Factory Shop Manual For Komatsu Wheel Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 337; 1339

Number: VEAM350100 (may 2005); VEBM350100 (june 2005)

Bookmarks: Yes

Searchable: Yes

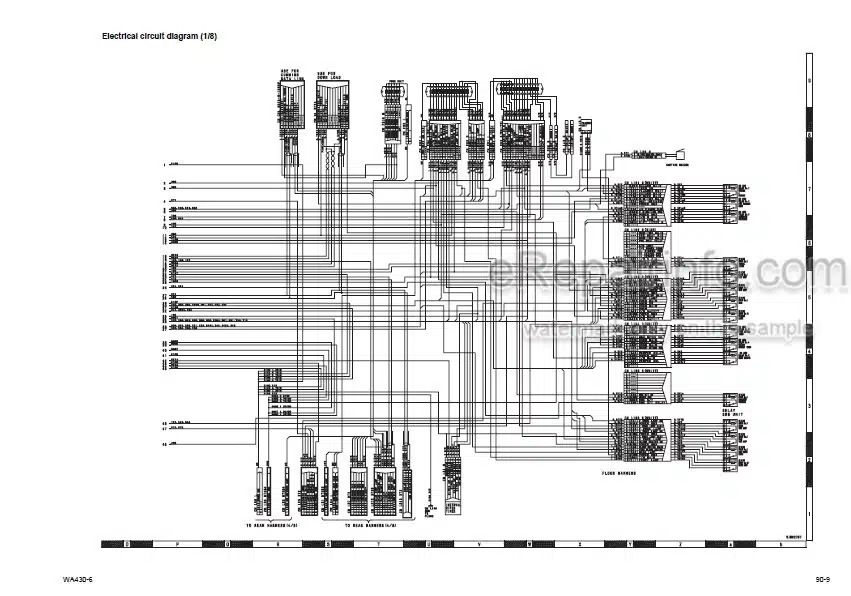

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Wheel Loader

WA430-6

Serial No.H50051 and up

Contents

-GENERAL

Specification Dimension Drawing

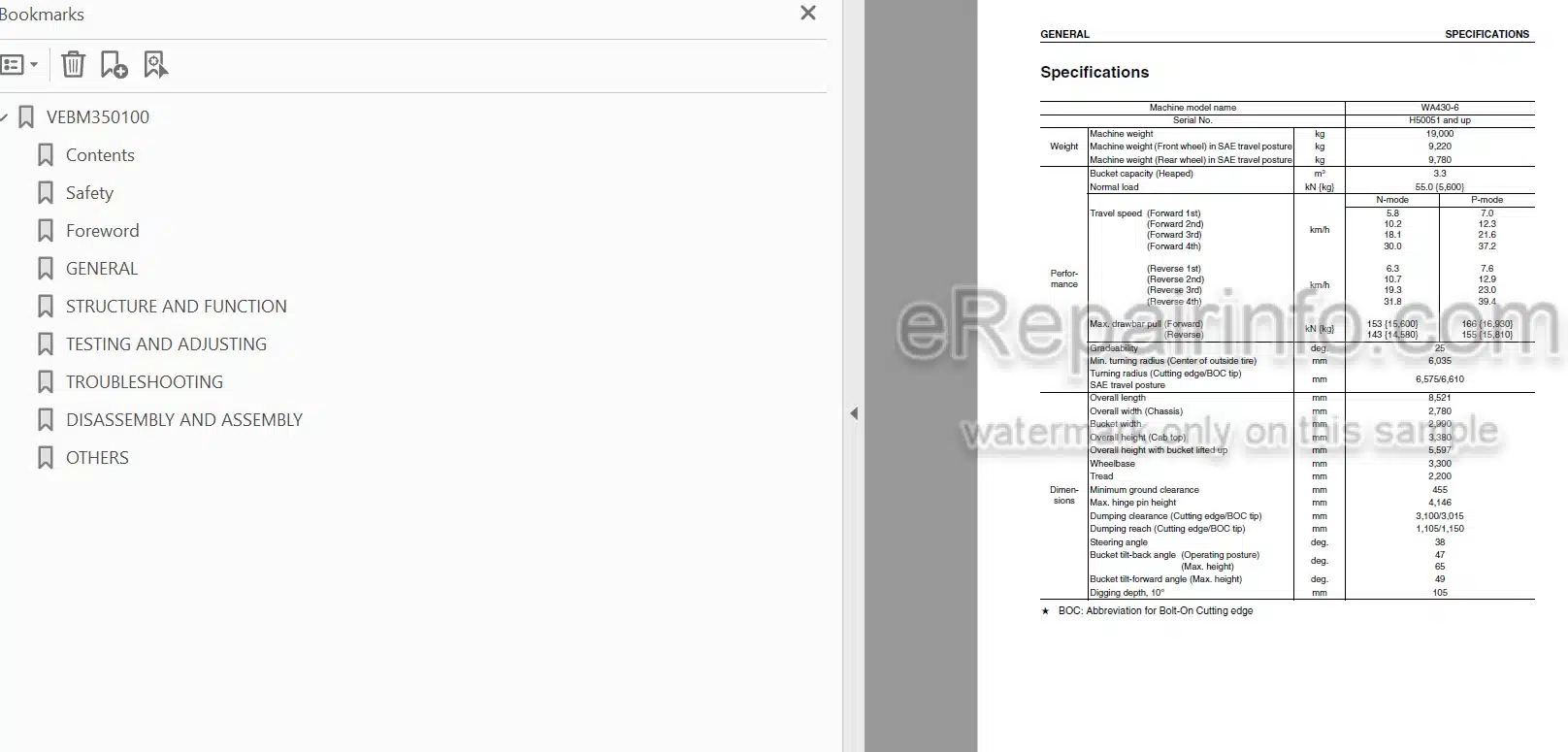

Specifications

Weight Table

Table Of Fuel, Coolant And Lubricants

-STRUCTURE AND FUNCTION

Engine Mount And Transmission Mount

Cooling System

Cooling Fan Pump

Cooling Fan Motor

Power Train Unit

Power Train System Diagram

Drive Shaft

Torque Converter And Transmission Piping Diagram

Torque Converter

Transmission

Transmission Control Valve

Axle

Differential

Limited Slip Differential

Final Drive

Steering Piping Diagram

Steering Column

Steering Pump

Steering Valve

Orbit-Roll Valve

Stop Valve

Steering Relief Valve

Steering Cylinder

Emergency Steering Motor

Emergency Steering Pump

Joystick Steering Lever Linkage

Steering Electric Lever

Joystick EPC Valve

Brake Piping Diagram

Charge Valve

Brake Valve

Accumulator (For Brake)

Brake

Parking Brake Control

Parking Brake

Parking Brake Solenoid Valve

Emergency Parking Brake Reset Valve

Axle Mount And Center Hinge Pin

Tires

Hydraulic Piping Diagram

Work Equipment Control Lever Linkage

Hydraulic Tank

Torque Converter Hydraulic Pump

Work Equipment Hydraulic Pump

Work Equipment Control Valve

CLSS

Each Function And Operation Of Each Valve

PPC Valve

Stabilizer Valve

Bypass Valve

Lock Valve

Accumulator (For PPC Circuit)

Accumulator (For ECSS)

Work Equipment Electric Lever

Work Equipment EPC Valve

Work Equipment EPC Cut-Off Solenoid Valve

Work Equipment Linkage

Bucket Positioner And Boom Kick-Out

Work Equipment Cylinder

Cab

Air Conditioner

Machine Monitor System

Machine Monitor

Electrical System (Transmission Controller System)

Transmission Controller

Electrical System (Work Equipment Controller System)

Work Equipment Controller

Electric Transmission Control

Kickdown Switch And Hold Switch

Engine Starting Circuit

Engine Stopping Circuit

Preheating And Post-Heating Circuit

Engine Power Mode Selector Circuit

Turbocharger Protection Function

Torque Derating Function

Automatic Warm-Up Function

Parking Brake Circuit

Sensors

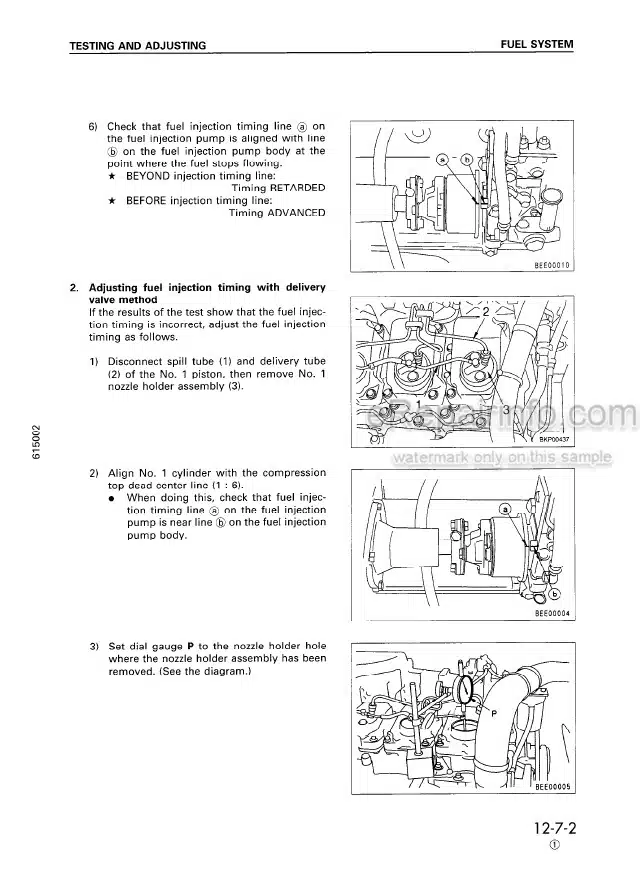

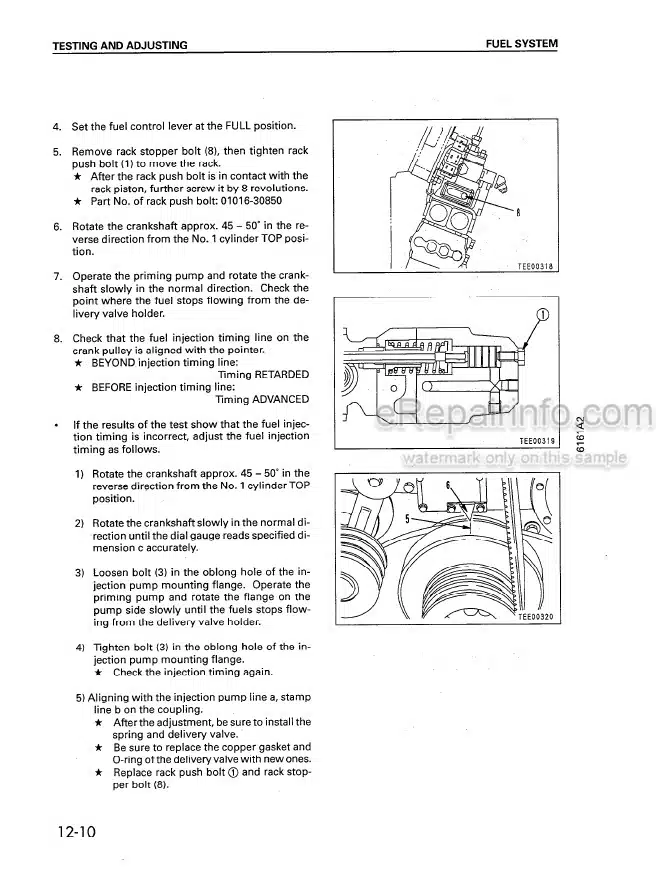

-TESTING AND ADJUSTING

Standard Value Table For Engine

Standard Value Table For Chassis

Posture Of Machine For Measuring Performance And Measurement Procedure

Tools For Testing, Adjusting, And Troubleshooting

Testing And Adjusting Engine Speed

Measuring Exhaust Gas Color

Measuring Exhaust Temperature

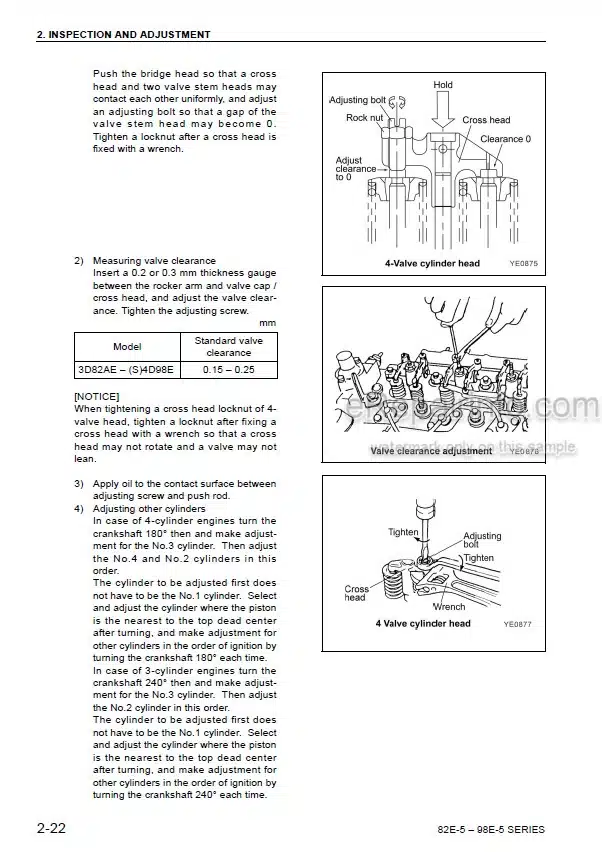

Adjusting Valve Clearance

Measuring Blow-By Pressure

Measuring Engine Oil Pressure

Measuring Intake Air (Boost) Pressure

Adjusting Engine Speed Sensor

Testing And Adjusting Air Conditioner Compressor Belt Tension

Bleeding Air From Fuel Circuit

Adjusting Accelerator Pedal Potentiometer

Adjusting Accelerator Pedal Microswitch

Adjusting Transmission Speed Sensor

Measuring Directional Lever

Testing And Adjusting Power Train Oil Pressure

Flushing Procedure For Torque Converter And Transmission Hydraulic Circuit

Method Of Moving Machine When Transmission Valve Is Broken

Testing And Adjusting Steering Control

Testing And Adjusting Steering Wheel

Testing And Adjusting Steering Oil Pressure

Bleeding Air From Steering Circuit

Testing Hydraulic Drive Fan

Bleeding Air From Fan Motor Circuit

Measuring Brake Pedal

Measuring Brake Performance

Testing And Adjusting Accumulator Charge Pressure

Testing Wheel Brake Oil Pressure

Measuring Wear Of Wheel Brake Disc

Bleeding Air From Wheel Brake Circuit

Releasing Residual Pressure In Brake Accumulator Circuit

Testing Parking Brake Performance

Measuring Parking Brake Oil Pressure

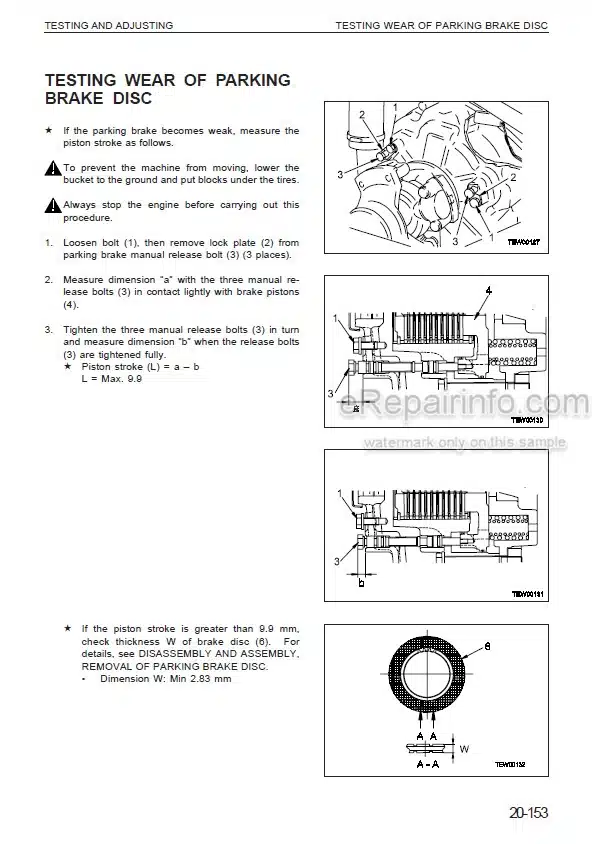

Testing Wear Of Parking Brake Disc

Method Of Releasing Parking Brake Manually

Measuring And Adjusting Work Equipment Control Lever

Testing And Adjusting Work Equipment Ppc Oil Pressure

Testing And Adjusting Work Equipment Oil Pressure

Bleeding Air From Work Equipment Circuit

Releasing Residual Pressure In Work Equipment Circuit

Testing And Adjusting Bucket Positioner

Testing And Adjusting Boom Kick-Out

Checking Proximity Switch Operation Pilot Lamp

Procedure For Testing Diodes

Adjusting Machine Monitor

Special Functions Of Machine Monitor

Pm Clinic Inspection Table

-TROUBLESHOOTING

Points To Remember When Troubleshooting

Sequence Of Events In Troubleshooting

Points To Remember When Carrying Out Maintenance

Testing Before Troubleshooting

Classification And Procedures Of Troubleshooting

Phenomena Looking Like Troubles And Troubleshooting Nos

Connector Arrangement Drawing And Electric Circuit Diagram Of Each System

Connection Table For Connector Pin Numbers T-Branch Box And T-Branch Table

Troubleshooting To Be Taken When Failure Code Is Recorded (Display Of Code)

Before Carrying Out Troubleshooting For Electrical System (E-Mode)

Method Of Using Troubleshooting Chart

Table Of Failure Modes And Causes

Method Of Using Troubleshooting Charts

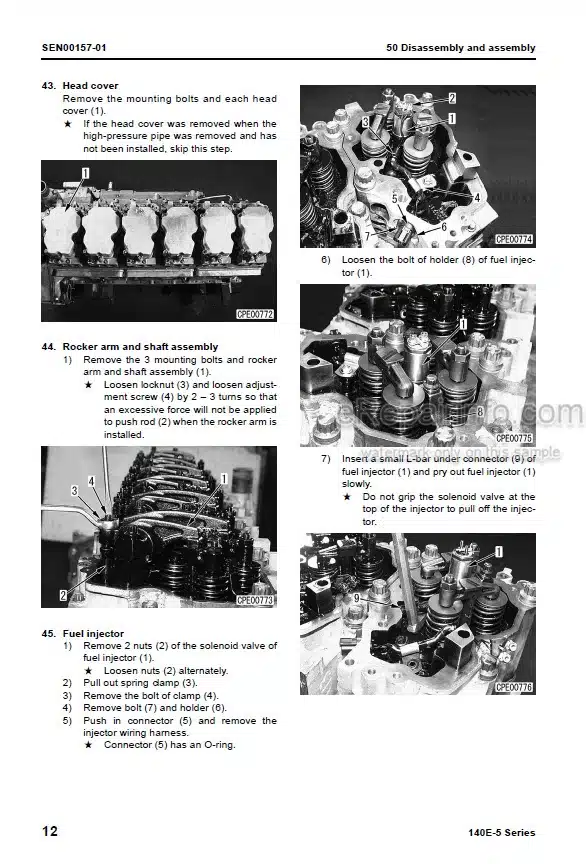

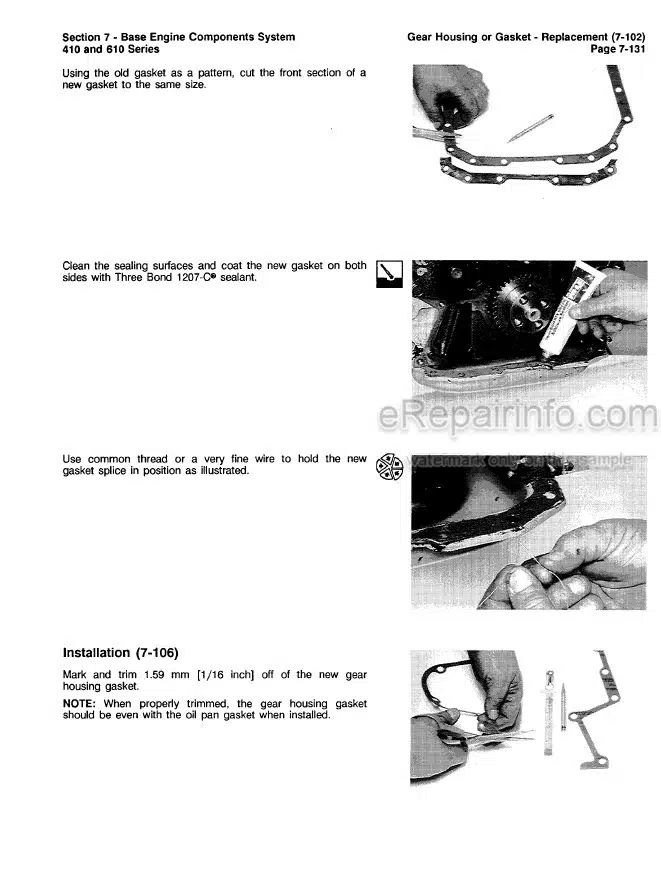

-DISASSEMBLY AND ASSEMBLY

How To Read This Manual

Precautions When Performing Operation

Special Tool List

Sketches Of Special Tools

Removal And Installation Of Fuel Injection Pump Assembly

Removal And Installation Of Fuel Injector Assembly

Removal And Installation Of Cylinder Head Assembly

Removal And Installation Of Radiator Assembly

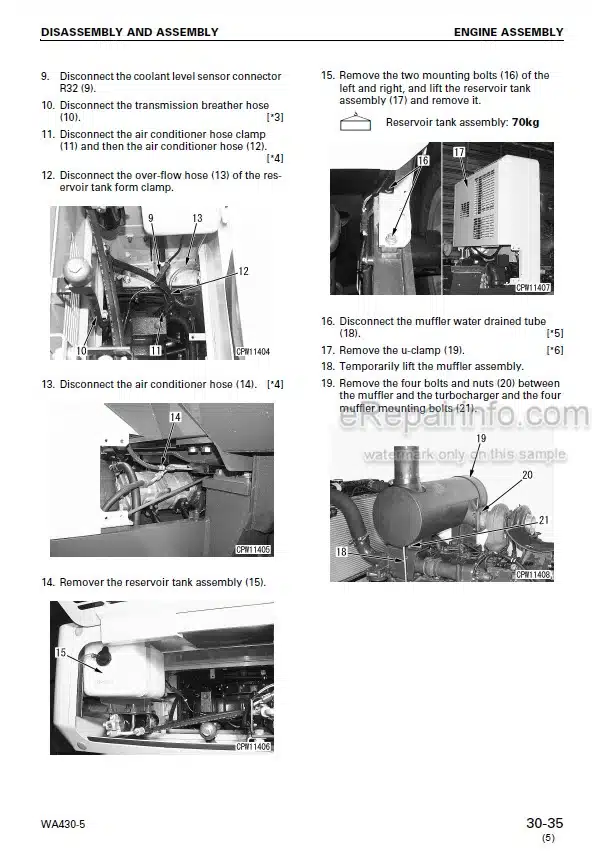

Removal And Installation Of Engine Assembly

Removal And Installation Of Engine Hood Assembly

Removal And Installation Of Fuel Tank Assembly

Removal And Installation Of Parking Brake Disc And Plate

Removal And Installation Of Torque Converter And Transmission Assembly

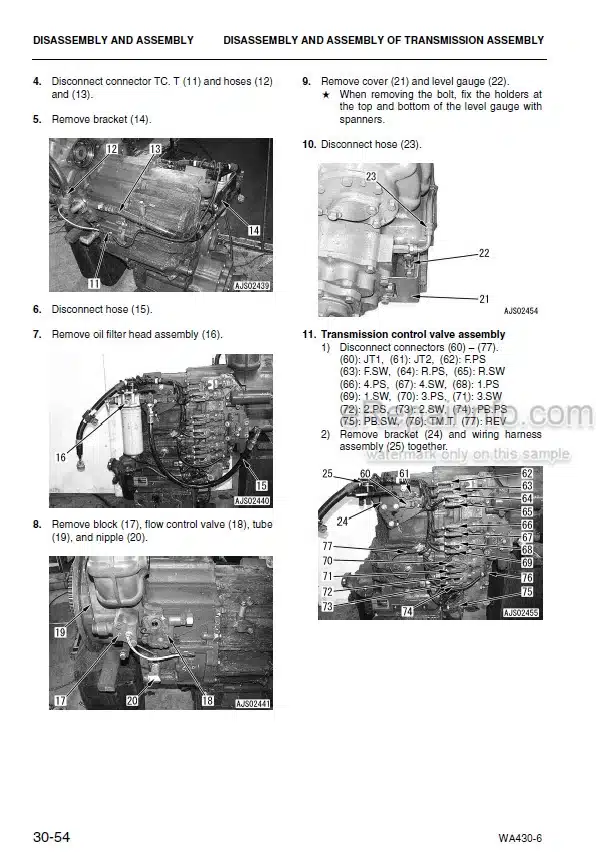

Disassembly And Assembly Of Transmission Assembly

Disassembly And Assembly Of Transmission Clutch Pack Assembly

Disassembly And Assembly Of Parking Brake Assembly

Disassembly And Assembly Of Torque Converter Assembly

Removal And Installation Of Front Axle Assembly

Removal And Installation Of Rear Axle Assembly

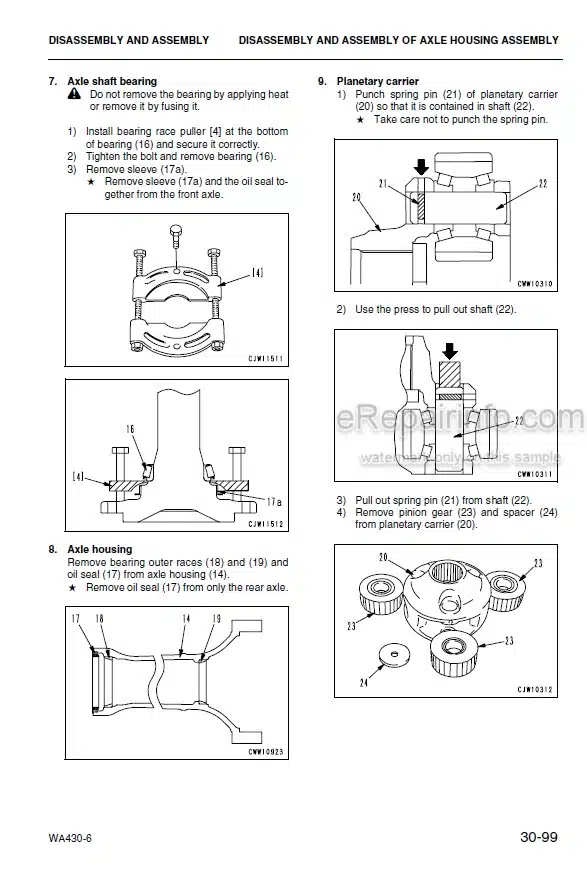

Disassembly And Assembly Of Axle Housing Assembly

Disassembly And Assembly Of Differential Assembly

Removal And Installation Of Steering Valve Assembly

Removal And Installation Of Hydraulic Tank Assembly

Disassembly And Assembly Of Hydraulic Cylinder

Removal And Installation Of Work Equipment

Removal And Installation Of Operator’S Cab Assembly

Removal And Installation Of Operator’s Cab Glass (Stuck Glass)

Removal And Installation Of Operator’S Cab And Floor Frame Assembly

Removal And Installation Of Center Hinge Pin

Removal And Installation Of Counterweight

Removal And Installation Of Air Conditioner Unit

-OTHERS

Power Train Hydraulic Circuit Diagram

Engine Electrical Circuit Diagram

Hydraulic Circuit Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet