Factory Shop Manual For Komatsu Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of manuals: 3

Pages: 404; 64; 652

Number: unknown; CEBM610AR0; CEBM610TR0

Bookmarks: Yes

Searchable: Yes

Model

Komatsu Engine

KDC410

KDC610

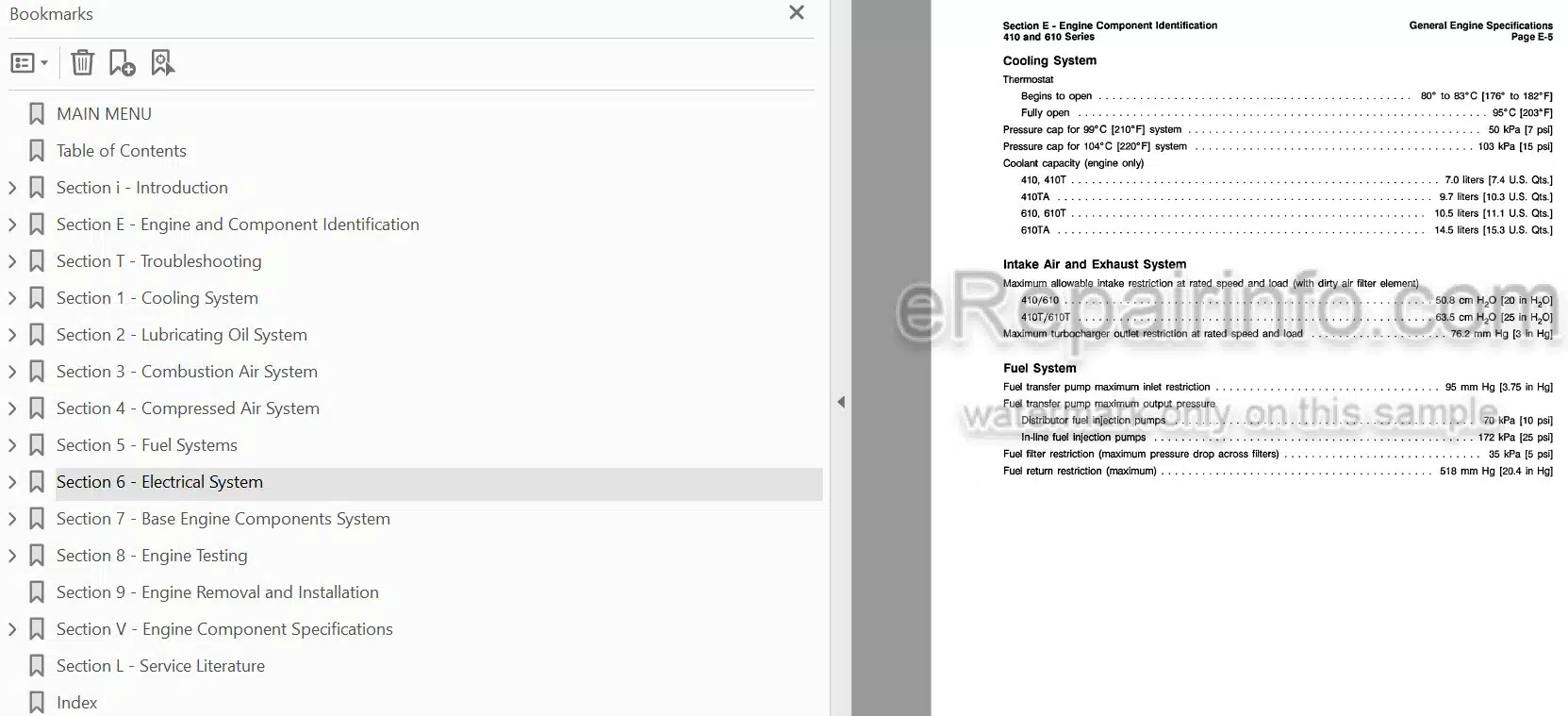

Contents

-INTRODUCTION

About the Manual

General Cleaning Instructions

General Repair Instructions

General Safety Instructions

Generic Symbols

Glossary of Terms

How to Use the Manual

Illustrations

-ENGINE AND COMPONENT IDENTIFICATION

Engine Diagram

Engine Identification

Injection Pump Dataplate

-TROUBLESHOOTING

Troubleshooting Symptoms Charts

-COOLING SYSTEM

Belt Tensioner – Replacement

Coolant

Coolant System Components and Flow

Coolant System Malfunctions

Cooling System Specifications

Cup Plugs – Replacement

Drive Belt – Replacement

Fan Hub – Replacement

Fan Pulley – Replacement

Thermostat – Replacement

Water Pump – Replacement

-LUBRICATING OIL SYSTEM

Cup Plugs – Replacement

Diagnosing Lubricating System Malfunctions

Flow Diagrams – Lubricating System

General Information – Lubrication System

High Oil Pressure

Low Oil Pressure

Lubrication for the Power Components

Lubrication for the Turbocharger

Oil Cooler Element and/or Gasket – Replacement

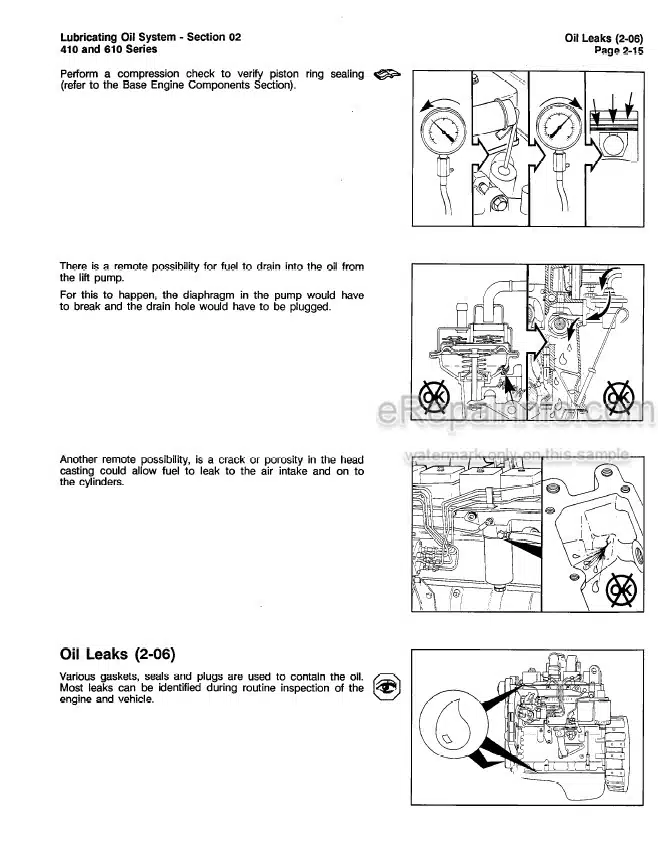

Oil Leaks

Oil Pan, Suction Tube and/or Gaskets – Replacement

Oil Pressure Regulating Valve

Oil Pressure Regulator Valve/ Spring – Replacement

Oil Pump – Replacement

Specifications – Lubricating Oil System

-COMBUSTION AIR SYSTEM

Aftercooler and Gasket

Air Crossover Tube

Air System Flow – Diagrams

Combustion Air System Flow – General Information

Combustion Air System – Service Tools

Diagnosing Air System Malfunctions

Exhaust Manifold and Gaskets

Intake Air and Exhaust System Specifications

Intake Manifold Cover and Gasket

Turbocharger

Turbocharger Boost Pressure Specifications

Turbocharger – Testing

-COMPRESSED AIR SYSTEM

Air Compressor – Removal

Air Governor and Compressor Unloader Valve – Check

Air Governor – Check

Carbon Buildup, Air Compressor – Check

Compressed Air System – General Information

Compressed Air System – Service Tools

Flow Diagrams – Compressed Air System

Gasket Leaks, Air Compressor, Check

Specifications – Compressor Air System

Unloader and Cylinder Head Disassembly

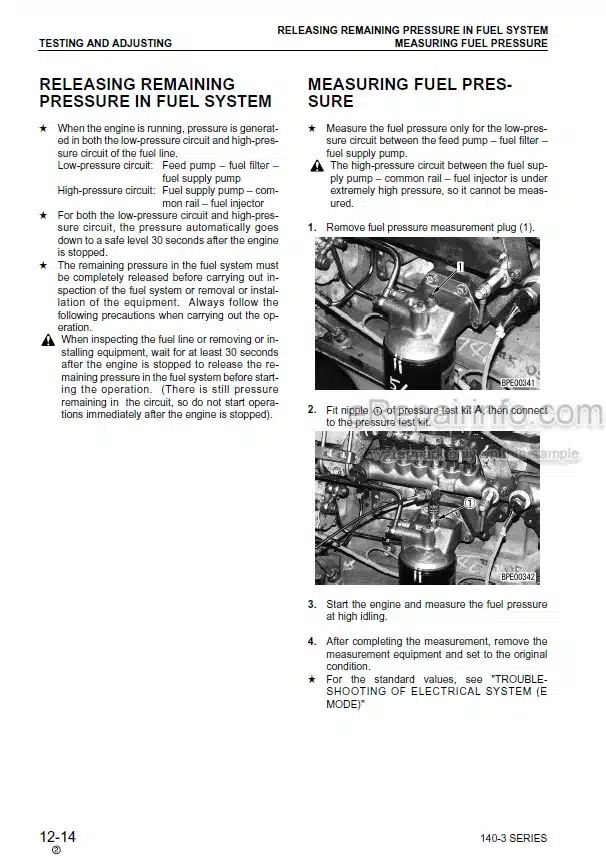

-FUEL SYSTEMS

Air Fuel Control Tube Replacement – Bosch VE Pump

Air In The Fuel System

Back Leakage Valve and Sealing Washer (Lucas CAV DPA) – Replacement Delivery Valve Holder and Sealing Washer (Bosch VE) – Replacement External Pump Leaks – Repair

Fuel Drain Manifold

Fuel Drain Manifold Replacement

Fuel Filter – Replacement

Fuel Shut Off Valve Replacement – Bosch VE

Fuel System Components and Flow

Fuel System Identification

Fuel System – Service Tools

Fuel System Specifications

Fuel Transfer (Lift) Pump Diagnosing Malfunctions

Fuel Transfer (Lift) Pump – Testing

Fuel Water Separator/Filter Unit

General Information – Fuel Systems

High Pressure Fuel Lines

High Pressure Line Replacement

Idle Speed Adjustment

Injection Pump Replacement (Bosch VE and Lucas CAV DPA)

Injection Pump Supply Line Replacement

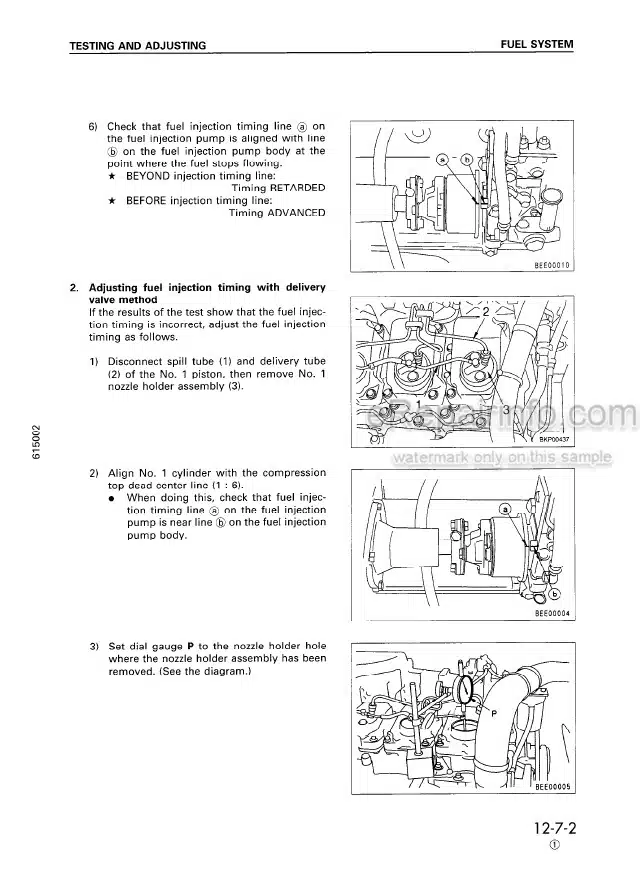

Injection Pump Timing

Injection Pump – Troubleshooting

Injector – Replacement

Injectors

Low Pressure Fuel Line Replacement

Pump Timing Check – (Lucas CAV DPA)

Timing Check – (Bosch VE Pump)

Transfer (Lift) Pump Replacement

Venting the Fuel Systems

-ELECTRICAL SYSTEM

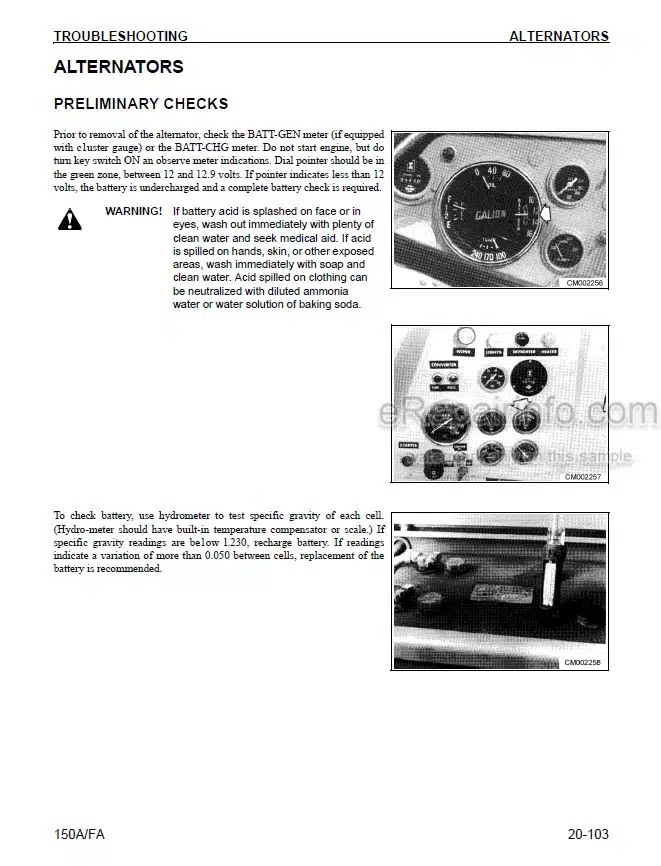

Alternator – Checking

Alternator – Replacement

Battery Checking

Battery Terminal Connections – Checking

Block Water Heater Replacement

Coolant or Pan Heater – Check

Electrical System – Service Tools

Engine Electrical System Replacement Procedures

Flow Diagrams – Electrical System

General Information – Electrical System

Oil Pan Heater Replacement

Oil Pressure Switch and Temperature Sensor – Checking

Oil Pressure Switch – Replacement

Starting Circuit – Checking

Starting Motor – Replacement

Temperature Sensor – Replacement

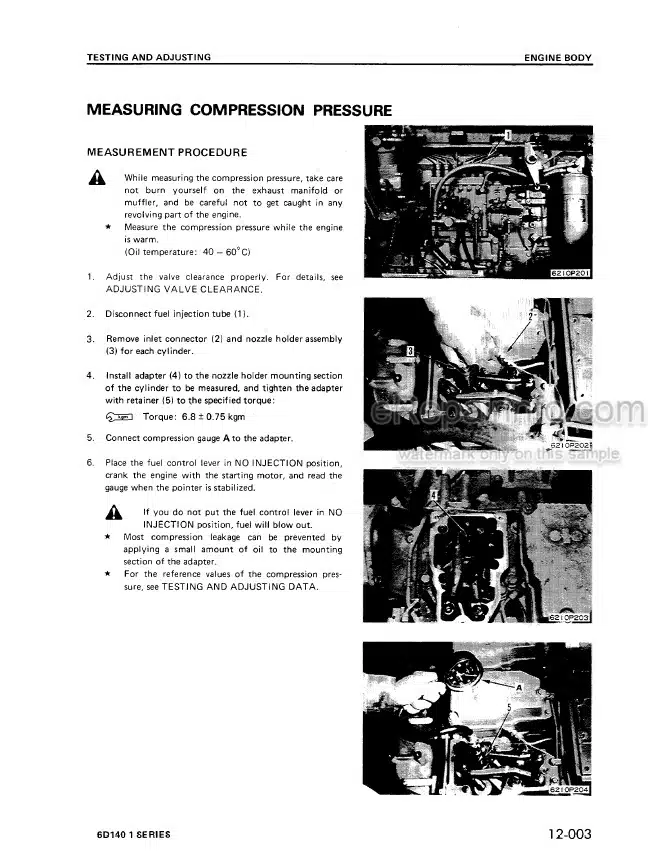

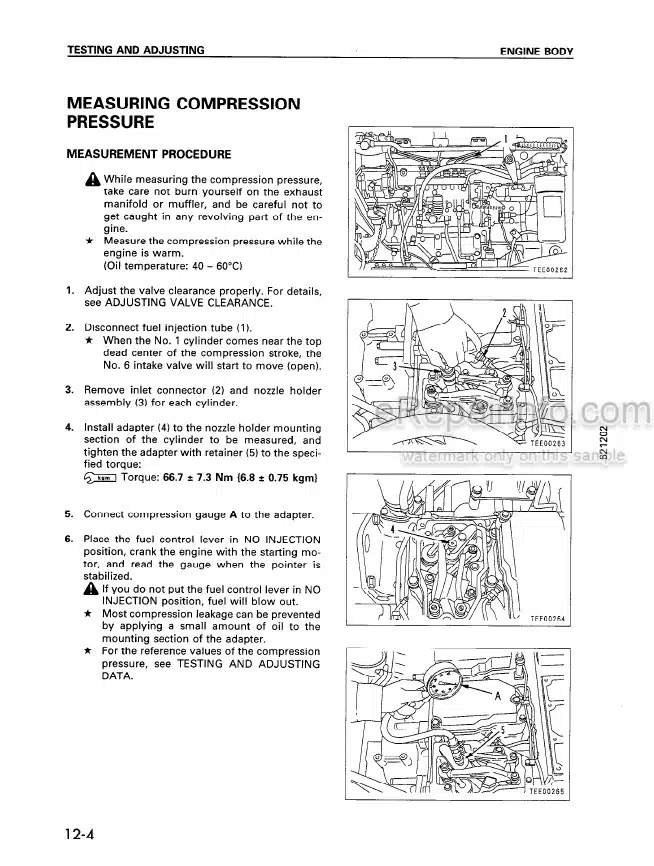

-BASE ENGINE COMPONENTS SYSTEM

Base Engine Components – General Information

Base Engine Components – Replacement Procedures

Base Engine Components Specifications

Camshaft and Tappet – Replacement

Camshaft Gear – Replacement

Connecting Rod Bearing – Replacement

Connecting Rods – Replacement

Crankshaft Gear – Replacement

Cup Plug Replacement

Cylinder Bore Deglaze

Cylinder Head – Replacement

Diagnosing Base Engine Component Malfunctions

Exhaust Manifold – Replacement

Flywheel Housing – Replacement

Flywheel/Ring Gear – Replacement

Front Seal – Replacement

Gear Cover – Replacement

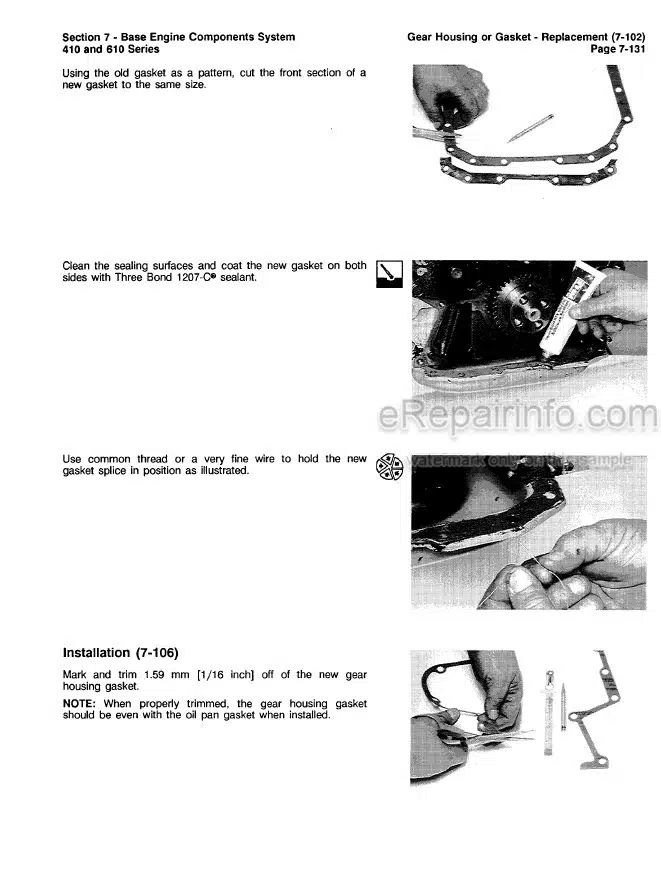

Gear Housing or Gasket – Replacement

Main Bearing – Replacement

Operation and Description Cylinder Head and Valve Train

Pipe Plug – Replacement

Piston and Rings – Replacement

Rear Seal – Replacement

Timing Pin Assembly – Replacement

Turbocharger – Replacement

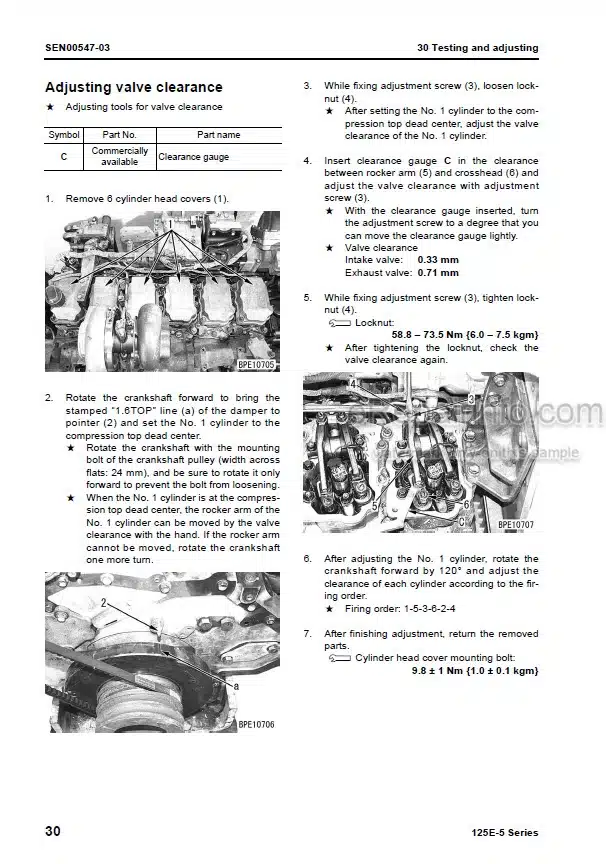

Valves – Adjustment

Vibration Damper/Crank Pulley – Replacement

-ENGINE TESTING

Blowby Conversion Chart (5.613 mm [0.221 in] Orifice)

Engine Run-In Procedure

Engine Testing – Engine Side Views

Engine Testing – General Information

Engine Testing – Service Tools

General Engine Test Procedures

-ENGINE REMOVAL AND INSTALLATION

-ENGINE COMPONENT SPECIFICATIONS

Capscrew Markings and Torque Values

Component Specifications and Torque Values

Drive Belt Tension

Newton-Meter to Foot-Pound Conversion Chart

Pipe Plug Torque Values

Tap-Drill – U.S. Customary & Metric

Weight and Measures – Conversion F actors

-SERVICE LITERATURE

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet