Factory Shop Manual For Komatsu Motor Grader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 926

Number: SEBM002308 (february 2011)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Motor Grader

GD825A-2

SN 11001 And Up

Contents

FOREWORD

-GENERAL

Specification Dimension Drawings

Specifications

Weight Table

Fuel, Coolant And Lubricants

-STRUCTURE AND FUNCTION

General

Powertrain Diagram

Joint

Hydroshift Transmission And Transfer Piping

Hydraulic Circuit For Power Train

Hydraulic Circuit Diagram For Powertrain

PTO (Power Take Off)

Hydroshift Transmission And Transfer

Transmission Control Valve

Transmission Control

Inching Control

Drive Shaft

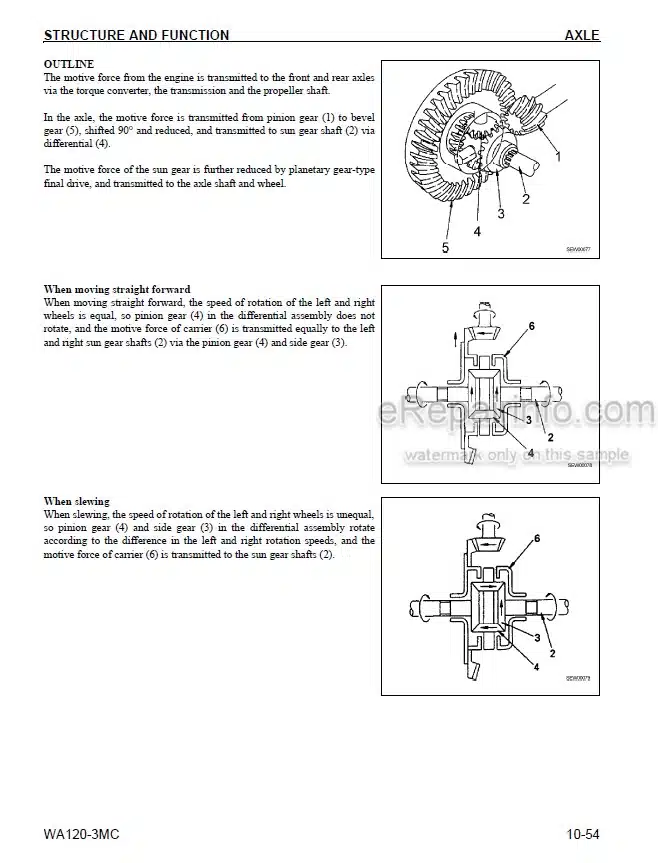

Final Drive, Differential Lock And Unlock Piping

Final Drive

Tandem Drive

Steering Piping

Steering Circuit System

Steering Circuit Diagram

Steering Valve

Double Relief Valve

Check Valve

Emergency Steering System

Front Axle

Wheel

Disc Brake

Parking Brake

Brake Air Piping

Brake Air Circuit System

Brake Air Circuit Diagram

Air Drier

Air Governor

Air Tank

Safety Valve

Automatic Drain Valve

Check Valve

Brake Valve

Parking Brake System

Parking Brake Solenoid Valve

Exhaust Valve

Spring Cylinder

Hydraulic Control Piping

Hydraulic Circuit System

Hydraulic Circuit Diagram

Closed Center Load Sensing System (CLSS)

Hydraulic Pump

Priority Flow Divider Valve

Surge Pressure Absorbing Valve

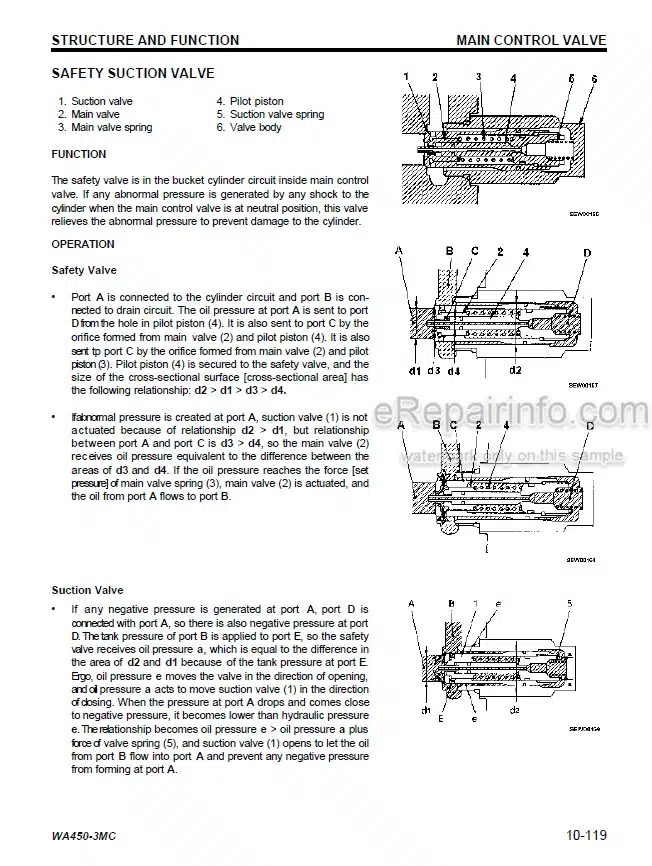

Hydraulic Control Valve

Pressure Compensating Mechanism Of Hydraulic Control Valve

Blade Lift Speed Adjustment Mechanism

Pilot Check Valve

Pilot Check Valve (With Safety Valve)

Circle Rotation Motor

Blade Accumulator System

Blade Float System

Drawbar And Lifter

Blade

Lifter Bracket Control Piping

Circle Rotation Gear

Rear Mount Ripper

Hydraulic Control Linkage

Main Frame

Air Conditioner

Electrical Wiring Diagram

Monitor Panel, Cluster Gauge And Pilot Lamp

Electrical Circuit Diagram

Electronic Vehicle Monitoring System (EVMS)

Transmission Control System

Sensors

Engine Starting Circuit

Engine Stopping Circuit

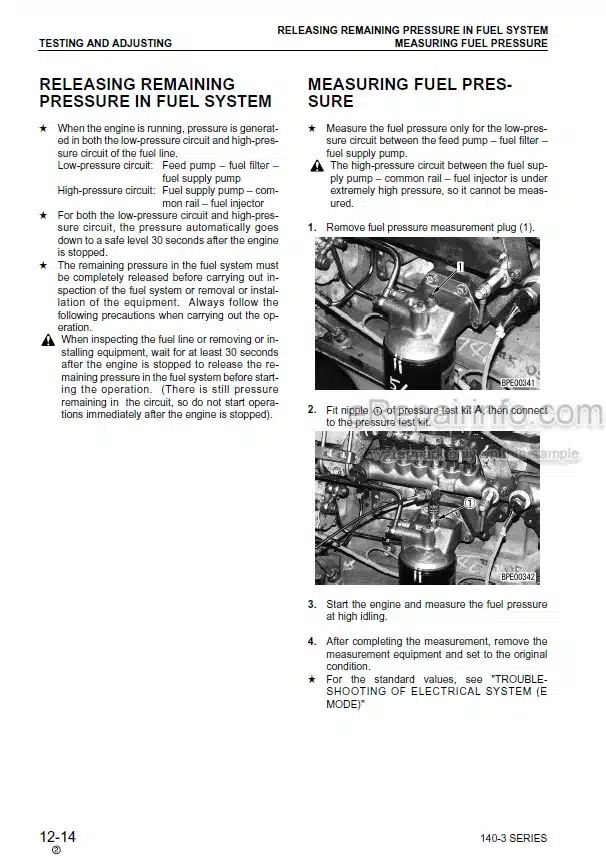

-TESTING AND ADJUSTING

Standard Value Table For Engine

Standard Value Table For Chassis

Tool List For Testing And Adjusting

Testing And Adjusting Valve Clearance

Measuring Compression Pressure

Testing And Adjusting Fuel Injection Timing

Measuring Blow-By Pressure

Measuring Engine Oil Pressure

Measuring Exhaust Gas Color

Measuring Exhaust Gas Temperature

Measuring Intake Air Pressure (Boost Pressure)

Testing And Adjusting Belt Tension

Procedure For Adjusting The Engine Stop Motor Cable

Adjusting Accelerator Control

Inching Pedal Travel And Operating Force

Measuring Transmission Oil Pressure

Checking Differential Locking Device Oil Pressure

Steering System

Checking Tire Runout

Checking Air Pressure Of Tire

Checking Toe-In

Installation Of Articulate Center Pins

Checking Wear Of Brake Disc

Checking Parking Brake

Checking Work Equipment Control Lever Travel And Operating Force

Checking Hydraulic Oil Temperature

Checking Work Equipment Hydraulic Pressure

Adjusting Work Equipment Hydraulic Pressure

Measuring Hydraulic Drift

Charging Blade Accumulator With Gas

Adjusting Blade Lift Speed

Bleeding Air From Hydraulic Pump

Adjusting Slip Load Of Circle Rotation Clutch

Adjusting Clearance Of F And R Switches

Adjusting Shift Potentiometer

Adjusting Inching Potentiometer

Adjusting Speedometer Module Of Machine Monitor

Troubleshooting

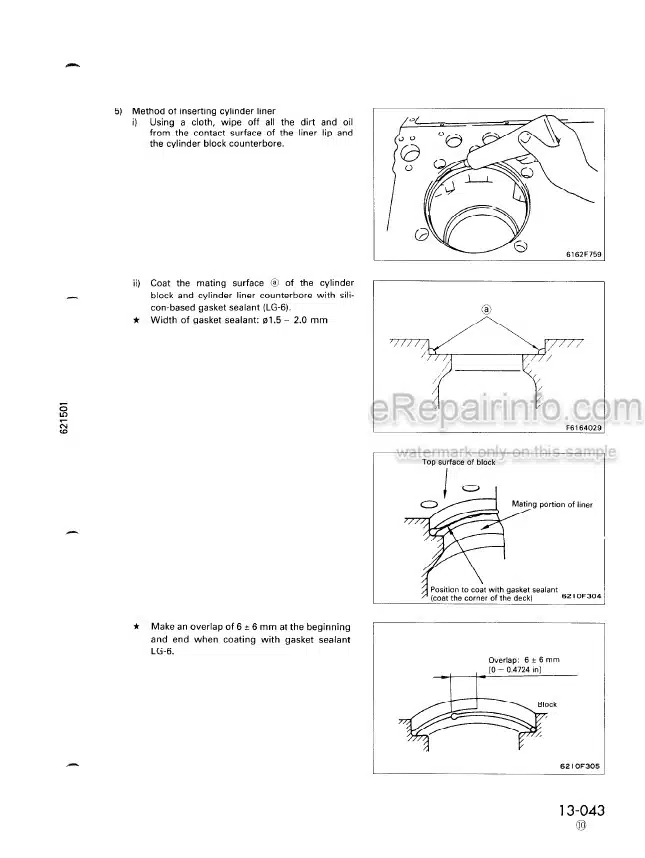

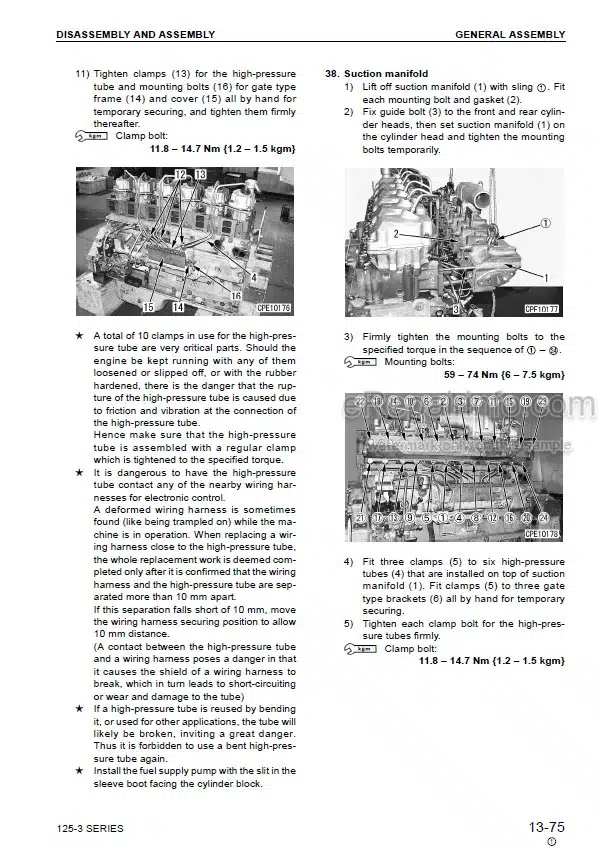

-DISASSEMBLY AND ASSEMBLY

Coating Materials List

Special Tool List

Starting Motor

Alternator

Nozzle Holder

Fuel Injection Pump

Water Pump

Engine Oil Cooler Core

Turbocharger

Air Compressor

Cylinder Head

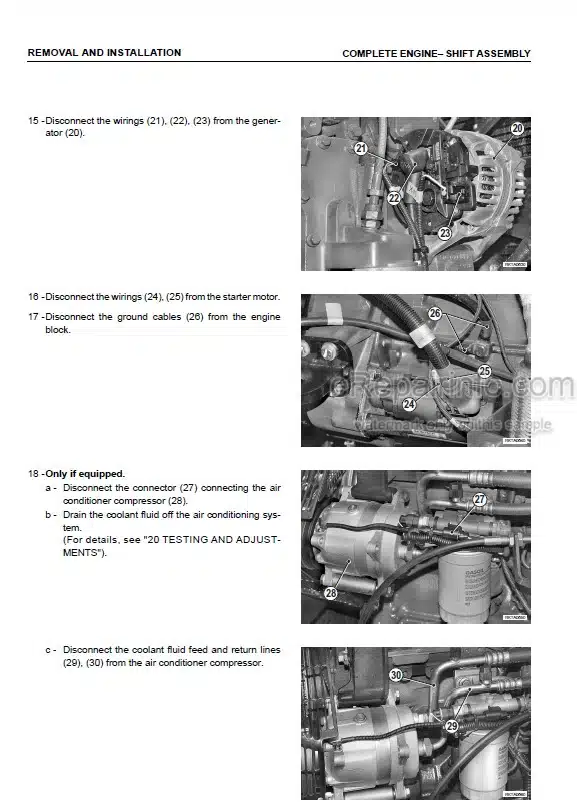

Engine (Incl. Transmission)

Radiator

Fuel Tank

PTO

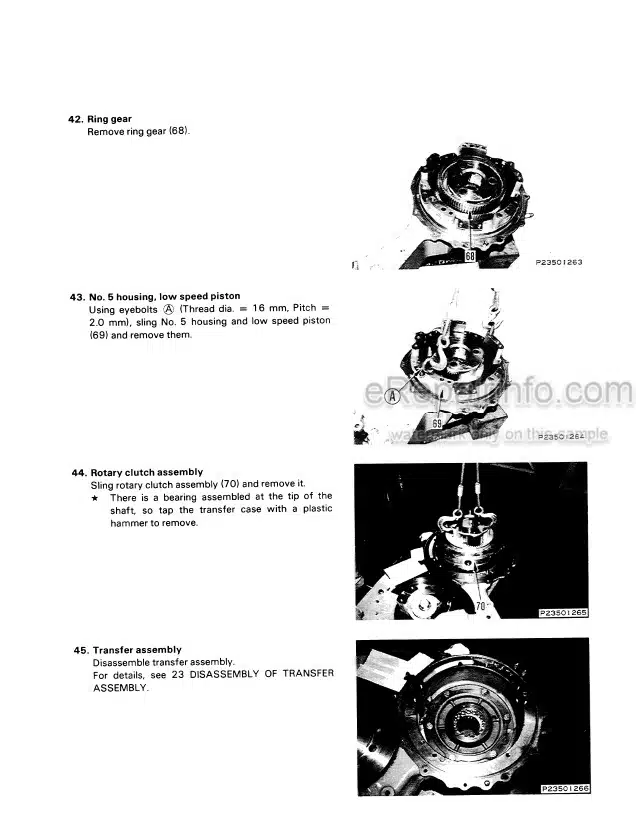

Transmission

Transfer

Transmission Control Valve

Hydroshift Transmission Pump

Tandem And Final Drive

Final Drive

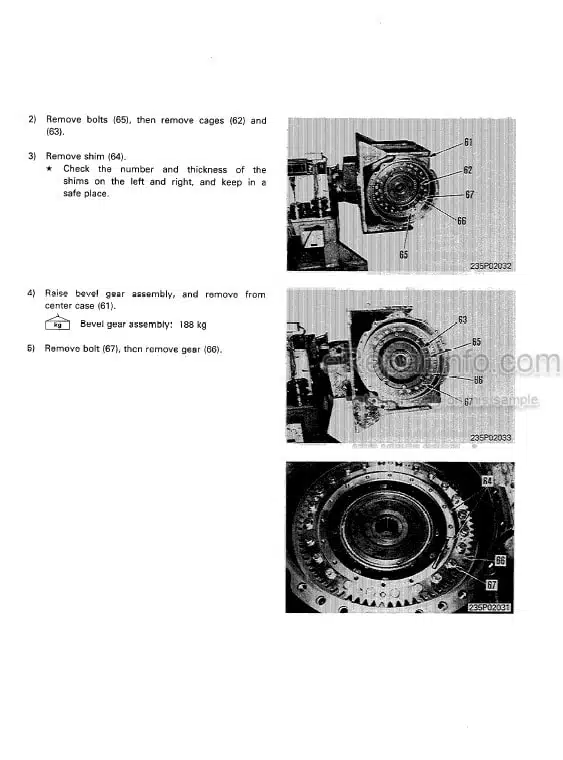

Bevel Gear

Bevel Pinion

Front Axle

Steering Valve

Wheel Brake

Air Tank

Hydraulic Tank

Hydraulic Pump

Hydraulic Control Valve

Main Control Valve

Circle Rotation Motor

Drawbar Shift Cylinder, Blade Lift Cylinder, Lifter Guide

Articulate Cylinder

Rear Mount Ripper Cylinder

Hydraulic Cylinder Serial No.: 11001 – 12502

Hydraulic Cylinder Serial No.: 12503 And Up

Circle Rotation Gear And Hydraulic Oil Motor

Blade

Circle And Drawbar

Rear Mount Ripper

Method Lifting Up ROPS Cab

Installation Of ROPS

ROPS Cab

Disconnection And Connection Of Articulate Section Serial No.: 11001 – 12502

Disconnection And Connection Of Articulate Section Serial No.: 12503 And Up

-MAINTENANCE STANDARD

Hydroshift Transmission And Transfer

Transmission Pump

Transmission Control Valve

Transmission Solenoid Valve

Final Drive

Differential Lock-Up Pump

Tandem Drive

Front Axle

Steering Cylinder

Disc Brake

Parking Brake

Spring Cylinder

Hydraulic Control Valve

Hydraulic Cylinder

Hydraulic Pump

Drawbar And Lifter

Blade

Circle Rotation Gear

Ripper

Frame

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet