Factory Service Repair Manual For Massey Ferguson 8200 Series Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1964

Bookmarks: Yes

Searchable: Yes

Number: 3378177 M1

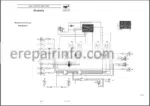

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Massey Ferguson 8200 Series

Contents

- -INTRODUCTION

Introduction - -SPLITTING THE TRACTOR

Splitting The Tractor Between Front Frame / Engine

Splitting The Tractor Between Engine / Gearbox

Splitting The Tractor Between Gearbox / Intermediate Housing

Splitting The Tractor Between Intermediate Housing / Centre Housing

Separating Pto Housing / Centre Housing

Chassis Reinforcements

Rear Wheels / Hubs - -ENGINE

General

Flywheel and dampers

Spacer

Spacer – Power Shuttle - -CLUTCH

Pressure Loaded Clutch - -GEARBOX

General – Operation

Input Unit With Mechanical Reverse Shuttle

Input Unit With Power Shuttle

Dynashift

Mechanical Reverse Shuttle

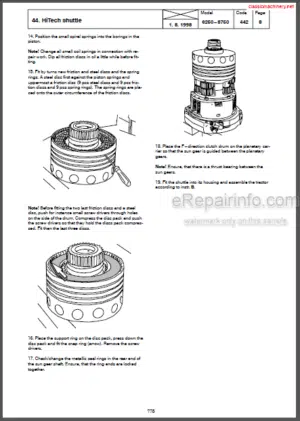

Power Shuttle

Selector Cover

Selector Cover – Optimised Hare / Tortoise Function

Output Shaft

Mainshaft

Layshaft

General

Transmission Hydraulic Circuit

Transmission – Repair

Creeper Unit - -REAR AXLE

Description

Standard Trumpets

Trumpets With Sealed Compartment

Trumpets With Composite Drive Unit

Trumpets With Double Reduction

Handbrake Unit And Control Link

Differential With Standard Bevel Gear And Hydromechanical Lock

Differential With Standard Bevel Gear And Multidisc Lock

Differential With Hypoid Bevel Gear And Multidisc Lock

Brake Pistons And Seals

Park Lock

Lift Cylinder Supports

Creeper

Brackets And Automatic Hook

Rear Hitch Mechanism - -POWER TAKE-OFF

Description Of The Power Take-Off

Driving Pinions – Bearings – Layshaft

Removable Shaft

Shiftable Pto Shaft

1000 Rpm Power Take-Off Shaft

Clutch And Brake - -FRONT AXLE

Generality – Carraro Front Axle

Dana Final Drive Units

Zf Final Drive Units

Carraro Final Drive Units

Dana Differential

Zf Differential

Carraro Differential

2 Wd Front Axle

Steering Column

Bearings And Transmission Shafts (Dana Front Axles)

Bearings And Transmission Shafts (Zf Front Axles)

Bearings And Transmission Shafts (Carraro Front Axle)

4 Wd Clutch

Carraro Suspension

Carraro Troubleshooting - -HYDRAULICS

Description Of The 110 L/Min Circuit

Description Of The 150 L/Min Circuit

Priority Blocks With Trailer Braking

Priority Blocks Without Trailer Braking

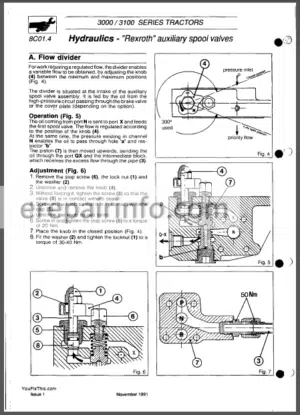

Auxiliary Spool Valves

Bosch Auxiliary Spool Valves

Electro-Hydraulic Spool Valves

Lift Control Spool Valve

Hydrostatic Steering

Hydrostatic Steering For 4Wd Front Axles – Apl5052

Right-Hand Cover 110 L/Min Load Sensing

150 L/Min Right-Hand Cover

Left-Hand Cover 110 L/Min And 150 L/Min Load Sensing

Brake And Clutch Master Cylinders Circuit And Bleeding

Brake And Clutch Master Cylinders Circuit And Bleeding

Clutch Control Valve

Power Shuttle Control Unit

Hydraulic Control Unit – Suspended Front Axle

Dynashift Control

Oil Decontamination

Hydraulic Tests - -ELECTRICAL EQUIPMENT

Electrical Equipment

Deutsch Electrical Equipment - -ELECTRONICS

Description

Checks Without A Tester

Description

Description And Operation

Calibration

Error Codes

Description Of Electronic Linkage

Linkage Auto-Diagnostics

Datatronic

Front Dual Control

Dual Control For Semi-Mounted Implement

Tic For Semi-Mounted Implements

Wintest – General

Autotronic 2 With Wintest

Autotronic 3 With Wintest

TC And Dcc With Wintest

Electronic Linkage With Wintest

Datatronic 2 With Wintest

Joystick With Wintest

Autotronic 3 To Kit Autotronic

Kit Autotronic To Autotronic 3

Carraro Suspension

Description - -CAB AND EQUIPMENT

- -ACCESSORIES

- -SERVICE TOOLS

Service Tools

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet