Factory Operation And Maintenance Manual For Mitsubishi Forklift. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 148; 128

Number: 99750-7C131; 99750-7C121

Bookmarks: Yes

Searchable: Yes

Model

Mitsubishi Forklift

FBC15N

SN A4BC1-10200-20199; A4BC1-40200-49999; A4BC1-40200-up

FBC18N

SN A4BC1-20200-30199; A4BC1-50200-59999; A4BC1-50200-up

FBC18LN

SN A4BC1-30200-40199; A4BC1-30200-39999;

FBC20N

SN A4BC2-10200-20199; A4BC2-30200-up; A4BC2-10200-30199; A4BC2-30200-40199

FBC25EN

SN A4BC3-20200-30199; A4BC3-50200-up; A4BC3-20200-40199

FBC25N

SN A4BC2-20200-30199; A4BC2-40200-up; A4BC2-40200-49999

FBC25LN

SN A4BC3-30200-40199

FBC30N

SN A4BC3-40200-50199; A4BC3-60200-up; A4BC3-50200-60199

FBC30LN

SN A4BC4-10200-20199; A4BC4-10200-19999

Contents

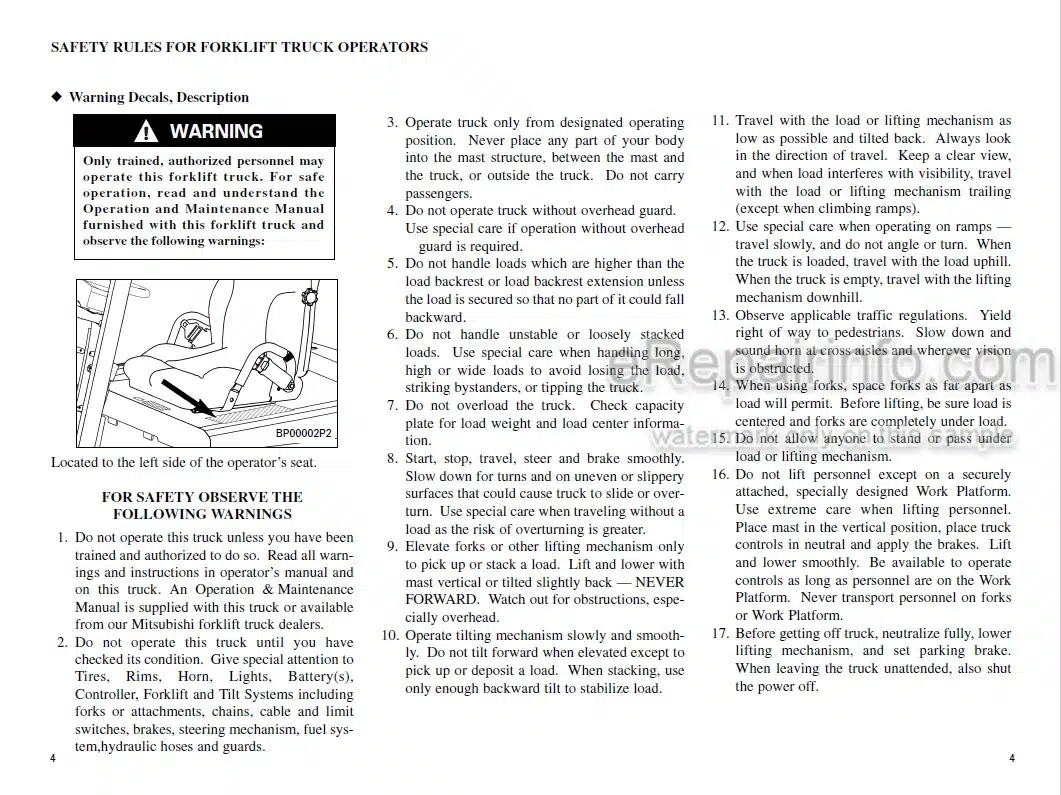

-SAFETY RULES FOR FORKLIFT TRUCK OPERATORS

General

Warning Decals and Description

Safety Rules

Operating Precautions

Working Precautions

-KNOW YOUR FORKLIFT TRUCK

Serial Number And Capacity Plate

Model View

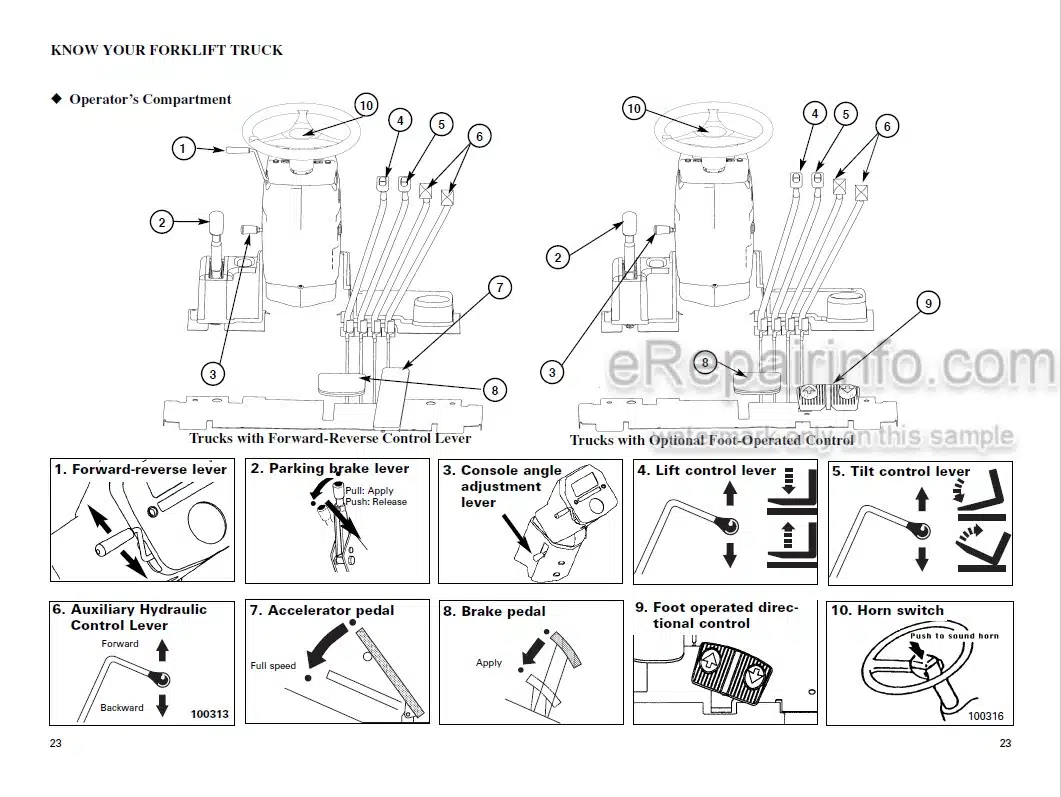

Operator Compartment

Parking Brake Warning Buzzer and Light

Seat Belt Warning Light and Buzzer

Mast Interlock System

Central Vehicle Monitoring System

Operator Seat

Seat Belt

Integrated Presence System

Fuses and Lights

Fork Locking Pins

Replacing Forks

Safety Equipment

Drawbar Pin

Assist Grip and Foot Step

Batten- Cover

Hydraulic Tank Oil Level / Filler Hole

Battery Disconnect

Manual Override

-HOW TO AVOID A TIPOVER; HOW TO SURVIVE ONE

Know What Forklift Truck Stability Is

Center of Gravity

Stability and Center of Gravity (Top View)

Stability and Center of Gravity (Side View)

Forklift Truck Stability Base

Capacity (Weight and Load Center-)

Capacity Plate

Do’s and Don’ts to Avoid Tipover

How to Survive a Tipover

-OPERATION

New Forklift Truck Break-in

Before Starting

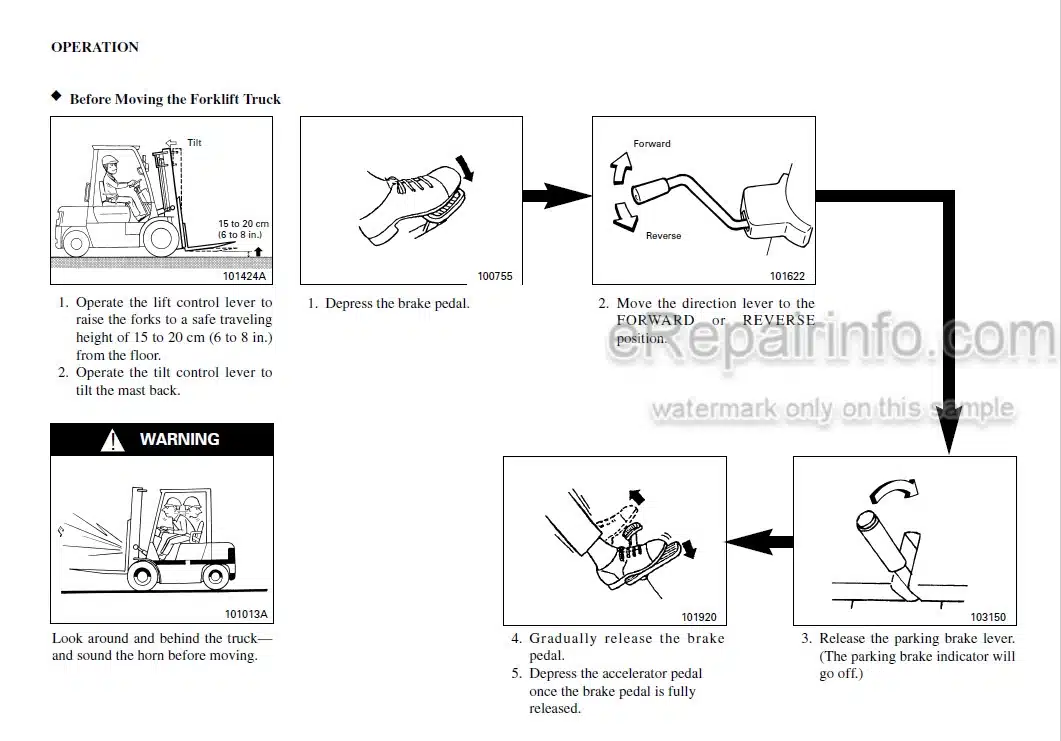

Before Moving Forklift Truck

Forklift Truck Operation

-OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

Lifting the Load

Traveling with the Load

Unloading

Handling Round Objects

Working 011 Grades

-STORING THE FORKLIFT TRUCK

End of Each Shift Storage

Long Term Storage

-TRANSPORTATION HINTS

Forklift Truck Loading and Shipping

Forklift Truck Lifting and Tiedown Information

-SPECIAL SITUATIONS

Special Situations

-MAINTENANCE

General

Maintenance Schedule

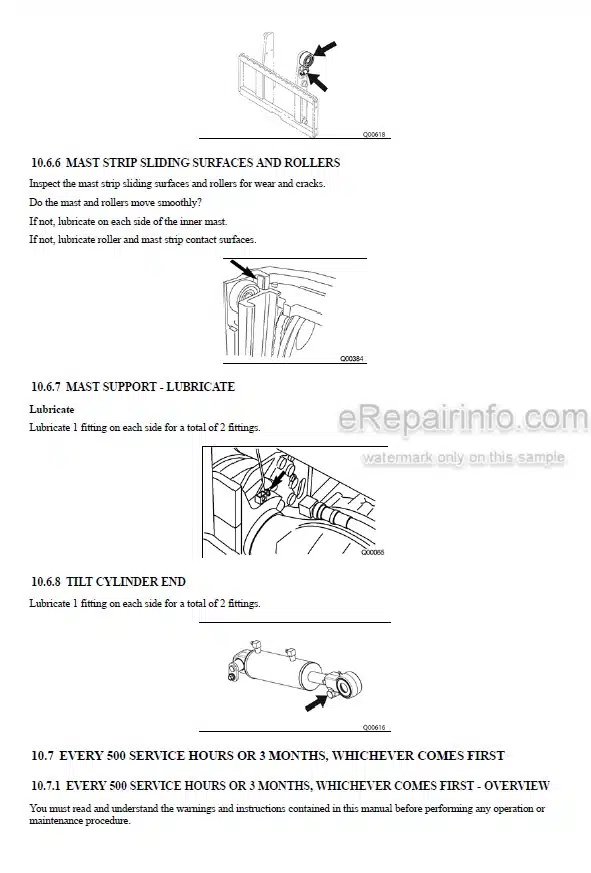

Every 10 Service Hours or Daily (Pre-Start). Whichever Comes First

Every 50 Service Hours or Weekly. Whichever Comes First

One Month (30 days) or 200 Service Hours After Delivery of a New Forklift Truck. Whichever Comes First

Every 500 Service Hours or 3 Months. Whichever Comes First

Every 1000 Service Hours or 6 Months. Whichever Comes First

Every 2000 Service Hours or 1 Year. Whichever Comes First

Battery

Parking Brake Lever

Tires

Parts to Be Changed Periodically

Tightening Torque for Standard Bolts

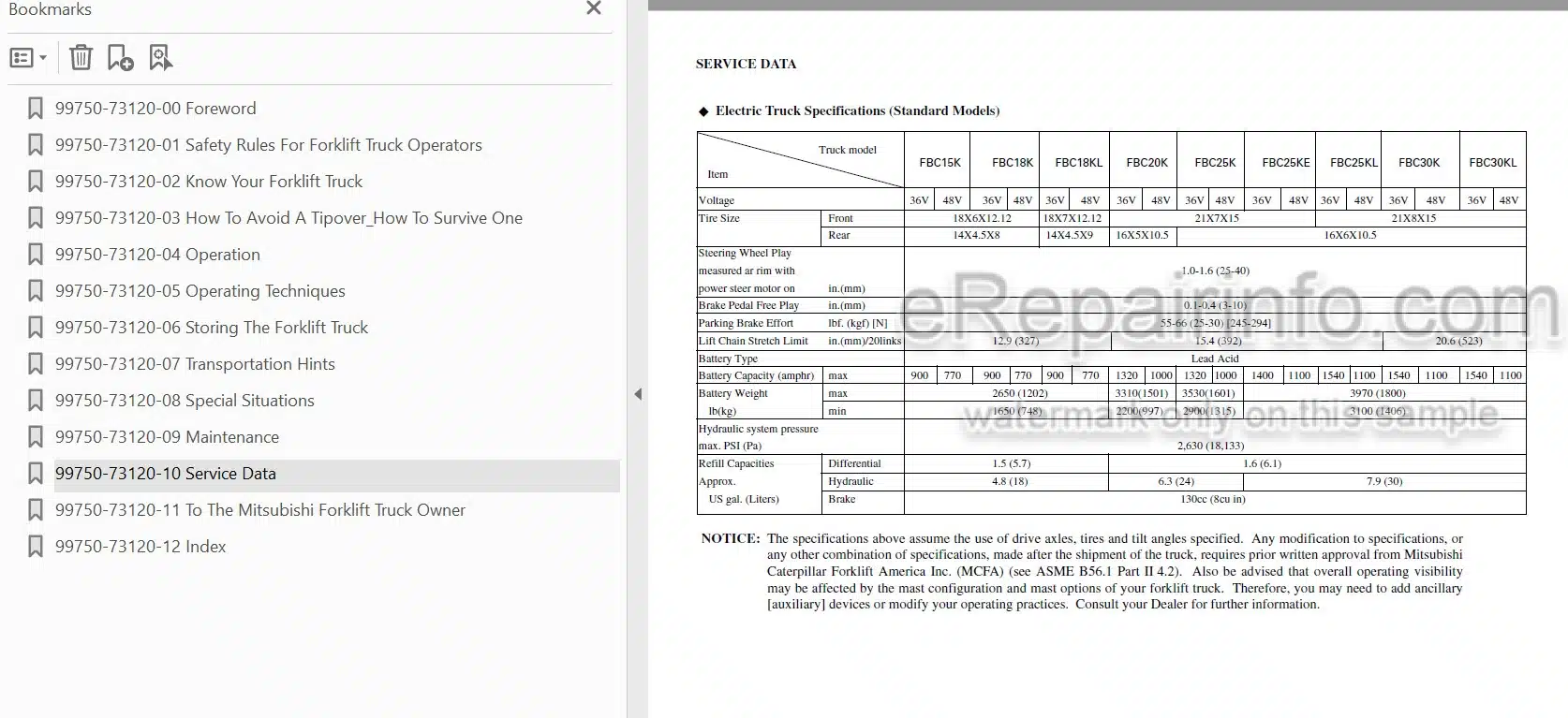

-SERVICE DATA

Recommended Oils and Greases

Specifications (Standard Models)

Capacities and Forklift Truck Weight (Standard Models)

-TO THE MITSUBISHI FORKLIFT TRUCK OWNER

The Importance of Genuine Parts

Instructions for Ordering Parts

Service Registration

Transfer of Ownership Report for Mitsubishi Forklift Trucks Customers Only

INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet