Factory Shop Manual For Komatsu Hydraulic Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 296

Number: WEBM000100 (issued 1999)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Hydraulic Excavator

PC12R-8

SN F30001 And Up

PC15R-8

SN F20001 And Up

Contents

SAFETY

FOREWORD

HOW TO READ THE SHOP MANUAL

HOISTING INSTRUCTIONS

STANDARD TIGHTENING TORQUE

COATING MATERIALS

ELECTRIC WIRE CODE

WEIGHT TABLE

TABLE OF OIL AND COOLANT QUANTITIES

-STRUCTURE AND FUNCTION

Powertrain

Swing Circle

Swing Motor

Final Drive

Track Frame And Recoil Spring

Carrier Roller

Steel Shoe

Hydraulic System

Hydraulic Circuit Diagram

Hydraulic Pump

Control Valve

CLSS

Swivel Joint

Travel Motor

Cylinders

Valve Control

Accumulator

PPC Valve

Solenoid Valve

Cutting Shovel Control Valve

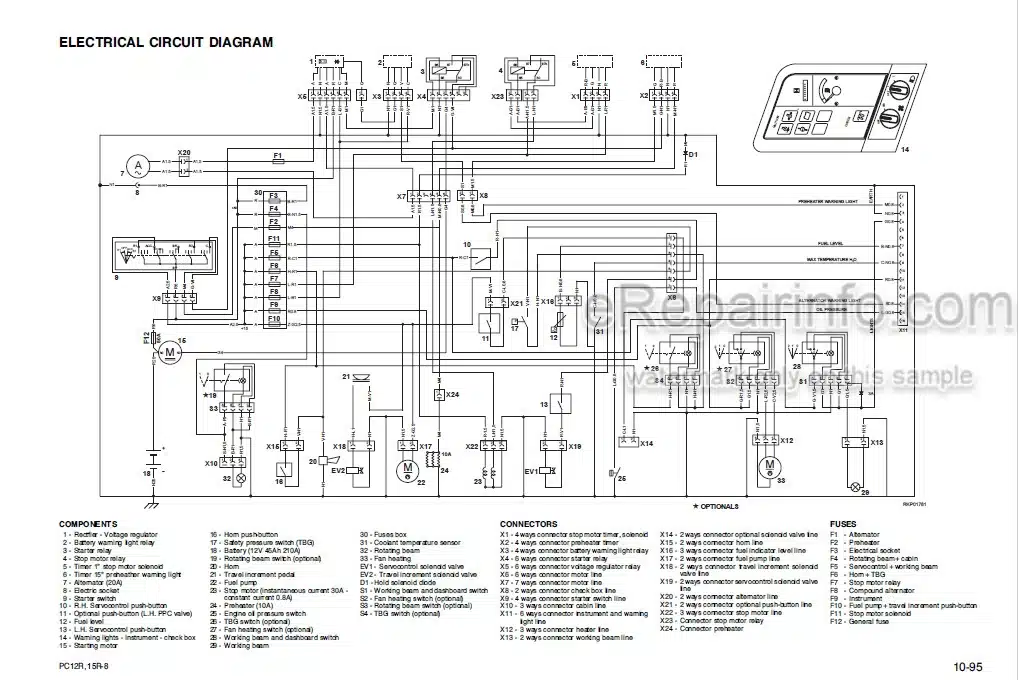

Electrical Circuit Diagram

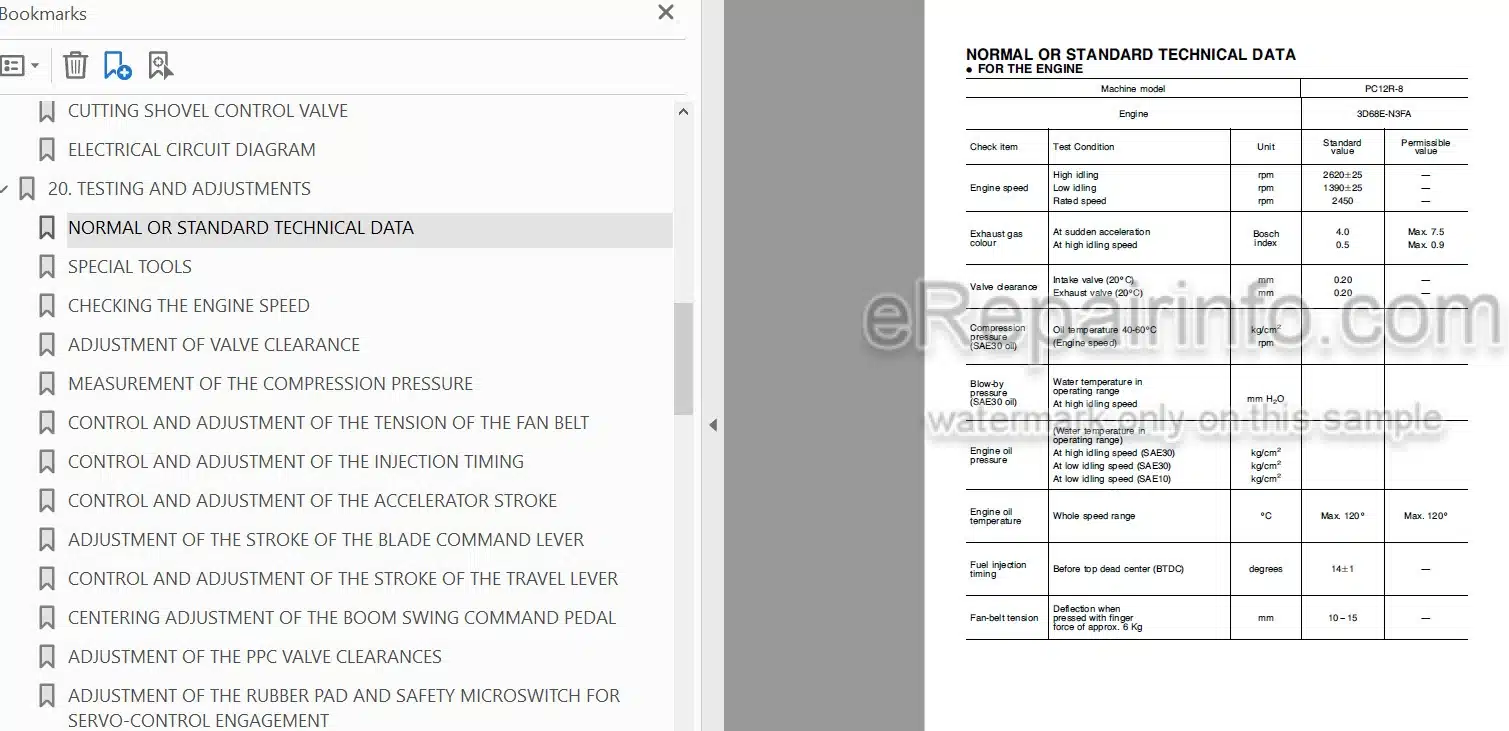

-TESTING AND ADJUSTMENTS

Normal Or Standard Technical Data

Special Tools

Checking The Engine Speed

Adjustment Of Valve Clearance

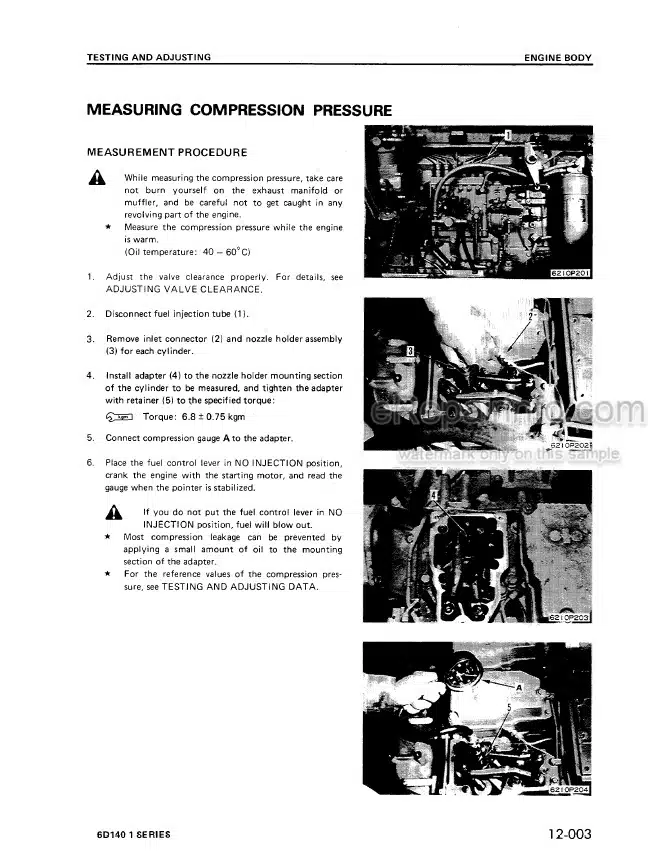

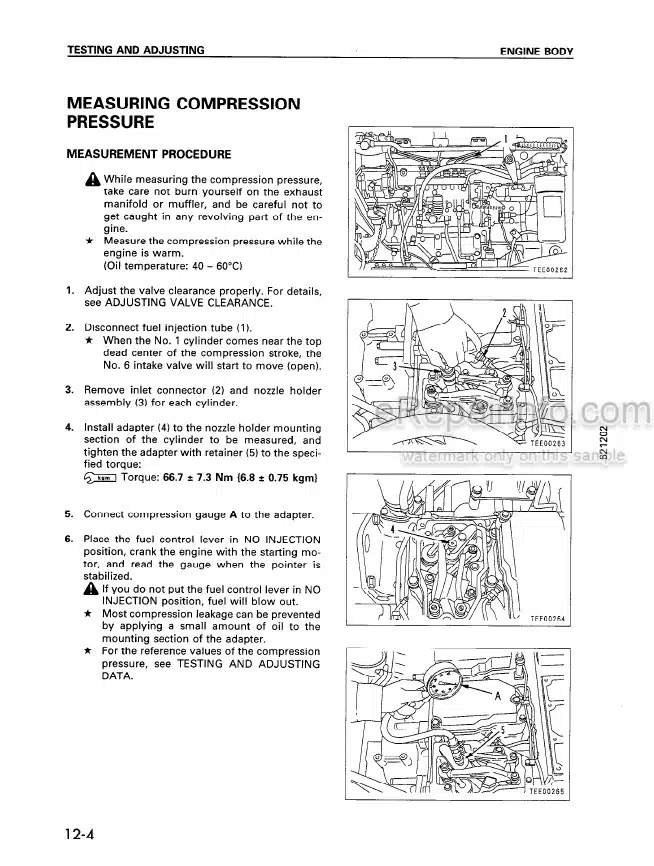

Measurement Of The Compression Pressure

Control And Adjustment Of The Tension Of The Fan Belt

Control And Adjustment Of The Injection Timing

Control And Adjustment Of The Accelerator Stroke

Adjustment Of The Stroke Of The Blade Command Lever

Control And Adjustment Of The Stroke Of The Travel Lever

Centering Adjustment Of The Boom Swing Command Pedal

Adjustment Of The PPC Valve Clearances

Adjustment Of The Rubber Pad And Safety Microswitch For Servo-Control Engagement

Control And Adjustment Of The Track-Shoe Tension

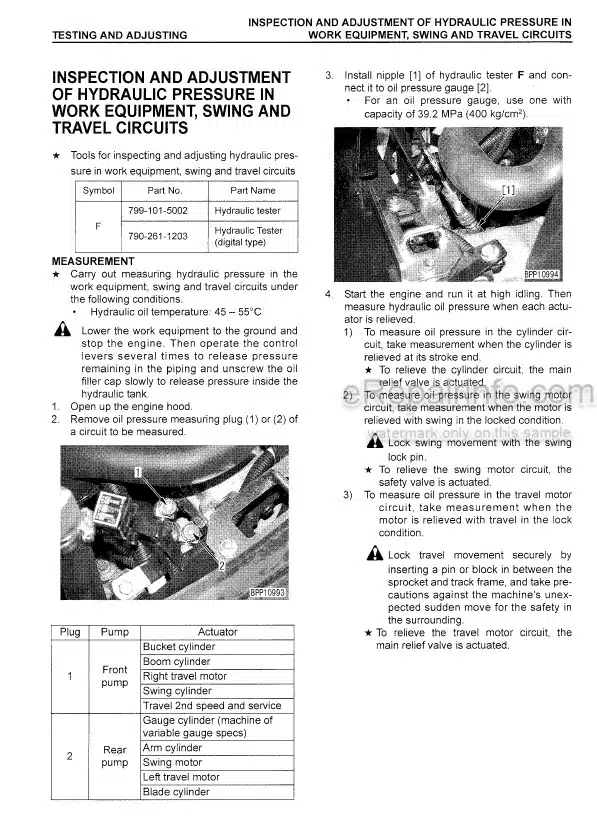

Control And Regulation Of Pressure In The Hydraulic Circuit

Control And Regulation Of The LS Differential Pressure And Adjustment Of The Ls Valve

Regulation Of The PC Valve

Control And Regulation Of The Servocontrol Power Supply

Elimination Of Residual Pressures – Pressurisation Of The Tank

Bleeding Air From The Hydraulic Circuits

Control Of Hydraulic Drifts – Analysis Of The Causes Of A Drift

Checking For Any Leakages Inside The Working Equipment Cylinders

Checking For Any Leakages Inside The Swing Motor

Methods For Testing For Leakages Inside The Swivel Joint

-REMOVAL AND INSTALLATION

Precautions To Be Taken While Working

Special Tools

Starter Motor

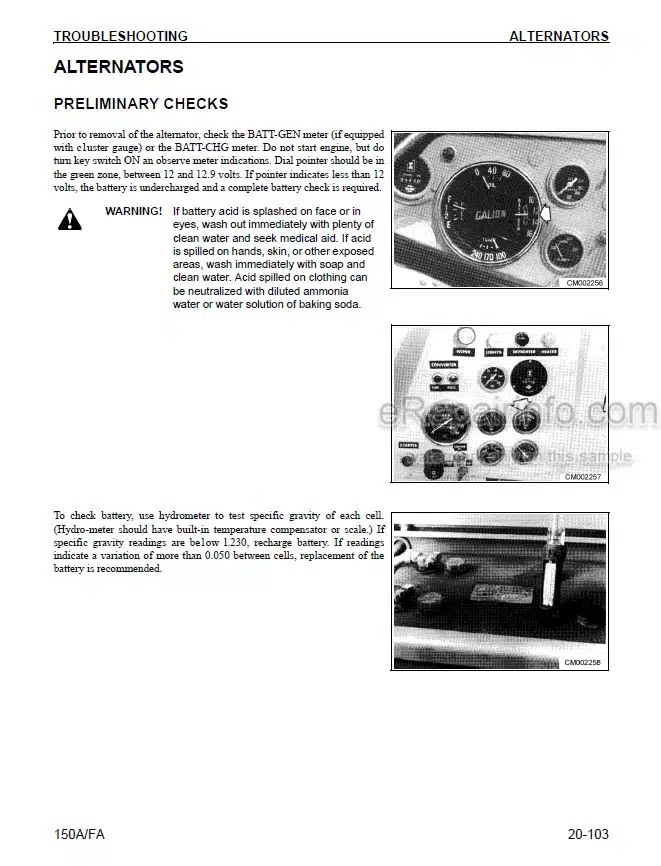

Alternator

Pump Group

Injection Nozzles

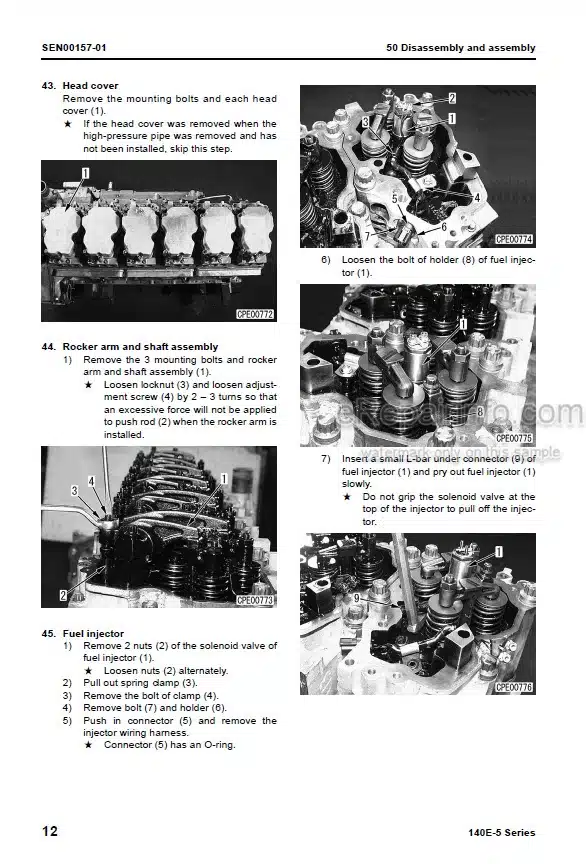

Cylinder Head

Oil Cooler

Radiator

Engine Hood

Cab And Canopy

Heating Fan

Rear Counterweight

Top Cover And Side Panels

Hydraulic Oil Tank

Fuel Tank

Engine Pump Group

Pump

Engine Pump Coupling

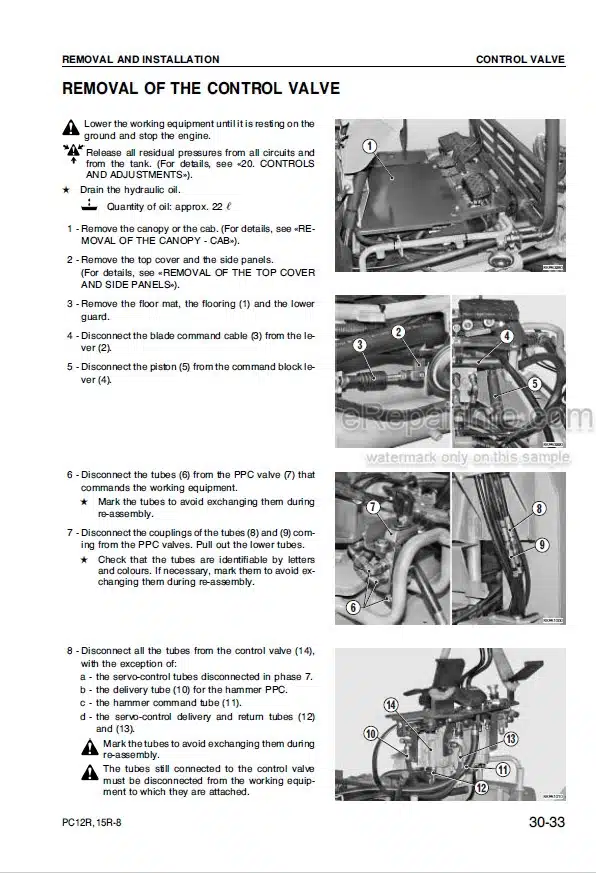

Control Valve

Right-Hand PPC Valve (Boom-Bucket)

Left-Hand PPC Valve (Arm-Bucket)

Servocontrol Solenoid Group

Swivel Joint

Swing Motor

Revolving Frame

Swing Circle

Travel Motor

Rubber Track Shoes

Track Shoes

Sprocket Wheel

Final Drive

Idler And Recoil Spring Assembly

Track Rollers

Boom Cylinder

Arm Cylinder

Bucket Cylinder

Boom Swing Cylinder

Blade Cylinder

Working Equipment Cylinder

Upper Working Equipment

Bucket

Arm

Boom

Boom Swing Support

Blade

-STANDARD MAINTENANCE

Swing Circle

Track Frame And Recoil Spring

Idler

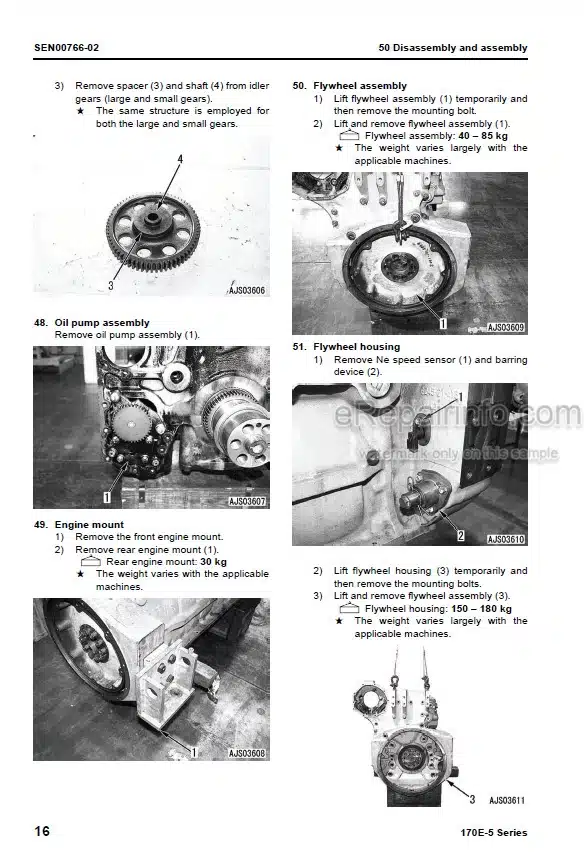

Final Drive

Sprocket

Track Roller

Track Shoe

Hydraulic Pump

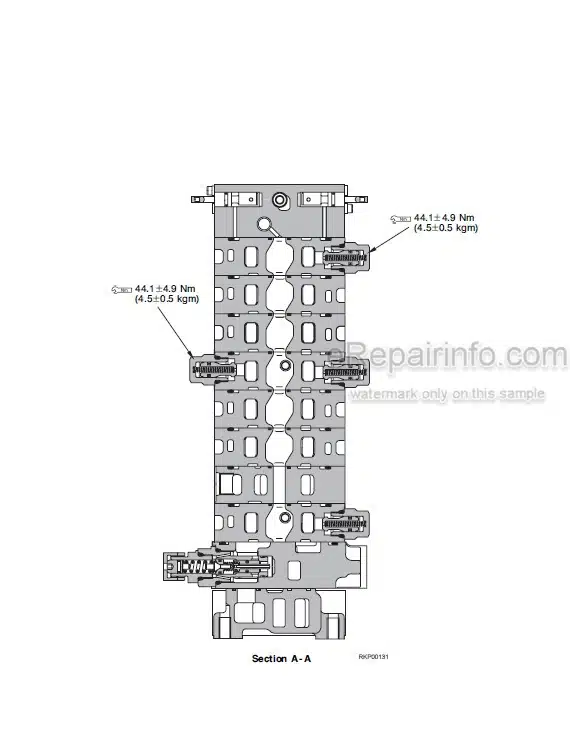

Control Valve

Swivel Joint

Swing Motor

Travel Motor

PPC Valve

Cylinders

Work Equipment

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet