Factory Service Repair Manual For Massey Ferguson 5400 Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 2110

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

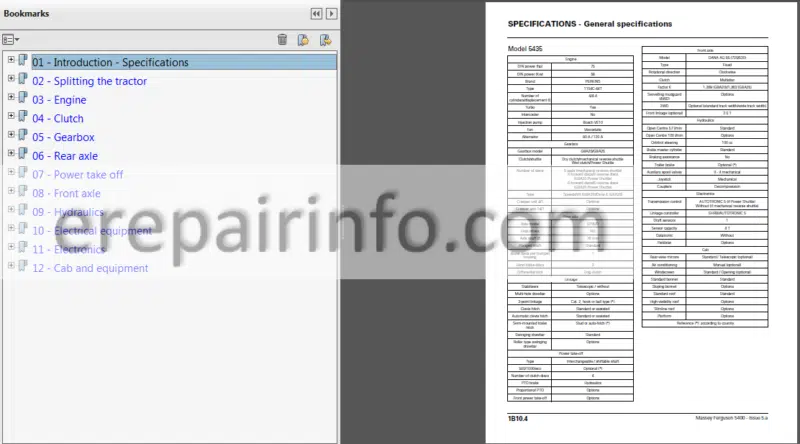

Model

Massey Ferguson 5400

Contents

- -INTRODUCTION – SPECIFICATIONS

Using The Manual

General

Structure Of The Manual

Service Tools

Repairs And Parts Replacement

–SPECIFICATIONS – GENERAL SPECIFICATIONS

General Specifications

–SPECIFICATIONS – FORWARD SPEEDS

Speedshift Models

Dyna 4 Models

–SPECIFICATIONS – DIMENSIONS

General Dimensions And Attachment Points For Speedshift Models

General Dimensions And Attachment Points For Dyna 4 Models

Adjusting Track Widths

–SPECIFICATIONS – CAPACITIES

Capacities: Gba20 Speedshift Models

Capacities: Gba25 Dyna 4 Models

–MISCELLANEOUS

Conversion Tables

Retaining Compounds And Sealing Products - -SPLITTING THE TRACTOR

–SPLITTING – FRONT FRAME / PERKINS ENGINE

-General

Disassembly And Reassembly (6-Cylinder Perkins Engine)

Disassembly And Reassembly (4-Cylinder Perkins Engine)

Shimming The Front Frame (4-Cylinder Perkins Engine)

–SPLITTING PERKINS ENGINE IGTA2020

General

Disassembly And Reassembly (Perkins 4-Cylinder Engine)

Replacing The Input Shaft Seal (Tractors With Dry Clutch)

Disassembly And Reassembly (6-Cylinder Perkins Engine)

Service Tool

–SPLITTING GBA20/GPA20 (CAB FIXED TO CENTRE HOUSING)

General

Disassembly And Reassembly With The Cab Fixed To The Centre Housing CP 2C13 –

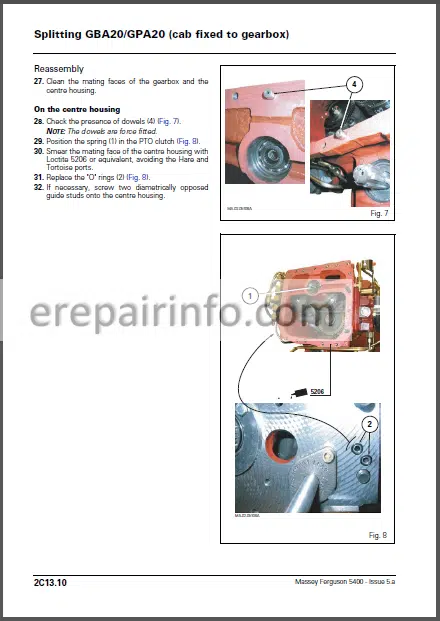

–SPLITTING GBA20/GPA20 (CAB FIXED TO GEARBOX)

General

Disassembly And Reassembly With The Cab Fixed To The Gearbox - – ENGINE

— PERKINS ENGINE – GENERAL

Introduction

Specifications And Standards Relating To Fuel, Oil And Coolant

Main Specifications

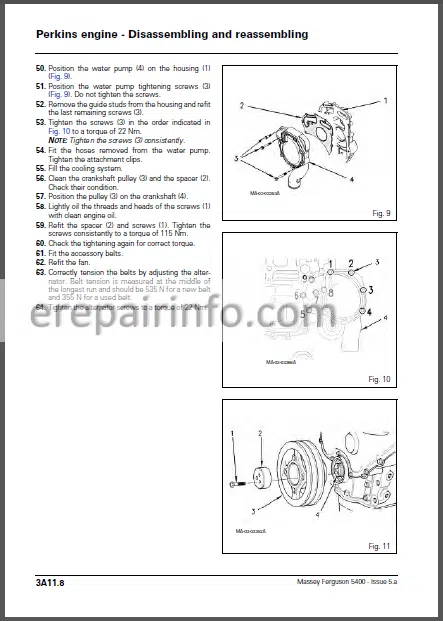

— PERKINS ENGINE – DISASSEMBLING AND REASSEMBLING

General

Removing And Refitting Adjacent Components (4-Cylinder Engine)

Timing The Engine At Top Dead Centre On The First Cylinder (4-Cylinder Engine)

Removing The Injection Pump (4-Cylinder Engine)

Refitting The Injection Pump (4-Cylinder Engine)

Removing And Refitting Adjacent Components (6-Cvlinder Engine)

Timing The Engine (6-Cylinder Engine)

Removing The Injection Pump (6-Cylinder Engine)

Refitting The Injection Pump (6-Cylinder Engine)

Service Tools

— SISU ENGINE – GENERAL

Introduction

Specifications And Standards Relating To Fuel, Oil And Coolant

Main Specifications - – CLUTCH

— DRY CLUTCH – DISASSEMBLING AND REASSEMBLING

General

Operation

Removing And Refitting The Diaphragm Mechanism And Friction Disc

Replacing The Clutch Thrust Bearing

Removing And Refitting The Hydraulic Slave Device Assembly

Replacing The Guide Rings And Piston Seals Of The Hydraulic Slave Device Assembly

Service Tool

— DRY CLUTCH – BLEEDING

General

Preliminary Steps

Bleeding The Clutch System - – GEARBOX

— MECHANICAL REVERSE SHUTTLE – GENERAL – OPERATION

General

Construction And Description

Operation

Specifications Of The Gba20 Transmission Assembly With Mechanical Reverse Shuttle

— MECHANICAL REVERSE SHUTTLE – INPUT UNIT

General

Removing And Refitting The Input Unit

Service Tools

— MECHANICAL REVERSE SHUTTLE – SHUTTLE

General

Operation

Preliminary Steps

Disassembling And Reassembling The Reverse Shuttle

Shimming The Secondary Shaft

Final Steps

— MECHANICAL REVERSE SHUTTLE – SPEEDSHIFT

General

Operation

Preliminary Steps

Removing And Disassembling The Front Cover Plate

Removing, Splitting And Disassembling The Planet Carrier Assembly

Disassembling The Hydraulic Cover Plate

Reassembling The Planet Carrier

Refitting The Hydraulic Cover Plate

Assembling The Planet Carrier

Assembling And Refitting The Front Cover Plate

Extracting And Replacing The Primary Shaft Needle Roller Bearing

Final Steps

— MECHANICAL REVERSE SHUTTLE – SELECTOR COVER PLATE

General

Operation

Removing And Refitting The Cover Plate

Disassembling And Reassembling The Gear Selector And Reverse Shuttle Mechanisms

Assembling And Adjusting The Gear Linkage And Reverse Shuttle Control Cables

— MECHANICAL REVERSE SHUTTLE – SELECTOR RAILS

General

Maintenance Guide

Creeper Gear Fork

Hare / Tortoise Fork And Lock- 1St / 2Nd – 3Rd / 4Th Fork Assembly And Selector Rail

Mechanical Reverse Shuttle Selector – Fork And Selector Rail

Service Tools

— MECHANICAL REVERSE SHUTTLE – OUTPUT SHAFT

General

Preliminary Steps

Disassembling And Reassembling The Selector Rail And The Forks

Disassembling, Reassembling And Shimming The Shaft

Final Steps

— MECHANICAL REVERSE SHUTTLE – LAYSHAFT

General

Preliminary Steps

Disassembling And Reassembling The Shaft

Final Steps

Service Tools

— MECHANICAL REVERSE SHUTTLE – INTERMEDIATE SHAFT

General

Preliminary Steps

Removing And Refitting The Shaft And Gear Assembly

Removing And Refitting The Gears

Replacing The Tapered Roller Bearings Of The Intermediate Shaft

Shimming The Gears

Shimming The Shaft

Final Steps

Service Tool

— POWER SHUTTLE – GENERAL – OPERATION

General

Construction And Description

Operation

Specifications Of The Gba20 Transmission Assembly With Power Shuttle

— POWER SHUTTLE – INPUT UNIT

General

Preliminary Steps

Removal

Refitting

Adjusting The Potentiometer Sensor

Final Steps

Service Tools

— POWER SHUTTLE – SHUTTLE

General

Removing And Refitting The Forward Clutch

Disassembling And Reassembling The Forward Clutch

Shimming The Forward Clutch

Disassembling And Reassembling The Reverse Clutch

Disassembling And Reassembling The Driving Gear And Shimming The Shaft

Service Tools

— POWER SHUTTLE – SPEEDSHIFT

General

Operation

Preliminary Steps

Removing And Disassembling The Front Cover Plate

Removing, Splitting And Disassembling The Planet Carrier Assembly

Disassembling The Hydraulic Cover Plate

Reassembling The Planet Carrier

Refitting The Hydraulic Cover Plate

Assembling The Planet Carrier

Assembling And Refitting The Front Cover Plate

Final Steps

— POWER SHUTTLE – SELECTOR COVER PLATE

General

Operation

Removing And Refitting The Cover Plate

Disassembling And Reassembling The Selector Mechanisms

Fitting And Adjusting The Gear Linkage

— POWER SHUTTLE – SELECTOR RAILS

General

Maintenance Guide

Creeper Gear Fork

Hare / Tortoise Fork And Lock- 1St / 2Nd – 3Rd / 4Th Fork Assembly And Selector Rail

Service Tools

— POWER SHUTTLE – OUTPUT SHAFT

General

Preliminary Steps

Disassembling And Reassembling The Selector Rail And The Forks

Disassembling, Reassembling And Shimming The Shaft

Final Steps

— POWER SHUTTLE – LAYSHAFT

General

Preliminary Steps

Disassembling And Reassembling The Shaft

Final Steps

Service Tools

— POWER SHUTTLE – INTERMEDIATE SHAFT

General

Preliminary Steps

Removing And Refitting The Shaft And Gear Assembly

Removing And Refitting The Gears

Replacing The Tapered Roller Bearings Of The Intermediate Shaft

Shimming The Gears

Shimming The Shaft

Final Steps

Service Tool

— GENERAL – OPERATION

General

Construction And Description

Kinematics Of The Gba25 Gearbox

Synchronisers

Main Gearbox Robotic Control

Disassembly Steps

Transmission Gba25 Specifications

— POWERSHUTTLE

General

Preliminary Steps

Remove And Reinstall The Powershuttle

Removing And Refitting The Powershuttle

Final Steps

Service Implements

— POWERSHIFT MODULE

General

Principles Of Operation

Kinematics

Preliminary Steps

Removing And Refitting The Powershift Module

Removing And Refitting The Powershift Module

Disassembling And Reassembling The Planetary Gears

Final Steps

Service Tools

— ROBOTIC MECHANICAL GEARBOX

General

Principles Of Operation

Description And Kinematics Of Ratios

Preliminary Operations

Removing And Refitting The Primary And Secondary Shafts

Disassembling And Reassembling The Primary And Secondary Shafts

Shimming The Primary And Secondary Shafts In The Housing

Adjusting The Selector Rails And Forks

Adjusting The Interlock Mechanism

Assembling The Intermediate Speed Sensor

Final Operations

Service Tools

— CREEPER UNIT

General

Operation

Removing The Unit And The Ring Gear

Disassembling The Planet Carrier

Reassembling The Planet Carrier, Refitting The Ring Gear And The Unit

Final Steps

Adjusting The Control

— SUPER CREEPER UNIT

General

Kinematics And Operation

Removing/Refitting And Disassembling/Reassembling The Epicyclic Gear Trains

Disassembling And Reassembling The Planet Carriers

Adjusting The Control

General

Operation - – REAR AXLE

— GENERAL – OPERATION

General

Centre housing assembly

— NORMAL DUTY TRUMPET HOUSINGS

General

Trumpet Housing Assembly

Planet Carrier

Bearings And Seals

Preloading The Axle Shaft Bearings

Replacing The Wheel Stud

— HEAVY DUTY TRUMPET HOUSINGS

General

Trumpet Housing Assembly

Planet Carrier

Bearings And Seals

Preloading The Axle Shaft Bearings

Replacing The Wheel Stud

— BRAKE PISTON

General

Disassembly

Reassembly

— HAND BRAKE UNIT AND CONTROL

General

Operation

Disassembly

Reassembly

Assembling And Adjusting The Control

— DIFFERENTIAL

General

Removing The Left-Hand Flange And Differential Lock Assembly

Disassembling And Reassembling The Differential Lock Assembly

Refitting The Left-Hand Flange And The Differential Lock Assembly

Removing The Differential Assembly

Disassembling The Differential Assembly And The Ring Gear

Removing And Disassembling The Pinion

Reassembling The Ring Gear And The Differential Assembly

Adjusting The Taper Distance, Refitting And Shimming The Pinion

Refitting And Shimming The Differential Assembly

Adjusting And Checking The Backlash

Service Tools

— HITCH AND LINKAGE

General

Removal

Disassembly

Reassembly

Refitting

Rear Hitch

Presentation Of The Hitch

Disassembling And Reassembling A Lift Ram

— AUTO-HITCH

General

Presentation Of The Different Hitch Hooks

Adjusting The Auto-Hitch Tie-Rods And The Control

Operating Principle Of The Dromone Retractable Hitch

–REAR WHEELS/HUBS

General

Description Of Rear Axle Wheel Assembly

Changing The Track Width

Replacing A Wheel Stud - – POWER TAKE OFF

— GENERAL – OPERATION

General

Existing Power Take-Off Types

— INTERMEDIATE SHAFT – DRIVING GEARS – BRAKE

General

Operation

2-Speed Pto (Without Shimming)

2-Speed Pto (With Shimming)

4-Speed Economy Pto (Without Shimming)

4-Speed Economy Pto (With Shimming)

Assembling And Adjusting The 4-Speed Economy Pto Control

— REMOVABLE SHAFT

General

Replacing The 540 Or 1000 Rpm Shaft

Removing And Refitting The Rear Bearing

Disassembling And Reassembling The Rear Bearing

Disassembling And Reassembling The 540 And 1000 Rpm Gears And The Front Bearing - – SHIFTABLE SHAFT

General

Layout Of Components And Presentation Of The Different Versions

Removing And Refitting The Rear Bearing

Disassembling And Reassembling The Rear Bearing

Disassembling And Reassembling The 540 Rpm And 1000 Rpm Gears And The Front Shaft Bearing

Controls

Flanged Shaft

Shaft With Reinforced Sealing

— GSPTO

General

Operation

Disassembling The Power Take-Off (2Wd Version)

Reassembling The Power Take-Off (2Wd Version)

Disassembling The Power Take-Off (4Wd Version)

Reassembling The Power Take-Off (4Wd Version)

Assembling And Adjusting The Control

— Clutch

General

Operation

Removing And Refitting The Pto Clutch (2-Speed Version)

Removing And Refitting The Pto Clutch (4-Speed Version)

Disassembling And Reassembling The Clutch

Service Tool - – FRONT AXLE

— DANA – GENERAL

General Description

Specifications And Dimensions

Product Identification

— DANA – FINAL DRIVE UNITS

General

Description Of The Main Components

Removing And Refitting, Disassembling And Reassembling The Planet Carrier, Sun Gear And Ring Gear

Disassembling And Reassembling The Wheel Hub

Replacing A Wheel Stud

Disassembling, Reassembling And Shimming The Swivel Housing

Removing And Refitting The Universal Joint Shaft

Service Tools

— DANA – DIFFERENTIAL

General

Disconnecting The Front Axle/Frame

Removing The Swivel Housings, Wheel Hubs And Transmissions

Removing The Drive Pinion Carrier

Removing The Differential Unit

Removing The Ring Gear – Disassembling The Planet Gears And Sun Gears

Removing The Differential Lock

Removing The Pinion

Adjusting The Position – Shimming And Refitting The Pinion

Refitting The Differential Lock

Reassembling Planet Gears And Sun Gears – Refitting The Ring Gear

Refitting And Shimming The Differential Unit

Piston Tightness Test

Refitting The Drive Pinion Carrier

Refitting Swivel Housings, Wheel Hubs And Transmissions

Assembling The Front Axle / Frame

Service Tools

— DANA – BEARING AND TRANSMISSION SHAFT

General

Removing And Refitting The Bearings

Replacing The Friction Rings And The Seal

— 4WD GPA20 CLUTCH

General

Operation

Removing The Clutch Assembly

Disassembling The Clutch

Reassembling The Clutch

Refitting The Clutch Assembly

Makeshift Tools

— CARRARO – GENERAL

General Description

Specifications And Dimensions

Product Identification

— CARRARO – Final drive units

General

Dismantling The Steering Ram Assembly

Disassembling The Final Drive Unit

Disassembling The Wheel Hub

Dismantling The Axle Beam Assembly

Reassembling The Axle Beam Assembly

Reassembling The Wheel Hub Assembly

Reassembling The Final Drive Assembly

Wheel Alignment

Adjusting The Steering Angle

Service Tools

— CARRARO – DIFFERENTIAL

General

Splitting The Front Axle / Frame

Removing The Wheel Hubs, Axle Beam Assembly And Steering Ram

Dismantling The Differential Housing Assembly

Dismantling The Pinion Assembly

Dismantling The Differential Assembly

Refitting The Pinion Assembly

Reassembling The Differential Unit

Refitting The Differential Housing Assembly

Service Tools

— CARRARO – BEARING AND TRANSMISSION SHAFT

General

Disassembling And Reassembling The 4Wd Transmission Shafts And The Universal Joint Spiders

Removing And Refitting The Bearing Support And Front Axle

Replacing The Friction Rings And Seal

— 4WD GPA20 CLUTCH

General

Operation

Removing The Clutch Assembly

Disassembling The Clutch

Reassembling The Clutch

Refitting The Clutch Assembly

Makeshift Tools

— 2WD FRONT AXLE

General

Disassembling And Reassembling The Wheel Hub

Removing And Refitting The Stub Axle And Its Support

Disassembling And Reassembling The Stub Axle Support

Removing And Refitting The Front Axle

Disassembling And Reassembling The Pivot Bearings

Removing And Refitting The Ram Pivot And The Steering Ram

Disassembling And Reassembling The Steering Ram

Wheel Alignment

Service Tools

— 2WD FRONT AXLE, 6-CYLINDER ENGINE

General

Removing And Refitting The Steering Rod

Removing And Refitting The Hub, The Stub Axle And The Telescopic Arm

Removing And Refitting The Steering Ram

Removing And Refitting The Front Axle

Wheel Alignment

Adjusting Track Widths - -Hydraulics

—- DESCRIPTION OF OPEN CENTRE SYSTEM (OC 57 L/MIN)

General

Low-Pressure System, Low Flow Rate

Layout Of The Main Speedshift And Power Shuttle System Components

Layout Of The Main Speedshift And Mechanical Reverse Shuttle System Components

High-Pressure System, High Flow Rate

Mechanical Reverse Shuttle And Speedshift Diagram

Power Shuttle And Speedshift Diagram

— DESCRIPTION OF OPEN CENTRE SYSTEM (OC 100 L/MIN)

General

System Schematic Diagrams

Low-Pressure System, Low Flow Rate

High-Pressure System, High Flow Rate

Pump Suction System

Layout Of The Main Speedshift And Power Shuttle System Components

Layout Of The Main Speedshift And Mechanical Reverse Shuttle System Components

100 L/Min Open Centre Hydraulic System Diagrams

— DESCRIPTION OF LOAD SENSING SYSTEM

General

Principle Of The Load Sensing System

Lubrication System Of The Dyna-4 And Gearbox

Rear Axle Lubrication System

Gearbox Low-Pressure System (20 Bar)

Layout Of The Main Components In Low And High-Pressure Systems

Diagrams

— OC 57 L/MIN HYDRAULIC TESTS

General

High Flow Rate System

Low Flow Rate System

— OC 100 L/MIN HYDRAULIC TESTS

General

High Flow Rate System

Low Flow Rate System

— LOAD SENSING HYDRAULIC TESTS

General

High Pressure System

Low Pressure System (20 Bar)

Cooling And Lubrication System

Suspended Front Axle Hydraulic Tests

Checking The Pressure Of The Front Axle Accumulators

Bypasses Used

— RIGHT-HAND COVER PLATE (OC 57 L/MIN)

General

Identification Of Channels And Ports

Removing And Refitting The Cover Plate

Disassembling And Reassembling The High Pressure Valve

Disassembling And Reassembling The Cover Plate

Removing And Refitting The Pump

Disassembling And Reassembling The Pump

Adjusting The Engine Speed Sensor

— RIGHT-HAND COVER PLATE (PC 100 L/MIN)

General

Removing And Refitting The Cover Plate

Disassembling And Reassembling The High Pressure Valve

Disassembling And Reassembling The Cover Plate

Removing And Refitting The Pump

Disassembling And Reassembling The Pump

Adjusting The Engine Speed Sensor

— LOAD SENSING RIGHT-HAND COVER PLATE

General

Identification Of Channels And Ports…

Removing And Refitting The Cover Plate

Description And Operation Of The Variable Displacement Pump

Removing And Refitting The Pump

Adjusting The Engine Speed Sensor

Priority Block

— LEFT-HAND COVER PLATE (OC 57 L/MIN)

General

Removing And Refitting

— LEFT-HAND COVER PLATE (PC 100 L/MIN)

General

Removing And Refitting The Cover Plate

Disassembling And Reassembling The Cover Plate

Removing And Refitting The Pump

Disassembling And Reassembling The Pump

— LOAD SENSING LEFT-HAND COVER PLATE

General

Identification Of Channels And Ports

Removing And Refitting The Cover Plate

Removing And Refitting The Charge Pump

Replacing The Pump Seals

— UNASSISTED BRAKE MASTER CYLINDERS

General

Layout Of Hydraulic Lines

Practical Maintenance Advice

Single-System Master Cylinders (Without Trailer Brake)

Double-System Master Cylinders (With Trailer Brake)

Adjusting Brake Pedals

Bleeding The Main Brake System

Bleeding The Trailer Brake System

— ASSISTED BRAKE MASTER CYLINDERS

General

Layout Of Hydraulic Lines

Practical Maintenance Advice

Brake Master Cylinders

Fte Valve

Adjusting Brake Pedals

Bleeding The Main Brake System

Bleeding the trailer brake system

— TRAILER BRAKING – BOSCH VALVE

General

Removing And Refitting The Brake Spool Valve

Operation, Trailer Brakes Released And Partial Braking

Partial And Maximum Trailer Braking

Version Without Trailer Braking

— LOAD SENSING TRAILER BRAKING

General

Identification Of 110 L/Min Load Sensing Ports

Spool Operation

Removing And Refitting The Braking Unit

Plug Torques In The Event Of Maintenance On The Spools

— LINKAGE SPOOL VALVE (OC)

General

Layout Of Components And Identification Of Ports

Neutral Position

Lifting Position

Lowering Position

Lowering Position

Security Valve

Removing And Refitting The Spool Valve

— LOAD SENSING LINKAGE SPOOL VALVE

General

Layout Of Components And Identification Of Ports

Removing And Refitting The Spool Valve Block

Diagram

Neutral Position

Lifting Position

Lowering Position

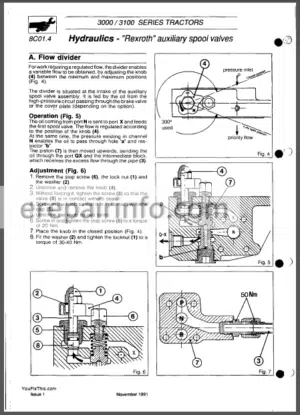

— OC AUXILIARY SPOOL VALVE

General

Layout Of Channels And Ports

Operating And Adjusting The Flow Divider

Removing And Refitting Spool Valves

3-Position Spool Valve, Se/De With Return To Neutral By Spring

3-Position Spool Valve, Se/De With Automatic Return To Neutral

3-Position Se/De Spool Valve With Non-Return Valve And Automatic Return

4-Position De Spool Valve, With Automatic Return To Neutral And Floating Position

Fitting And Adjusting A Control Cable

— AUXILIARY LOAD SENSING SPOOL VALVES

General

Operation

Layout Of Components And Identification Of Ports

Diagram

Spool Valve Assembly

Assembly Procedure

Fitting And Adjusting The Control Cables

–17 BAR VALVE

General

Description Of The 17 Bar Low Pressure Valve

Removing And Refitting, Disassembling And Reassembling The 17 Bar Valve

Adjusting The 17 Bar Valve

Operation Of The Cooling System

Assembling The 5 Bar Valve

Description Of The 1.5 Bar Lubricating Valve

Removing And Refitting, Disassembling And Reassembling The 1.5 Bar Valve

— POWER SHUTTLE CONTROL UNIT

General

Presentation Of The Control Unit And Hydraulic Lines

Power Shuttle Control

Speedshift Control

Explanation Of Speedshift Ratios

Removing And Refitting The Control Unit - – ELECTRICAL EQUIPMENT

— ELECTRICAL DIAGRAMS – CAB EQUIPMENT

General

Cab equipment

— ELECTRICAL DIAGRAMS – ENGINE EQUIPMENT

General

Engine equipment

— ELECTRICAL DIAGRAMS – TRANSMISSION

General

Transmission

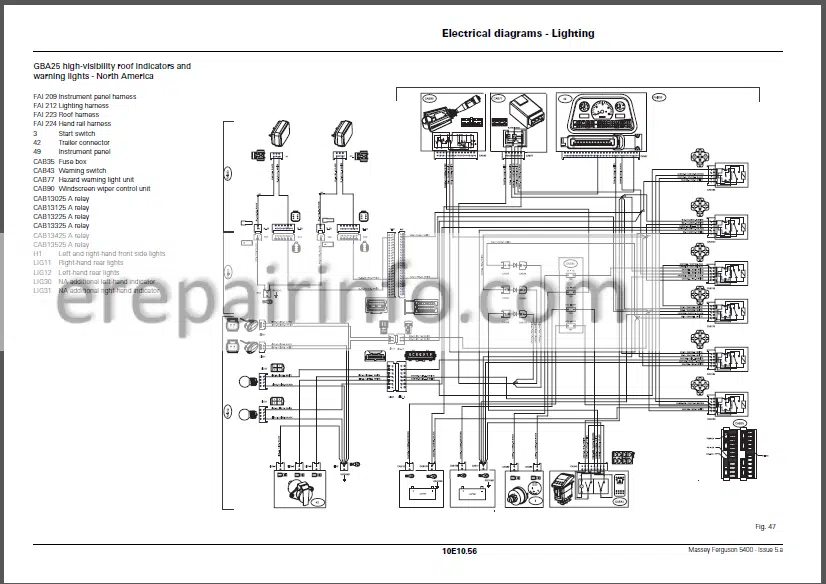

— ELECTRICAL DIAGRAMS – LIGHTING

General

Types Of Bulb

Lighting

— ELECTRICAL DIAGRAMS – POWER SUPPLY TO ELECTRONIC BOXES

General

Controller Power Supply

-Electronics

— ELECTRONIC INJECTION – PERKINS – PROGRAMMING

Configuration

Programming

— PERKINS ELECTRONIC INJECTION – TESTS AND DIAGNOSTICS

Tests and diagnostics

— PERKINS ELECTRONIC INJECTION – ERROR CODES

Reading Error Codes

List Of Error Codes

Reaction Of The System When An Error Code Occurs

Reaction Of The System When An Error Code With An Event Occurs

— PERKINS ELECTRONIC INJECTION – ELECTRICAL DIAGRAMS

Perkins Engine Harness

General Tractor With Dcc2

Electrical Diagrams For Tractors With Dcc2

General Tractor Without Dcc2

Electrical Diagrams For Tractors Without Dcc2

— AUTOTRONIC 5 – DESCRIPTION

General

Autotronic 5 Status Flowcharts

Autotronic 5 Connector Pin Allocation

Automatic Responses Of The Autotronic 5

Power Shuttle principles - – AUTOTRONIC 5 – POWER SHUTTLE – PROGRAMMING AND SETTING PARAMETERS

Programming

Saving To A File

Setting Parameters - – AUTOTRONIC 5 – POWER SHUTTLE – TESTS AND DIAGNOSTICS

Autotronic 5 Statuses

Gearbox Function

Power Take-Off Function - – AUTOTRONIC 5 – POWER SHUTTLE – ERROR CODES

Reading Error Codes

List Of Error Codes

Analysing Components And Their Error Codes

Analysing Other Error Codes - – AUTOTRONIC 5 – POWER SHUTTLE – CALIBRATION AND ADJUSTMENTS

Calibrating The Powershuttle

Adjusting The Powershuttle Progressive Shifting

Adjusting The Manoeuvring Pedal

Calibrating The (Manoeuvring) Clutch Pedal

— AUTOTRONIC 5 – POWER SHUTTLE – ELECTRICAL DIAGRAMS

General

Electrical Diagrams

Layout Of Components

— ELECTRONIC LINKAGE – DESCRIPTION

Description

Console

Electronic Calculator Ehrb Connector Pin Allocation

— ELECTRONIC LINKAGE – TESTS AND DIAGNOSTICS

Electronic Linkage Component Testing And Diagnostics

— ELECTRONIC LINKAGE – ERROR CODES

Reading Error Codes

List Of Error Codes

Analysing Components And Their Error Codes

— ELECTRONIC LINKAGE – ADJUSTMENT

Adjusting The Position Sensor

— ELECTRONIC LINKAGE – ELECTRICAL DIAGRAMS

General

Electrical Diagrams

— AUTOTRONIC 5 – LINKAGE – DESCRIPTION

Description

Console

Autotronic 5 Calculator Connector

— AUTOTRONIC 5 – LINKAGE – PROGRAMMING AND SETTING PARAMETERS

Programming

Saving To A File

Setting Parameters

Table Of Constants

— AUTOTRONIC 5 – LINKAGE – TESTS AND DIAGNOSTICS – MF5400

Autotronic 5 Statuses

Electronic Linkage Functions

— AUTOTRONIC 5 – LINKAGE – ERROR CODES – MF5400

Reading Error Codes

List Of Error Codes

Analysing Components And Their Error Codes

— AUTOTRONIC 5 – LINKAGE – CALIBRATION AND ADJUSTMENTS

Adjusting The Position Sensor

Calibrating The Linkage

— AUTOTRONIC 5 – LINKAGE – ELECTRICAL DIAGRAMS – MF5400

General

Electrical Diagrams

— AUTOTRONIC 5 – DYNA-4 – DESCRIPTION

General

Components Description

Creeper Function

4 Wd Function

Differential Lock Function

Power Take-Off Function

Powershuttle Function

Transmission Function

Allocation Of Autotronic 5 Transmission Controller Pins

— AUTOTRONIC 5 – DYNA-4 – PROGRAMMING AND SETTING PARAMETERS

Programming

Saving To A File

Setting Parameters

— AUTOTRONIC 5 – DYNA-4 – ERROR CODES

Reading Error Codes

List Of Error Codes

Analysing Components And Their Error Codes

Analysing Other Error Codes

— AUTOTRONIC 5 – DYNA-4 – CALIBRATION

Power Shuttle Calibration

Adjusting The Clutch (Manoeuvring) Pedal

— AUTOTRONIC 5 – DYNA-4 – ELECTRICAL DIAGRAMS

General

Electrical Diagrams - – CAB AND EQUIPMENT

— AIR CONDITIONING – GENERAL

General

Schematic Diagram

Technical Specifications

Safety Instructions

General Maintenance

System Troubleshooting

— AIR CONDITIONING – STANDARD

General

Electrical Diagram

— AIR CONDITIONING – REFILLING THE UNIT

Draining The System And Checking For Leaks

Drafting The System And Detecting Leaks

Refilling The Unit (Engine Stopped)

Checking Pressures

Service Tools

— ORCHARD CAB

General

Dimensions And Attachment Points

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Wery good service manual!