Factory Shop Manual For Komatsu Hydraulic Mining Shovel. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 475

Number: SMPC30006174 (july 2006)

Bookmarks: Yes

Wiring Diagrams: Yes

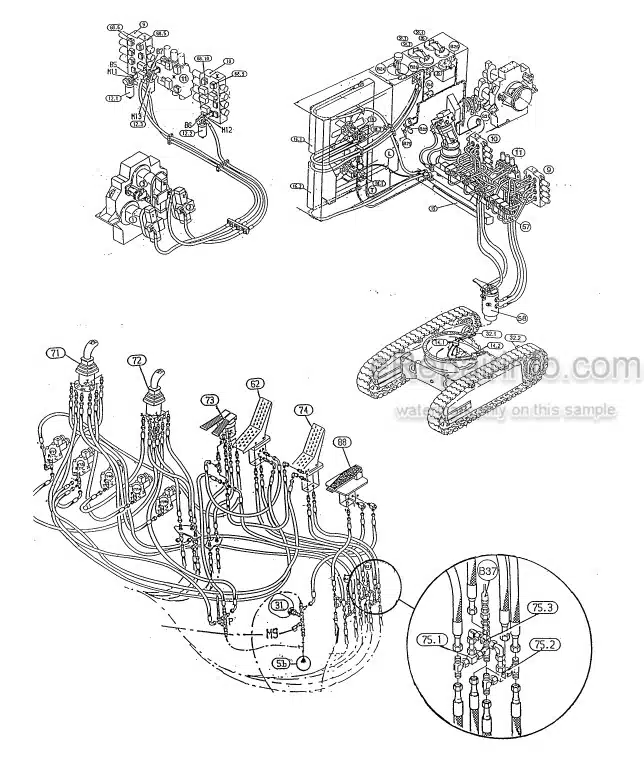

Hydraulic Diagrams: Yes

Model

Komatsu Hydraulic Mining Shovel

PC3000-1

SN 6174

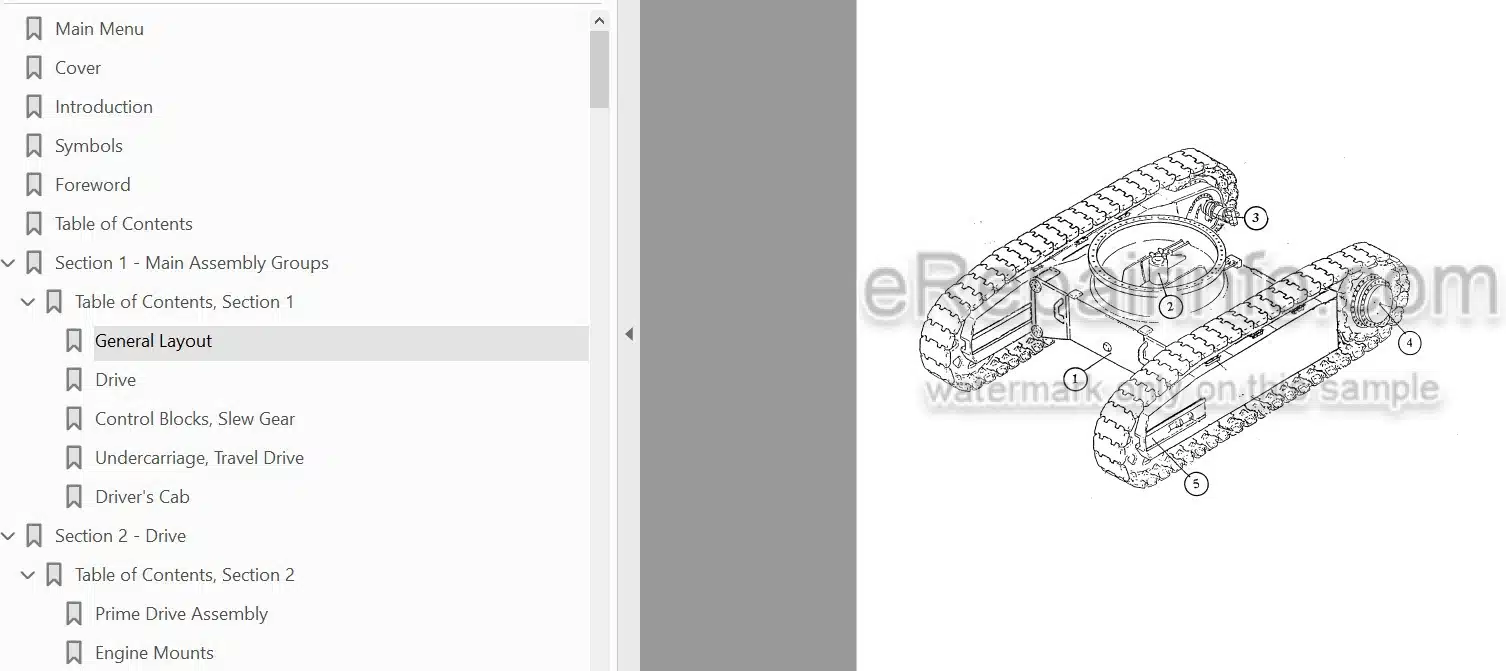

Contents

INTRODUCTION

SYMBOLS

FOREWORD

-MAIN ASSEMBLY GROUPS

General Layout

Drive

Control Blocks, Slew Gear

Undercarriage, Travel Drive

Driver’s Cab

-DRIVE

Prime Drive Assembly

Engine Mounts

Fan Drive and Cooler Assy.

Coupling

Air Filter

Pump Distributor Gear

Pump Spline – Lubrication

PTO – Gear Lubrications

-HYDRAULIC OIL TANK

Main Oil Tank

Return and Leak Oil Filter

Breather Filter

Location of Pressure Switches and Sensors

-HYDRAULIC OIL COOLING

General

Hydraulic Oil Cooling Circuit

Measuring / Setting the Back Pressure Valve

Fan Drive

Axial Piston Pump

Measuring and Setting of the Fan Speed

Function Check for RPM-Control

-CONTROLLING

Pilot Pressure Supply

Checks and Adjustment of Pilot Pressure

Measuring and Adjustment of Control Pressure

Travel Parking Brake

Function Check of Travel Parking Brake

Slew Parking (House) Brake

-COMPONENTS

Main Control Blocks and High Pressure Filter (Bull-Clam Attachment)

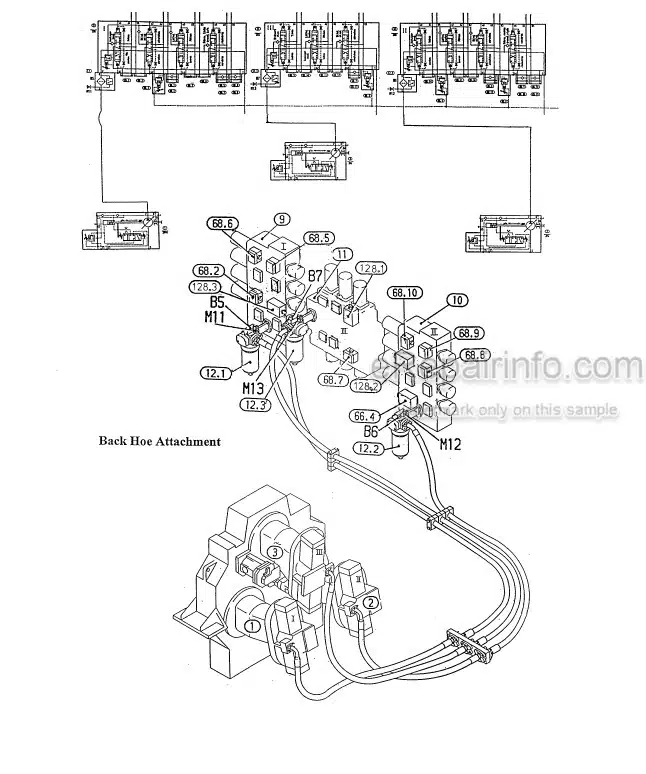

Main Control Blocks and High Pressure Filter (Back Hoe Attachment)

Distributor Manifold (Bull-Clam Attachment)

Distributor Manifold (Back Hoe Attachment

Restrictor Block with Pressure Valve

Restrictor Block

Anti Cavitation Valve Block

Proportional Solenoid Valve

Pressure Filter

Control Blocks

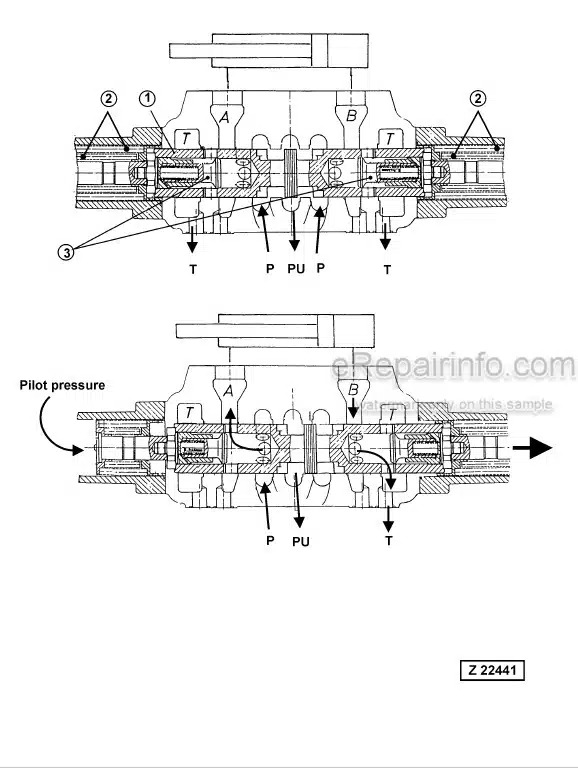

Travel Brake Valve

Pressure Reducing Valve

Directional Control Valve (Solenoid Valve)

Hydraulic Cylinder

Auxiliary Pumps, Fan Drive

Auxiliary Gear Pumps

Slew Ring

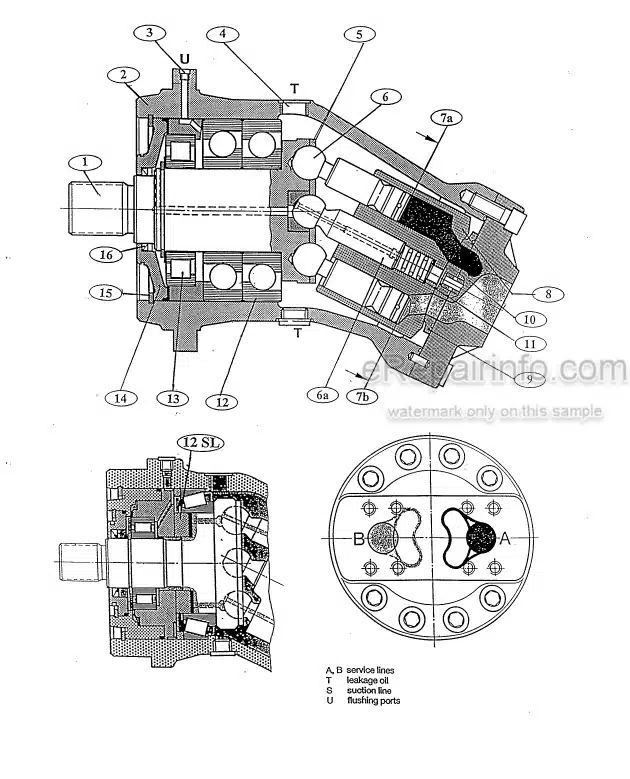

-MAIN HYDRAULIC PUMPS AND PUMP REGULATION

Main Hydraulic Pump A7V / HDD

SL-Bearing

Function Of The Pump Governor

Pump Bearing Lubrication

Pump Governor Adjustments

Pump Regulation, General

Determination Of Peak Point (Engine Performance Test)

Hydraulic Regulation Adjustment, Stop Gap Operation

Detailed Explanation For Electronic Pump Regulation

Adjustments / Checks For Electronic Pump Regulation

Adjusting The Rpm Sensor (MPU)

Adjustments At The Ell – Module, Normal Fine Tuning

Checks / Function Test / Fault Finding At Jobsite

EPM – Module, Function And Test

ERM – Module, Function And Test

ELL – Module, Function And Test

Amplifier Module, Function And Test

Simplified Trouble Shooting Of Electronic Regulation

-OPERATING HYDRAULIC

Hydraulic For Attachment Cylinder

Adjustments For Attachment Cylinder Hydraulic

Slew Circuit, General

Slew Motor

Slew Gear And House Brake

Slew Brake Valve

Slew Function

Checks And Adjustments

Travel Circuit

Rotary Distributor

Travel Motor (Axial Piston Motor A2Fm)

Travel Gear And House Brake

Travel, Function

Anti-Cavitation Circuit

Adjustments / Checks

-HYDRAULIC TANK TENSION SYSTEM

Function

Pressure Increasing Valve

Pressure Relief Valve. Direct Operated

Adjustments / Pressure Checks

-HINTS FOR THE HYDRAULIC CIRCUIT DIAGRAM

Hints for Reading Circuit Diagrams

Legend of the Hydraulic Circuit Diagram

Pressure Check Points

How to Read the Circuit Diagram

Hydraulic Diagram

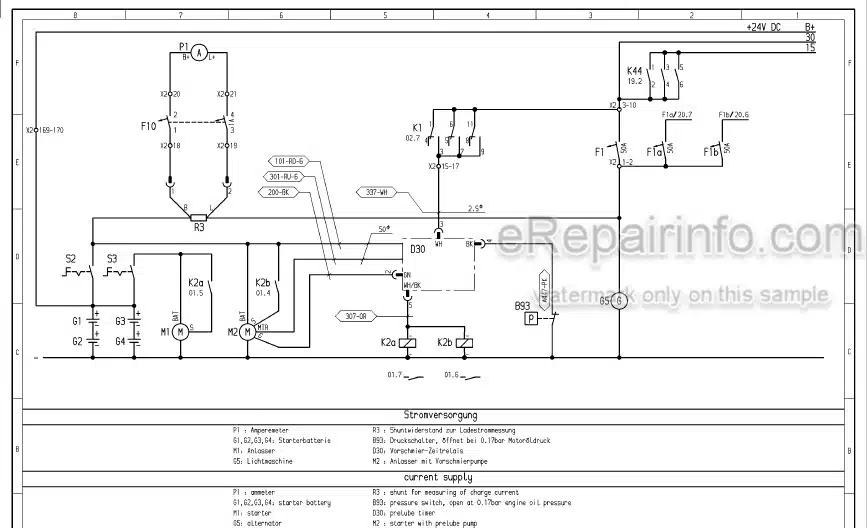

-HINTS FOR THE ELECTRIC CIRCUIT DIAGRAM

Markings of Electrical Components in Circuit Diagrams

Symbols

KGM Circuit Diagrams

Adjustments

Component List / Function

Electrical Diagrams

-ELECTRONIC TEXT MONITORING SYSTEM

Introduction

Function

Lay Out of Dash Board

Text Monitoring System

Frequency / Voltage Converter (EFD-Module)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet