Mustang 1750RT 2100RT 2500RT NXT2 NXT3 Service Manual

Comprehensive Guide for Maintenance and Repair of Mustang Compact Track Loaders

The Mustang 1750RT 2100RT 2500RT NXT2 NXT3 Service Manual (50940165) is an essential resource for owners, operators, and technicians responsible for maintaining and repairing Mustang compact track loaders. This factory service manual, formatted as a searchable PDF with convenient bookmarks, spans 440 pages and is available in English. It includes extensive illustrations, instructions, and diagrams to facilitate step-by-step procedures for removal, installation, assembly, disassembly, service, inspection, repair, troubleshooting, and tune-ups.

Format and Accessibility

- Format: PDF

- Language: English

- Pages: 440

- Number: 50940165 (July 2018)

- Bookmarks: Yes

- Searchable: Yes

- Hydraulic Diagrams: Yes

Models Covered

This service manual covers the following Mustang compact track loader models:

- 1750RT

- 1750RT NXT2

- 1750RT NXT3

- 2100RT NXT2

- 2100RT NXT3

- 2500RT

- 2500RT NXT3

Contents Overview

The manual is meticulously organized into various sections, each dedicated to specific systems and components of the compact track loaders. Here’s a brief overview of the contents:

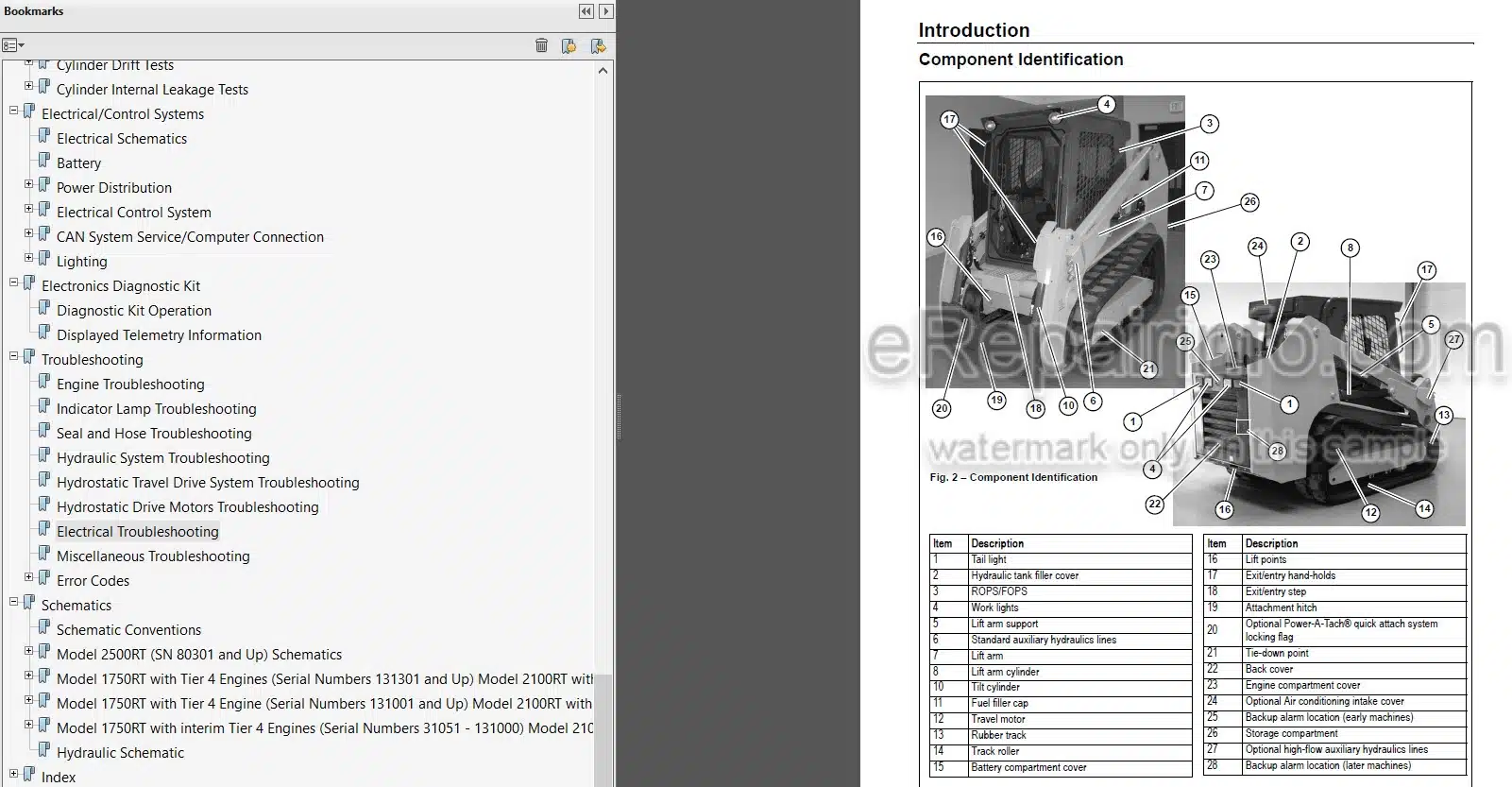

Introduction

- Safety symbol, contents and use of this manual, safety symbols and signal words, machine orientation, proper machine use, service and registration, ROPS/FOPS certification label, component identification, fields of application, using attachments, vibration information, fire extinguisher, manufacturer information, and indicator and operation symbols.

Safety

- Safety symbol and signal words, mandatory safety shutdown procedure, pre-starting safety checks, operational safety guidelines, load-handling safety, parking safety, electrical energy safety, maintenance and service safety practices, battery hazards, fire hazards, additional safety equipment, crystalline silica exposure, machine transportation safety, and safety decals.

Specifications

- Fluids/lubricants types and capacities, dimensions, payloads/capacities, weights, track drive, coolant compound table, engine specifications, hydraulic system specifications, electrical system specifications, sound power/pressure levels, vibration levels, standard and optional features, common materials and densities.

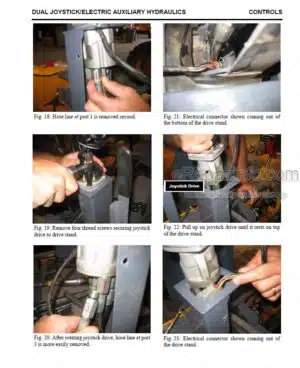

Controls

- Multi-function display, switches/indicators, control joysticks, straight tracking adjust, parking brake/work hydraulics lock-out, cab heat and air conditioning (optional), operator’s seat, seat belt, armrest/joystick console adjustment, throttle controls, travel controls, travel speed range selection, lift arm float button, Hydraglide button (optional), work lights, battery disconnect switch (optional), windshield wipers/washers.

Operation

- Operational checks, pre-operation procedures, engine starting and stopping procedures, engine warm-up, run-in period, diesel particulate filter (DPF) regeneration procedures, post-operation checks, jump-starting, travel drive operation, lift arm operation, self-leveling, lift arm float, Hydraglide ride control system (optional), hydraulics control lock, lift arm support, connecting/disconnecting attachments, powering attachments with hydraulic function, optional 14-pin connector, machine lifting and transportation, storage box.

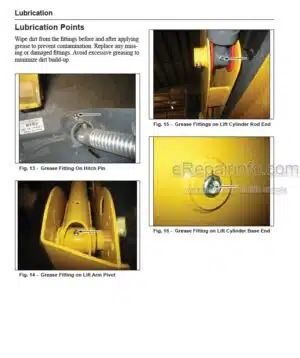

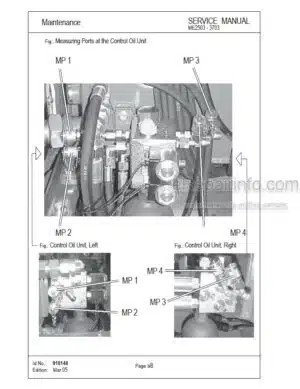

Maintenance

- Maintenance schedule, maintenance intervals, engine maintenance, DPF service, fuel system maintenance, hydraulic system maintenance, hydraulic hose maintenance, travel motor maintenance, track maintenance, general lubrication, tilting ROPS/FOPS, electrical system maintenance, long-term storage, air conditioning maintenance, windshield washer reservoir maintenance, final shutdown/decommissioning, maintenance log.

Lift Arm and ROPS/FOPS

- Lift arm alignment stops, tilt stop adjustment, lift arm removal and installation, ROPS/FOPS service, ROPS/FOPS removal and installation.

Model 2500RT Engine Removal/Installation

- Detailed procedures for engine removal and installation for Model 2500RT.

Models 1750RT/2100RT Tier 4 Engine Removal/Installation

- Tier 4 engine removal and installation procedures for Model 1750RT (S/N 131001 and Up) and Model 2100RT (S/N 241001 and Up).

1750RT/2100RT Interim Tier 4 Engine Removal/Installation

- Interim Tier 4 engine removal and installation procedures for Model 1750RT (S/N 131000 and Before) and Model 2100RT (S/N 241000 and Before).

Hydraulic Equipment

- Overview and maintenance procedures for hydraulic equipment.

Conclusion

In conclusion, the Mustang 1750RT 2100RT 2500RT NXT2 NXT3 Service Manual (50940165) is an invaluable tool for anyone involved in the maintenance and repair of these compact track loaders. Its comprehensive coverage, detailed instructions, and user-friendly format make it an essential resource for ensuring that Mustang compact track loaders remain in optimal working condition. Whether performing routine maintenance or extensive repairs, this manual provides all the necessary information to keep your machine running smoothly and efficiently.

Anonymous (verified owner) –

Its good and holding every thing i need