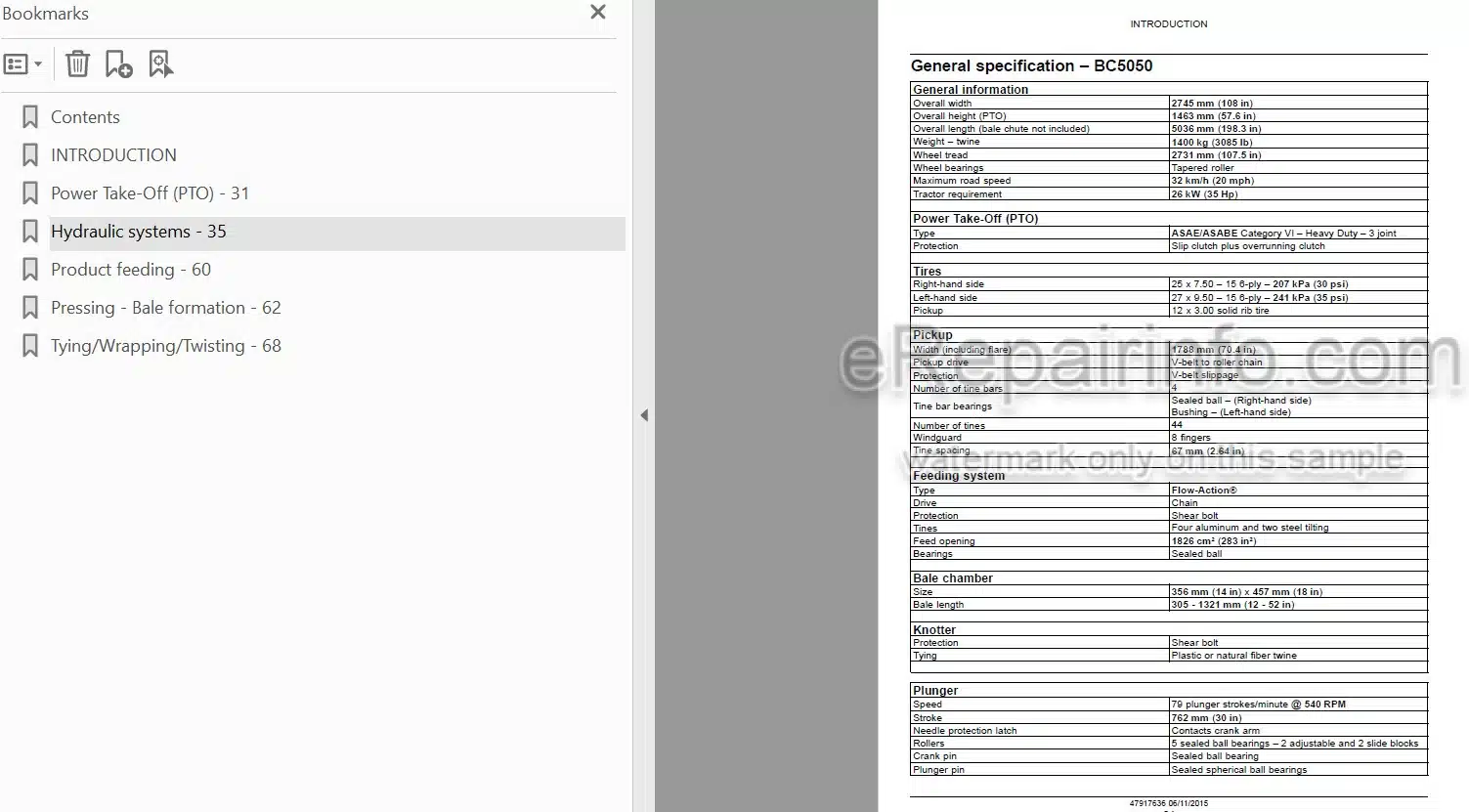

New Holland BC5050 BC5060 BC5070 BC5070 Hayliner BC5080 Service Manual Square Baler

Introducing the comprehensive Factory Service Manual for the New Holland Square Baler models BC5050, BC5060, BC5070, BC5070 Hayliner, and BC5080. This indispensable manual, identified by the number 47917636 and published in November 2015, spans 660 pages of detailed instructions, illustrations, and diagrams. It is designed to guide you through every aspect of maintenance, service, and repair of your New Holland square baler, ensuring optimal performance and longevity.

Key Features:

Format: PDF

Language: English

Pages: 660

Number: 47917636 (November 2015)

Bookmarks: Yes

Searchable: Yes

Hydraulic Diagrams: Yes

Applicable Models:

New Holland Square Baler:

- BC5050

- BC5060

- BC5070

- BC5070 Hayliner

- BC5080

Contents Overview:

INTRODUCTION

- Overview and Safety Information: Provides an introduction to the manual, emphasizing safety precautions and general information about the baler.

POWER TAKE-OFF (PTO)

- Power Take-Off (PTO) Drive Shaft: Detailed instructions for the removal, inspection, and installation of the PTO drive shaft.

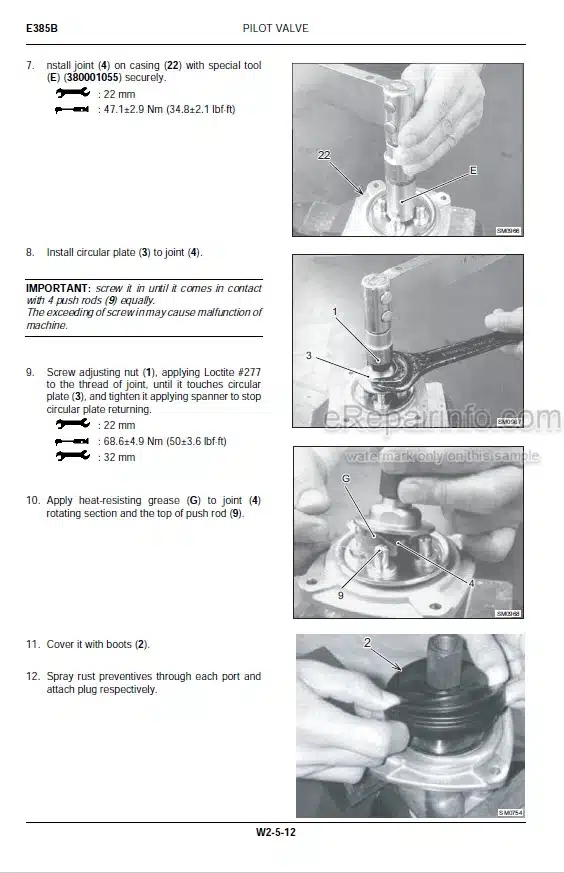

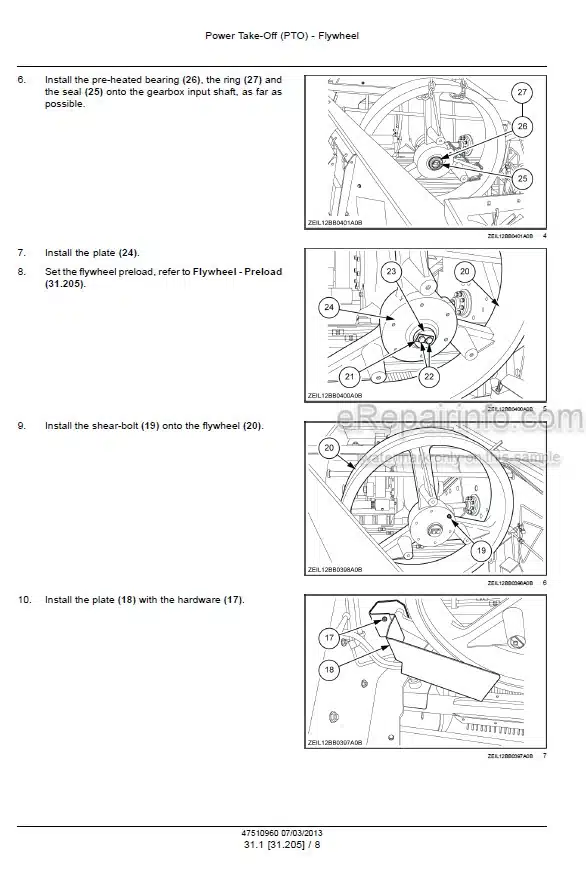

- Flywheel: Procedures for servicing the flywheel, including removal and reinstallation.

- Gearbox: Comprehensive gearbox maintenance, including disassembly, inspection, and reassembly instructions.

- Clutches: Instructions for inspecting and servicing the clutches to ensure proper operation.

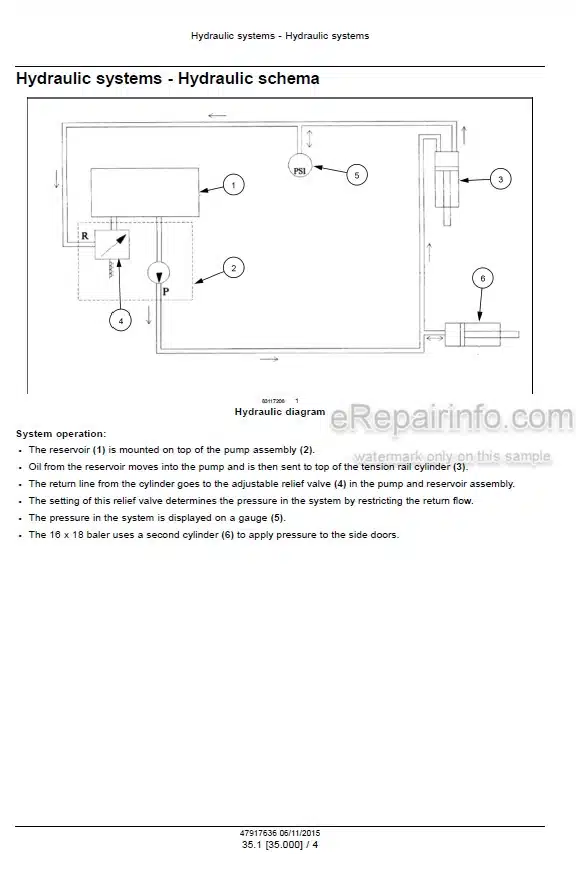

HYDRAULIC SYSTEMS

- Hydraulic Systems Overview: Detailed descriptions and diagrams of the hydraulic systems.

- Variable Displacement Pump: Maintenance and troubleshooting procedures for the variable displacement pump.

- Bale Density Circuit: Instructions for maintaining the bale density circuit to ensure consistent bale quality.

- Pickup Lift Circuit: Procedures for servicing the pickup lift circuit.

- Frame Positioning Swinging: Detailed maintenance of the frame positioning system.

PRODUCT FEEDING

- Feeder Housing: Instructions for the removal, inspection, and reinstallation of the feeder housing.

- Feeder Drive System: Comprehensive maintenance procedures for the feeder drive system.

- Pickup: Detailed servicing instructions for the pickup mechanism.

- Packer: Procedures for maintaining and troubleshooting the packer.

- Rotor: Instructions for inspecting and servicing the rotor to ensure efficient product feeding.

PRESSING – BALE FORMATION

- Plunger And Connecting Rod: Detailed instructions for servicing the plunger and connecting rod.

- Bale Chamber: Maintenance procedures for the bale chamber to ensure proper bale formation.

TYING/WRAPPING/TWISTING

- Knotter Drive System: Detailed servicing instructions for the knotter drive system.

- Knotter Clutch And Brake: Procedures for inspecting and maintaining the knotter clutch and brake.

- Knotter Trip Mechanism: Instructions for servicing the knotter trip mechanism.

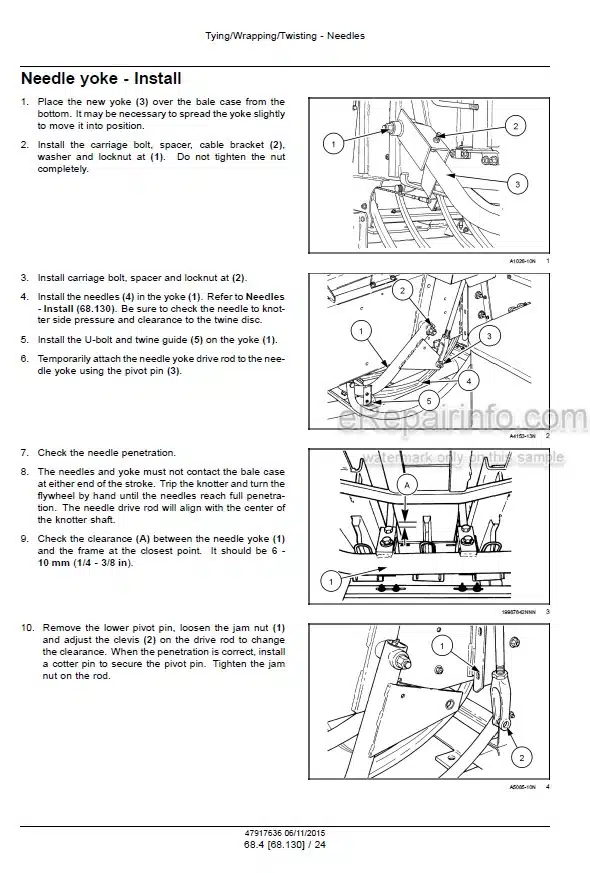

- Needles: Maintenance and replacement procedures for the needles.

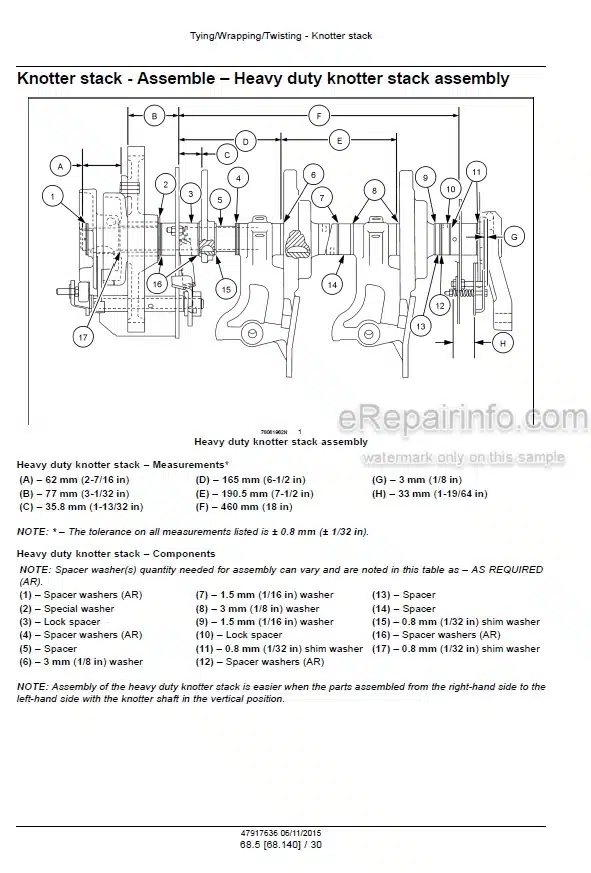

- Knotter Stack: Detailed servicing of the knotter stack.

- Twine Guide System: Instructions for maintaining the twine guide system.

- Knotter Frame: Procedures for inspecting and servicing the knotter frame.

- Twister Frame: Detailed instructions for maintaining the twister frame.

- Twister Stack: Comprehensive maintenance procedures for the twister stack.

- Twister Drive System: Instructions for servicing the twister drive system.

- Twister Clutch And Brake: Procedures for inspecting and maintaining the twister clutch and brake.

Whether you are a professional mechanic or a dedicated owner, this service manual provides all the knowledge and procedures necessary to keep your New Holland square baler in top condition. From PTO systems to tying mechanisms, this manual is your complete guide to ensuring the longevity and reliability of your New Holland baler.

Reviews

There are no reviews yet