Factory Operation And Maintenance Manual For Mitsubishi Forklift. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 152

Number: 99700-79120

Bookmarks: Yes

Searchable: Yes

Model

Mitsubishi Forklift

FD80

SN F32B-10011-up

FD90

SN F32B-60001-up

Contents

-SAFETY RULES FOR FORKLIFT TRUCK OPERATORS

In General

Warning Decals, Location

Warning Decals, Description

General Precautions

Before Operating Forklift Truck

Operating Precautions

Operating on Grades

Steering (Turning) Precautions

Working Precautions

Stopping/Parking Precautions

-KNOW YOUR FORKLIFT TRUCK

Serial Number & Capacity Plate

Model View

Operator’s Compartment

Instrument Panel

Side Instrument Panel (Former)

Driving Interlock System

OK Monitor (Warning Lights and Indicators)

Operator’s Seat

Seat Belt

Fuses and Lights

Fork Adjustment

Safety Equipment

Drawbar Pin

Assist Grip and Foot Step

Engine Hood

Radiator Cover

Hydraulic Tank Oil Level/Filler Hole

Fuel Filler

Fuel Shutoff Valve

-HOW TO AVOID A TIPOVER & HOW TO SURVIVE ONE

Know What Forklift Truck Stability Is

Center of Gravity (CG)

Stability and Center of Gravity

Forklift Truck Stability Base

Rated Capacity (Weight and Load Center)

Capacity Chart

Do’s and Don’ts to Avoid Tipover

How to Survive in a Tipover

-REFUELING

Refueling

-OPERATION

New Forklift Truck Break-In

Before Starting Engine

Starting Engine

Starting with Jumper Cables

After Starting Engine

Before Moving Forklift Truck

Forklift Truck Operation

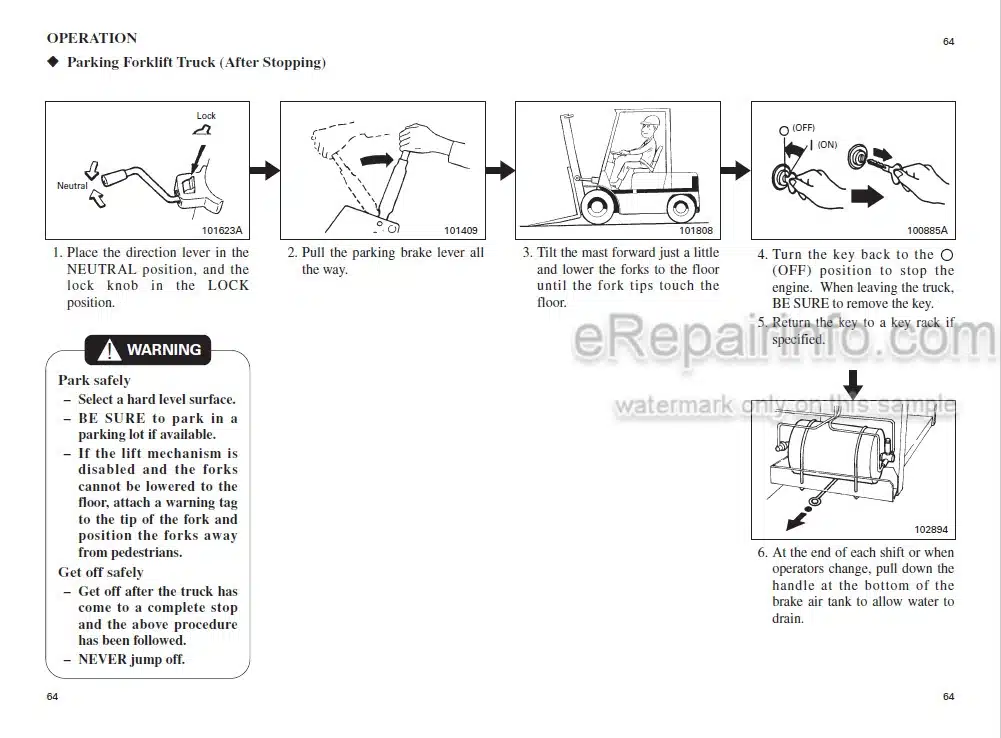

Stopping Forklift Truck

Parking Forklift Truck (After Stopping)

-OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

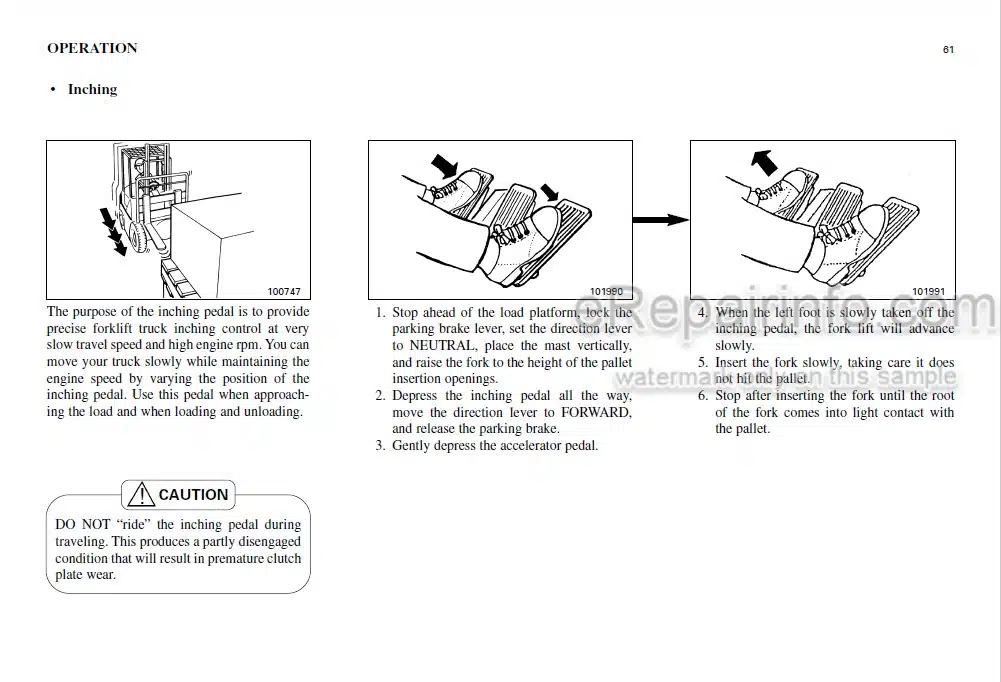

Inching Into and Lifting the Load

Traveling With the Load

Unloading

Working on Grades

-STORING A FORKLIFT TRUCK

Storing a Forklift Truck

-TRANSPORTATION HINTS

Forklift Truck Shipping

Machine Lifting and Tiedown Information

-SPECIAL SITUATIONS

Care in Cold Weather

Care in Hot Weather

Care in Severe Dust or Lint Conditions

-TROUBLESHOOTING

If a Tire Has to be Changed

If Powershift Transmission Oil Temperature Warning Light Glows

If Engine Stalled

If Engine Coolant Temperature Gauge Needle Moves into the Red Zone

Driving Interlock Indicator Light Flickers or Flashes, and the Truck Stops Moving

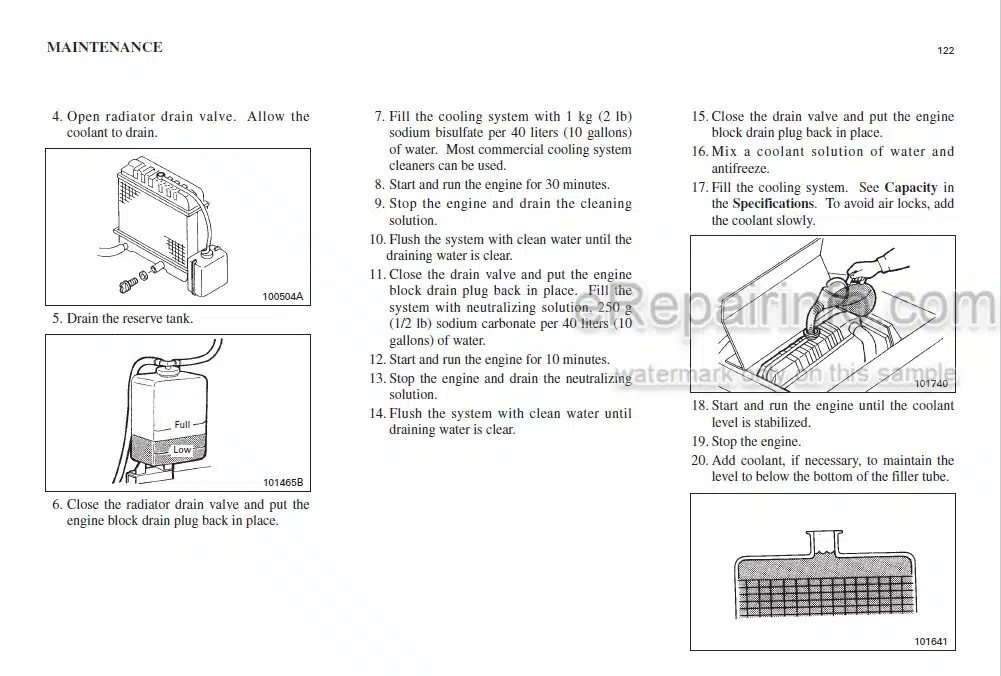

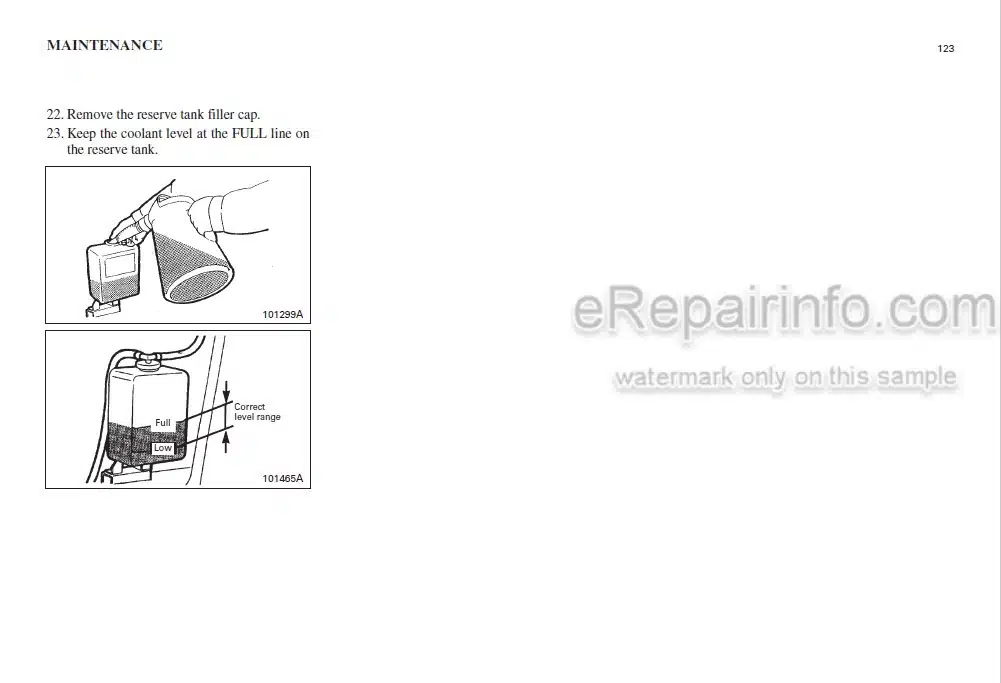

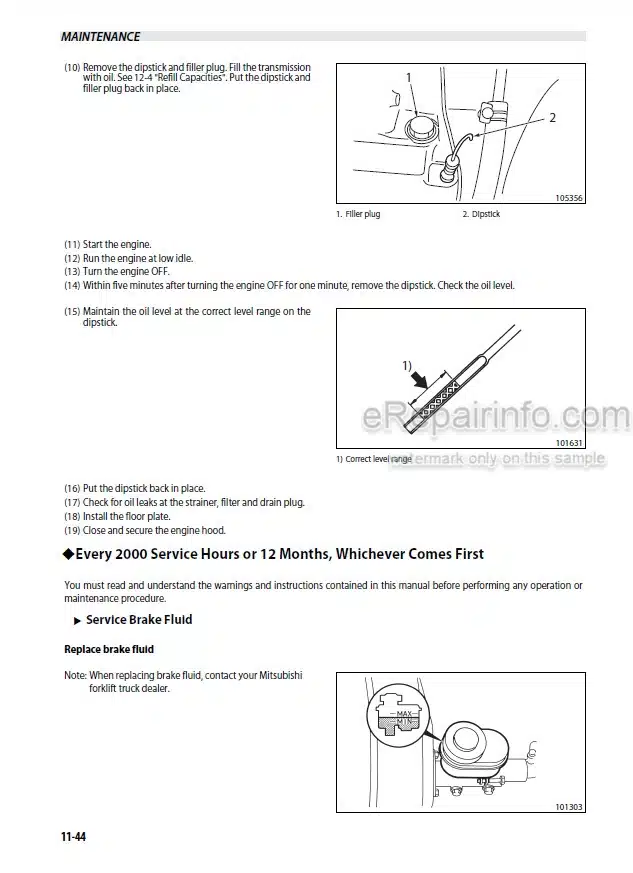

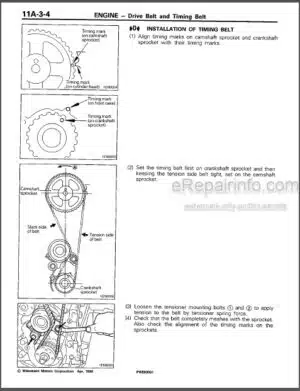

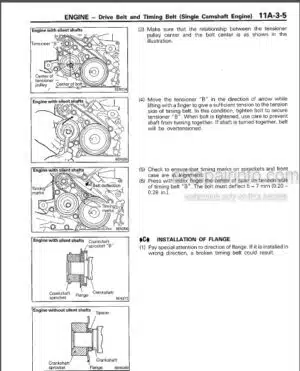

-MAINTENANCE

General

Inspection Precautions

Maintenance Schedule

Every 10 Service Hours or Daily (Pre-start), Whichever Comes First

Every 50 Service Hours or Weekly, Whichever comes first

One Month After Delivery of a New Truck

Every 200 Service Hours or Monthly, Whichever Comes First

Every 1200 Service Hours or 6 Months, Whichever Comes First

Every 2400 Service Hours or 1 Year, Whichever Comes First

Parts to be Changed Periodically

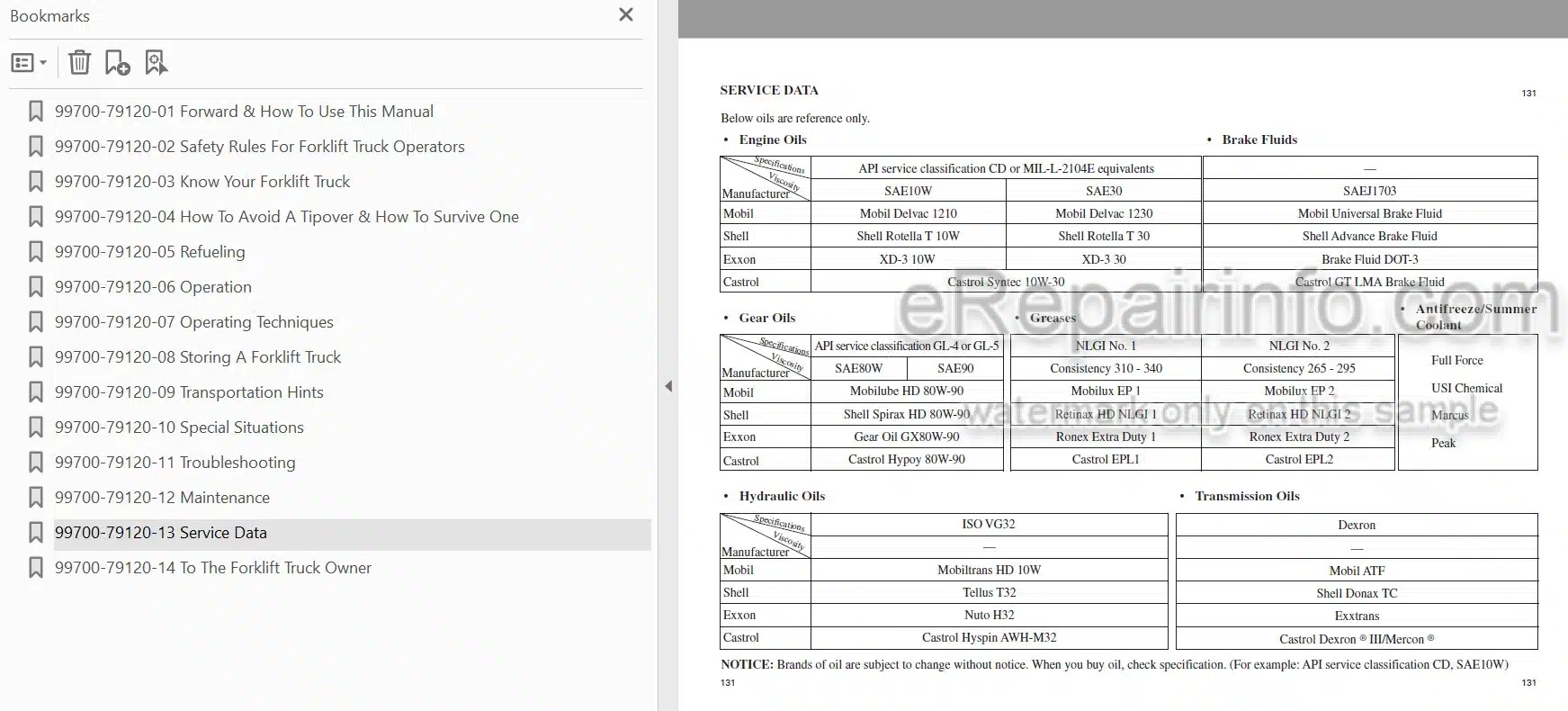

-SERVICE DATA

Fuel Information

Diesel Fuel Specifications

Coolant Information

Antifreeze

Recommended Fuels and Oils

Specifications (Standard Models)

Rated Capacity and Truck Weight

-TO THE FORKLIFT TRUCK OWNER

The Importance of Genuine Parts

Instructions for Ordering Parts

Service Registration

Transfer of Ownership Report

INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet