Factory Service And Maintenance Manual For Manitowoc Crane. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 330

Number: CTRL235-13 (march 2020)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Manitowoc Crane

MLC300

SN XXXXXRef

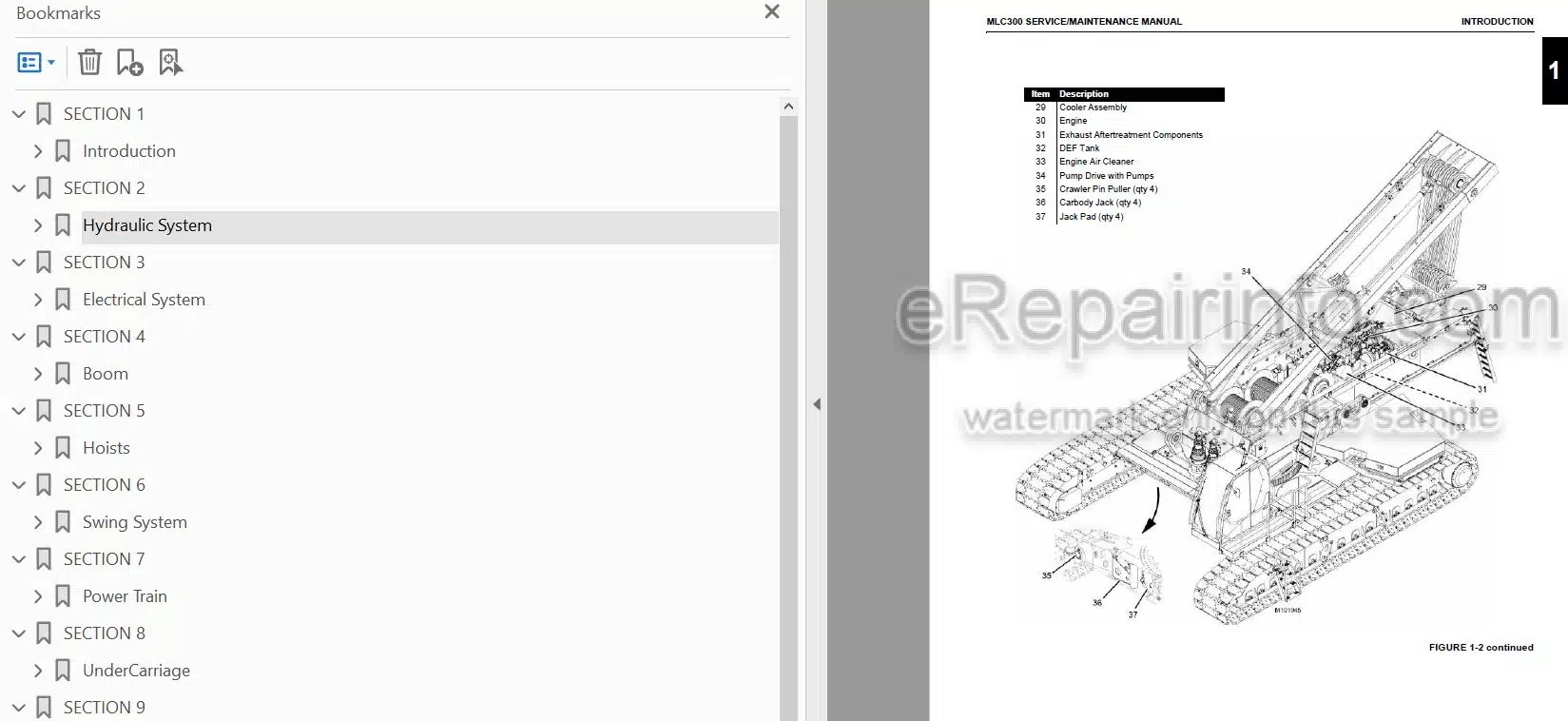

Contents

-INTRODUCTION

Continuous Innovation

Safety Messages

Safe Maintenance Practices

Protection of the Environment

Identification and Location of Major Components

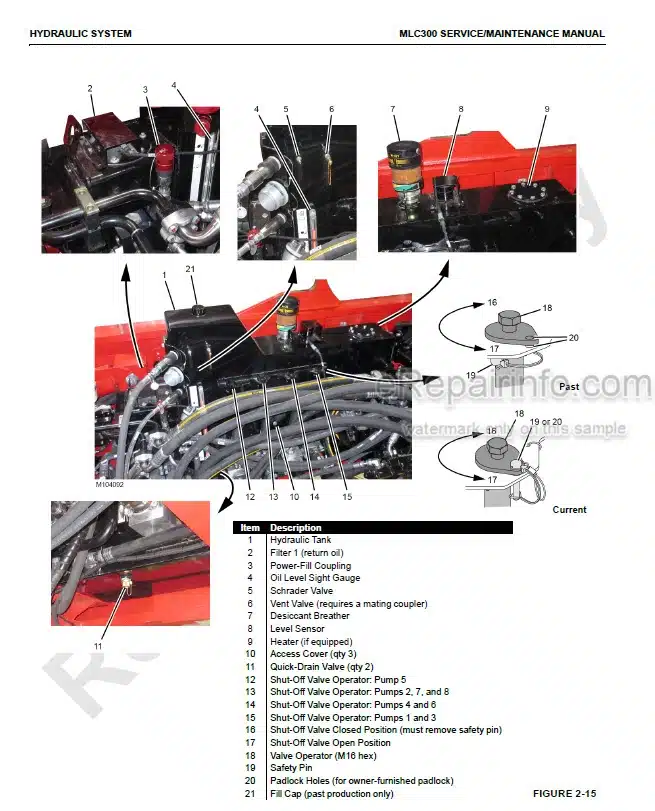

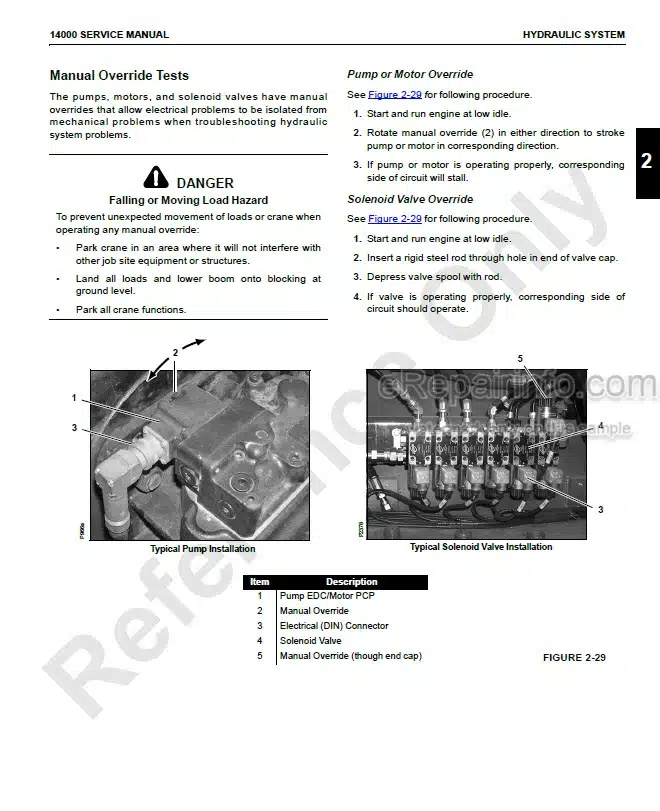

-HYDRAULIC SYSTEM

Hydraulic System Overview

Hydraulic System Maintenance

Replacing Pressure Transducers

Shop Procedures

Hydraulic Tests and Calibrations

Disc Brake Operational Test

Free Fall Brake Operational Test

Accumulator Maintenance

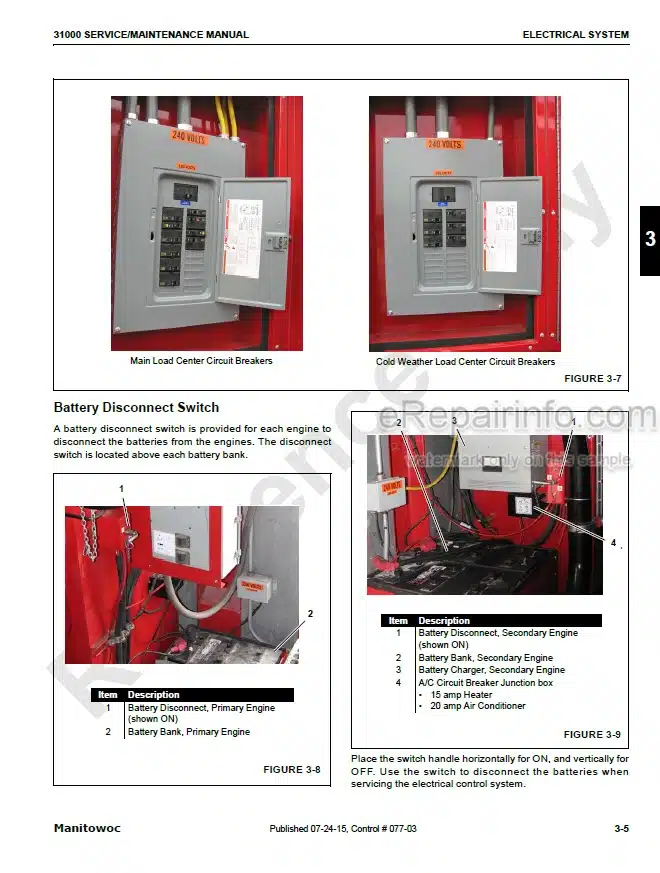

-ELECTRICAL SYSTEM

Electrical Drawings and Schematics

Electrical Power Sequence

Circuit Breakers, Fuses, and Relays

Inspect Electrical Components

CAN Bus Control System

-BOOM

General Maintenance

Boom and Luffing Jib Angle Indicator Calibration

Boom Stop Limit Switch

Automatic Luffing Jib Stop Adjustment and Maintenance

Fleeting Sheave Maintenance

Boom Electrical Schematic

Luffing Jib Electrical Schematic

Strap Inspection and Maintenance

Lattice Section Inspection and Lacing Replacement

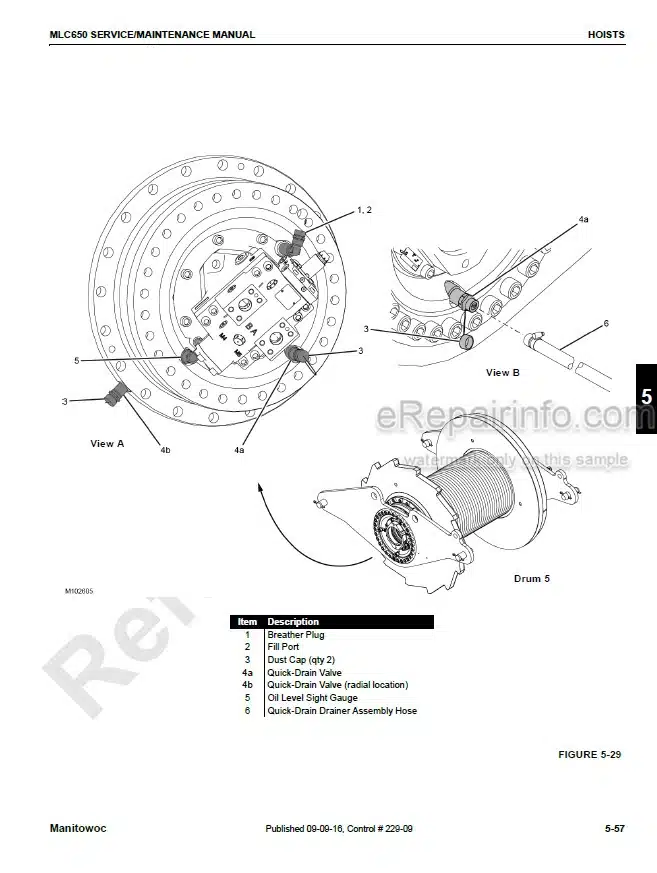

-HOISTS

General

Drum Identification

Drum 1—Main Hoist

Drum 2—Auxiliary Front Hoist

Drum 3—Auxiliary Rear Hoist

Drum 4—Boom Hoist (VPC) or Mast Hoist (VPC-MAX)

Drum 5—Boom Hoist (VPC-MAX)

Drum 6—Auxiliary Hoist

Drum Gearbox Oil Change

Drum 4 Pawl

Drum 5 Pawl

Drum 6 Pawl

Drum 1 Minimum Bail Limit

Drum 2/3 Minimum Bail Limit (non-free Fall Drum)

Drum 2/3 Minimum Bail Limit (Free Fall Drum)

Drum 6 Minimum Bail Limit

Speed Sensor—Hoist Motors

Block Level

Block-Up Limit Installation and Adjustment

Wire Rope Inspection and Replacement

Sheave. Roller, and Drum Inspection

Load Block and Hook-and-Weight Ball Inspection

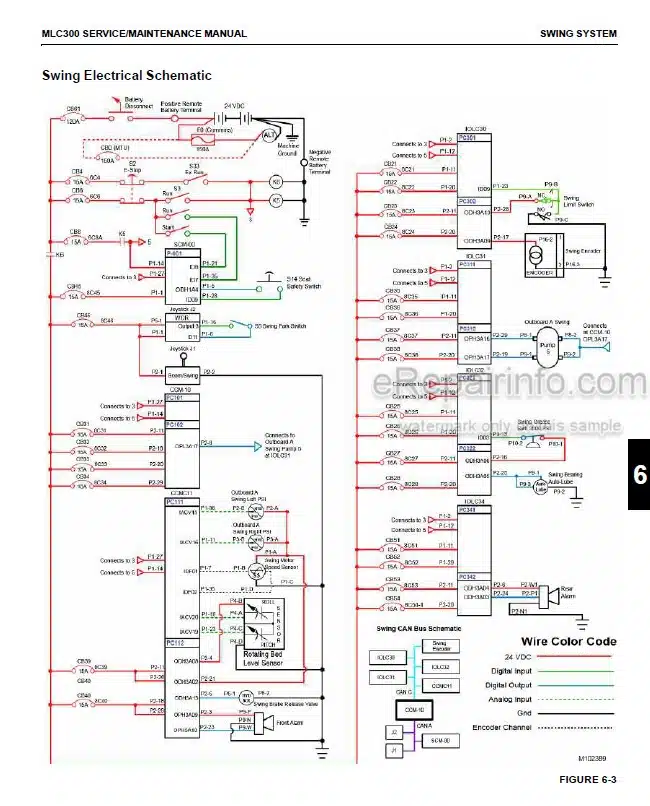

-SWING SYSTEM

General

Swing System Overview

Swing Brake Operation

Swing Operation

Swing Brake Manual Release

Swing Gearbox Oil Change

Swing Motor Speed Sensor

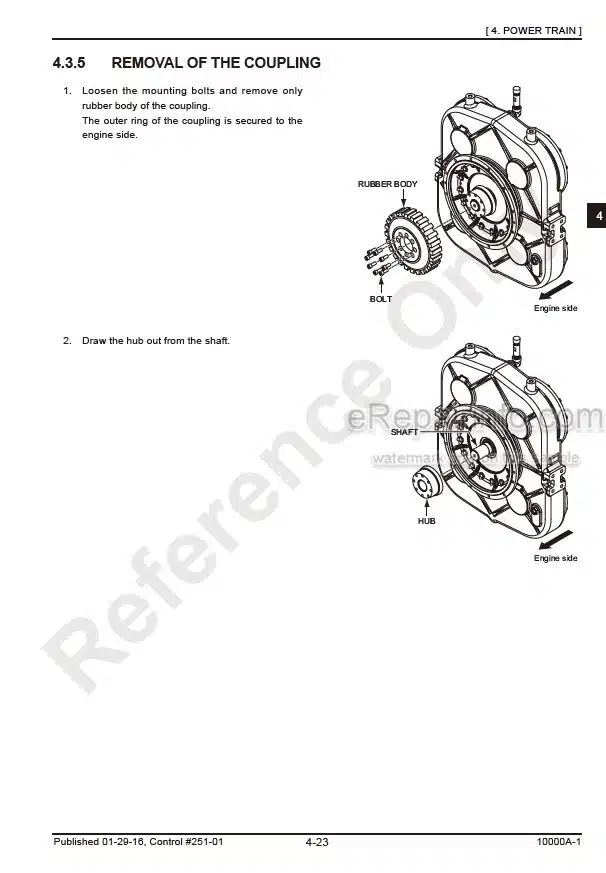

-POWER TRAIN

Batteries

Battery Disconnect Switch

Battery Charger (optional)

Engine Controls

Engine Enclosure

Engine Component Identification

Engine Belt Routing

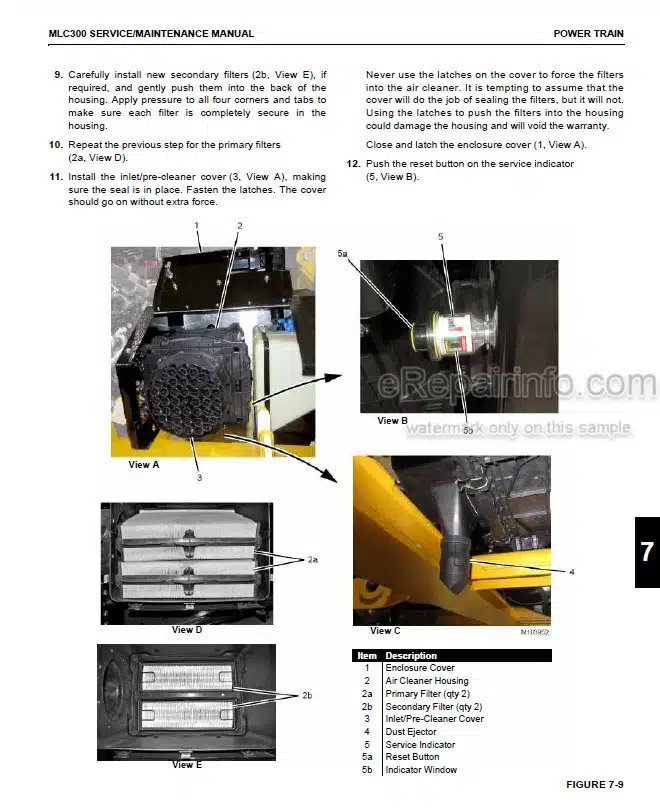

Air Cleaner Maintenance

Replacing the Fuel Filter—MTU

Replacing the Fuel Filter—Cummins QSG12 Engine

Engine Radiator

Changing the Pump Drive Oil

Engine Clutch Maintenance

Adjusting the Engine Throttle

Engine Electrical Schematic

Exhaust Aftertreatment System

-UNDERCARRIAGE

General

Hydraulic Travel System

Travel Motor Case Flushing

Carbody Jacks

Crawler Pins

Carbody Track Tension Cylinders

Crawler Preventive Maintenance

Crawler Tread Slack Measurement

Crawler Tread Slack Adjustment – Past Production

Crawler Tread Slack Adjustment – Current Production

Hydraulic Hand Pump

Turntable Bearing Alignment

Tightening Turntable Bearing Bolt

Replacing Turntable Bolts

Crawler Gearbox Oil Change

-LUBRICATION

Lubrication

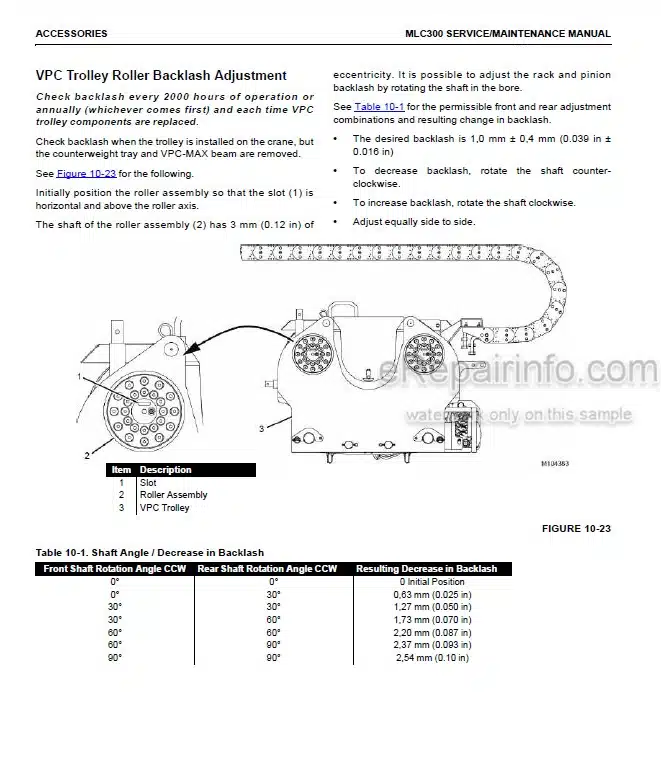

-ACCESSORIES

Warming Circuit

Live Mast Pin Pullers

Gantry Equalizer Pin Pullers

Live Mast Assist Arms

Cab Tilt Cylinder

Rigging Winch (Drum 0)

Boom Butt Pin Pullers

Self-Erect Cylinder

VPC System Operation

VPC-MAX System Operation

Active Fixed Mast Stop System

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet