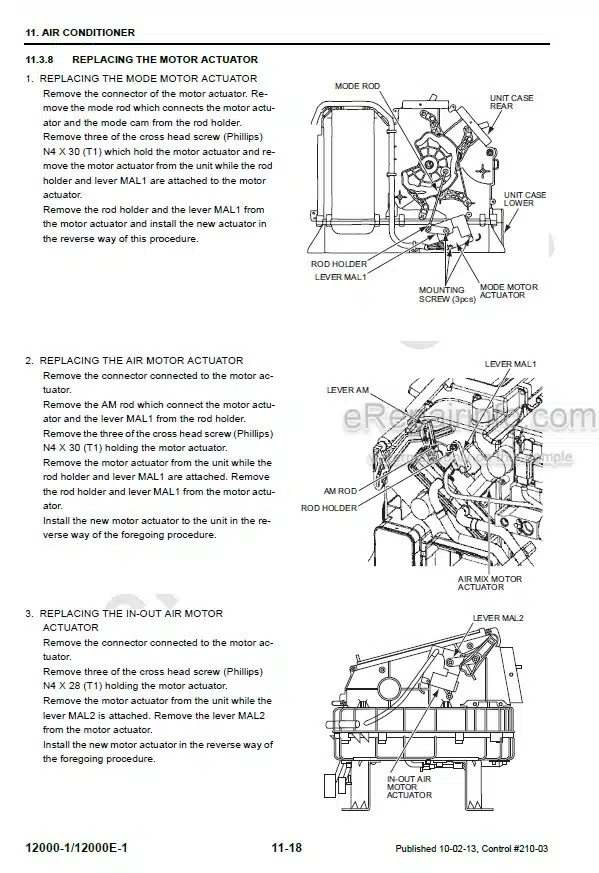

Factory Service And Maintenance Manual For Manitowoc Crane. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 306

Number: CTRL045-08 (october 2012)

Bookmarks: Yes

Searchable: Yes

Model

Manitowoc Crane

777

SN 7771Ref

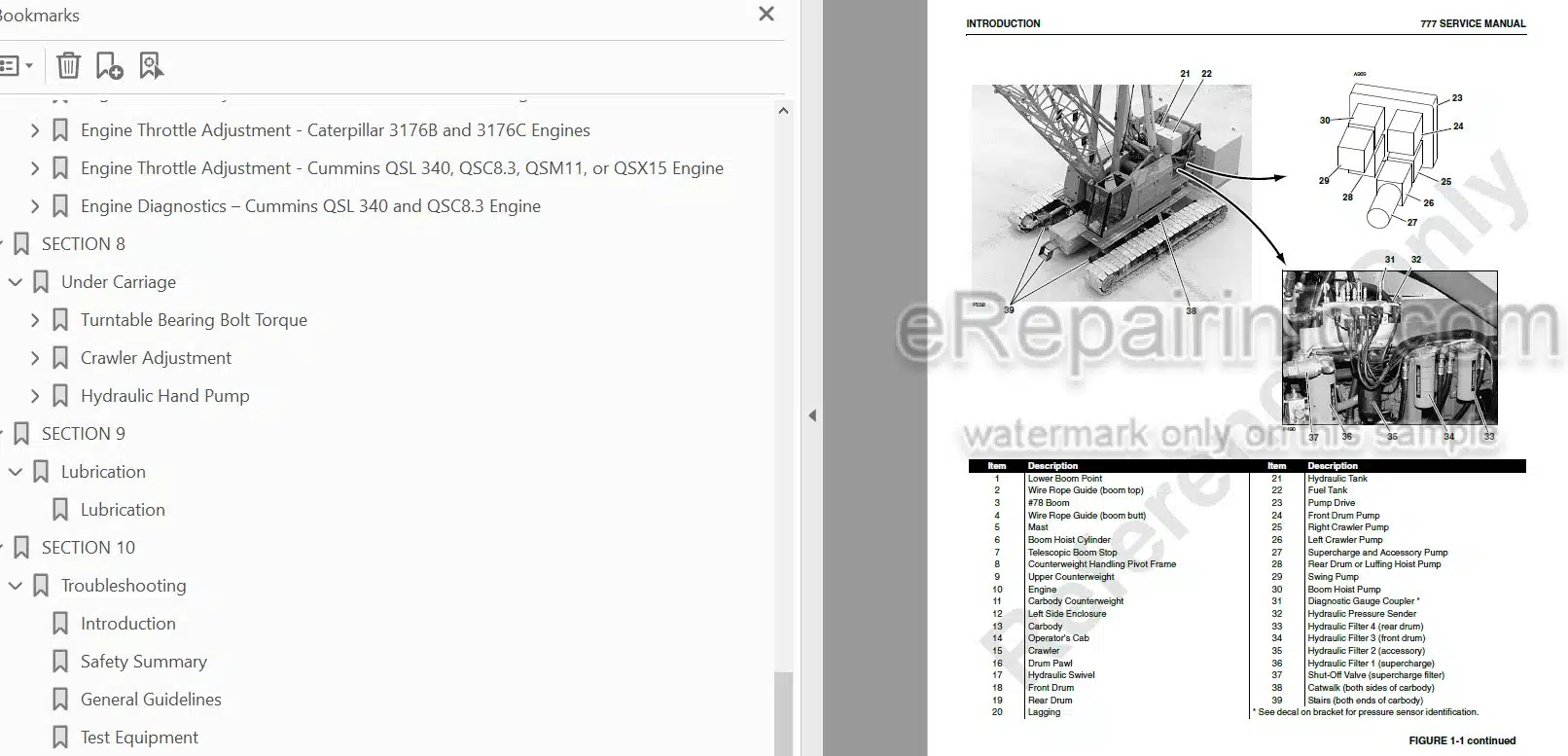

Contents

-INTRODUCTION

Safe Maintenance Practices

Identification and Location of Components

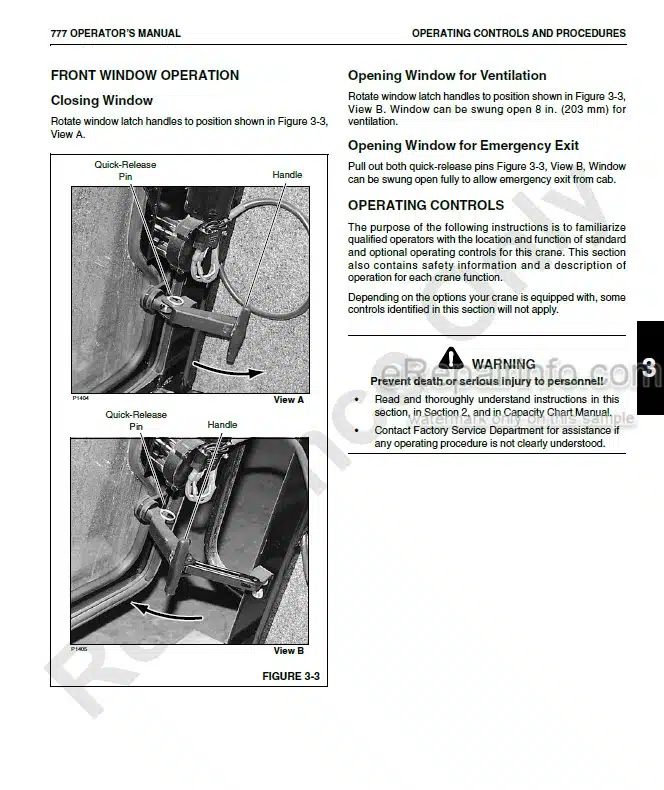

General Operation

Boom System

Swing System

Travel System

Load Drum Pawl

Load Drum (Full Power Mode)

Load Drum (Free Fall Mode)

Crane Setup Systems

Optional Systems

Abbreviations

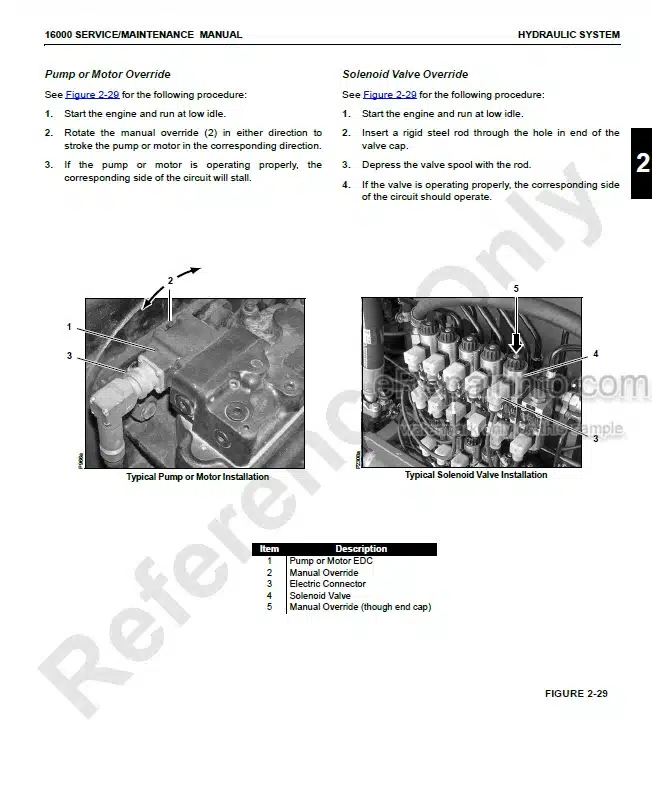

-HYDRAULIC SYSTEM

Hydraulic Schematics

Hydraulic System – General

Checking and Replacing Hydraulic Hoses

Hydraulic System Maintenance

Programmable Controller Calibration Procedures

Pressure Sender Replacement

Disc Brake Operational Test

Shop Procedure

-ELECTRIC SYSTEM

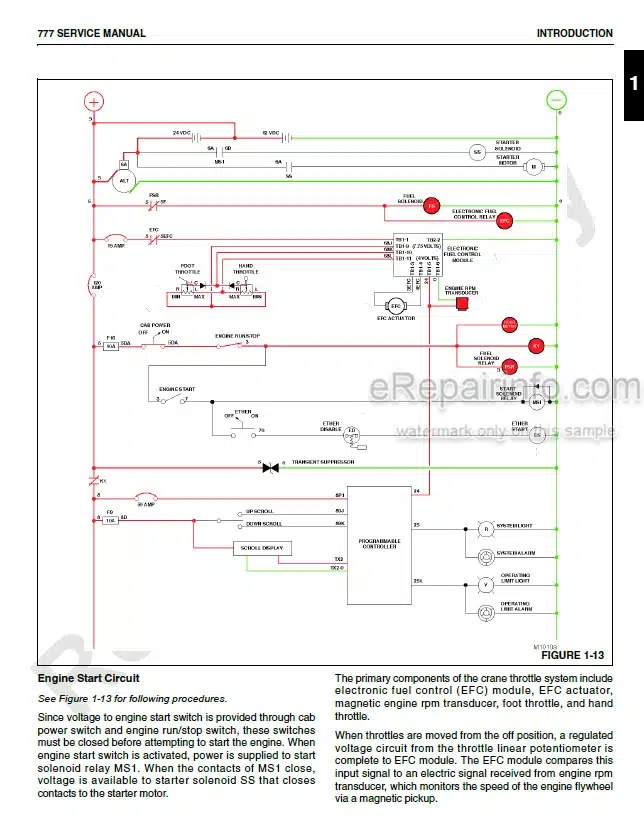

Electrical Drawings and Schematics

Checking and Replacing Electrical Components

Abbreviations and Symbols

Test Voltages

Display Readings

Crane Diagnostics

Crane Software Installation

CPU and Eprom Compatibility

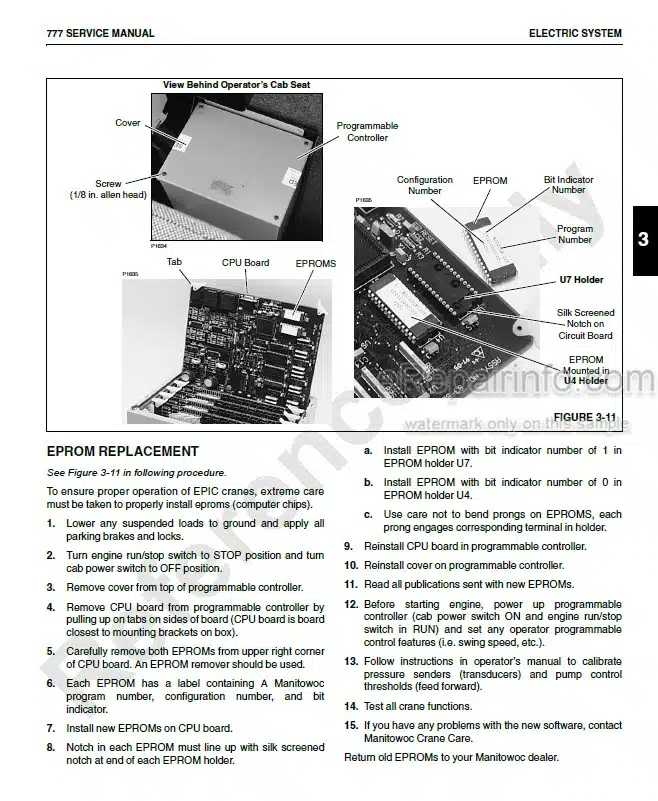

EPROM (Chip) Identification

Eprom Replacement

Counterweight Limit Switch Adjustment

Engine Control Module Ground Modification

Dielectric Grease

Connector Pin Identification

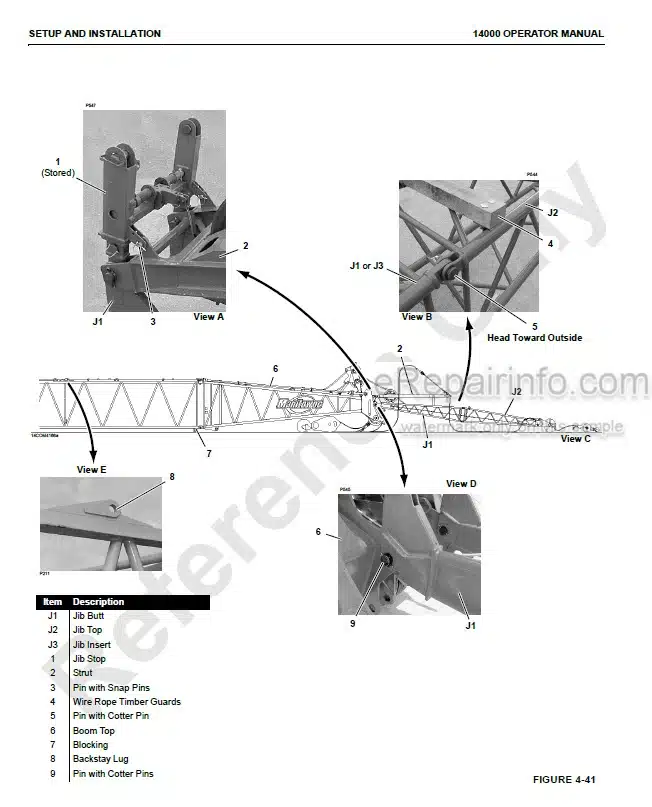

-BOOM

Automatic Boom Stop Adjustment

Physical Boom Stop

Boom Angle Indicator

Servicing Boom Hoist Cylinder

Boom Hoist Cylinders — Welding

Boom and Jib Inspection and Lacing Replacement

Ordering Lacings

Repair Procedure

Inspection Checklist

Record Keeping

-HOISTS

Hoist Drawings

Minimum Bail Limit Adjustment

Block-Up Limit Installation and Adjustment

Drum Brake Adjustment

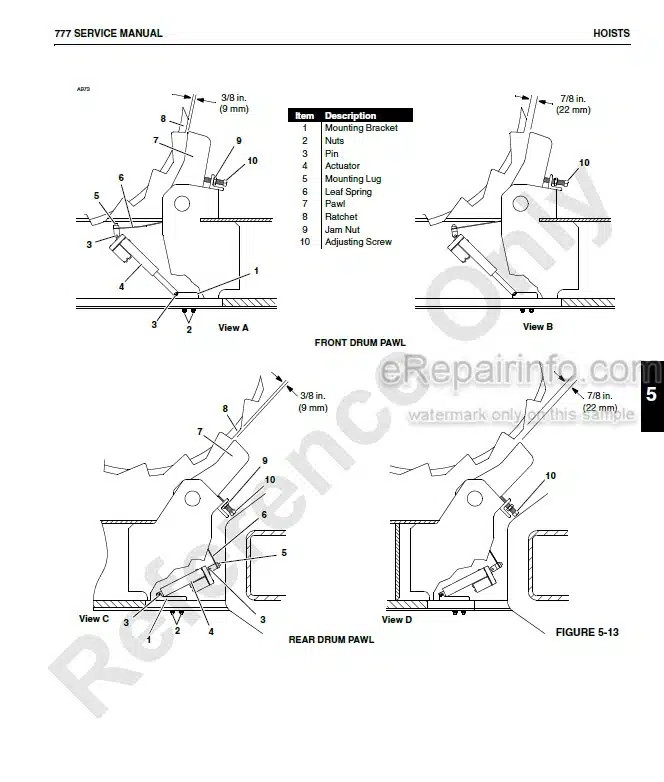

Drum Pawl Adjustment

Drum Pressure Roller Adjustment

Wire Rope Lubrication

Wire Rope Inspection and Replacement

-SWING

Manual Release of Swing Brake and Lock

-POWER TRAIN

Battery Maintenance

Engine Air Cleaner Maintenance

Engine Clutch Adjustment

Engine Throttle Adjustment – Cummins C330

Engine Throttle Adjustment – Cummins 6CTA8.3-C260 Engine

Engine Throttle Adjustment – Caterpillar 3176B and 3176C Engines

Engine Throttle Adjustment – Cummins QSL 340, QSC8.3, QSM11, or QSX15 Engine

Engine Diagnostics – Cummins QSL 340 and QSC8.3 Engine

-UNDER CARRIAGE

Turntable Bearing Bolt Torque

Crawler Adjustment

Hydraulic Hand Pump

-LUBRICATION

Lubrication

-TROUBLESHOOTING

Introduction

Safety Summary

General Guidelines

Test Equipment

Troubleshooting Charts

Testing

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet