Factory Service Manual For Link-Belt Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1309

Issued: september 2011

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Link-Belt Excavator

350X3

Contents

-SAFETY

Safety, General Information And Standard Torque Data

General Information

Standard Torque Data For Cap Screws And Nuts

-LOWER

Specifications

Main Equipment Table

Main Equipment Structure and Operation Explanation

Port Diagram

Basic Functions

Removal and Installation of Track

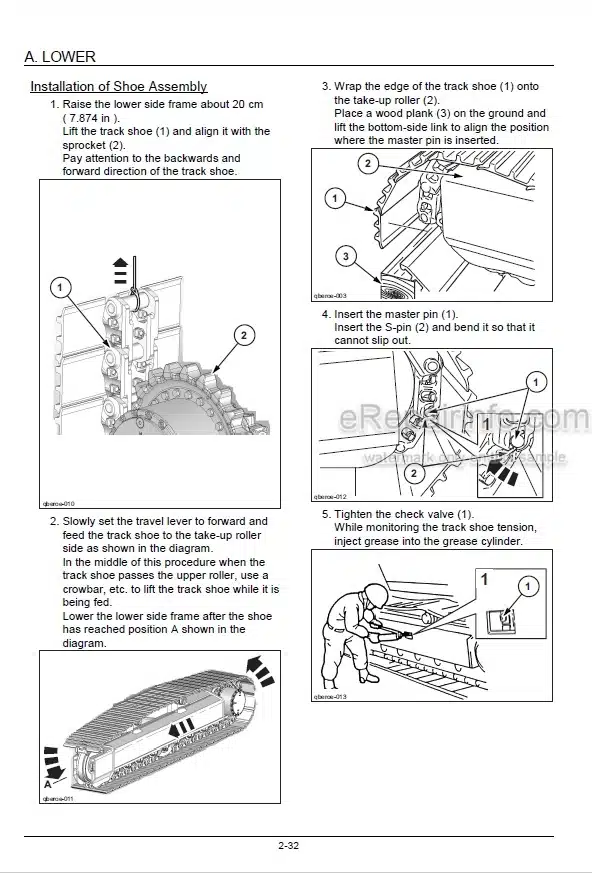

Removal and Installation of Shoe Assembly

Removal and Installation of Shoe Plate

Removal and Installation of Roller

Removal and Installation of Upper Roller

Assembly and Disassembly of Upper Roller

Removal and Installation of Lower Roller

Assembly and Disassembly of Lower Roller

Removal and Installation of Sprocket

Removal and Installation of Take-up Roller

Assembly and Disassembly of Take-up Roller

Removal and Installation of Grease Cylinder

Assembly and Disassembly of Grease Cylinder

Removal and Installation of Center Joint

Assembly and Disassembly of Center Joint

Removal and Installation of Travel Motor

Assembly and Disassembly of Travel Motor

Maintenance Standards

Pressure Measurement and Adjustment Procedures

Drain Volume Measurement Procedures

Air Bleed Procedure

-SWING UNIT, COUNTERWEIGHT

Specifications

Main Equipment Table

Main Equipment Structure and Operation Explanation

Port Diagram

Basic Functions

Removal and Installation of Swing Unit

Assembly and Disassembly of Swing Motor

Assembly and Disassembly of Swing Unit

Removal and Installation of Counterweight

Pressure Measurement and Adjustment Procedures

Drain Volume Measurement Procedures

Air Bleed Procedure

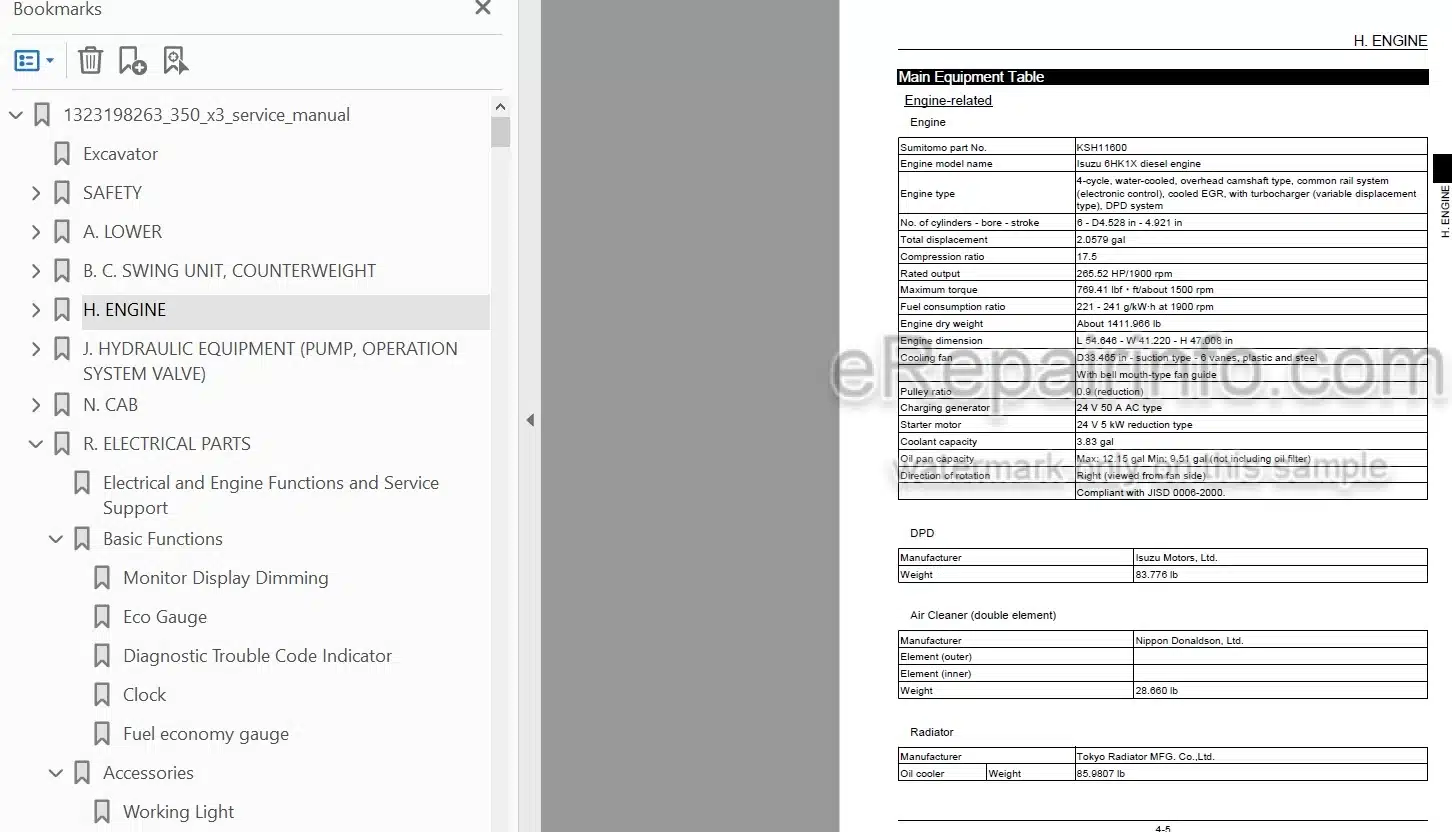

-ENGINE

Specifications

Main Equipment Table

Basic Functions

Primary Specifications

Function, Structure, Operation

Symptom

Functional Inspection

Maintenance Precautions

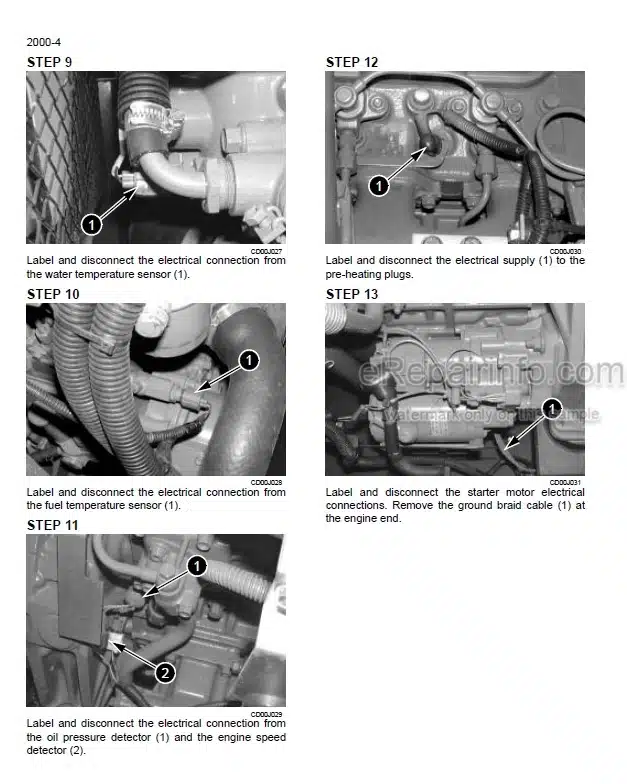

Removal And Installation Of Engine Assembly

Removal And Installation Of The Fuel Cooler Engine Inter-Cooler Radiator And Oil Cooler

Removal And Installation Of Turbo Charger

Removal And Installation Of EGR Cooler And EGR Valve

Removal And Installation Of Engine Hood

Removal And Installation Of Muffler

Removal And Installation Of Cylinder Head Cover

Removal And Installation Of Cylinder Block

Lubrication System

Cooling System

Removal And Installation Of Exhaust Manifold

Disassembly, Removal And Installation Of DPD Assembly

Removal And Installation Of Fuel Tank

Removal And Installation Of Fuel Supply Pump

Removal And Installation Of Common Rail Assembly

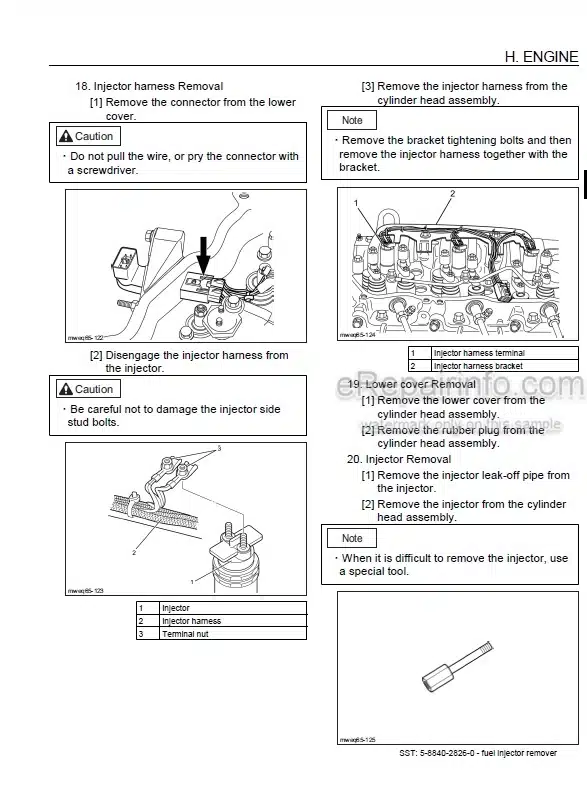

Removal And Installation Of Injector

Removal And Installation Of Starter Motor

Removal And Installation Of Alternator

Preheating System

Introduction To The Trouble Diagnosis

-HYDRAULIC EQUIPMENT (PUMP, OPERATION SYSTEM VALVE)

Specifications

Main Equipment Table

Basic Functions

Port Diagram

Main Equipment Structure and Operation Explanation

Control Valve

4 Stack Solenoid Valve Operation Explanation

Upper Pilot Valve (remote control valve)

Travel Pilot Valve (remote control valve)

Cushion Valve

Removal and Installation of Hydraulic Oil Tank

Removal and Installation of Hydraulic Pump

Removal and Installation of Control Valve

Removal and Installation of Pilot Blocs

Removal and Installation of Travel Remote Control Valve

Removal and Installation of Operation Remote Control Valve

Removal and Installation of 4 Stack Solenoid

Removal and Installation of Cushion Valve

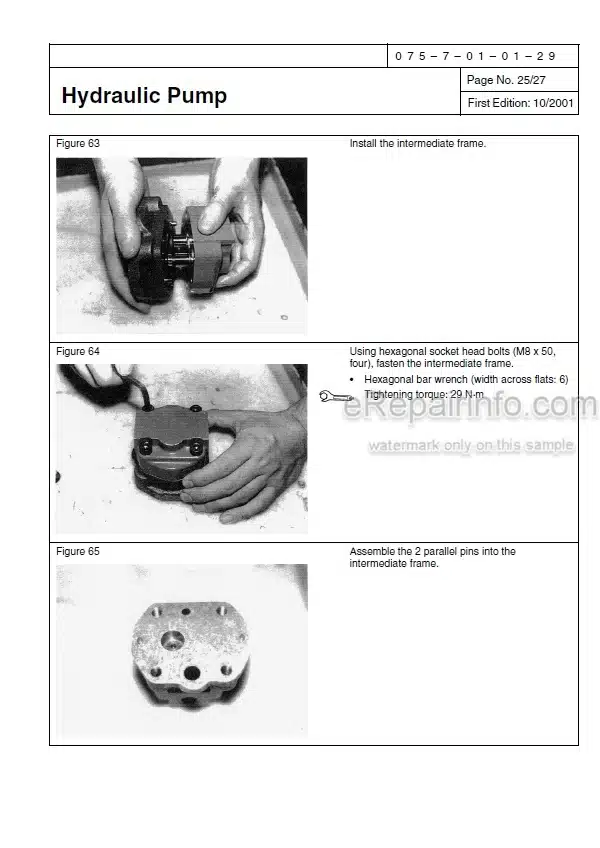

Procedures for Assembly and Disassembly of Hydraulic Pump Main Unit

Pump Main Unit Maintenance Standards

Procedures for Assembly and Disassembly of Control Valve

Procedures for Assembly and Disassembly of Operation Remote Control Valve

Procedures for Assembly and Disassembly of Travel Remote Control Valve

Assembly and Disassembly of Cushion Valve

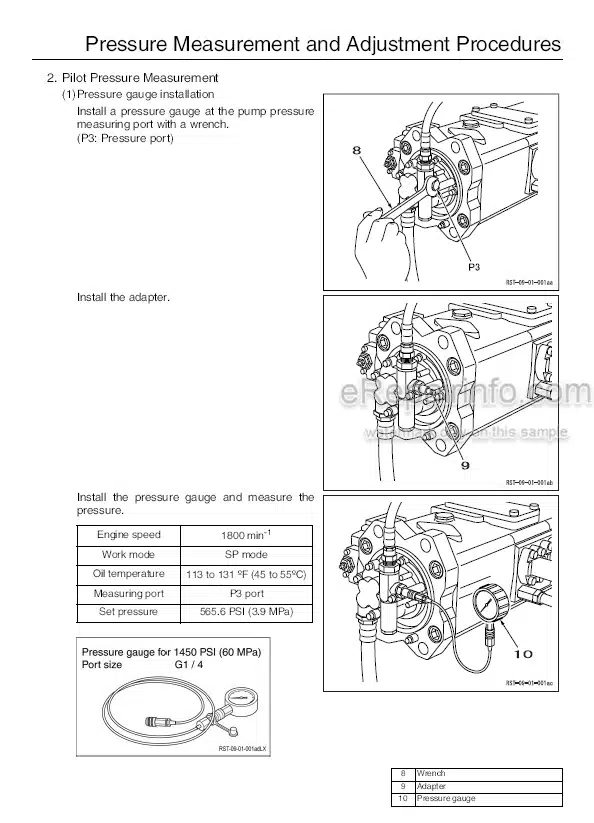

Pressure Measurement and Adjustment Procedures

Hydraulic Pump Flow Measurement Procedures

Air Bleed Procedure

Hydraulic Equipment Layout

Overall View

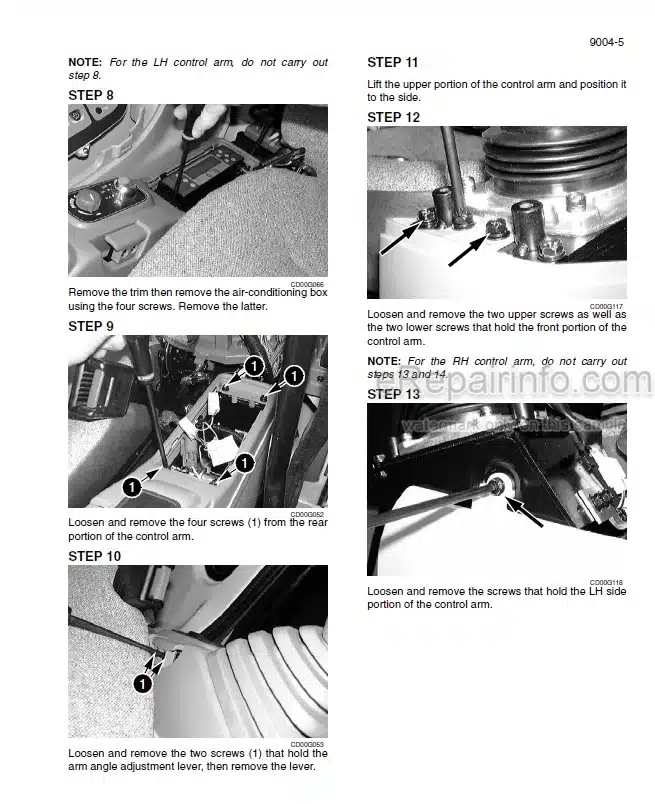

-CAB

Removal and Installation of Operator’s Seat

Removal and Installation of Cab Assembly

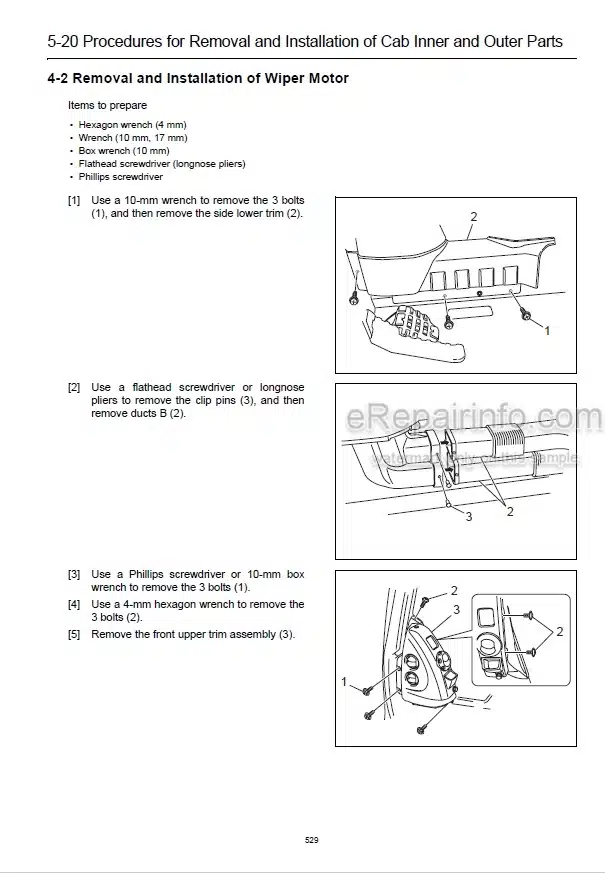

Removal and Installation of Wiper

Removal and Installation of Cab Front Glass

Window Lock Adjustment Procedures

Tightening Torque

-ELECTRICAL PARTS

Electrical And Engine Functions And Service Support

Basic Functions

Accessories

Milli-Amp List

Safety

Service Support

Setting

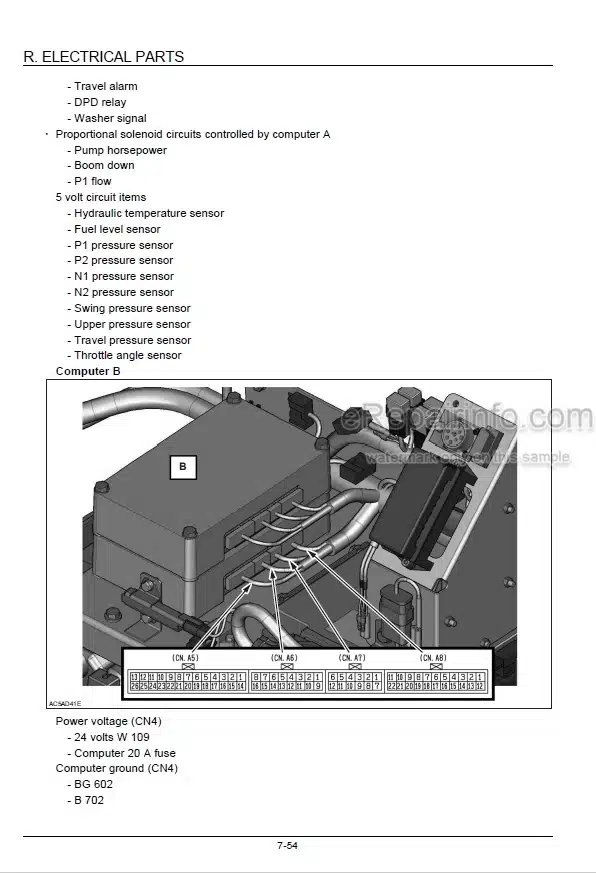

Explanation On The Computers

Connection Connector Pin Layout

Sequence Circuit Diagram

Block diagram

Electrical Equipment Layout Diagram

Removal and Installation of Wiper Controller

Removal and Installation of Wiper Motor

Removal and Installation of Monitor

Air Conditioner Overall Diagram

Assembly and Disassembly of Unit

Removal and Installation of Compressor

Removal and Installation of Condenser

Removal and Installation of Receiver Dryer

Work Precautions

-ATTACHMENTS

Main Equipment Table

Maintenance Standards

Removal and Installation of Bucket Cylinder

Removal and Installation of Arm Cylinder

Removal and Installation of Boom Cylinder

Procedures for Operation/Assembly and Disassembly of Hydraulic Cylinder

Removal and Installation of Bucket

Removal and Installation of Bucket Link

Removal and Installation of Arm

Removal and Installation of Boom

-OTHER

Specifications

Main Unit Weight

Bolt Size And Torque Table

Overall View

Work Range Diagram

New Machine Performance Judgment Table

Fluids And Lubricants

Main Unit-Side Dtc List

Main Unit-Side Trouble

List Of Special Tools

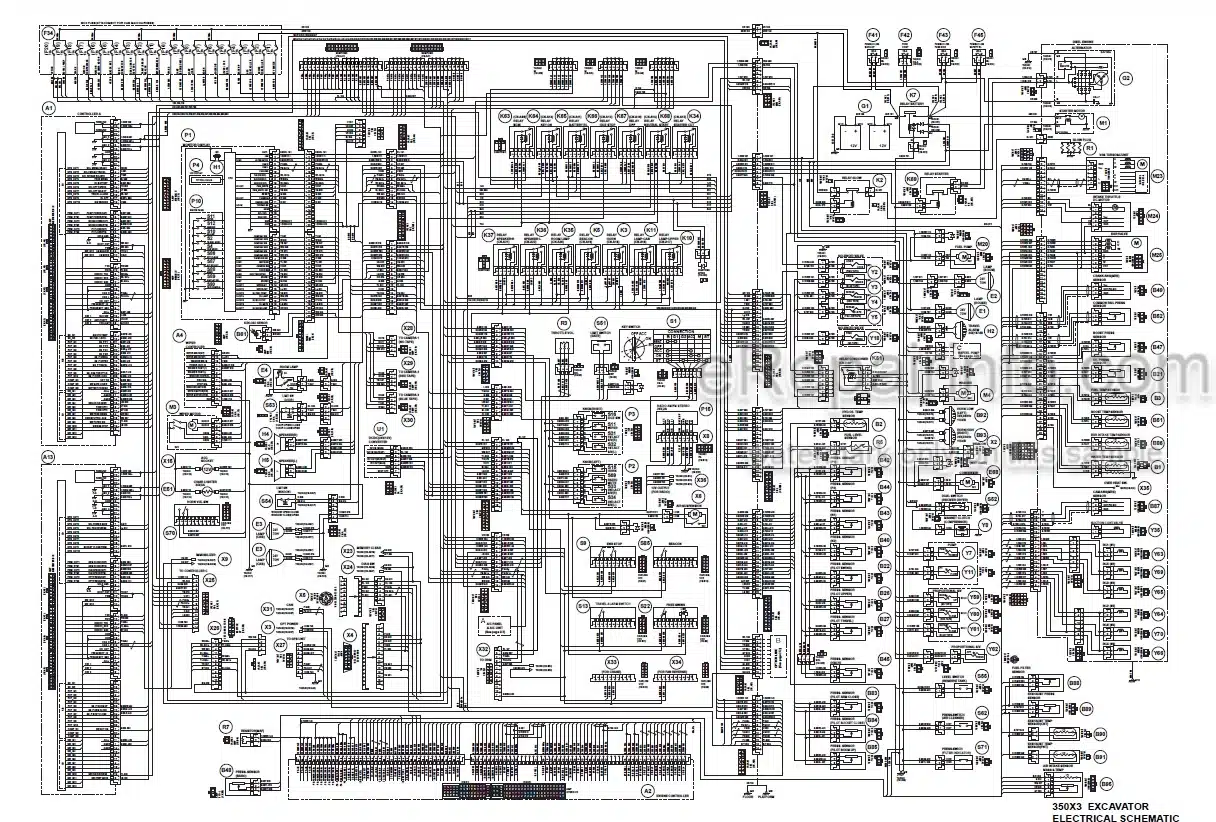

350X3 ELECTRICAL SCHEMATIC I

350X3 ELECTRICAL SCHEMATIC II

350X3 HYDRAULIC SCHEMATIC

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Excellent!