Factory Service Repair Manual For McCormick GX40 GX45 GX50 Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 462

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

McCormick GX40, GX45, GX50

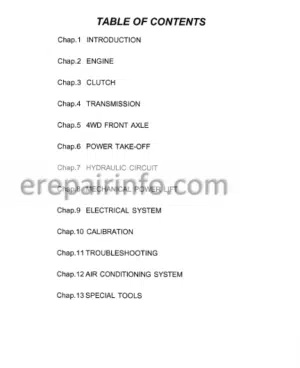

Contents

- INTRODUCTION

LIABILITY

PURPOSE OF THE MANUAL

COPYRIGHT - -GENERAL INFORMATION

SAFETY NOTES

Personal Risk

Avoid Accidents

General Rules

Starting

Engine

Electrical Systems

Hydraulic Circuits

Wheels And Tyres

Splitting And Remounting Parts

GENERAL INSTRUCTIONS

Battery

Adjuster Shims

Spinning Shaft Seals

“O-Ring” Seals

Bearings

Spring Pins

Notes About Spare Parts

Specific Equipment

SYMBOLS

Meaning And Use

DANGER SIGNS

Positions Of The Danger Decals – Weo Markets

Positions Of The Danger Decals – Nao Markets

SEALING AND FIXING SEALANTS

LUBRICANTS AND FUELS

CONVENTIONAL UNITS OF MEASUREMENT

Units Of Measurement (International System)

Conversion Values For Imperial Measurement System

STANDARD DRIVING TORQUE VALUES

Screws With Metric Threads

Nuts With Metric Threads - -ENGINE

GENERAL FEATURES

MAIN SPECIFICATIONS

DRIVING TORQUES

SPECIFIC EQUIPMENT

SECTIONS

LUBRICATION, COOLING AND FUELLING CIRCUIT DIAGRAMS

ENGINE TROUBLESHOOTING

ENGINE SPLITTING AND REMOUNTING

Splitting

Remounting

COMPRESSION TEST

Compression degree

Measuring procedure

ENGINE – OVERHAUL

Demounting

Assembly Of Tappets And Drive Shaft With Main Bearing Caps, Bearings And Bearing Rings

Assembly Of Pistons Complete With Piston Rings, Pins, Connecting Rods, Caps And Bearings

Assembly Of Timing, Lubrication, Starting, Recharging, Cooling And Fuelling Components

Valve Play Adjustment

How To Check The Belt Tension

INJECTOR NOZZLE AND INJECTION PRESSURE MEASURING AND MONITORING

Injection Pressure Measurement

Jet Inspection

Atomizer Valve Sliding Test

Identification Number Of The Atomizer Casing

INJECTION TIMING ADJUSTMENT AND MONITORING

IDLING RATE ADJUSTMENT (MINIMUM AND MAXIMUM)

HOW TO CHECK THE COOLING SYSTEM AND RADIATOR TO FIND LEAKS

SENSOR INSPECTION

Thermostat

Thermal Switch

Hydraulic Switch

CYLINDER HEAD INSPECTIONS, MEASUREMENTS AND REPAIRS

Warping And Inspection Of The Combustion Surfaces

Valve Impression

Valve Housing Width And Angle

Valve Housing Intervention Procedure

Grinding And Milling Tool Use Procedure

Valve Housing Removal

Valve Housing Insertion

Valve Stem Wear And Warping

Valve Stem And Valve Guide

Valve Head Thickness

Valve Guide Replacement

Valve Stem Seal

Valve Spring Inspection

Spring Cap And Cotter Inspection

CRANKCASE AND CYLINDER LINER INSPECTIONS, MEASUREMENTS AND REPAIRS

Crankcase Inspection

Measurement Of Cylinder Liner Bore And Warping

Lapping

ROCKER ARM INSPECTIONS, MEASUREMENTS AND REPAIRS

Measurement Of The Outer Diameter Of The Rocker Arm Pin And Inner Diameter Of The Rocker Arm

Tappet Rod Curve Inspection, Measurement Of The Outer Diameter Of The Tappets And Inspection Of The Contacting Surfaces

Other Inspections

PISTON AND PISTON RING INSPECTIONS, MEASUREMENTS AND REPAIRS

Piston Inspection

Measurement Of The Outer Piston Diameter

Shape Of The Piston Rings

Measurement Of The Groove Width Of The Piston Ring, The Piston Ring And The Distance

Between Ends

Piston Ring Assembly

Measurement Of The Outer Diameter Of The Pin And Relative Hole

CONNECTION ROD INSPECTIONS, MEASUREMENTS AND REPAIRS

Visual Inspection

Twist And Parallelism Measurement

Measurement Of The Bush And Connecting Rod Pin Play

Measure The Play Between The Pin Bush And The Pin Itself

Checking The Connecting Rod Pin Bearing Contact

Mounting The Piston And Connecting Rod

Connecting Rod Side Play

CAMSHAFT INSPECTIONS, MEASUREMENTS AND REPAIRS

Camshaft Float

Visual Inspection Of The Camshaft

Camshaft Incurvation Measurement

Intake/Exhaust Cam Height Measurement

Measurement Of The Play Between The Camshaft Pins

And Their Relative Bushes

DRIVE SHAFT INSPECTIONS, MEASUREMENTS AND REPAIRS

Drive Shaft Float

Checking The Colour Of The Drive Shaft

Bearing Inspection

Drive Shaft Incurvation

Measurement Of The Connecting Rod Pin And Main Bearing

Precautions For Bearing Assembly

GEAR INSPECTIONS, MEASUREMENTS AND REPAIRS

Gear Inspections

Play Measurement

Checking And Measuring The Intermediate Gear Shaft And The Gear Itself

Gear Train

OIL PUMP INSPECTIONS, MEASUREMENTS AND REPAIRS

Play Between The External Rotor And Pump Casing

Play Between Inner And Outer Rotor

Float Between The Pump Casing And The Inner And Outer Rotor

Play Between The Rotor Shaft And Housing Hole

Miscellaneous

YANMAR INJECTION PUMP

How To Bleed Air From The Fuel Circuit

INJECTION PUMP – OVERHAUL

Demounting

Assembly

Plunger Inspection

Delivery Valve Inspection

Plunger Guide, Plunger Cylinder Inspection

Camshaft And Bearing Inspection

Fuel Regulating Pinion And Rack Inspection

REGULATOR UNIT – OVERHAUL

Demounting

Assembly

Checking The Centrifugal Weights Of The Regulator

Regulator Sleeve Inspection

Regulator Lever Shaft Assembly Inspection

Spring Inspection

Checking The Torque Adjuster Spring Assembly

Checking The Torsion Spring Assembly - -CLUTCH

General Specifications Of The Lx 9”/9” Clutch

Driving Torque Values

Specific Equipment

Sections

Troubleshooting For The Clutch Assembly

Where The Sealant Is Applied For The Clutch Housing On The Transmission Housing

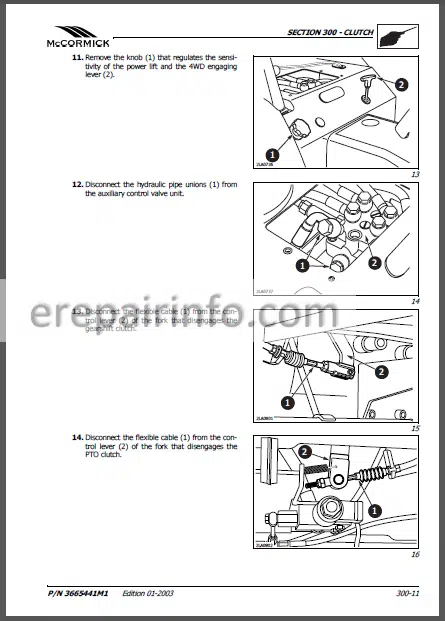

Clutch Splitting-Remounting

Splitting

Remounting

Control Adjustment

Gearshift Clutch

Control Adjustment

Power Take-Off Clutch - -(12 + 12) AND (16 + 16) MECHANICAL GEARBOX

MAIN SPECIFICATIONS OF THE GEARBOX AND FINAL DRIVE

MAIN SPECIFICATIONS OF REVERSE SHUTTLE

MAIN SPECIFICATIONS OF THE SUPPLEMENTARY FINAL DRIVE ( +VERSION)

DRIVING TORQUE VALUES

SECTIONS

DESCRIPTION AND OPERATION

Gearbox And Reverse Shuttle

Supplementary Final Drive (16 + 16 Version)

TROUBLESHOOTING FOR THE GEARBOX, FINAL DRIVE AND REVERSE SHUTTLE

TROUBLESHOOTING FOR THE SUPPLEMENTARY FINAL DRIVE ( VERSION)

WHERE THE SEALANT IS APPLIED FOR THE GEARBOXREAR TRANSMISSION HOUSING

GEARBOX TRANSMISSION HOUSING SPLITTINGREMOUNTING

Splitting

Remounting

GEARBOX TRANSMISSION HOUSING – OVERHAUL

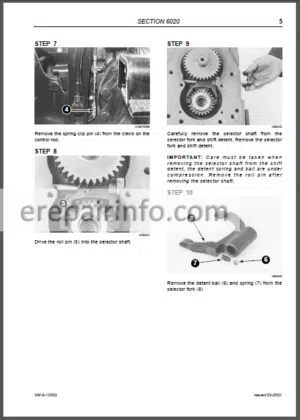

Demounting

Assembly

Main Shaft Float Adjustment

Reverse Shuttle Gear Float Adjustment

CLUTCH HOUSING – OVERHAUL

Demounting

Assembly - -REAR DIFFERENTIAL AXLE

MAIN SPECIFICATIONS OF THE BEVEL GEAR PAIR AND DIFFERENTIAL

DRIVING TORQUE VALUES

SECTIONS

DESCRIPTION AND OPERATION

TROUBLESHOOTING FOR THE BEVEL GEAR PAIR AND DIFFERENTIAL

TROUBLESHOOTING FOR THE SIDE FINAL DRIVES

WHERE THE SEALANT IS APPLIED FOR THE GEARBOXREAR TRANSMISSION HOUSING

REAR TRANSMISSION HOUSINGOVERHAUL

Demounting

Assembly

RIGHT OR LEFT SIDE FINAL DRIVE HOUSING ASSEMBLY SPLITTING REMOUNTING

Splitting

Remounting

DRIVING WHEEL SHAFTOVERHAUL

Demounting

Assembly

BEVEL GEAR PAIR ADJUSTMENT - -FRONT AXLE

MAIN SPECIFICATIONS

DRIVING TORQUE VALUES

SPECIFIC EQUIPMENT

SECTIONS

DESCRIPTION AND OPERATION

Axle Assembly

Differential Lock

TROUBLESHOOTING FOR THE FRONT AXLE DIFF LOCK DEVICE

FRONT AXLE

Splitting

Remounting

FRONT AXLE DIFFERENTIAL AND BEVEL GEAR PAIR SUPPORT

Splitting

Remounting

FRONT BEVEL GEAR PAIR – OVERHAUL

Demounting

Bevel Pinion Bearing Preload

Adjustment Of The Axial Position Of The Bevel Pinion

Pinion – Ring Gear Play Adjustment

Ring Gear Bearing Float Adjustment

FRONT DIFF LOCK – OVERHAUL

Demounting

Assembly

WHEEL HUB – OVERHAUL

Demounting

Assembly

FRONT FINAL DRIVE – SPLITTING REMOUNTING

Splitting

Remounting

FRONT FINAL DRIVE – OVERHAUL

Demounting

Assembly

AXLE STEERING CYLINDER – SPLITTING REMOUNTING

Splitting

Remounting - -POWER TAKE-OFF

MAIN SPECIFICATIONS

DRIVING TORQUE VALUES

SECTIONS

DESCRIPTION AND OPERATION

Power Take-Off Controlled Directly By The Main Clutch

Power Take-Off Synchronized With The Gearbox

TROUBLESHOOTING FOR THE MECHANICALLY ENGAGED POWER TAKE-OFF

WHERE THE SEALANT IS APPLIED ON THE POWER TAKEOFF COVER

MECHANICALLY ENGAGED POWER TAKEOFF OVERHAUL

Demounting

Assembly - -HYDRAULIC CIRCUITS – REAR POWER LIFT

MAIN SPECIFICATIONS – REAR HYDRAULIC POWER LIFT

SPECIFIC EQUIPMENT

SECTIONS AND PERSPECTIVE VIEWS

DESCRIPTION OF THE OPERATING MODE OF THE HYDRAULIC POWER LIFT

Position Control

Draft Control

Mixed Position And Draft Control

Floating Position

DESCRIPTION OF THE OPERATING MODE OF THE HYDRAULIC POWER LIFT’S VALVE SYSTEM

Neutral Phase

Lifting Phase

Discharge Phase

POWER LIFT’S VALVE SYSTEM – OVERHAUL

Demounting

Assembly

VALVE SYSTEM OF THE HYDRAULIC POWER LIFT – HYDRAULIC TESTS

Check For Leaks From The Discharge Valve

Checking And Adjusting The Cylinder Safety Valve

NonReturn Valve Test

Over-Pressure Valve Setting Test

POWER LIFT – ADJUSTMENTS

Sensitivity Adjustment

Draft Control Adjustment

Position Control Adjustment

HYDRAULIC POWER LIFT – OPERATING PRESSURE TEST

Checking The Valve Pressure Setting For The Auxiliary Control Valves - -HYDRAULIC CIRCUITS – AUXILIARY CONTROL VALVES

MAIN SPECIFICATIONS

DESCRIPTION AND OPERATION

Description Of The Circuit

Description Of The Auxiliary Control Valves - -STEERING SYSTEM

MAIN SPECIFICATIONS

SECTIONS AND EXPLODED VIEWS

DESCRIPTION AND OPERATION

Power Steering Circuit Oil Supply

Differential Locking And Unlocking

Reverse Shuttle And Gearbox Lubrication

OPERATING PRESSURE TESTS

Steering Circuit Pressure Test

Checking The Pressure Setting Of The Utility Pressure Governor Valve (16 Bar) - -BRAKES

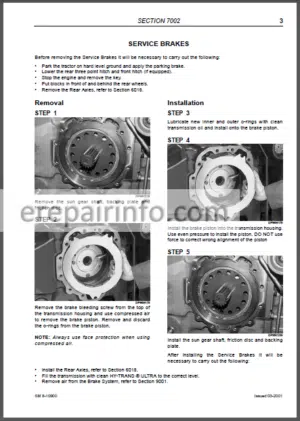

MAIN SPECIFICATIONS

DRIVING TORQUE VALUES

SECTIONS

DESCRIPTION AND OPERATION

Main Brakes

Parking Brake

BRAKE SYSTEM TROUBLESHOOTING

WHERE THE SEALANT IS APPLIED ON THE BRAKE ASSEMBLY AND SIDE FINAL DRIVES ON THE

TRANSMISSION HOUSING

RIGHT OR LEFT BRAKE SPLITTINGREMOUNTING

Splitting

Remounting

ADJUSTMENTS

Adjustment Of The Right And Left Brakes

Parking Brake Hand Lever Travel Adjustment - -ELECTRICAL SYSTEM – INSTRUMENTS

INSTRUMENTS

Warning Light Identification

Instrument Panel

Wiring Diagram Of Indicator Light Panel Interior

Indicator Lights

Rpm Meter And Hour Counter

Fuel Level Gauge

Engine Coolant Temperature Indicator

TRANSMITTERS, SENSORS AND SWITCHES

MAINTENANCE

Warning Light Replacement - -ELECTRICAL SYSTEM – COMPONENTS

CONTROL PANEL WITH ANALOGUE INSTRUMENT

LIGHT SWITCH

Turn Indicators

Driving Beam Blinking Function

Side Lights

Driving/Dipped Beams

Horn

HAZARD LIGHT SWITCH

ROTATING BEAM SWITCH

IGNITION SWITCH

CONTROLS ON THE RIGHTHAND SIDE

DIFF LOCK CONTROL BUTTON

CONTROLS ON THE LEFTHAND SIDE

MAINTENANCE

Headlight Bulbs Replacement

Bulbs In Front Side Lights And Turn Indicators Replacement

Rear Field Light Bulb Replacement

Bulbs In Rear Side Lights, Brake Lights And Turn Indicators Replacement

License Plate Light Bulb Replacement - -ELECTRICAL SYSTEM – IGNITION SYSTEM

TECHNICAL SPECIFICATIONS

DESCRIPTION AND OPERATION

TROUBLESHOOTING

TESTS

Ignition System Test On The Tractor

Power Draw In The Starter Motor Circuit

Resistance In The Ignition System Circuit (Voltage Drop)

Positive Battery Cable

Ground Connection Of The Starter Motor

Battery Ground Cable

STARTER MOTOR SPLITTINGREMOUNTING - -ELECTRICAL SYSTEM – RECHARGING SYSTEM

TECHNICAL SPECIFICATIONS

DESCRIPTION AND OPERATION

Description Of The Alternator

Alternator Operation

TESTS AND TROUBLESHOOTING

Precautions To Take During The Operation

Preliminary Inspections

Initial Tests

Alternator Connection Test

Charge Current And Regulated Voltage Tests

Alternator Component Tests

ALTERNATOR SPLITTING-REMOUNTING - -ELECTRICAL SYSTEM – BATTERY

TECHNICAL SPECIFICATIONS

DESCRIPTION AND OPERATION

BATTERY SPLITTING-REMOUNTING

Splitting

Remounting

MAINTENANCE AND BATTERY INSPECTION

Specific Gravity

Maintenance

Batteries Charged Dry

Battery Charging

Charging Very Discharged Batteries

Tests

COMMON CAUSES OF BATTERY FAULTS - -ELECTRICAL SYSTEM – ELECTRICAL CIRCUITS

ELECTRICAL SYSTEM COMPONENTS

TRACTOR – COMPONENT LOCATIONS

CONTROL PANEL – COMPONENT LOCATIONS

LOCATIONS OF FUSES AND RELAYS

Fuse box

Fuse box location

FUSES

MAXI FUSES

HAZARD LIGHTS AND TURN INDICATOR BLINKERS – NAO PLANT (NORTH AMERICAN MARKETS)

POWER SOCKET – SEVEN-PIN CONNECTION

SYMBOLS USED IN THE ELECTRICAL CIRCUITS

COLOUR CODES OF THE ELECTRICAL WIRES

IDENTIFICATION CODE OF THE WIRING DIAGRAMS AND CONNECTIONS

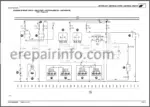

MAIN WIRING AND WIRING DIAGRAMS

MAIN WIRING

MAIN FRONT WIRING (DIAGRAM OF ENGINE AND LIGHTS)

STARTING AND RECHARGING DIAGRAM (DIAGRAM A)

OPERATOR SAFETY DIAGRAM (DIAGRAM B)

DIAGRAM OF SIDE LIGHTS, DRIVING BEAMS, DIPPED BEAMS,

LICENSE PLATE LIGHT AND INSTRUMENT LIGHTING (DIAGRAM C)

DIAGRAM OF HAZARD LIGHTS AND TURN INDICATOR BLINKERS – HORN (DIAGRAM D)

MAIN REAR WIRING

DIAGRAM OF BRAKE LIGHTS – FIELD LIGHT – ROTATING BEACON -DIFFERENTIAL LOCK (DIAGRAM E)

DIAGRAM OF SENSORS AND TRANSMITTERS (DIAGRAM F)

DIAGRAM OF 7-PIN SOCKET, POWER SOCKET (DIAGRAM G)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet