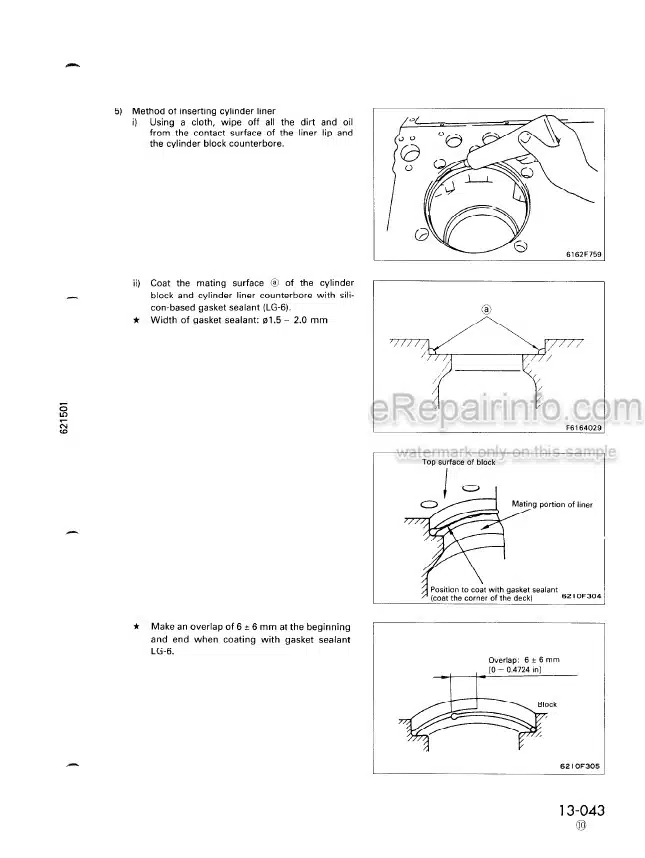

Coating Materials

Standard Tightening Torque

Electric Wire Code

Conversion Table

Temperature

Weight Table

Table Of Fuel, Coolant And Lubricants

-STRUCTURE AND FUNCTION

General

Power Train Hydraulic Circuit Diagram

Torque Converter

Torqflow Transmission

Disc Clutches

Transmission Powertrain

Torqflow Hydraulic Piping

Torqflow Hydraulic System

Torqflow Hydraulic Circuit Diagram

Transmission Control Valve

Control Valve System Diagram

Safety Valve

Transmission Lubrication Relief Valve

Transmission Pump

Transmission And Steering Oil Strainer

Transmission Oil Filter

Bevel Gear Shaft And Steering Clutch

Steering And Brake Piping

Steering And Brake Hydraulic System

Steering And Brake Hydraulic Circuit Diagram

Steering Control Valve

Steering Main Relief Valve

Steering Brake And Booster

Steering Pump

Steering Oil Filter

Spring Assist Brake Device

PTO

Final Drive

Track Frame

Recoil Spring

Idler

Track Roller And Carrier Roller

Track (Lubricated Track Link)

Track (Dry Type Track Link)

Suspension

Hydraulic Piping

Hydraulic Circuit Diagram

Hydraulic Tank

Hydraulic Pump

Hydraulic Control Valve

Hydraulic Cylinder

Ripper Selector Valve And Pilot Check Valve

Pilot Valve

Servo Valve Hydraulic System

Rotary Servo Valve

Pin Puller Hydraulic System And Diagram (For Giant Ripper)

Pin Puller Valve (For Giant Ripper)

Pin Puller Cylinder (For Giant Ripper)

Straight Tilt Dozer

Variable Multiple Shank Ripper

Variable Giant Ripper

Cylinder Stay

EVMS (Electronic Vehicle Monitoring System)

Air Conditioner

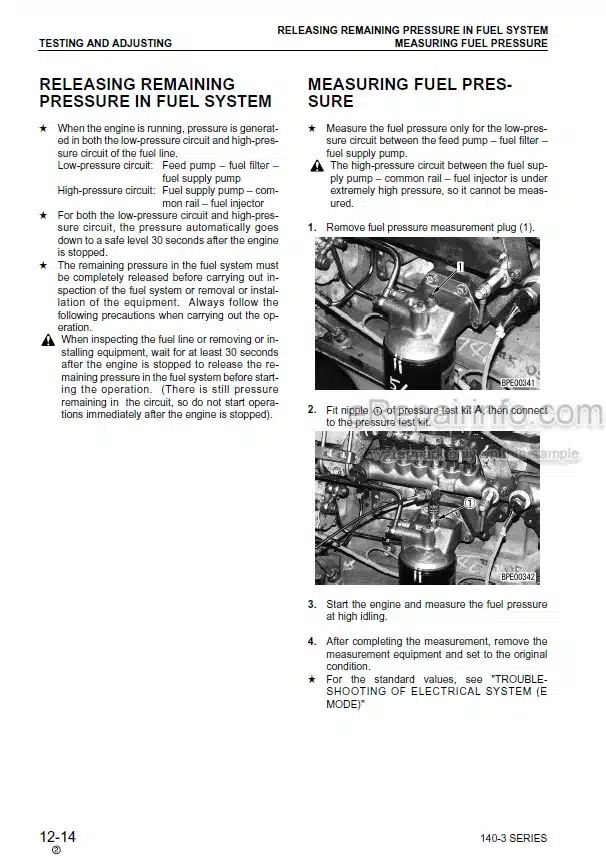

-TESTING AND ADJUSTING

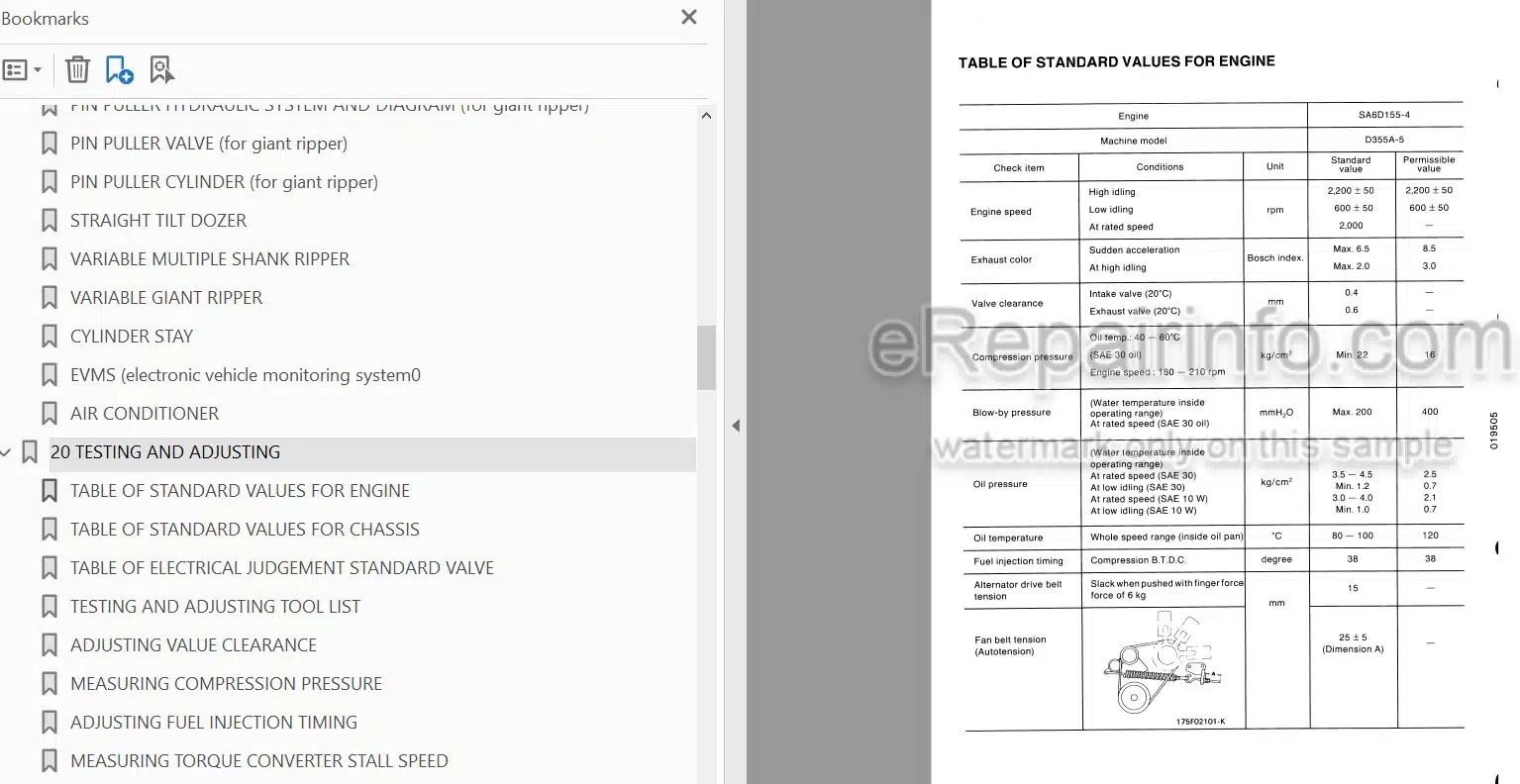

Table Of Standard Values For Engine

Table Of Standard Values For Chassis

Table Of Electrical Judgement Standard Valve

Testing And Adjusting Tool List

Adjusting Value Clearance

Measuring Compression Pressure

Adjusting Fuel Injection Timing

Measuring Torque Converter Stall Speed

Measuring Hydraulic Pressure

Bleeding Air From Hydraulic Cylinder

Adjusting Linkage

Troubleshooting

-TROUBLESHOOTING

Preparation For Troubleshooting

Position Of Connectors

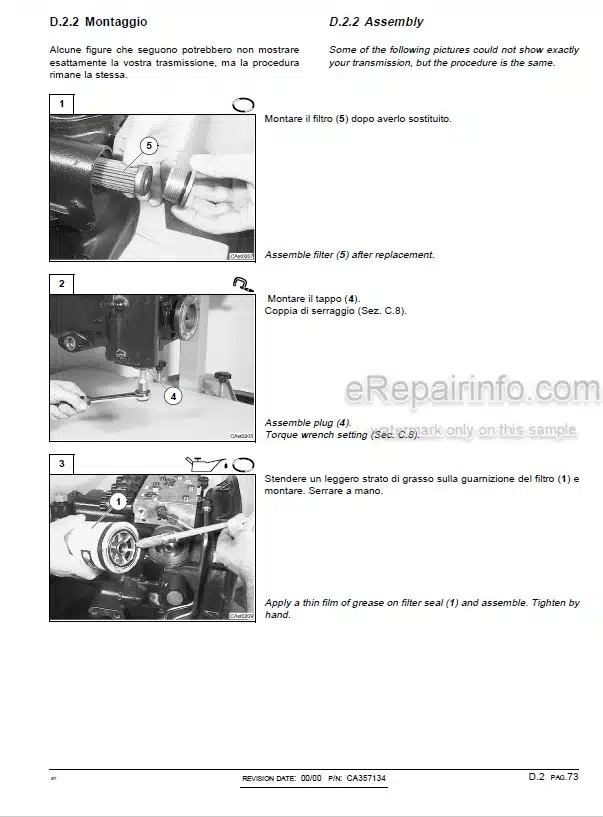

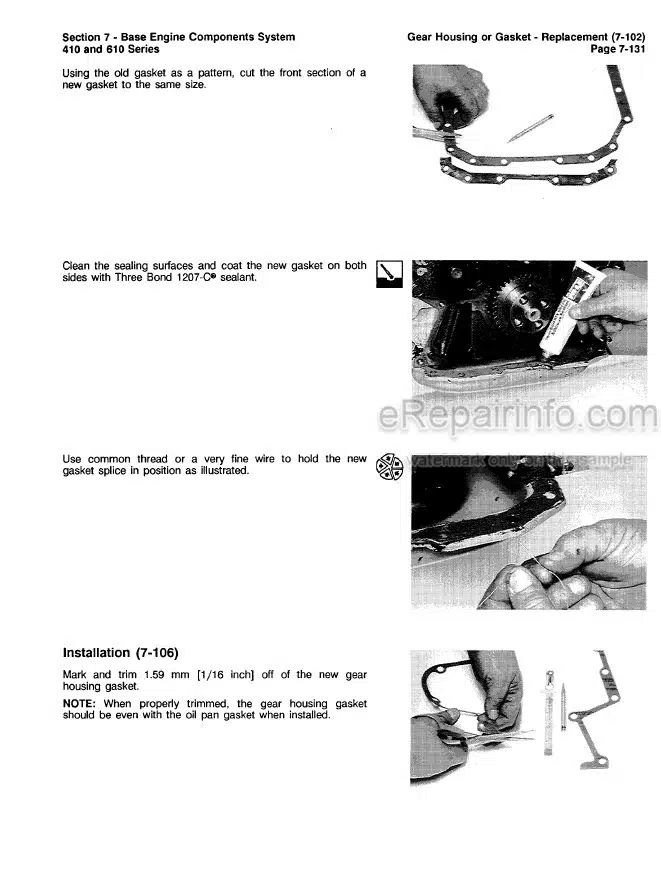

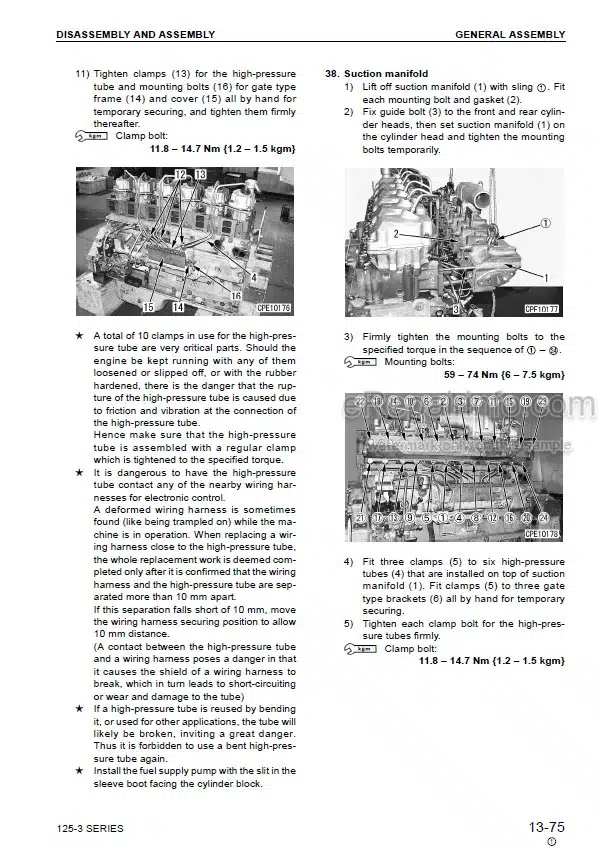

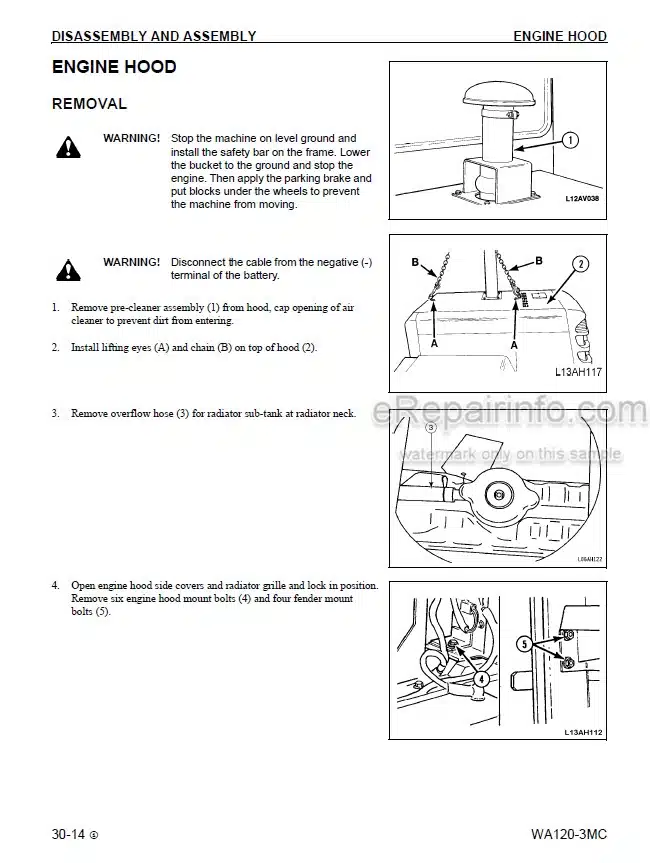

-DISASSEMBLY AND ASSEMBLY

Precautions when carrying out operation

Starter Motor

Fan Belt

Alternator

Engine Oil Cooler

Fuel Injection

Water Pump

Turbo Charger

After Cooler

Nozzle Holder

Cylinder Head

Radiator

Fuel Tank

PTO

Torque Converter Oil Cooler

Engine

Chassis-Related Parts from Engine

Torque Converter

Torque Converter

Torque Converter Relief Valve

Torque Converter Regulator Valve

Torqflow Transmission

Torqflow Transmission

No. 1,3 Carriers and No. 1,2 Sun gears and bearing cage

No. 4 Housing and No. 5,6 Gears and PTO Shaft

Torqflow Transmission

No. 4 Housing and No. 5,6 Gears and PTO Shaft

No. 1,2 Sun Gears and Bearing Cage

Torqflow Transmission Lubrication Valve

Transmission Control Valve

Transmission Control Valve of Steering Clutch

Disassembly / Assembly of Steering Clutch

Bevel Gear Shaft and Bevel Gear

Steering / Brake Interlocking Valve

Steering / Brake Interlocking Valve

Steering Bake Booster

Steering Main Relief Valve

Steering Main Relief Vallve

Brake Assister Cylinder Ass’y

Brake Assister Cylinder Ass’y

Final Drive 1st Pinion

Final Drive

Transmission Pump

Steering Pump

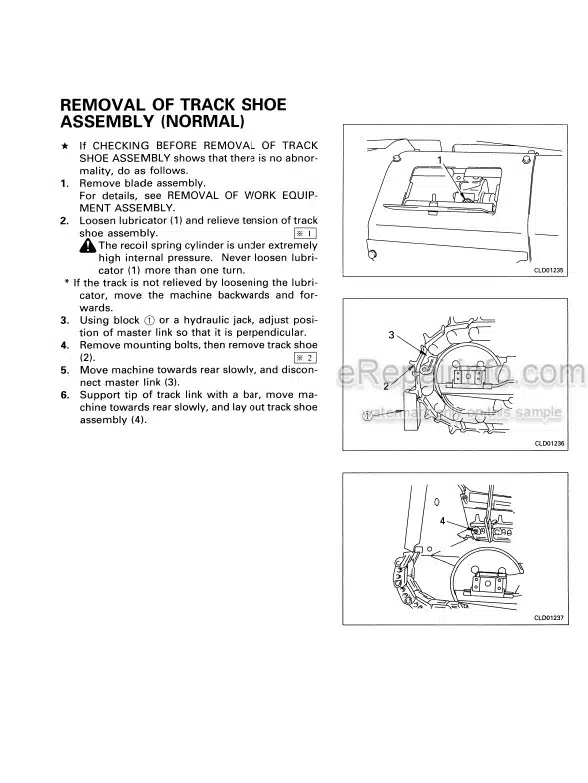

Checking before removal of Track Shoe Assembly

Removal of Track Shoe Assembly (Normal)

Removal of Track Shoe Assembly (When there is abnormality inside track frame)

Installation of Track Shoe Assembly

Truck Line Disassembly and Assembly

Track Shoe

Press-Fitting Jig Dimension Table for Link Press

One link

Master Link

Carrier Roller

Track Roller

Idler

Recoil Spring

Track Frame

Ripper and Blade Control Valve

Blade Tilt Control Valve

Hydraulic Pump

Ripper and Blade Servo Valve

Blade Tilt Servo Valve

Pin Puller Valve

Ripper Selector Control Valve

Ripper Selector Valve

Blade Lift Cylinder

Ripper Lift Cylinder

Ripper Tilt Cylinder

Ripper Cylinder

Pin Puller Cylinder

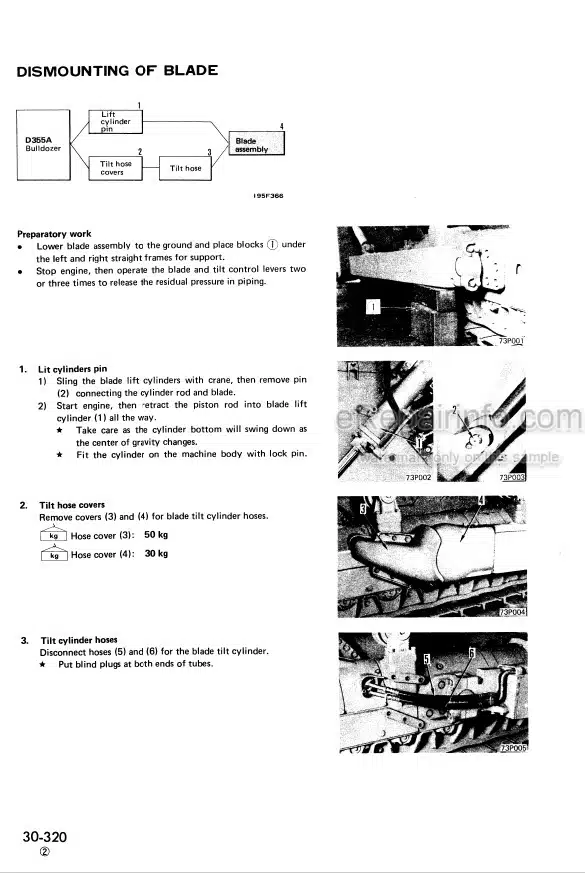

Blade

Variable Giant Ripper

Floor Frame

ROPS Cab

-MAINTENANCE STANDARD

Transmission Pump

Steering Pump

Torque Converter

Transmission Lubrication Relief Valve

Torqflow Transmission

Transmission Control Valve

Bevel Gear Shaft

Steering Clutch

Steering Control Valve

Steering Main Relief Valve

Brake Assister Turomatic Drain Valve

Brake Assister Check Valve

Spring Assist Brake Cylinder

Spring Assist Brake Auto Drain Valve

Steering Brake and Booster

Final Drive

Track Frame

Recoil Spring

Idler

Track Roller

Carrier Roller

Track Shoe (Lubricated track link)

Track (Dry type track link)

Hydraulic Pump

Hydraulic Control Valve

Quike Drop Valve

Ripper Selector Valve and Pilot check Valve

Ripper Pilot Valve

Ripper Pin Puller Valve (for Giant Ripper)

Hydraulic Cylinder

Pin Puller Cylinder (for Giant Ripper)

Servo Valve

Straight Tilt Dozer

Cylinder Stay

Variable Multiple Shank Ripper

Variable Giant Ripper

-DRAWINGS

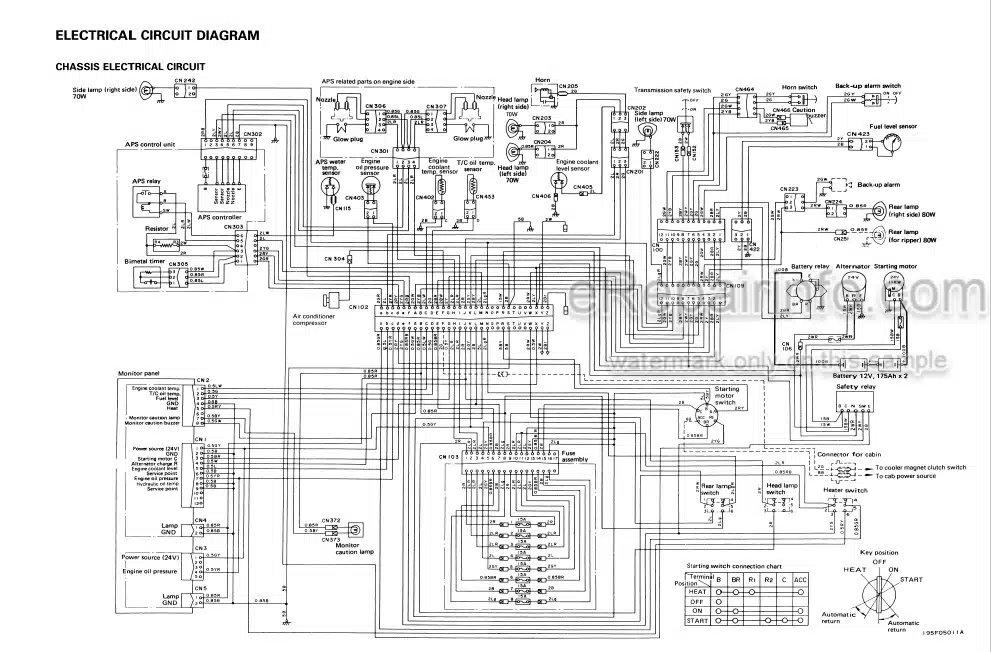

Electrical Circuit Diagram

Location Of Connectors

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet