Factory Service And Maintenance Manual For Manitowoc Crane. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 352

Number: CTRL077-03 (july 2015)

Bookmarks: Yes

Searchable: Yes

Model

Manitowoc Crane

31000

SN 31001Ref

Contents

-INTRODUCTION

Continuous Innovation

Safety Messages

Safe Maintenance Practices

Environmental Protection

Identification and Location of Major Components

General Abbreviations

General Crane Operation

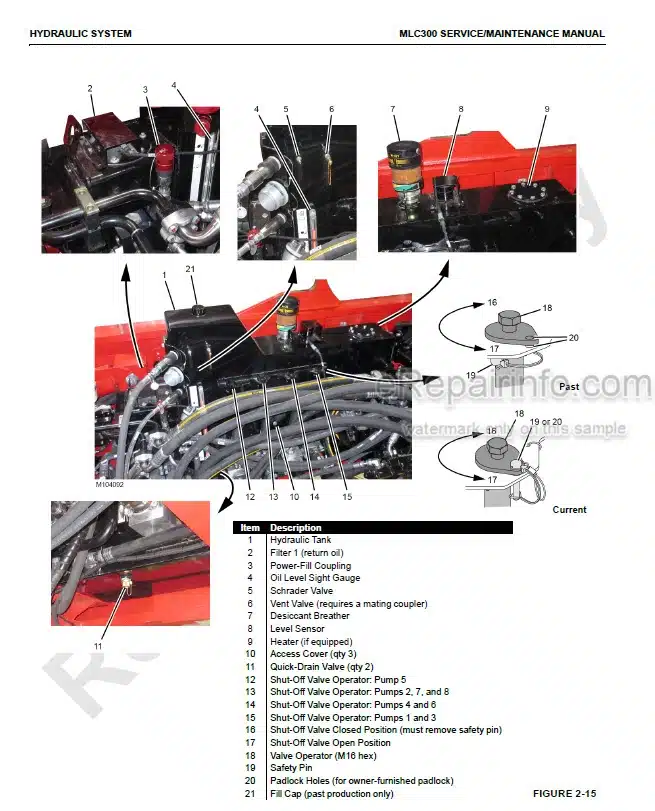

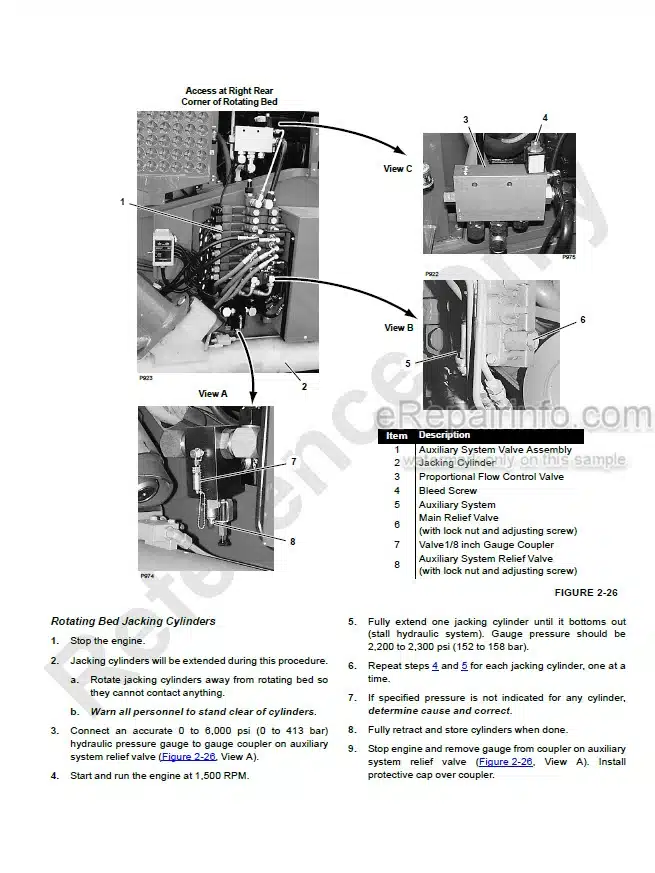

-HYDRAULIC SYSTEM

Hydraulic Schematics

Hydraulic System – General

Checking and Replacing Hydraulic Hoses

Hydraulic System – Maintenance

Hydraulic Solenoid Valve Identification

Inspecting System

Hydraulic Component Identification

Hydraulic System Specifications

Accessory System Checks

Hydraulic System Test, Calibration, and Adjustment Procedures

Section 2 Inserts

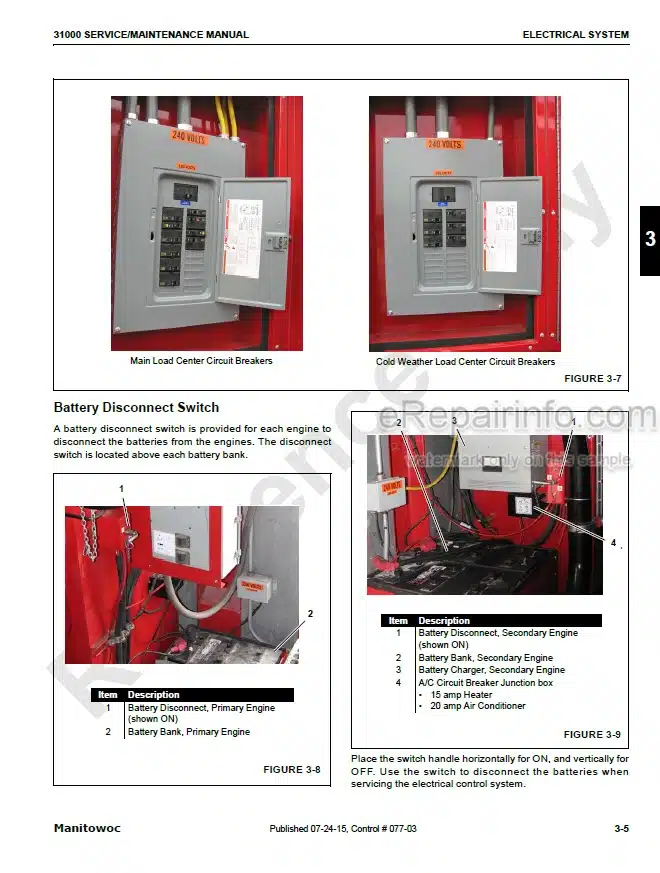

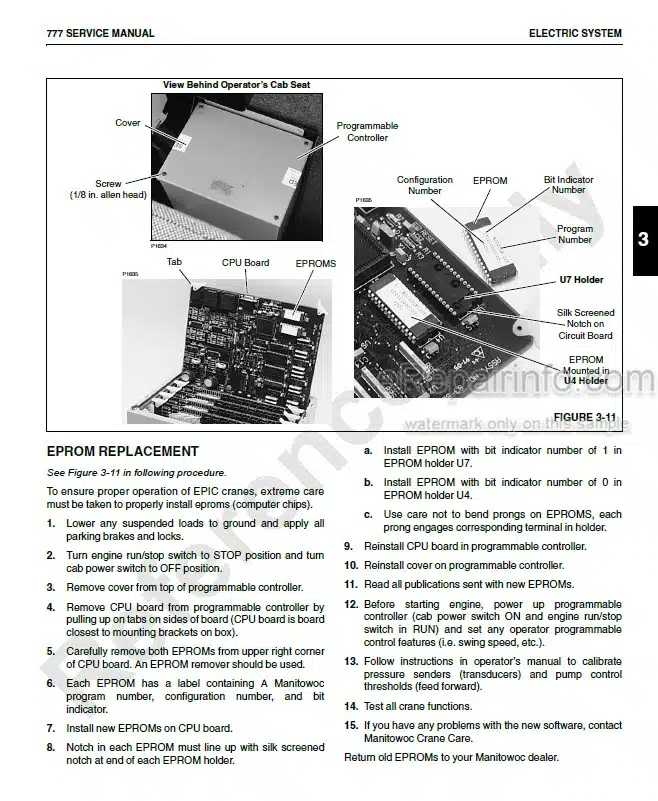

-ELECTRICAL SYSTEM

Electrical Schematics

Checking and Replacing Electrical Components

Circuit Breaker, Junction boxes & Node Locations

Rotating Bed Angle Sensor

Fire Suppression Control Relays

Electrical Control System Overview

Test Voltages

Node Diagnostics (CAN Bus diagnostic Screen)

Checking Electrical Inputs/Outputs

Dielectric Grease

Connector Pin Identification

Section 3 Inserts

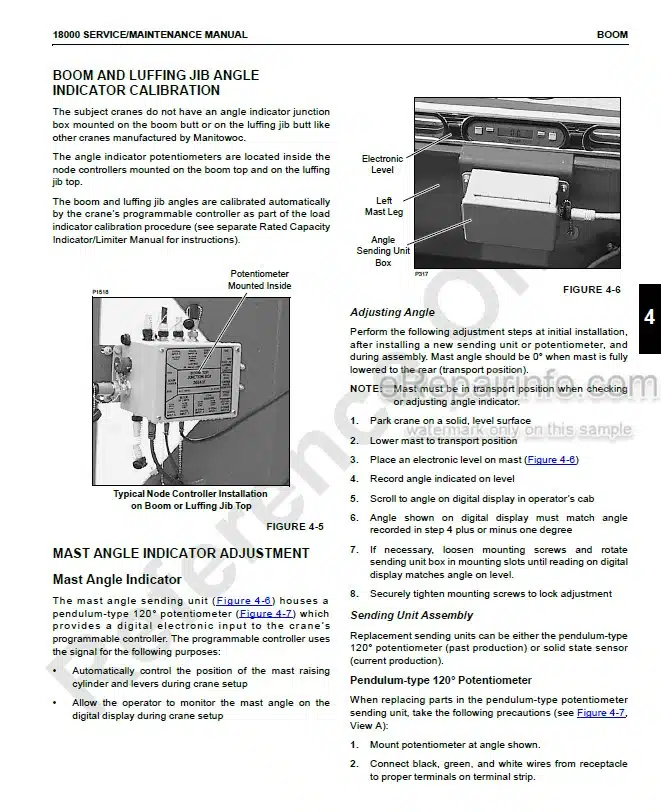

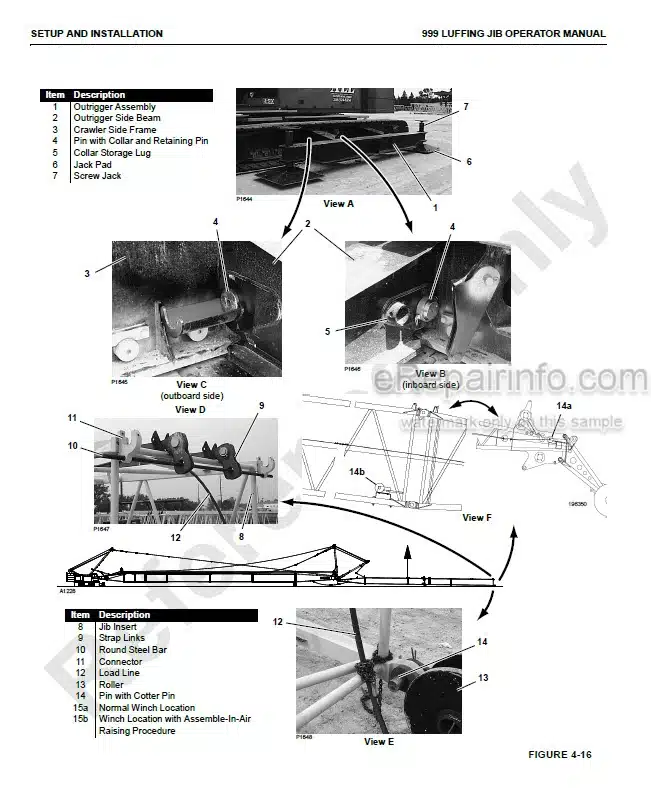

-BOOM

Boom Hoist System Operation

Automatic Boom Stop

Physical Boom Stop

Physical Luffing Jib Stop

Boom and Luffing Jib Angle Sensor Calibration

Actuator Mast Pocket Limit Switch

Removing Upper Boom Point

Boom Components

Upper Boom Point Components

Aircraft Warning Light

Strap Inspection And Maintenance

Boom, Jib, Backhitch, And Mast Inspection/Repair

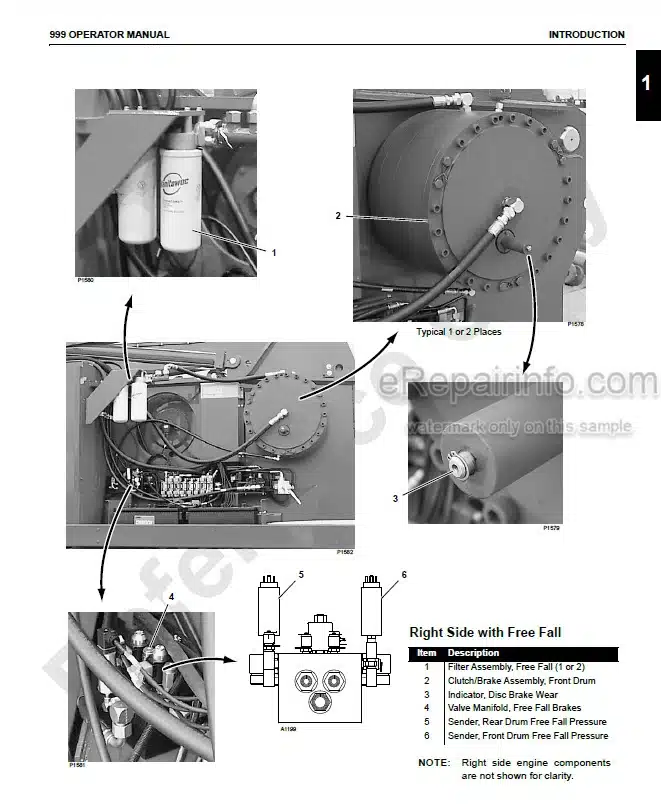

-HOISTS

Main Hoist

Main Hoist (Drum 1) System Diagnostics Overview

Main Hoist (Drum 2) System Diagnostics Overview

Main Hoist (Drum 3) System Diagnostics Overview

Main Hoist (Drum 1) Electrical Circuit

Main Hoist (Drum 2) Electrical Circuit

Main Hoist (Drum 3) Electrical Circuit

Luffing Drum 5 (Optional)

Luffing Hoist (Drum 5) Diagnostics Overview

Luffing Hoist (Drum 5) Electrical Circuit

Load Drum Identification

Drum Guards

Boom/Luffing Hoist Pawl

Speed Sensor

Minimum Bail Limit

Drum Roller Pressure assembly

Block Level Sensor

Block-Up Limit Control

Block-Up Limit Maintenance

Wire Rope Lubrication

Wire Rope Inspection and Replacement

Sheave. Roller. And Drum Inspection

Sheave Inspection Criteria

Load Block And Hook-and-Weight Ball Inspection

-SWING SYSTEM

Swing System Operation overview

Swing System Diagnostics Overview

Swing System Electrical Schematic

Swing System Electrical Schematic (Cont)

Manual Release of Swing Brake

Swing Major Component Identification

Backlash Adjustment

Parallel Adjustment

Ring Gear

Swing Motor Speed Sensor Replacement and Adjustment

Rotating Bed Roller carrier Equalizer Removal

Rear House Roller Load Pin Harness

-POWER TRAIN

Engine Controls Overview

Power Plant Panel Identification

Power Plant Enclosure safety barricade

Power Plant Enclosure Identification

Battery Maintenance

Engine Air Cleaner Maintenance

Engine Clutch Adjustment

Engine Throttle Adjustment

Hydraulic Power Generator

Power Plant Fuel System

Power Plant Cooling System

Mobile Power Washing

Fire Suppression System

Storage and maintenance Access Panels

Section 7 Inserts

-UNDER CARRIAGE

Travel System Operation

Travel diagnostic display

travel electrical schematic

Crawler Adjustment

-VARIABLE POSITION COUNTERWEIGHT (VPC)

General

VPC Component Identification

VPC System Diagnostics Overview

VPC Electrical Schematic

VPC EXT/RET Limit Switch

VPC Secured Limit Switch

VPC Assist Cylinder Cradle Limit Switch

VPC Actuator Seated in the Mast Raising Frame

Pivot Frame Actuator Catch Assembly

Counterweight Beam Limit Switch

VPC Angle Sensors

-ACCESSORIES

Accessory System Components

Operator Cab Heater

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet