Factory Shop Manual For Komatsu Bulldozer. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1004

Number: SEBM023507 (december 2004)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Bulldozer

D375A-5

SN 18001 And Up

Contents

-SAFETY

Safety Notice

-FOREWORD

General

How To Read The Shop Manual

Hoisting Instructions

Method Of Disassembling, Connecting Push-Pull Type Coupler

Coating Materials

Standard Tightening Torque

Electric Wire Code

Conversion Table

Units

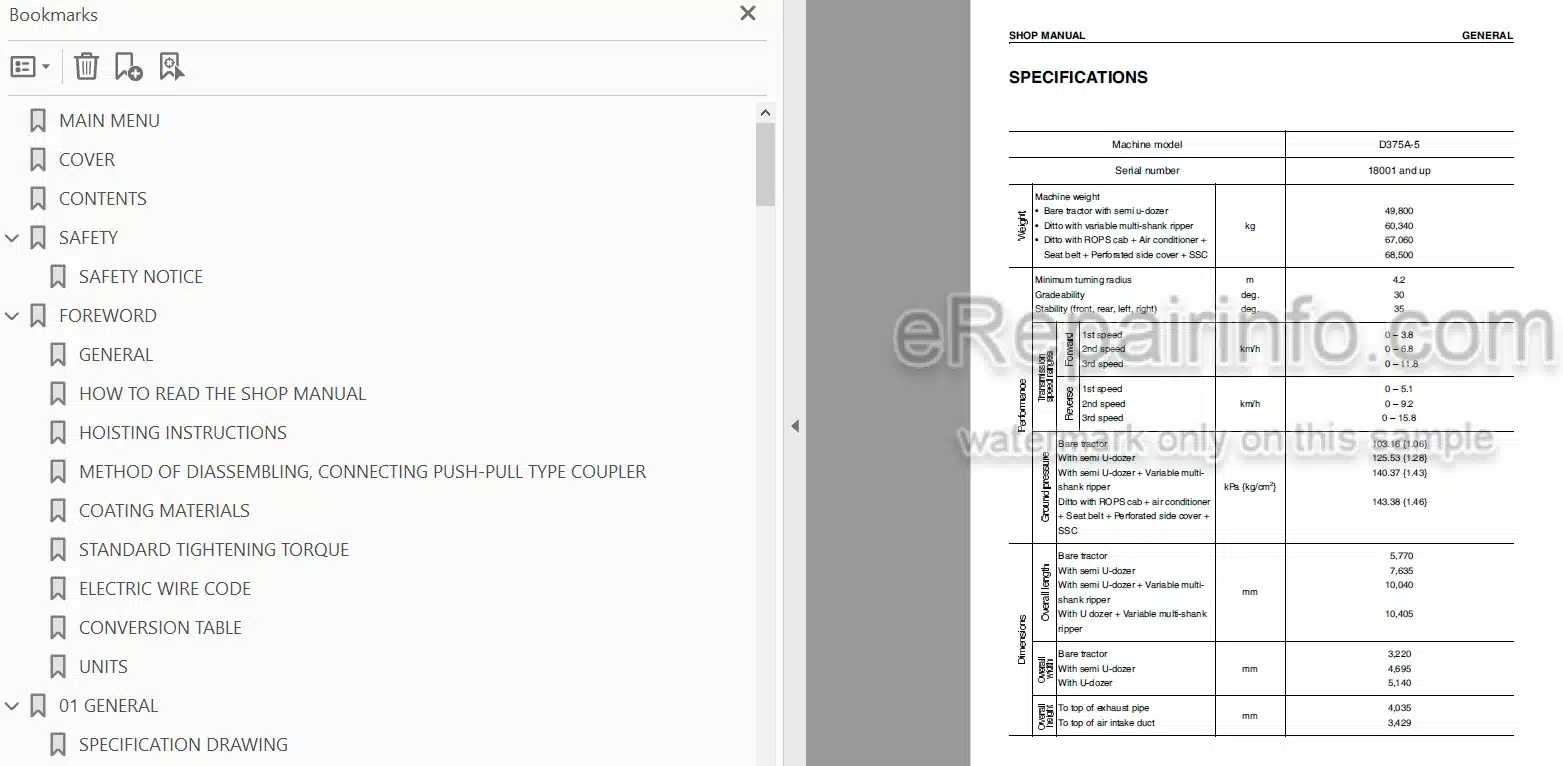

-GENERAL

Specification Drawing

Specifications

Weight Table

Table Of Fuel, Coolant And Lubricant

-STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

Powertrain

Overall Drawing Of Powertrain Unit

Powertrain Hydraulic Piping Drawing

Damper, Universal Joint

Torque Converter, PTO

Torque Converter Valve

Scavenging Pump

Transmission Control

Transmission

Transmission ECMV

Transmission Lubrication Relief Valve

Powertrain Pump+ Lubrication Pump

Steering. Brake Control

Transfer, Bevel Gear Shaft, Steering

Steering ECMV

Steering Clutch, Steering Brake ECMV

Parking Brake Valve

Sudden Stops Prevention Valve

Final Drive

Track Frame

Recoil Spring

Idler

Track Roller

Carrier Roller

Track Roller Bogie

Track Shoe

Main Frame

Suspension

Work Equipment Hydraulic Piping Diagram

PPC Control Piping Diagram

Work Equipment Control

Hydraulic Tank

PPC Charge Valve

Accumulator

PPC Lock Valve

PPC Valve

Work Equipment Cylinder

Piston Valve

Quick Drop Valve

Pin Puller Switch

Pin Puller Solenoid Valve

Blade Control Knob

Pitch, Dual Tilt Solenoid Valve

Work Equipment + PPC Charge Pump

Main Control Valve

Cylinder Stay

Blade

Ripper Equipment

Cab Mount

Cab

Air Conditioner

Engine Control

Engine Control System

Decelerator Potentiometer

HPI Engine Control System

Monitor System

Monitor Panel

Sensors

Mode Selection System

Sensors (Engine And Speed Sensor)

Electrical Device

Steering Electronic Control

APS

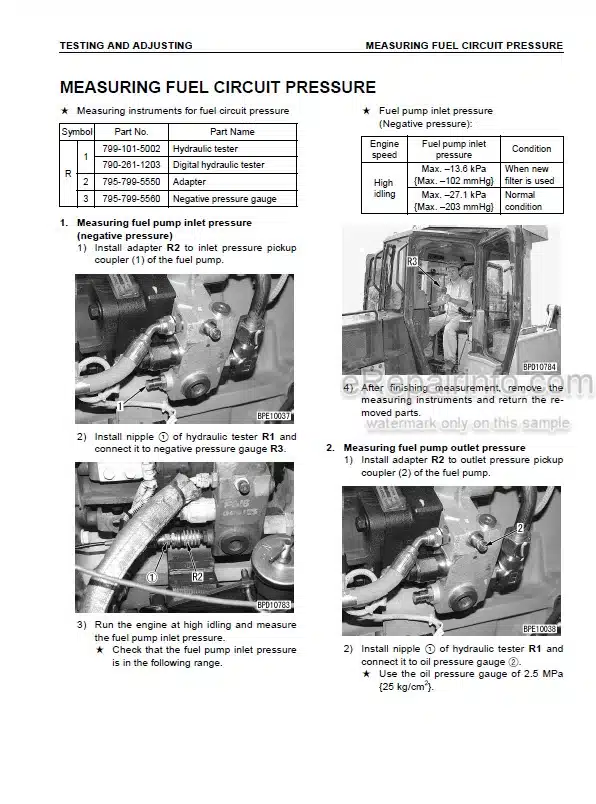

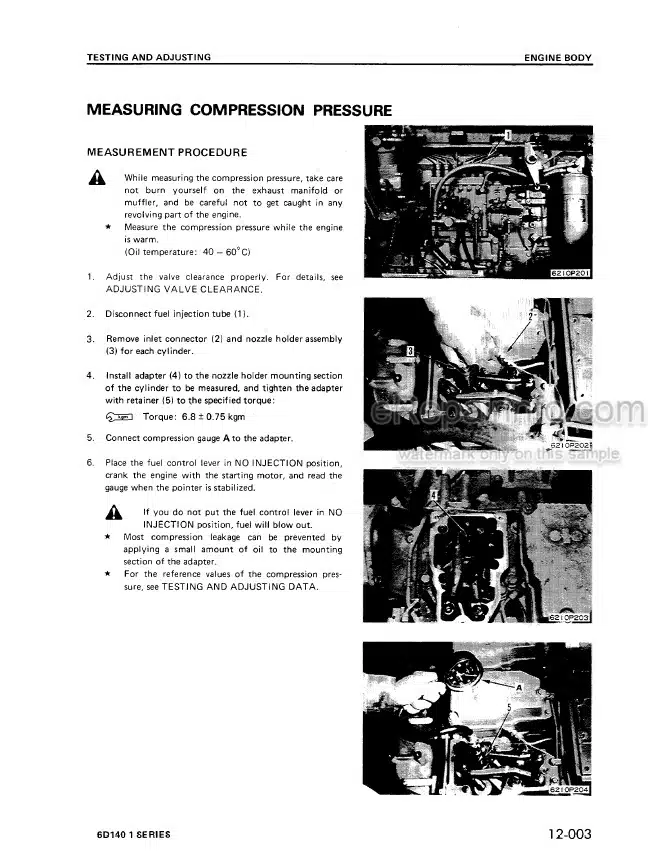

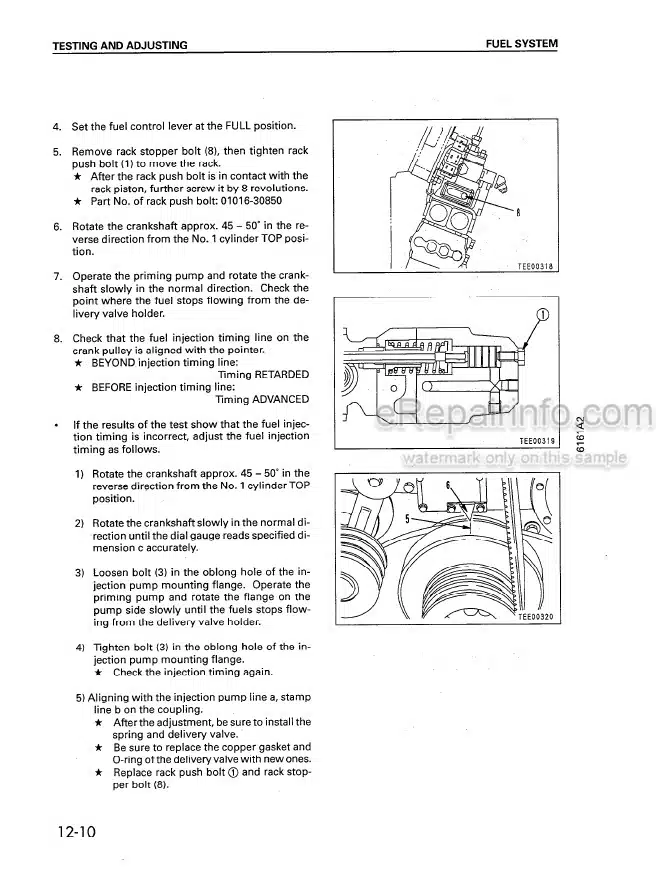

-TESTING AND ADJUSTING

Standard Value Tables

Testing And Adjusting

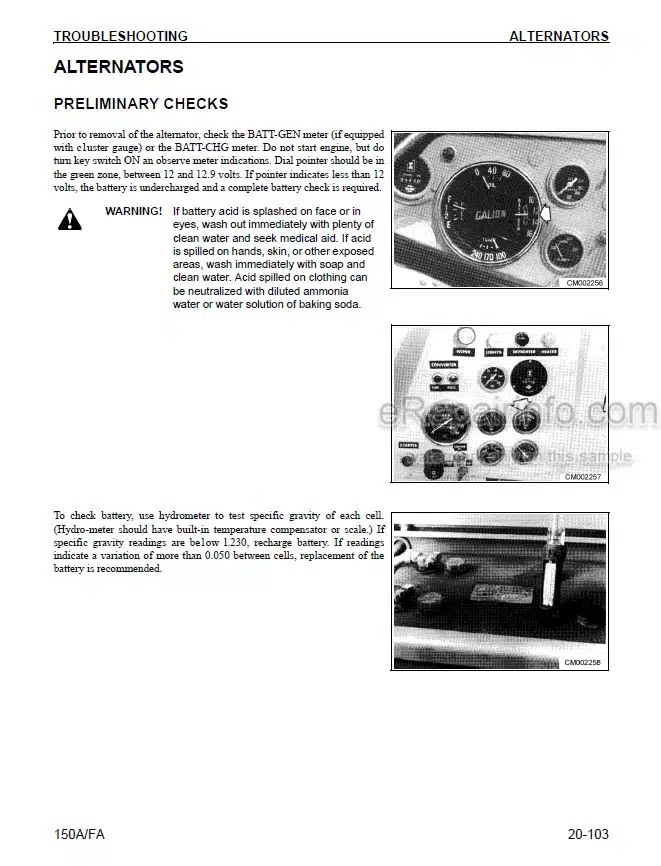

Troubleshooting

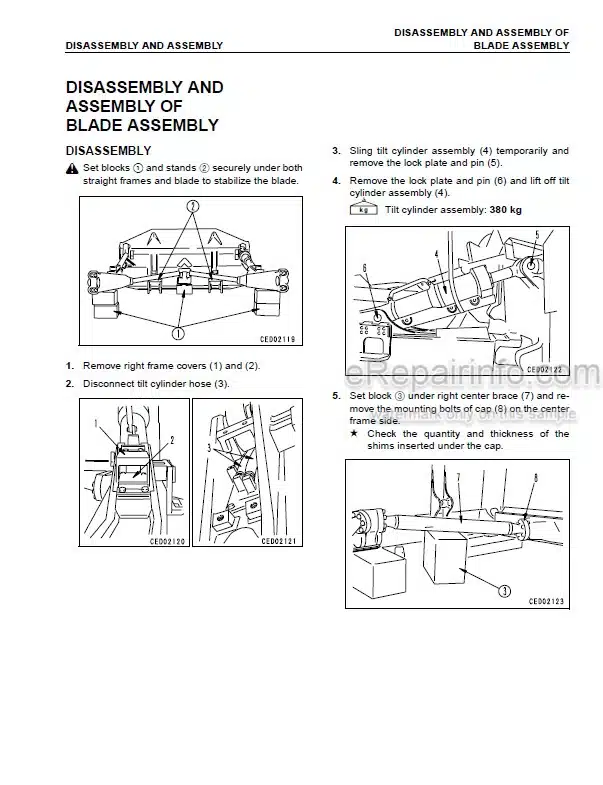

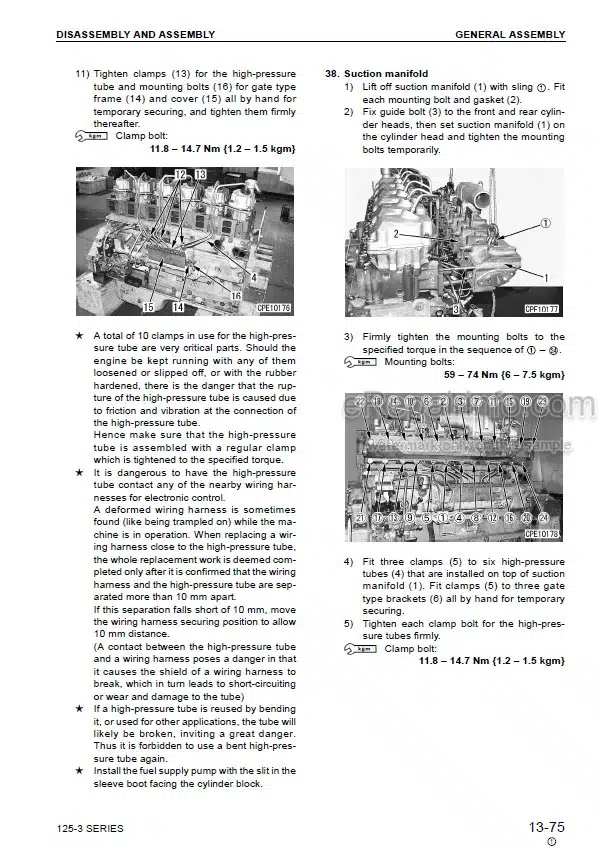

-DISASSEMBLY AND ASSEMBLY

Precautions When Carring Out Operation

Special Tool List

Removal And Installation Of Fuel Pump Assembly

Removal And Installation Of Engine Front Seal

Removal And Installation Of Engine Rear Seal

Removal And Installation Of Cylinder Head Assembly

Removal And Installation Of Fuel Tank Assembly

Removal And Installation Of Radiator Assembly

Removal And Installation Of Radiator Guard Assembly

Removal And Installation Of Engine Assembly

Removal And Installation Of Damper Assembly

Disassembly And Assembly Of Damper

Removal And Installation Of Powertrain Unit Assembly

Disconnection Of Powertrain Unit Assembly

Connection Of Powertrain Unit Assembly

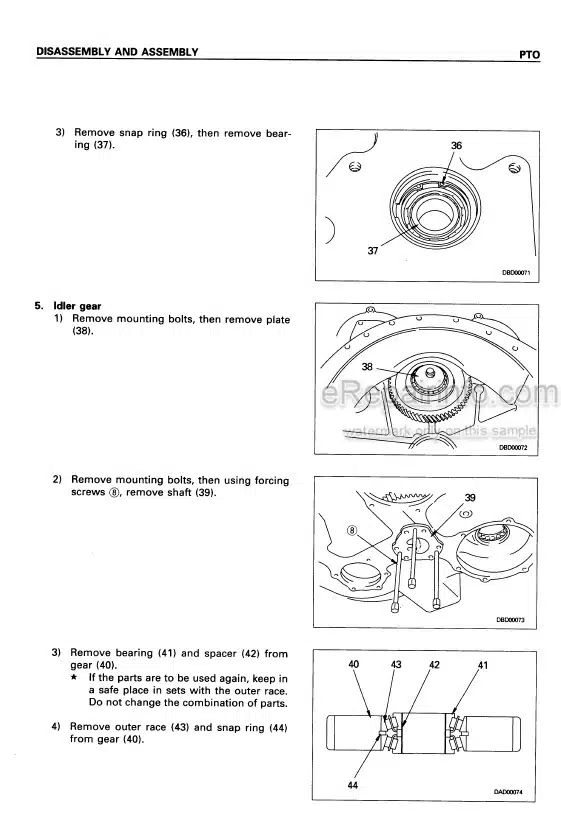

Disassembly And Assembly Of PTO Assembly

Disassembly And Assembly Of Torque Converter Assembly

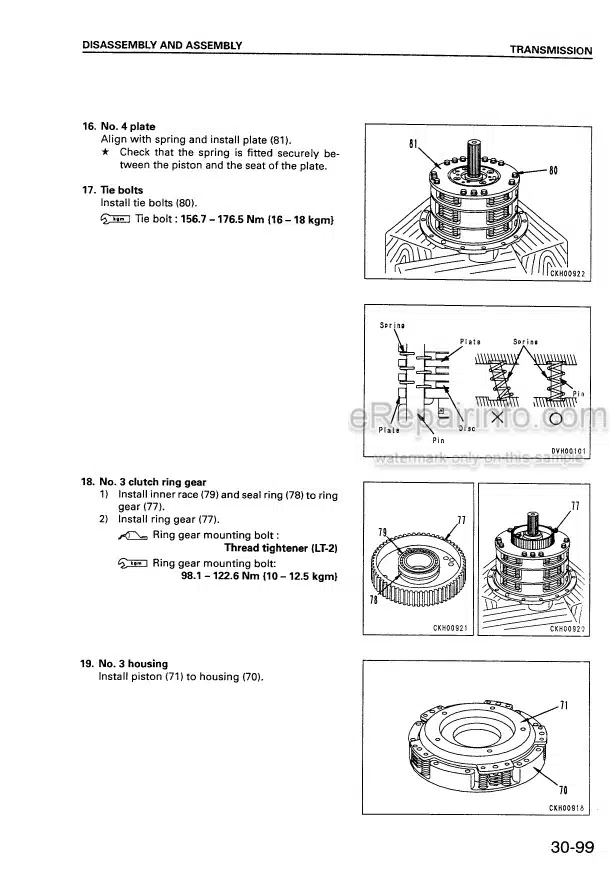

Disassembly And Assembly Of Torqflow Transmission Assembly

Disassembly And Assembly Of Steering Case Assembly

Removal And Installation Of Powertrain, Lubrication Pump Assembly

Removal And Installation Of Scavenging Pump Assembly

Removal And Installation Of Final Drive Assembly

Disassembly And Assembly Of Final Drive Assembly

Removal And Installation Of Track Frame Assembly

Removal And Installation Of Idler Assembly

Disassembly And Assembly Of Idler Assembly

Removal And Installation Of Recoil Spring Assembly

Disassembly And Assembly Of Recoil Spring Assembly

Removal And Installation Of Track Roller Assembly

Disassembly And Assembly Of Track Roller Assembly

Removal And Installation Of Bogie Assembly

Disassembly And Assembly Of Bogie Assembly

Removal And Installation Of 1St Bogie Assembly

Expanding And Assembly Track Shoe Installation

Whole Disassembly And Assembly Of Track Shoe

Dimensions Table Of Fitting Jig Of Link Press

Disassembly And Assembly Of 1 Link In The Field

Disassembly And Assembly Of Master Link

Removal And Installation Of Pivot Shaft Assembly

Removal And Installation Of Equalizer Bar

Disassembly And Assembly Of Equalizer Bar Bushing

Removal And Installation Of Segment Tooth

Removal And Installation Of Hydraulic Tank Assembly

Removal And Installation Of Work Equipment And PPC Pump Assembly

Removal And Installation Of Blade Lift Valve Assembly

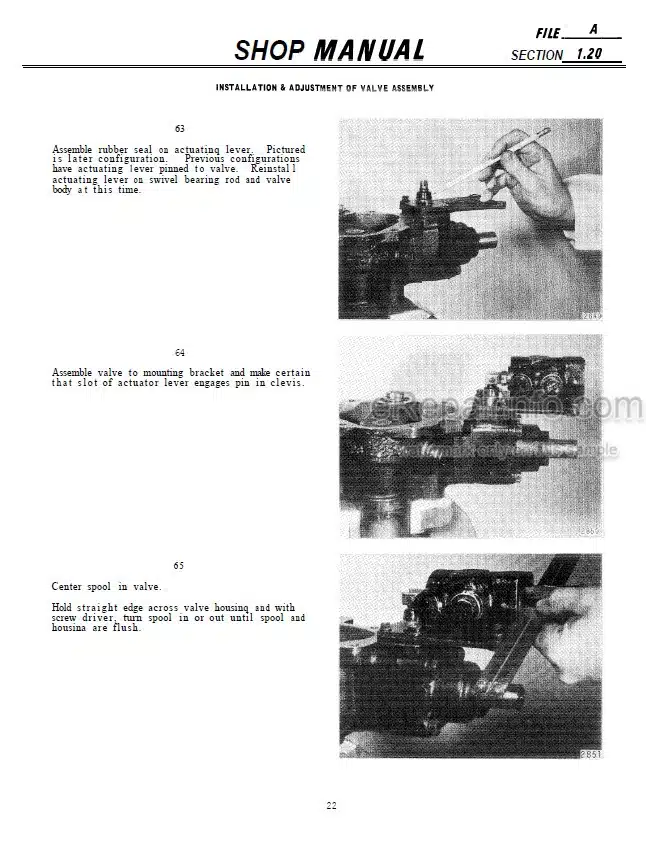

Disassembly And Assembly Of Blade Lift Valve Assembly

Disassembly And Assembly Of Blade Tilt And Ripper Low Valve Assembly

Disassembly And Assembly Of Ripper High Valve Assembly

Disassembly And Assembly Of PPC Charge Valve Assembly

Disassembly And Assembly Of Blade PPC Valve Assembly

Disassembly And Assembly Of Ripper PPC Valve Assembly

Disassembly And Assembly Of Hydraulic Cylinder Assembly

Disassembly And Assembly Of Ripper Pin Puller Cylinder Assembly

Removal And Installation Of Blade Assembly

Disassembly And Assembly Of Blade Assembly

Disassembly And Assembly Of Giant Ripper Assembly

Removal And Installation Of ROPS Guard

Removal And Installation Of Operator’s Cab Assembly

Removal And Installation Of Floor Frame

Removal And Installation Dashboard Assembly

Removal And Installation Of Monitor Panel Assembly

Removal And Installation Of Air Conditioner Unit Assembly

-OTHERS

Power Train Hydraulic Circuit Diagram

Work Equipment Hydraulic Circuit Diagram

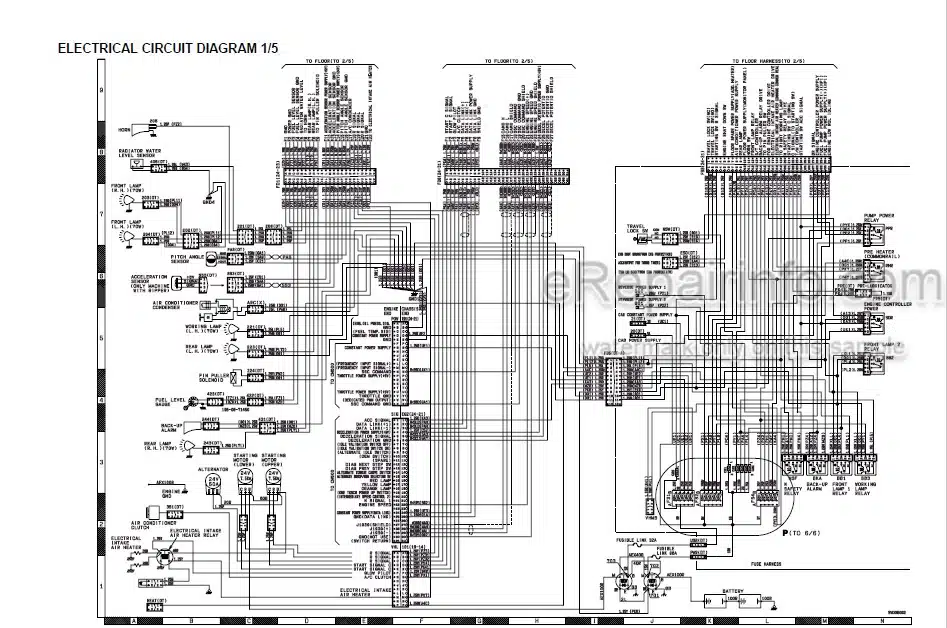

Diagram For Electrical Circuit

Diagram For Electrical Circuit Of Air Conditioner

Electric Circuit Diagram Of Inside Cab

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet