Factory Service And Maintenance Manual For Manitowoc Crane. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 410; 370

Number: CTRL040-13 (november 2015); CTRL249-01 (july 2016)

Bookmarks: Yes

Searchable: Yes

Model

Manitowoc Crane

2550

SN XXXXXREF

Contents

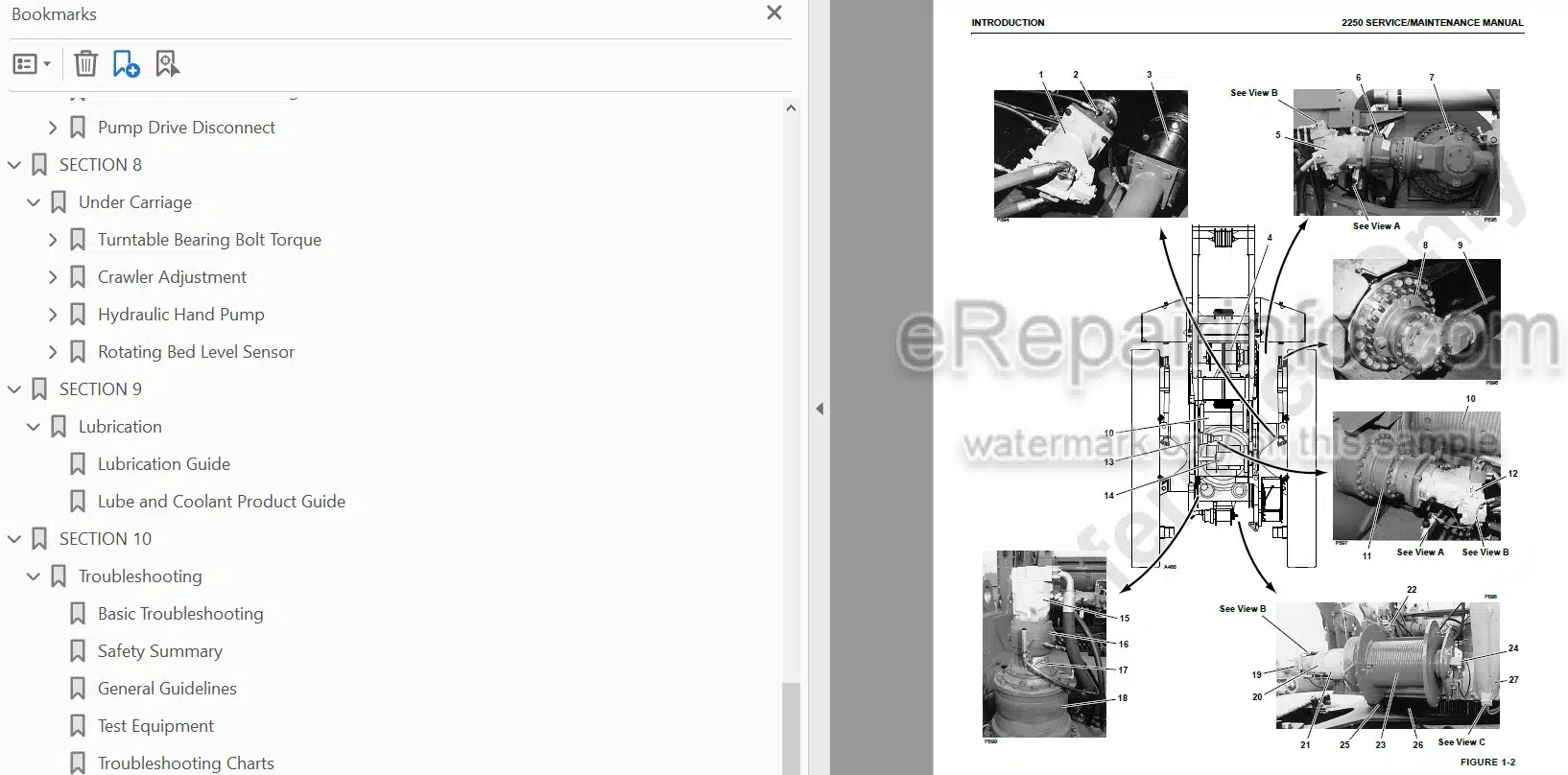

-INTRODUCTION

Continuous Innovation

Safety Messages

Safe Maintenance Practices

Environmental Protection

Identification and Location of Components

Crane Description of Operation

MAX-ER 2000 Description Of Operation

Hydraulic Cooler Fan Drive — Tier 4 Only

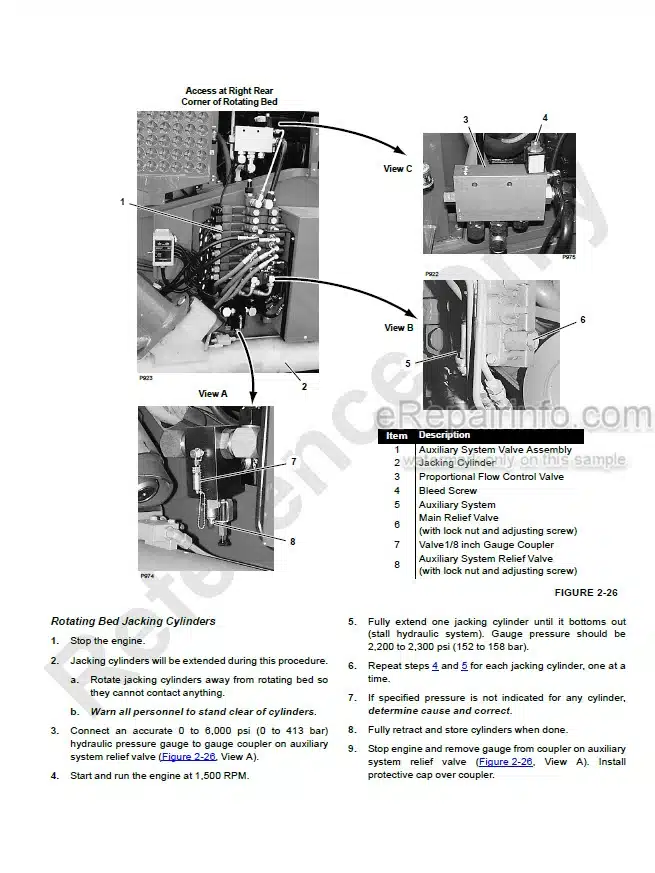

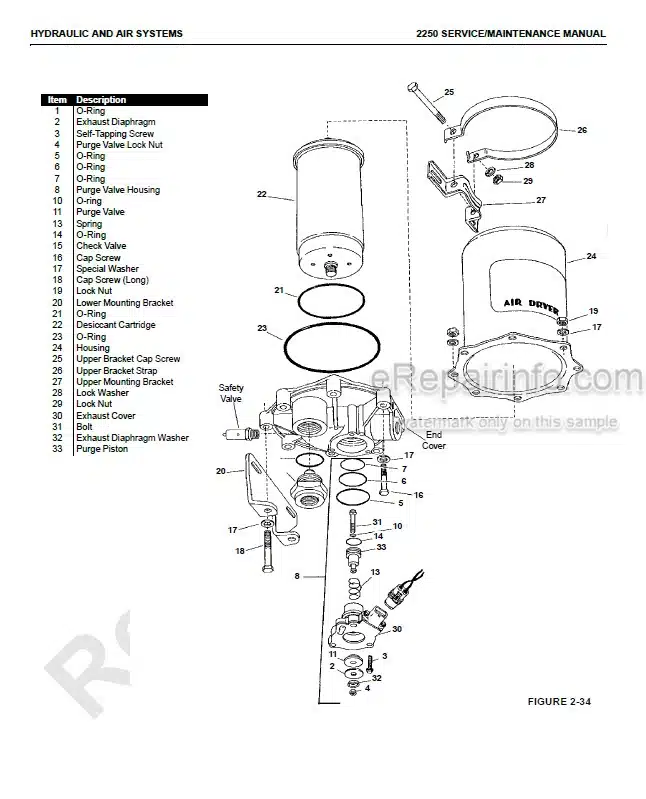

-HYDRAULIC AND AIR SYSTEMS

Hydraulic Schematics

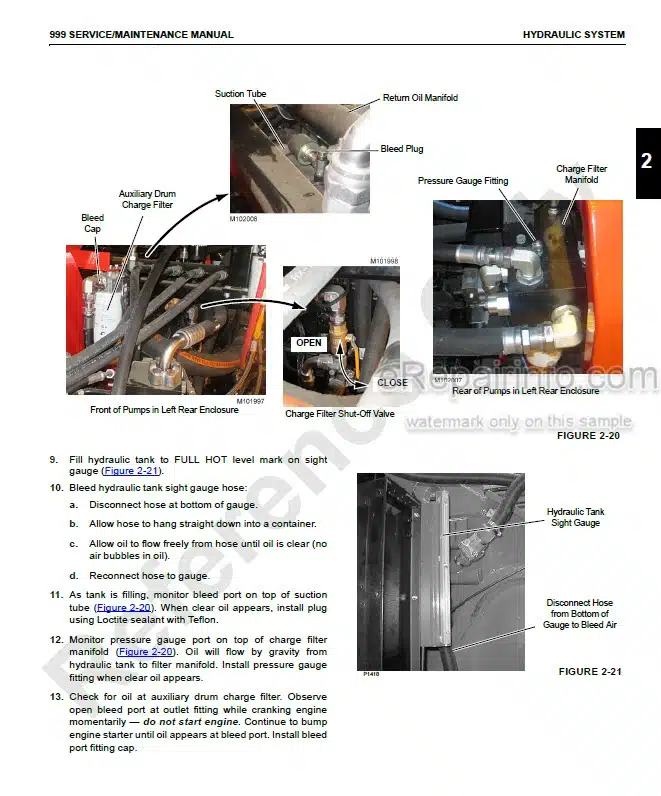

Hydraulic System – General

Checking and Replacing Hydraulic Hoses

Hydraulic System Maintenance

Tightening Hydraulic Connections

Programmable Controller Calibration Procedures — Past

Programmable Controller Calibration Procedures — Current

Pressure Sender Replacement

Disc Brake Operational Test

Shop Procedure

Unloader Pilot Valve Maintenance

Moisture Ejector Valve Maintenance

Air System Filter Maintenance

Air System De-icer Maintenance

Air Dryer Maintenance (Current Production)

Air Dryer Maintenance (Past Production)

Breather Vent Maintenance

Solenoid Valve Maintenance

Quick Release Valve Maintenance

Air Pressure Safety Switches Maintenance

Shuttle Valve Maintenance

Type A Air Regulator Maintenance

N-1 Pressure Reducing Valve Maintenance

Type S Relay Valve Maintenance

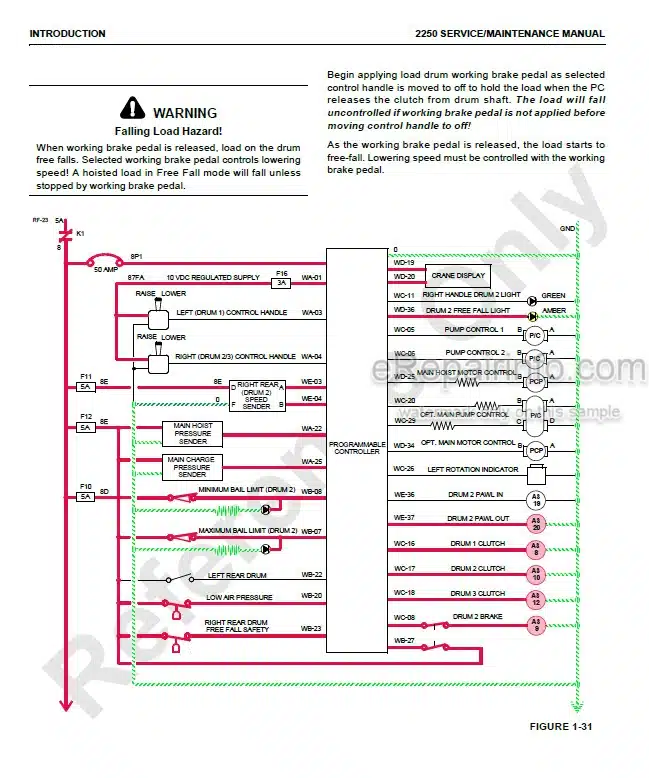

-ELECTRIC SYSTEM

Electrical Drawings and Schematics

Checking or Replacing Electrical Components

Circuit Breaker and Fuse ID

Test Voltages For Crane Controller

Model 2250 MAX-ER 2000 Test Voltages

Abbreviations

Digital Display Readings

Diagnostic Display

EPROM Replacement

Dielectric Grease

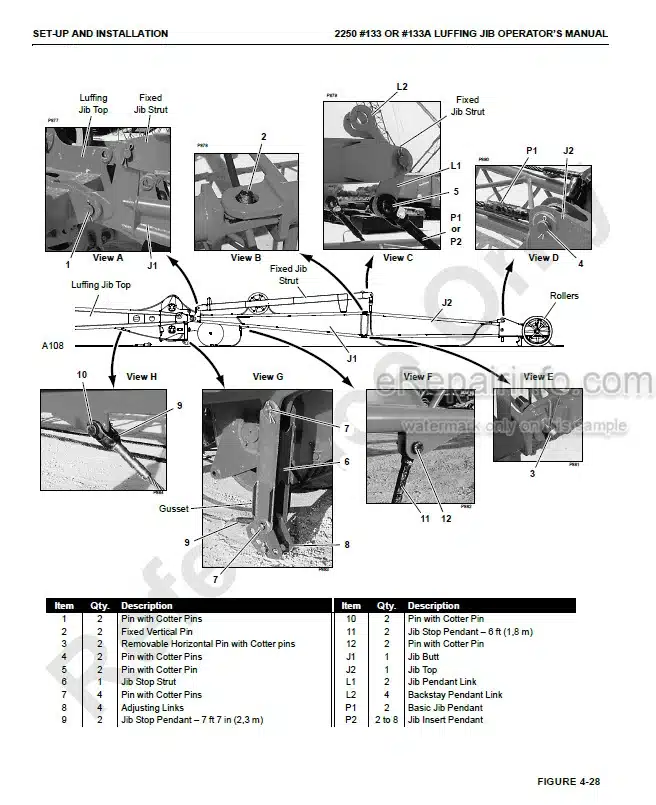

-BOOM

Automatic Boom Stop Adjustment

Setup Boom Angle

Physical Boom Stop

Angle Indicator Adjustment

Boom Hoist Ratchet and Pawl Adjustment

Strap Inspection and Maintenance

Lattice Section Inspection and Lacing Replacement

-HOISTS

Minimum Bail Limit Adjustment

Block-up Limit Control Adjustment

Drum Brake Inspection and Adjustment

Drum Clutch Inspection and Adjustment — Standard

Drum Clutch Inspection and Adjustment— Right Rear Drum Clutch (421339)

Gearbox Cooling Blower

Slack Line Sensor Adjustment

Drum Pawl Adjustment

Wire Rope Lubrication

Wire Rope Inspection and Replacement

Distributing Wire Rope Wear

Sheave, Roller, And Drum Inspection

Load Block and Hook-And-Weight Ball Inspection

-SWING

Manual Release of Swing Brake and Lock

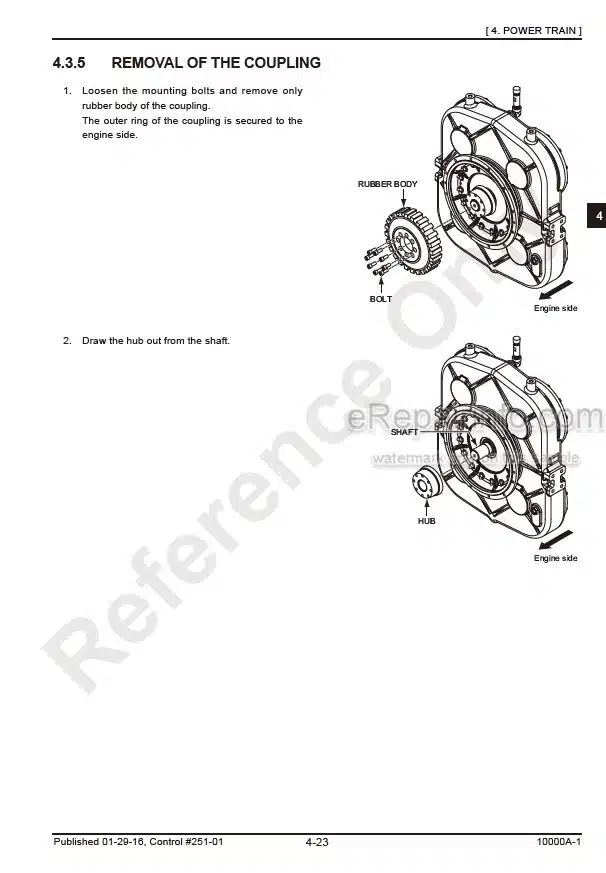

-POWER TRAIN

Battery Maintenance

Engine Diagnostics (Celect Plus Engine)

Engine Diagnostics (QSX 15 Engine)

Engine Air Cleaner Maintenance — Tier 3 Engine

Engine Air Cleaner Maintenance — Tier 4 Engine

Engine Cooling System — Past Production

Engine Cooling System with Cummins QSX-15 Engine — Current Tier 3

Engine Cooling System Fill — Current Production Tier 4

Engine Throttle Adjustment

Engine Belt Routing — Tier 4 Engine ONLY

Diesel Particulate Filter Regeneration — Tier 4 ONLY

Pump Drive Disconnect

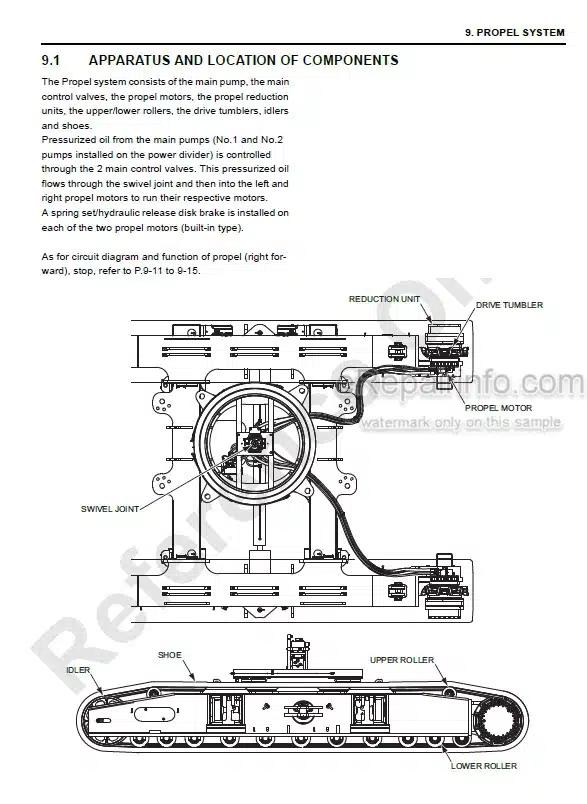

-UNDER CARRIAGE

Turntable Bearing Bolt Torque

Crawler Adjustment

Hydraulic Hand Pump

Rotating Bed Level Sensor

-LUBRICATION

Lubrication Guide

Lube and Coolant Product Guide

-TROUBLESHOOTING

Basic Troubleshooting

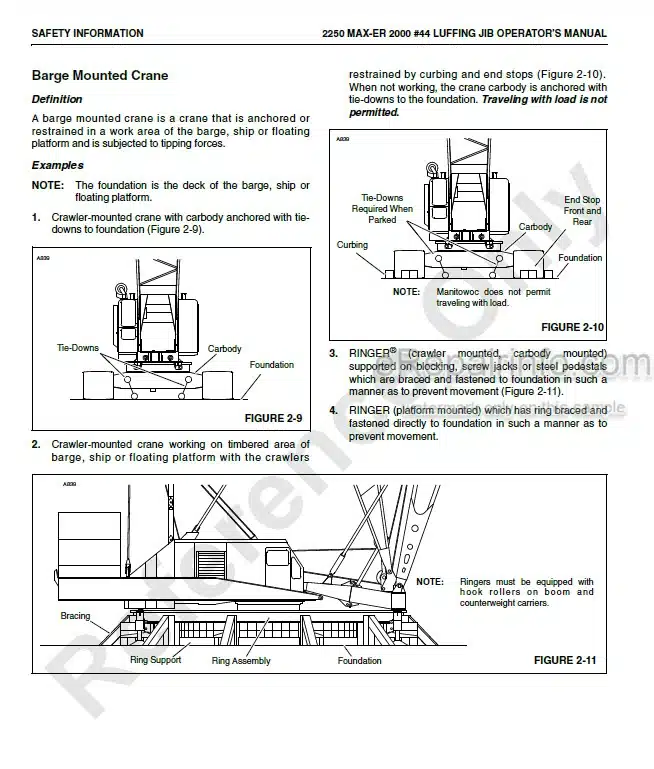

Safety Summary

General Guidelines

Test Equipment

Troubleshooting Charts

Testing Components

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet