Factory Operators Manual For Manitowoc Crane. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 876

Number: CTRL076-04 (july 2015)

Bookmarks: Yes

Searchable: Yes

Model

Manitowoc Crane

31000

SN 31001000

Contents

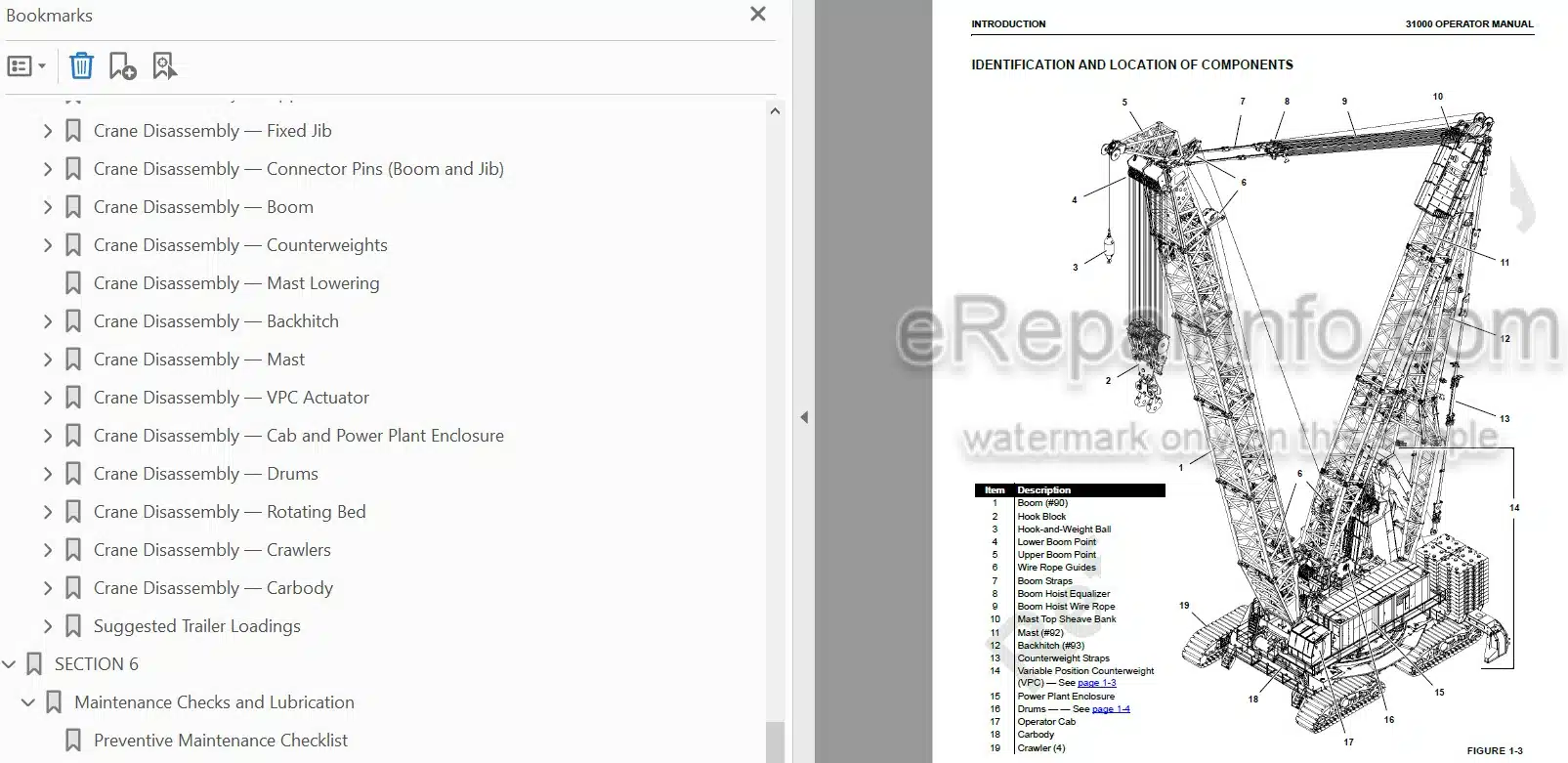

-INTRODUCTION

Crane Data

Crane/attachment Identification

Manitowoc Dealer

Change of Ownership Registration

Crane Orientation

Outline Dimensions

Crane Weights

Identification And Location Of Components

English And Metric Conversions

Symbols

Abbreviations

Section 1 Inserts

-SAFETY INFORMATION

Continuous Innovation

Nameplates and Decals

Safety Messages

Safety and Information Signs

Crane Access Points

Getting On or Off Crane

Personal Fall-Protection

Operator Manual/Capacity Chart Storage

Safe Operating Practices

Signals

Safety Devices

Operational Aids

Below-the-Hook Lifting Devices

Assembling. Disassembling, or Operating Crane Near Electric Power and Transmission Lines

Refueling

Fire Extinguishers

Accidents

Safe Maintenance Practices

Environmental Protection

Boom Disassembly Safety

Personnel Handling Policy

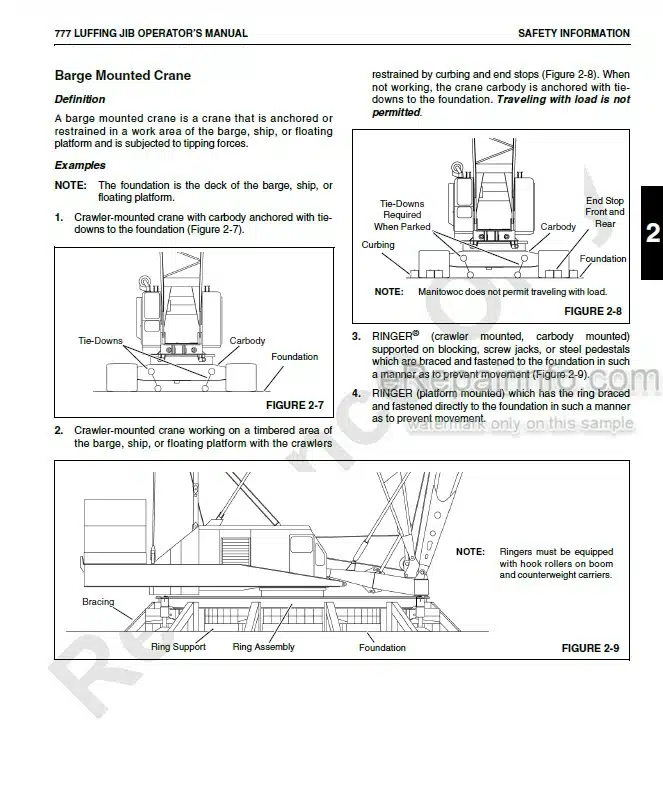

Pedestal/barae Mounted Cranes

Section 2 Inserts

-OPERATING CONTROLS AND PROCEDURES

Operating Controls

Operating Procedures

Appendix

Section 3 Inserts

-CRANE ASSEMBLY

General Safety

Crane Orientation

Rigging Drawings

Assembly Notes

Assembly Area

Accessing Parts

Personnel Fall-Protection

Handling Components

Retaining Connecting Pins

Assist Crane Requirements

Aerial Work Platform

Crane Weights

Hose and Cable Cleanliness

Pin and Connecting Hole Cleanliness

Hydraulic Hose Identification

Tightening Hydraulic Couplers

Symbols

Portable Power Unit

Tools

Dolly

Lifting Slings

Platform Identification

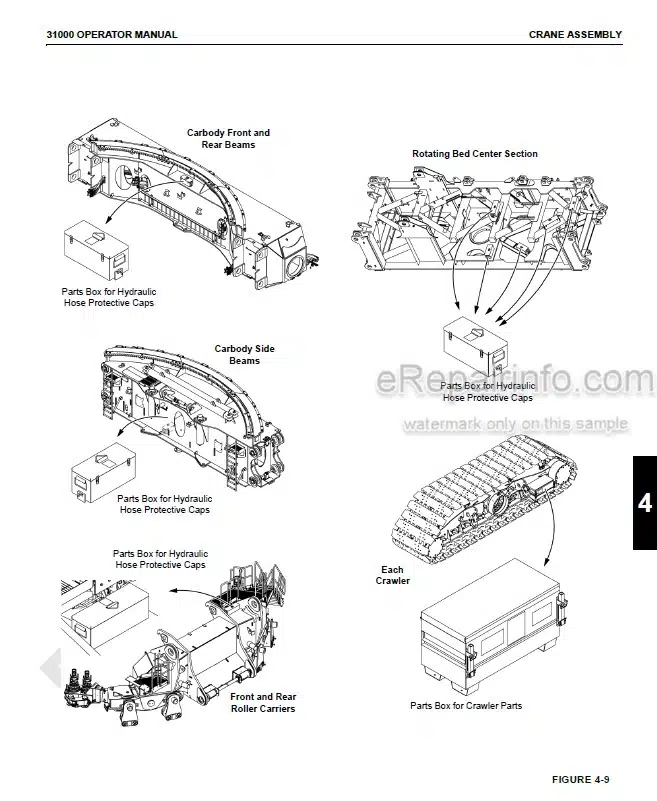

Crane Assembly — Carbody

Crane Assembly — Crawlers

Crane Assembly— Rotating Bed

Crane Assembly— Drums

Crane Assembly — Cab and Power Plant Enclosure

Crane Assembly — Setup Mode

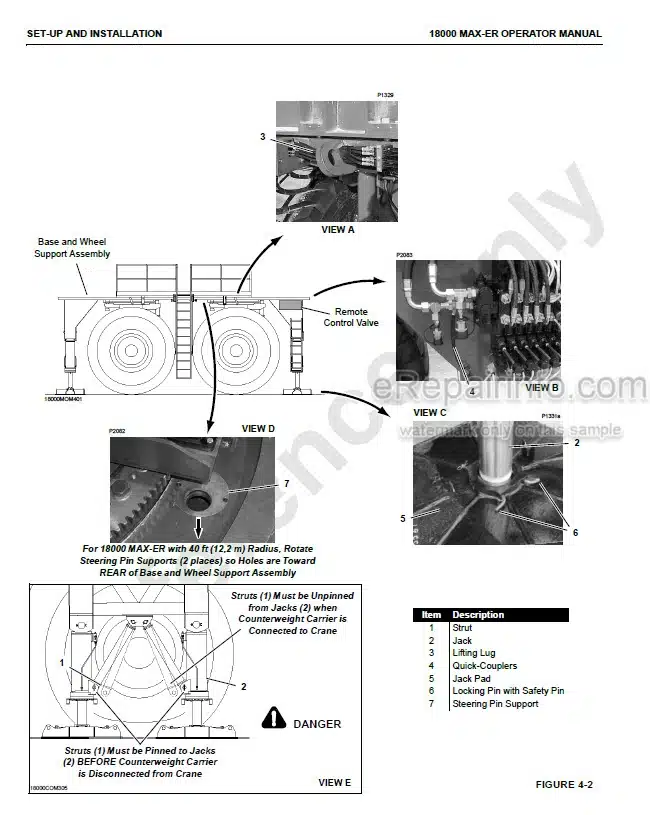

Crane Assembly — VPC Beam Assembly

Crane Assembly— Mast

Crane Assembly — Operating Rigging Winch

Crane Assembly— Backhitch

Crane Assembly — Mast Raising

Crane Assembly — Counterweight

Crane Assembly— Physical Boom Stop

Crane Assembly— Physical Boom Stop Pressure Setting

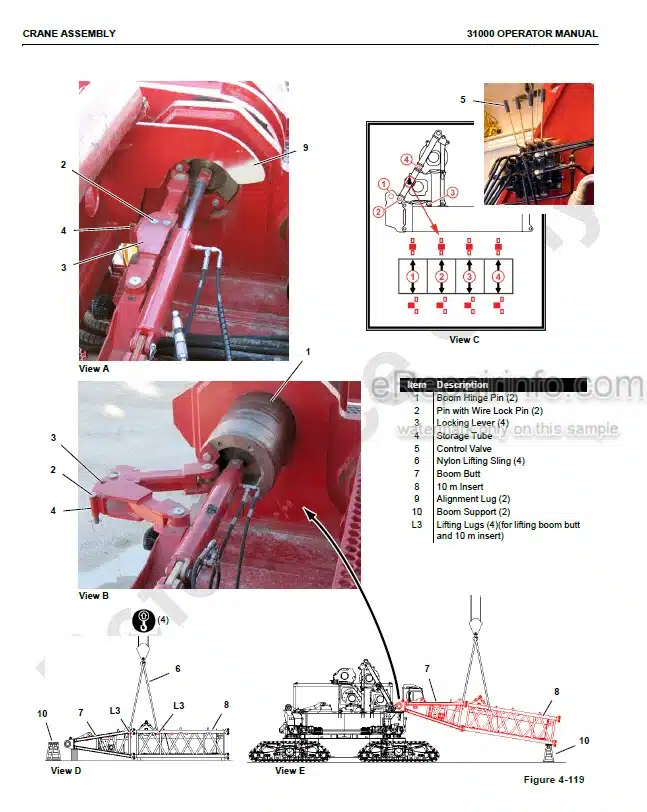

Crane Assembly— Boom Connector Pins

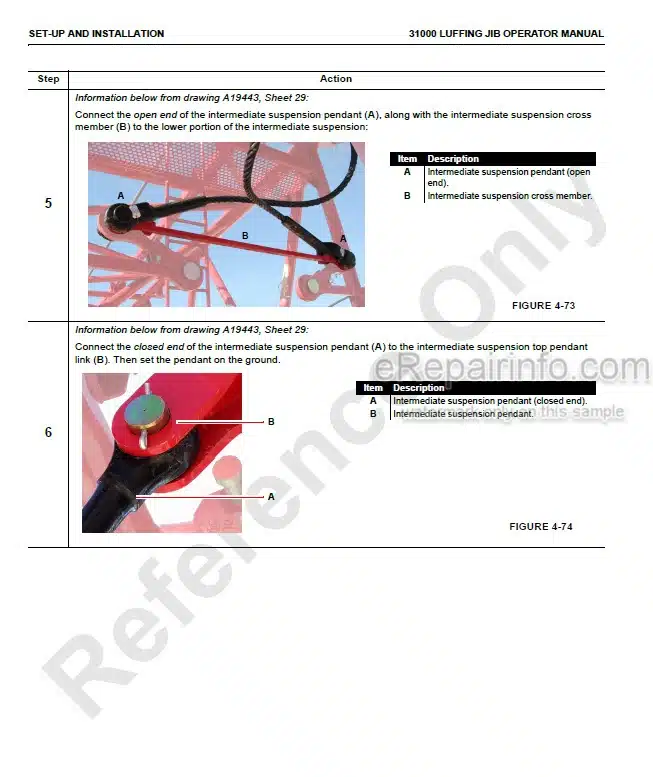

Crane Assembly— Boom

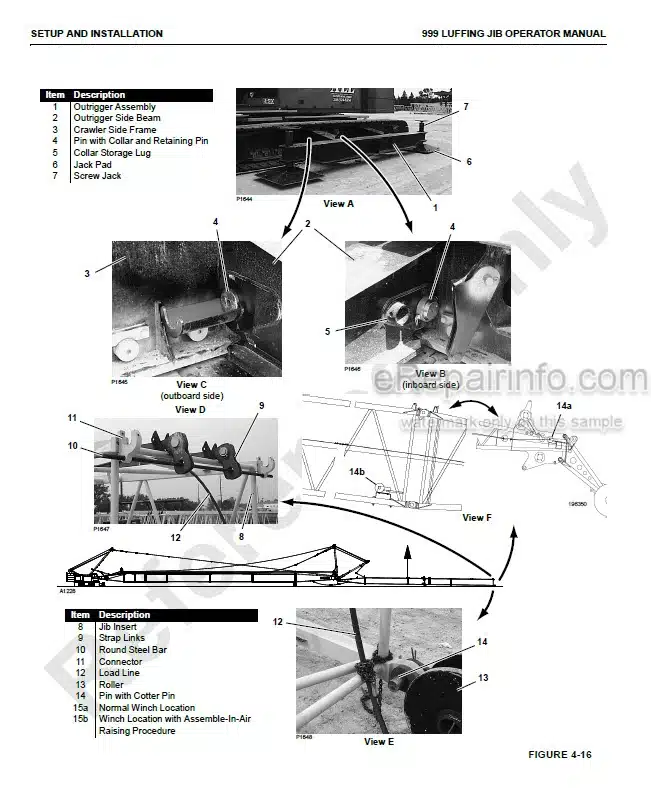

Crane Assembly— Fixed Jib

Pre-Raising Checks

Wire Rope Installation

Hook Block Reeving

Boom Hoist Reeving

Section 4 Inserts

-CRANE DISASSEMBLY

General Safety

Crane Orientation

Rigging Drawings

Disassembly Notes

Disassembly Area

Accessing Parts

Personnel Fall-Protection

Handling Components

Assist Crane Requirements

Aerial Work Platform

Crane Weights

Hose and Cable Cleanliness

Symbols

Portable Power Unit

Tools

Dolly

Lifting Slings

Shipping Data

Shipping Crane Components

Operating Rigging Winch

Setup Mode and Controls

Crane Disassembly—Lowering Procedure

Crane Disassembly— Hook Block and Load Lines

Crane Disassembly— Boom and Jib Point Electronics

Crane Disassembly— Upper Boom Point or Jib Point

Crane Disassembly— Fixed Jib

Crane Disassembly — Connector Pins (Boom and Jib)

Crane Disassembly— Boom

Crane Disassembly — Counterweights

Crane Disassembly— Mast Lowering

Crane Disassembly— Backhitch

Crane Disassembly— Mast

Crane Disassembly — VPC Actuator

Crane Disassembly — Cab and Power Plant Enclosure

Crane Disassembly— Drums

Crane Disassembly — Rotating Bed

Crane Disassembly — Crawlers

Crane Disassembly — Carbody

Suggested Trailer Loadings

-MAINTENANCE CHECKS AND LUBRICATION

Preventive Maintenance Checklist

Lubrication Guide

Fiberglass Maintenance

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet