Factory Repair Manual For New Holland 5610S, 6610S, 7610S, 7010, 8010 Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 706

Number: 87032901

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

New Holland Tractor

5610S

6610S

7610S

7010

8010

Contents

-GENERAL

Health And Safety Precautions

Acids And Alkalis

Adhesives And Sealers

Antifreeze

Arc Welding

Battery Acids

Brake And Clutch Fluids

Brazing

Chemical Materials – General

Do.S

Do Nots

Corrosion Protection Materials

Dusts

Electric Shock

Exhaust Fumes

Fibre Insulation

Fire

First Aid

Foams

Fuels

Gas Cylinders

General Workshop Tools And Equipment

Legal Aspects

Lubricants And Greases

Paints

Solder

Solvents

Suspended Loads

Welding

-ENGINE

Diesel Engines

Engine Cooling System

Air Cleaning System

Fuel System

Turbocharger

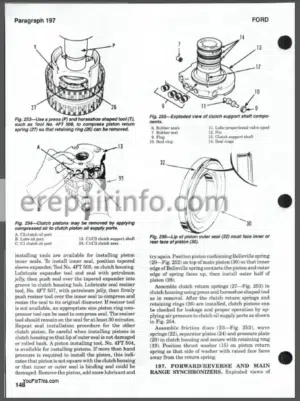

-CLUTCH

Single Clutches

Servicing Clutch Associated Parts

-TRANSMISSION SYSTEMS

8 x 2 Transmission

16 x 4 Dual Command (Dual Power) Transmission

Reduction Gearbox Assembly

-FRONT AXLE TRANSFER BOX

Specifications

Clearances and Tolerances

Shim Thickness Available

Oil Capacity

Special Tools

Torque Values

Description and Operation

Overhaul

-FRONT AXLE – FOUR WHEEL DRIVE

Specifications

Clearances and Tolerances

Shim Thickness Available

Oil Capacity

Special Tools

Torque Values

Description and Operation

Adjustment

Hub and Planetary Reduction Gear Assembly – Overhaul

Axle Shafts – Overhaul

Steering Swivel Pin Bearings – Overhaul

Steering Cylinder and Track Rods Overhaul

Front Axle Removal and Installation

Differential Crown Wheel and Pinion Assembly Overhaul

Drive Shaft – Overhaul

-MECHANICAL REAR WHEEL DRIVE

Specifications

Rear Axle Shaft Bearing Pre-load Spacers

Differential Bearing Pre-load Spacers

Clearances and Tolerances

Torque Values

Oil Capacity

Special Tools

Maximum Permissible Rear Axle Loading with Ballast and Mounted Equipment

Fault Finding

Description and Operation

Final Reduction Gear Assembly (Planetary Gear)

Separating the Tractor Between the Front Transmission and the Rear Axle

Rear Axle Shaft Assembly Overhaul

Planetary Gear Assembly and Axle Housing Overhaul

Differential and Differential Lock Assembly Overhaul

Differential Lock Control Linkage Overhaul

Drive Pinion Assembly Overhaul

Adjustments

Rear Axle Assembly Final Reduction Drop Trumpet (Drop Box) – Component

Overhaul

-POWER TAKE-OFF

Specifications

Clearances and Tolerances

Shim Thickness Available

Torque Values

Special Tools

PTO — Fault Finding

Description and Operation

Mechanically Operated P.T.O. Clutch

P.T.O. Clutch Oil Flow Disengaged

P.T.O. Clutch Oil Flow – Engaged

P.T.O. Pressure Test

Pressure Regulating Valve Test

Cooling and Lubrication Circuit Relief Valve Test

P.T.O. Clutch Overhaul

P.T.O. Shafts and Gears Overhaul

Single Speed Shafts and Gears – Overhaul

Two-speed Shafts and Gears Overhaul

16×4 Dual Command (Power) Transmission

-BRAKING SYSTEM

Specifications

Special Tools

Fault Finding

Torque Values

Description and Operation

Disc Brake Assembly Overhaul

Parking Brake Assembly Overhaul

Brake Pedal and Linkage Overhaul

-HYDRAULIC SYSTEM

Hydraulic Circuits

Hydraulic Pumps

Remote Control Circuit

Component Overhaul

Adjustments and Testing

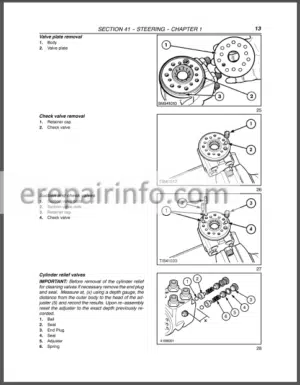

-STEERING SYSTEM

Hydrostatic Steering System

Component Overhaul

-FRONT AXLE – TWO WHEEL DRIVE

Specifications

Clearances and Tolerances

Front Axle Track Adjustment

Shim Thickness Available

Special Tools

Torque Values

Description and Operation

Adjustments

Front Wheel Spindle – Overhaul

Center Steering Arm – Overhaul

Front Axle – Overhaul

-ELECTRICAL SYSTEMS

Description, Operation and Overhaul

Alternator and Charging System

Starting Motor and System

Battery, Servicing and Testing

Electrical System Diagrams

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet