Factory Shop Manual For Komatsu Hydraulic Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 676

Number: CEBM012100 (march 2004)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

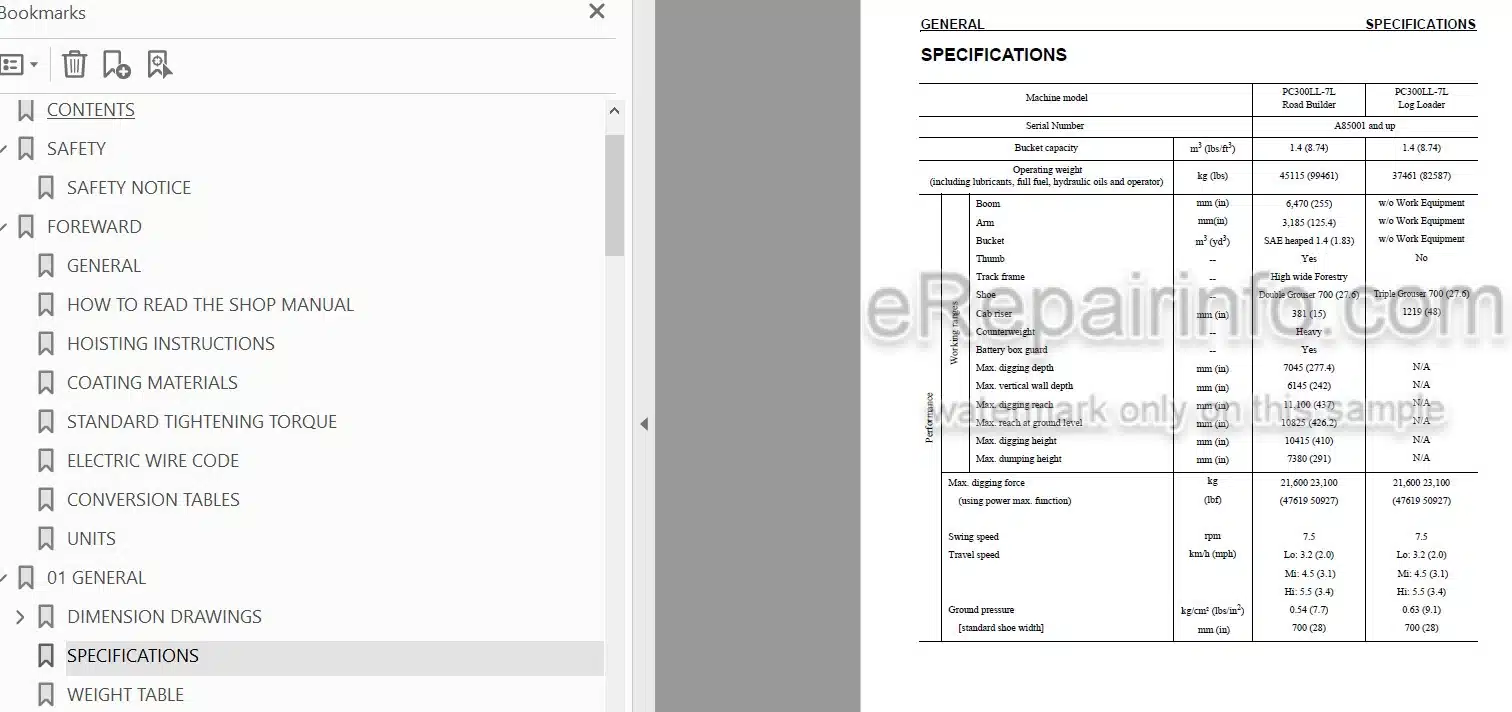

Model

Komatsu Hydraulic Excavator

Galeo PC300LL-7L

SN A85001 And Up

Contents

-SAFETY

Safety Notice

-FOREWORD

General

How To Read The Shop Manual

Hoisting Instructions

Coating Materials

Standard Tightening Torque

Electric Wire Code

Conversion Tables

Units

-GENERAL

Dimension Drawings

Specifications

Weight Table

Powered Cab Riser Tilt Unit Targets

Fuel Coolant And Lubricants

-STRUCTURE AND FUNCTION

Engine Related Parts

Radiator, Oil Cooler, Aftercooler

Final Drive System

Swing Machinery

Swing Circle

Track Frame . Recoil Spring

Idler

Track Roller

Track Shoe

Triple Grouser Shoe

Hydraulic Equipment

Hydraulic Tank

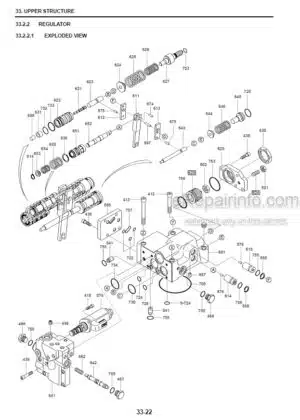

Hydraulic Pump

Variable Volume Valve

Control Valve

CLSS

Self Pressure Reducing Valve

Swing Motor

Center Swivel Joint

Travel Junction Valve

Travel PPC Shuttle Valve

Valve Control

Work Equipment. Swing PPC Valve

Travel PPC Valve

Attachment Solenoid Valve

PPC Accumulator

Boom Hydraulic Drift Prevention Valve

Quick Return Valve

Lift Check Valve

Hydraulic Cylinder

Work Equipment

Air Conditioner

Engine Control

Electronic Control System

Multi Monitor System

Sensors

Cab Riser And Related Parts

Cab Riser Hydraulic System

-TESTING, ADJUSTING AND TROUBLESHOOTING

Standard Value Tables

Service Tools

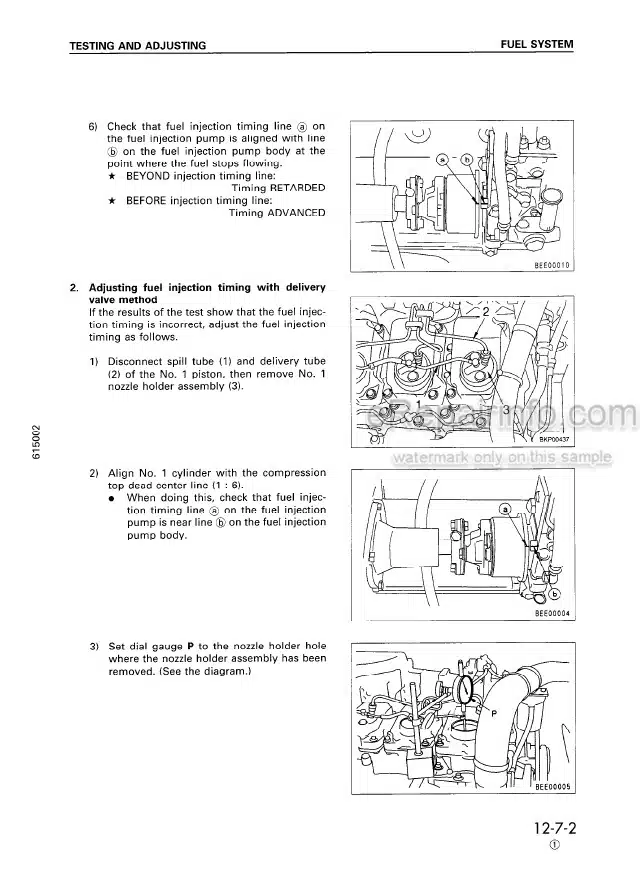

Engine

Emergency Escape From Engine Control Failure

Swing Circle Bearings

Track Shoe Tension

Sprocket

Oil Pressure

Work Equipment And Swing PPC Valve

Work Equipment, Hydraulic Drift Locations

Oil Leakage Amount

Air Bleeding Of Various Parts

Diode Inspection Procedures

Multi-Monitor Panel

Electrical System Troubleshooting Preparations

PM Tune Service

Troubleshooting (General)

-DISASSEMBLY AND ASSEMBLY

Precautions During Operation

Special Tool List

Sketches Of Special Tools

Connector Repair Procedures

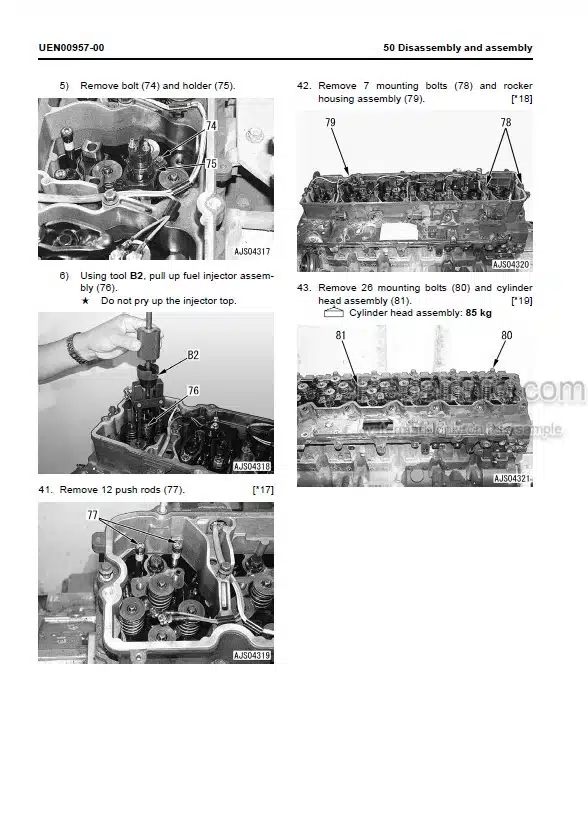

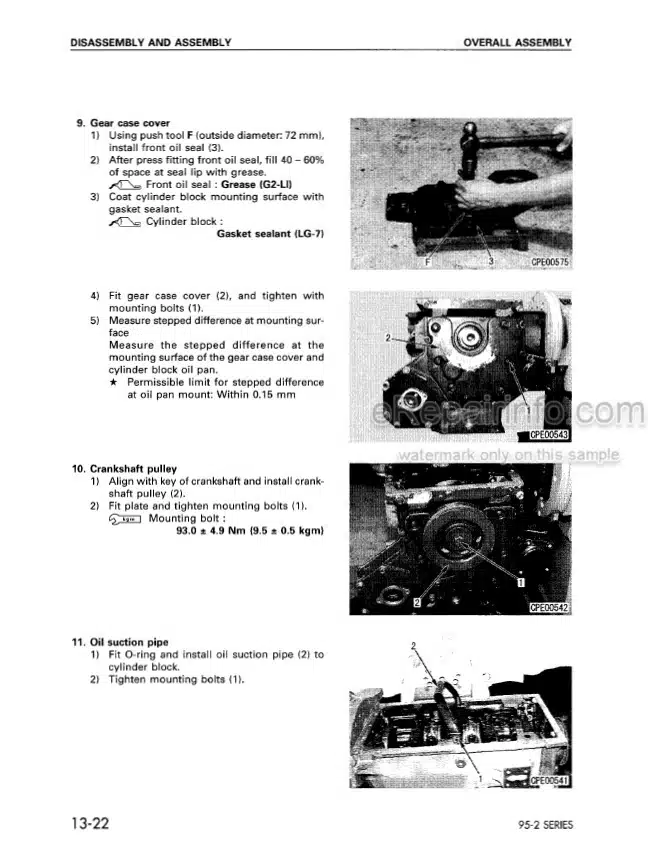

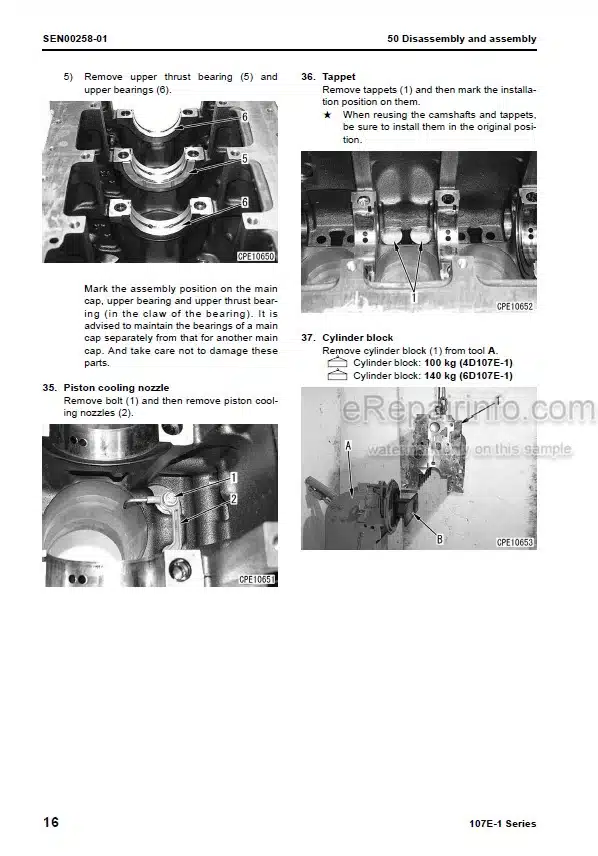

Engine

Radiator

Hydraulic Oil Cooler

Engine And Hydraulic Pumps

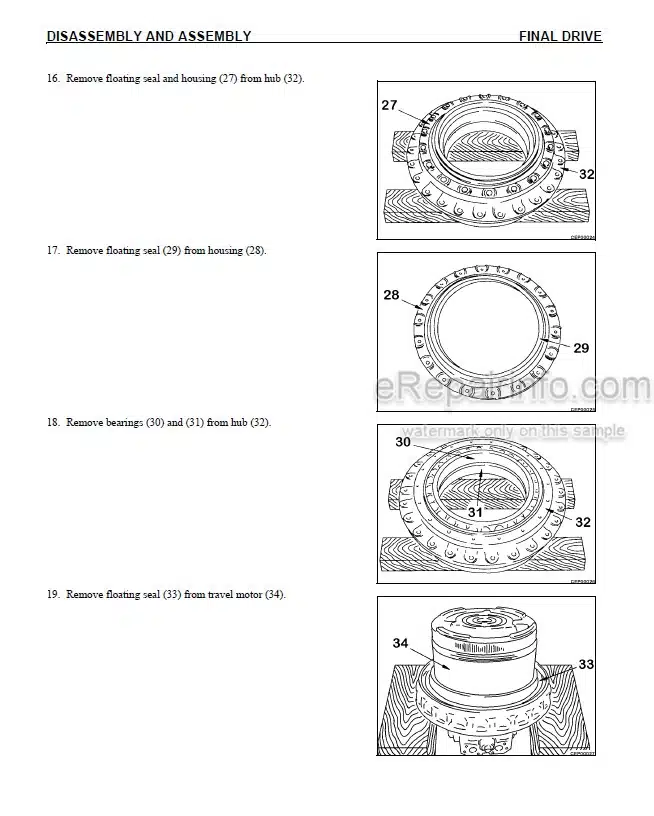

Final Drive

Travel Motor

Swing Motor

Swing Machinery

Idler And Recoil Spring

Track Roller

Sprocket

Track Shoe

Swing Circle

Revolving Frame

Center Swivel Joint

Hydraulic Tank

Control Valve

Replacing Pressure Compensation Valve Seal

Hydraulic Pump

Work Equipment PPC Valve

Travel PPC Valve

Hydraulic Cylinder

Work Equipment

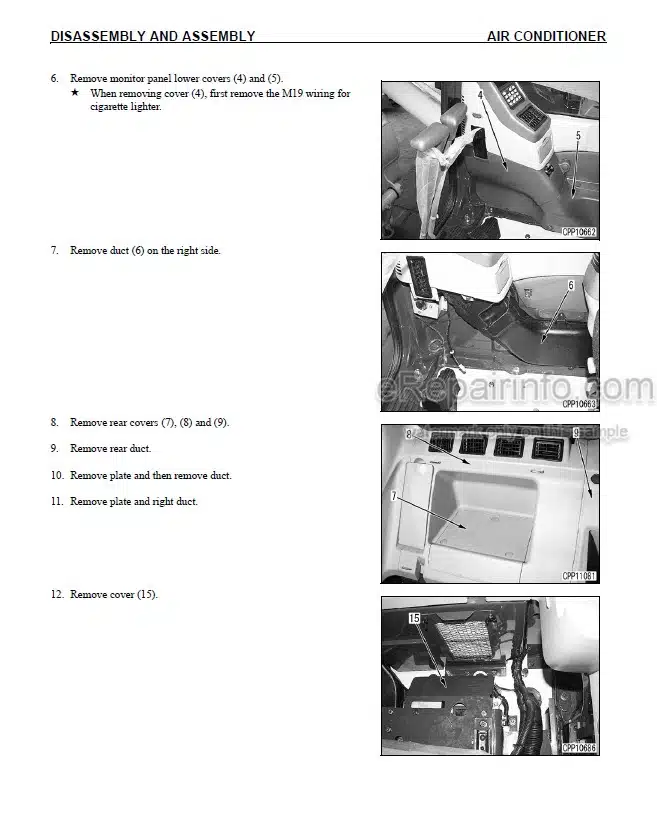

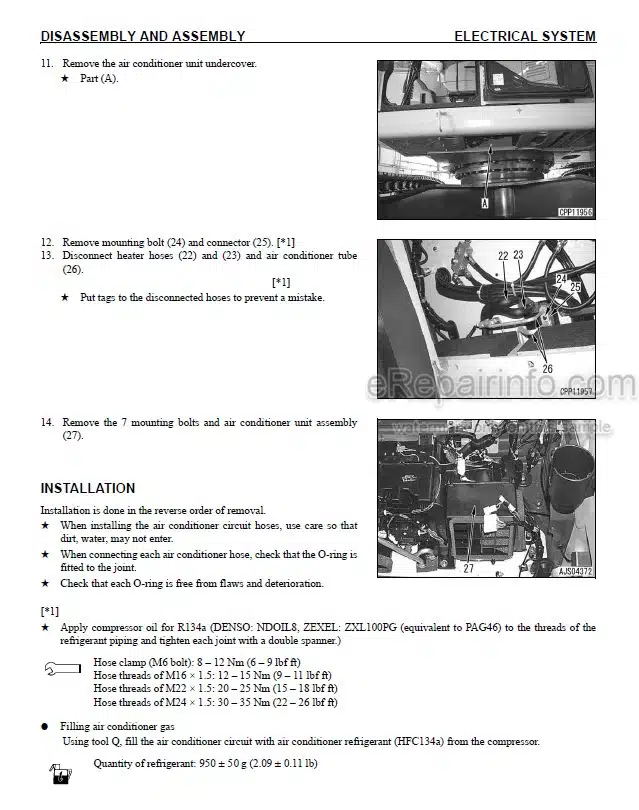

Air Conditioner

Counterweight

Operator’s Cab

Monitor

Governor Pump Controller

-OTHERS

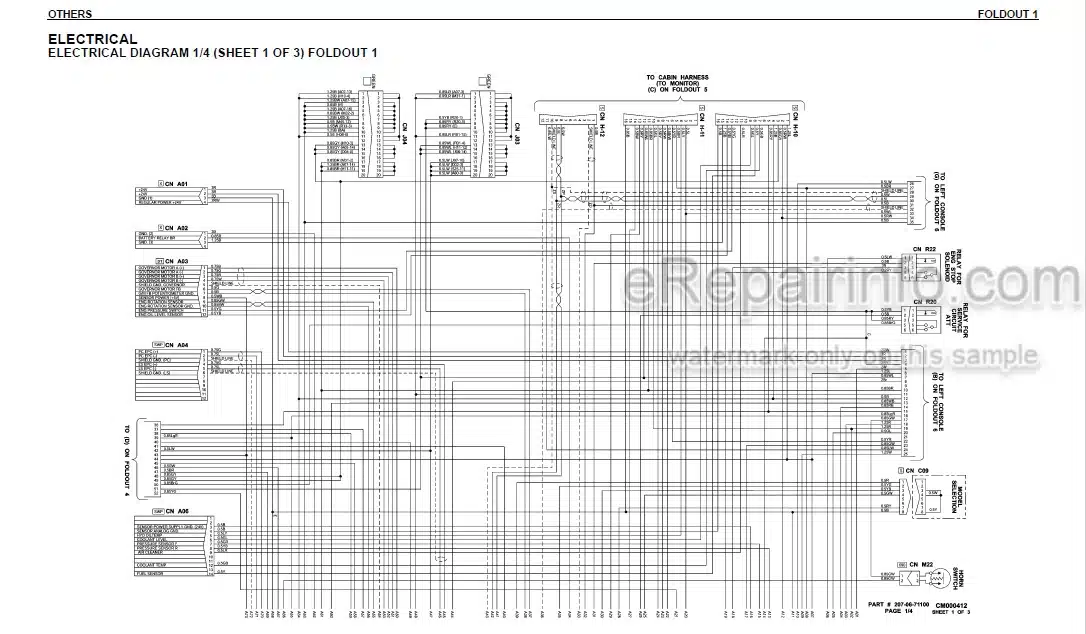

Electrical

Hydraulic

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet