Factory Shop Manual For Komatsu Articulated Dump Truck. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1236

Number: CEBM015200 (august 2008)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

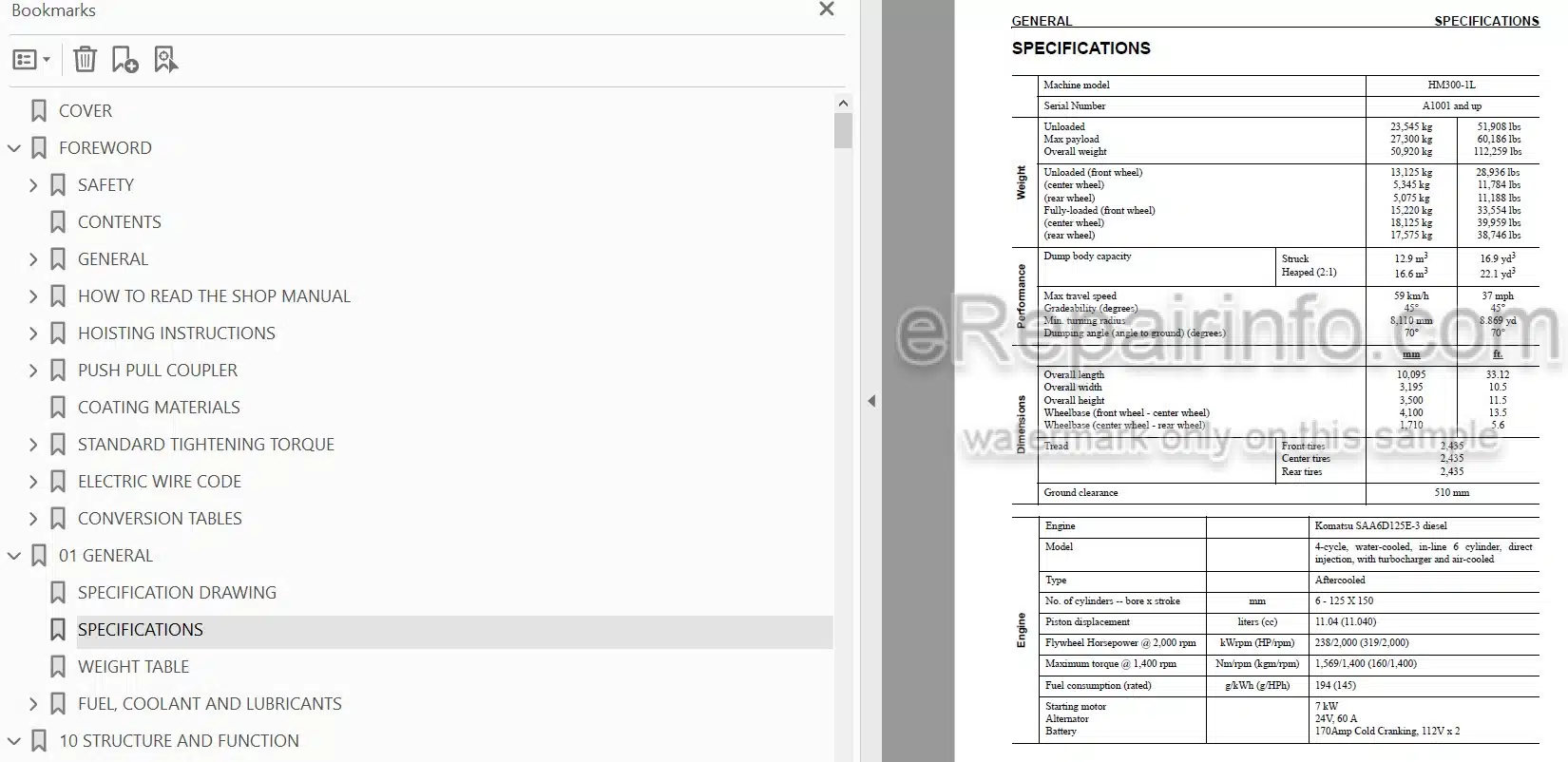

Model

Komatsu Articulated Dump Truck

HM300-1L

SN A10001 And Up

Contents

-FOREWORD

Safety

General

How To Read The Shop Manual

Hoisting Instructions

Push Pull Coupler

Coating Materials

Standard Tightening Torque

Electric Wire Code

Conversion Tables

-GENERAL

Specification Drawing

Specifications

Weight Table

Fuel, Coolant And Lubricants

-STRUCTURE AND FUNCTION

Cooling Systems

Powertrain

Output Shaft

Torque Converter And Transmission Hydraulic Piping

Torque Converter

Transmission Power Flow

Transmission

Clutch And Transmission Operations

Transmission Valve

ECMV (Electronic Control Modulation Valve)

Main And Torque Converter Relief Valve

Drive Shaft

Drive Axle

Locking Differential

Limited Slip Differential

Final Drive System

Steering Column

Wheel Braking System

Parking Brake

Suspension System

Oscillation Hitch Joint

Steering, Hoist Oil Piping Diagram

Dump Body Control

Hydraulic Tank And Filter

Flow Amplifier Valve

Steering Valve

Steering Cylinder

Hoist Valve

EPC Valve

Pilot Check Valve

Hoist Cylinder

Hydraulic Pump

Cab Tilt System View

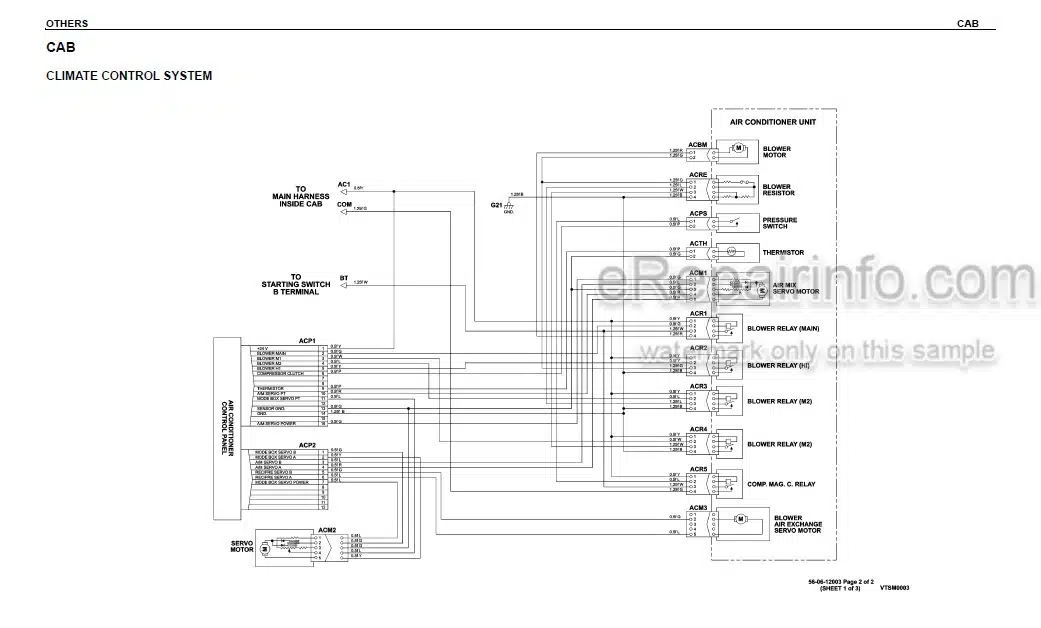

Air Conditioning System View

Machine Monitor System

Automatic Shift Control System

Transmission Controller

Emergency Steering System

Sensors And Switches

Retarder Control System

Brake Control System (E-Spec)

Dump Control Lever

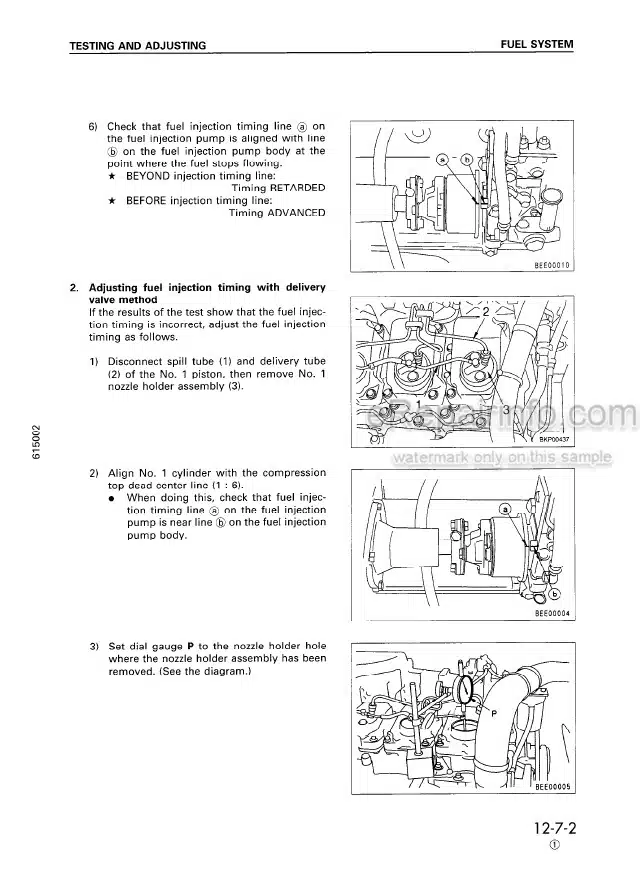

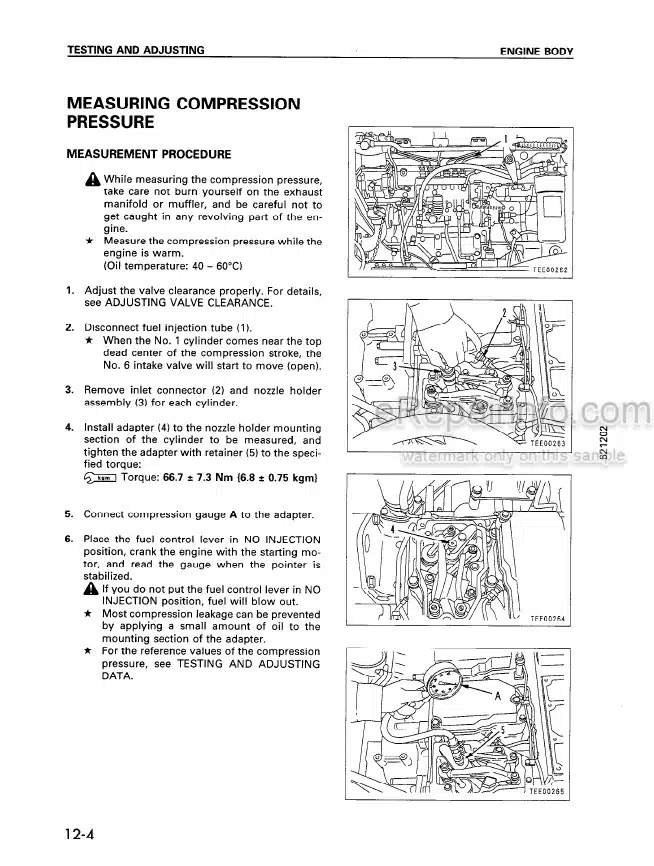

-TESTING, ADJUSTING AND TROUBLESHOOTING

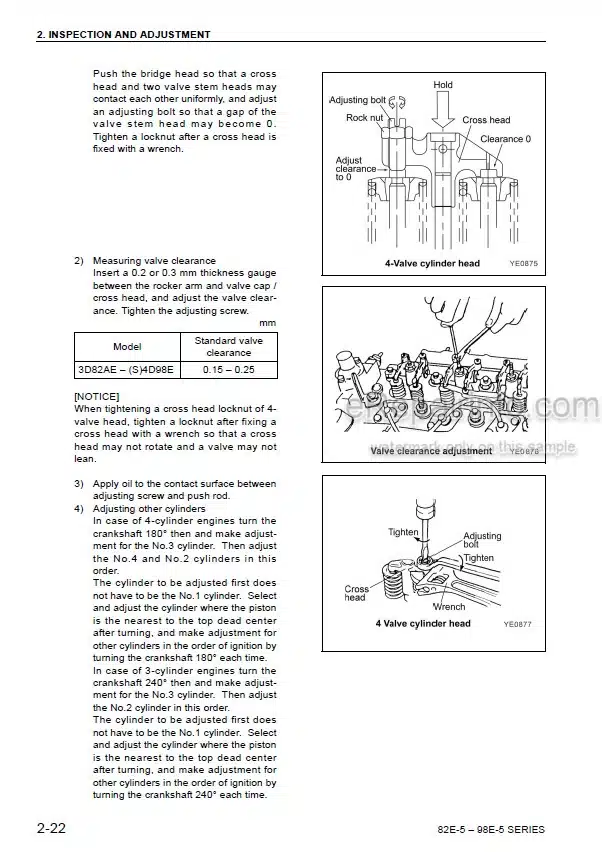

Standard Value Table For Engine

Standard Value Table For Chassis

Standard Value Table For Electrical Components

Tools For Testing And Adjusting

Engine Components

Adjusting Engine Speed Sensor

Testing Torque Converter Stall Speed

Power Train Oil Pressures

Adjusting Transmission Speed Sensor

Brake Oil Pressure

Testing Brake Performance

Bleeding Air From Brake Circuit

Checking Wear Limit On Wheel Brake Disc And Pad

Releasing Emergency Parking Brake

Steering Circuit Pressure

Suspension Cylinder

Tilting The Cab

Dump Circuit Pressure

Body Positioner Sensor

Handling Engine Controller High-Voltage Circuit

Transmission Controller

Escape Method For Electrical System

Machine Monitor

Functions Of Machine Monitor

Points To Remember When Troubleshooting

Sequence Of Events In Troubleshooting

Precautions When Carrying Out Maintenance

Checks Before Troubleshooting

Connector Types And Mounting Locations

Connection Table For Connector Pin Numbers

T-Adapter Table

Connector Layout Drawing

Connector Arrangement And Locations

Engine Control System Circuit Diagram

Content Of Code Display

Information Contained In Testing Procedures

Failure Codes

Connector Arrangement And Locations

TM Mode Control System Circuit Diagram

Content Of Code Display

Information Contained In Testing Procedures

Connector Arrangement And Locations

BK Control System Circuit Diagram

Hydraulic Power Train Circuit Diagram

Steering And Hoist Hydraulic Circuit Diagram

Using Troubleshooting Charts

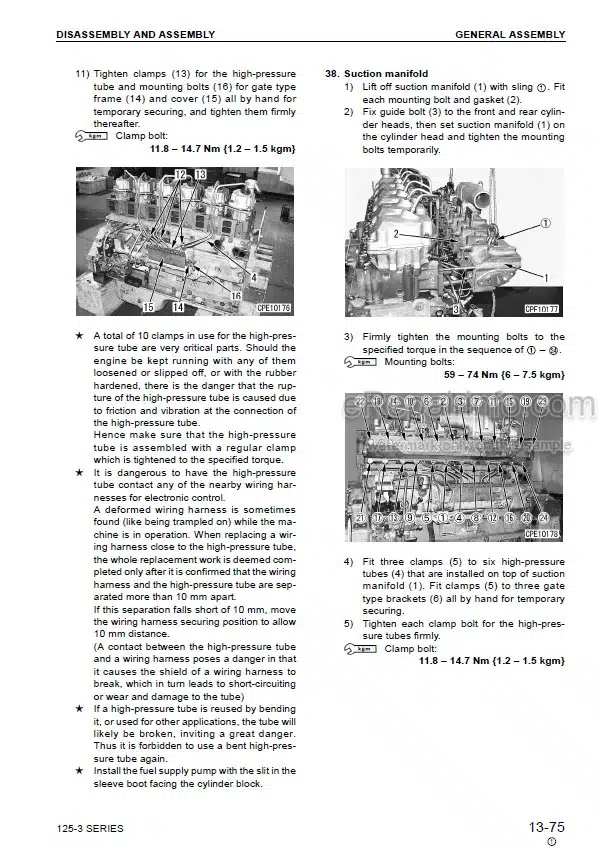

-DISASSEMBLY AND ASSEMBLY

Precautions When Carrying Out Repair Operation

Special Tool List

Sketches Of Special Tools

Connector Repair Procedures

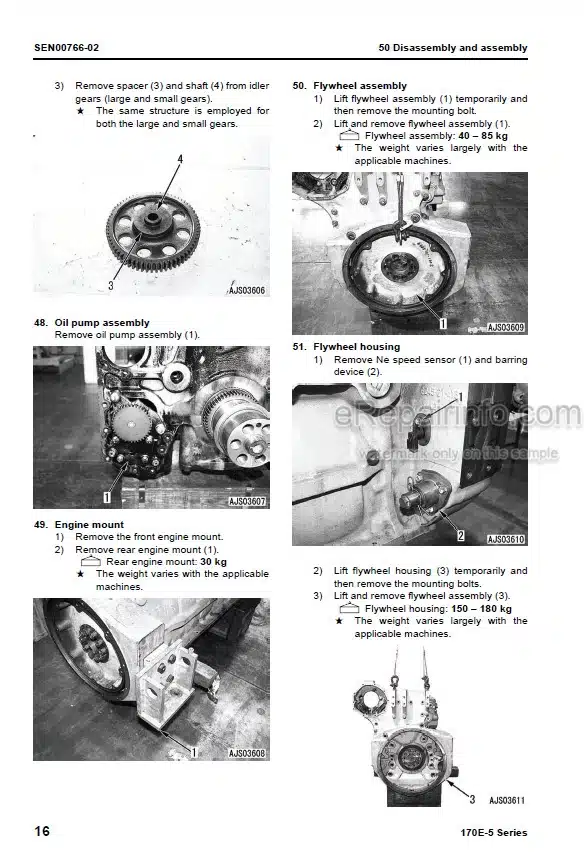

Engine

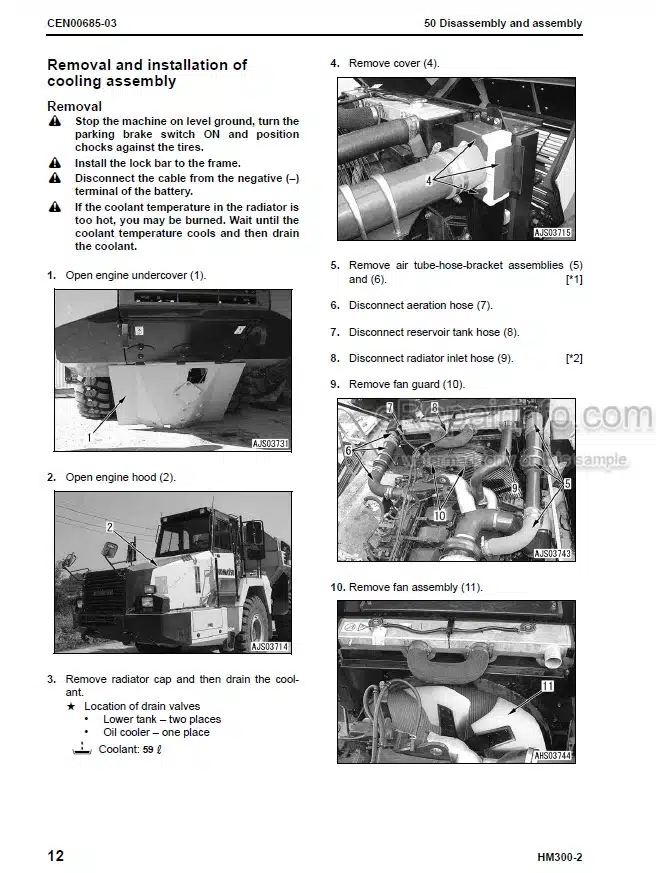

Radiator

Output Shaft System

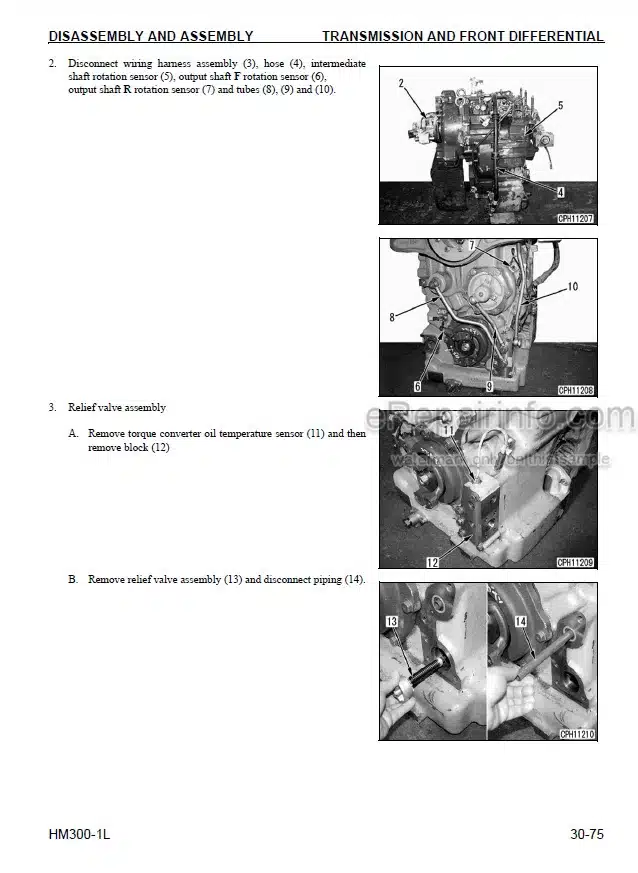

Transmission And Front Differential

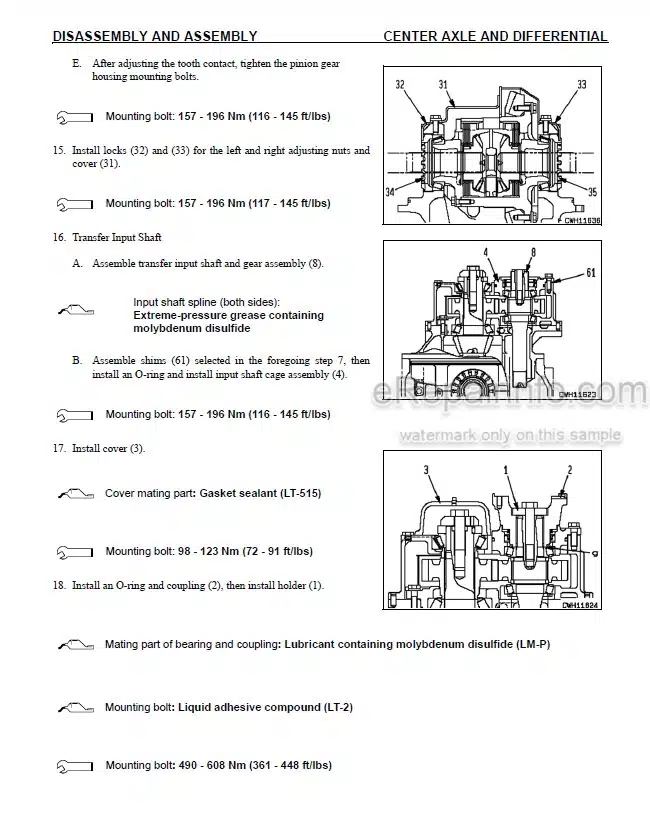

Center Axle And Differential

Rear Axle And Differential

Front Final Drive And Brake Assembly

Center Final Drive And Brake Assembly

Rear Final Drive And Brake Assembly

Suspension System

Hitch Frame System

Orbital Steering Unit

Flow Amp Valve

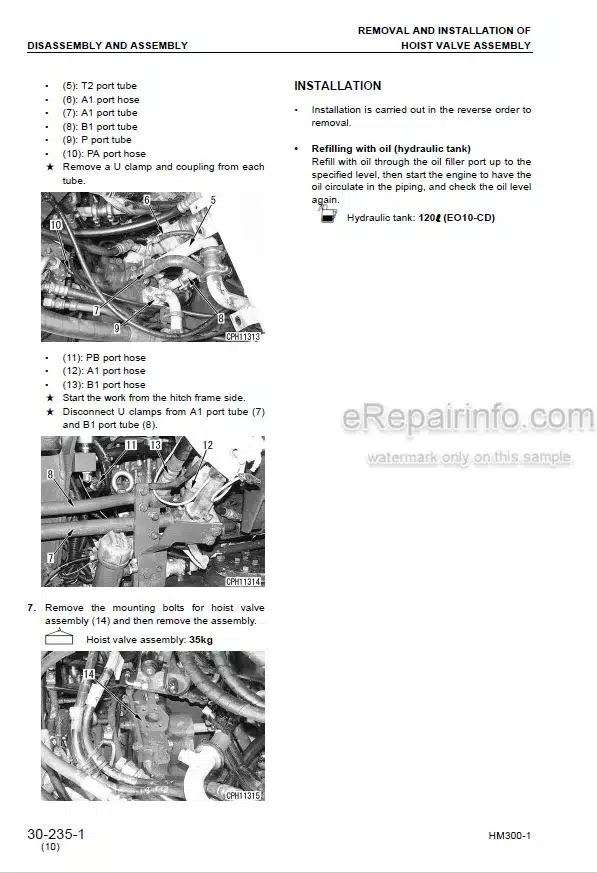

Hoist Valve

Hydraulic Cylinder

Truck Body Assembly

Operator’s Seat

-DIAGRAMS AND SCHEMATICS

Cab

Chassis

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet