Repair Manual For New Holland E18SR Crawler Excavator. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 680

Bookmarks: Yes

Searchable: Yes

Number:

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland E18SR

Contents

- – Safety

General Safety Information

Safety Precautions - – Outline

General Precautions For Making Repairs

Preparation Before Disassembling

Safety When Disassembling And Assembling

Disassembling And Assembling Hydraulic Equipment

Electrical Equipment

Hydraulic Parts

Weld Repair

Environmental Issues

International Unit Conversion System - – Specifications

Components Name

Machine Dimensions

Specifications And Performance

Machine Components Weight

Transportation

Type Of Crawler Shoes

Type Of Bucket

Engine Specifications

Specifications

Engine Performance Curve - – Attachment Dimensions

Boom

Boom Dimensional Drawing

Boom Maintenance Standard

Arm

Arm Dimensional Drawing

Arm Maintenance Standard

Bucket

Bucket Dimensional Drawing

Detail Dimensional Drawings Of Lug Section

Detail Dimensional Drawings Of Boss Section

Dozer

Dozer Dimensional Drawings

Dozer Maintenance Standards

Swing

Swing Bracket Dimensional Drawings

Swing Portion Maintenance Standards‘ - – Tools

Standard Torque Specifications For Capscrews And Nuts

Metric Coarse Thread Standard Tightening Torque Values Make Certain To Tighten All Capscrews & Nuts To Proper Torque Values

Metric Fine Thread Standard Tightening Torque Values Make Certain To Tighten All Capscrews & Nuts To Proper Torque Values

Screw And Tool Size

Capscrew

Socket Set Screw

Torque Specifications For Joints And Hoses

Joints For Piping (ORing Sealing Type)

Hydraulic Hose

Torque Specifications For Sleeve Type Tube Fittings

Sleeve Type Tube Fitting

Part No

Plug

Plug For Hydraulic Pipe Joint

Plug For Hydraulic Equipment

Special Spanner For Tube

Special Tools

Application Of Screw Locking Compound And Sealing Compound

Counter Weight Lifting Jig

Standard Maintenance Timetable

Standard Working Time Table For The Maintenance Of Excavator - – Maintenance Standard And Test Procedure

How To Use The Maintenance Standard

Performance Inspection Standard Table

Standard Value Table

Measurement Engine Speed

Engine Speed Measurement

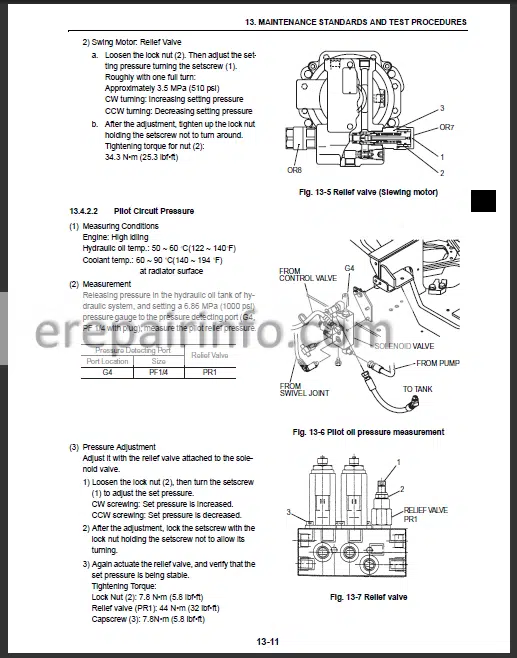

Measuring Hydraulic Pressure

Standard For Hydraulic Pressure Measurement

Pressure Measurement And Adjustment

Measuring Travel Performances

Travel

Travel Deviation

Movement Drift Due To Gravity

Drain Rate On Travel Motor

Measuring Swing Performances

Swing Time

Overrun When Swing Stops

Swing Drift Due To Gravity

Drain Rate Of Swing Motor

Measuring Attachment Operating Performances

Cylinder Speed

Gravity Drift Of Cylinders

Measuring Swing Bearing Performances

Swing Bearing Bucket Tip Play

Swing Bearing Play

Measuring Crawler Tension

Crawler Tension - – Hydraulic System

Summary

Function And Features Of Hydraulic Circuit

Hydraulic Circuits And Component Models

Hydraulic Circuit Operation

Color Coding Standard For Hydraulic Circuits

Neutral Circuit

Travel Operating Circuit

Swing Operating Circuit

Bucket Operating Circuit

Boom Operating Circuit

Arm Operating Circuit

Swing Operating Circuit

Dozer And Ajuustable Crawler Frame Width Operating Circuit

Travel/Dozer Combined Operating Circuit

Travel/Boom Combined Operating Circuit

Nibbler & Breaker Operating Circuit

Schematic Piping For Hydraulic System - – Electrical System

How To Read Circuit Diagram And Harness Connection

Electrical Circuit Diagram

Harness Connection

Electrical Equipment & Harness

Electrical Equipment List

Harness & Cable List

Arrangement Drawing For Components & Harness

Detail Of Harness & Cable - – Components System

Hydraulic Components

Hydraulic Pump

Pilot Valve (Att)

Pilot Valve (Travel)

Control Valve

Swing Motor

Travel Motor

Swivel Joint

Cylinder

Electric Equipment

Electric Equipment List

Specification Electric Equipment - – Disassembly And Assembling

General Disassembly & Assembly

Contents Of General Disassembly & Assembly

Specification Of Tightening Torque - – Attachment

Removing And Installing

Attachment Assembly And Name

Bucket

Arm

Boom

Swing

Dozer

Disassembling And Assembling

Cylinder - – Upper Structure

Removing And Installing

Canopy

Guard (Cover)

Counterweight

Battery

Floor Plate Assembly

Air Cleaner

Hydraulic Oil Tank

Fuel Tank

Pump

Control Valve

Solenoid Valve

Multi Control Valve

Muffler

Alternator

Startor

Radiator

Pilot Valve

Control Stand

Engine

Swing Motor

Swivel Joint

Upper Frame

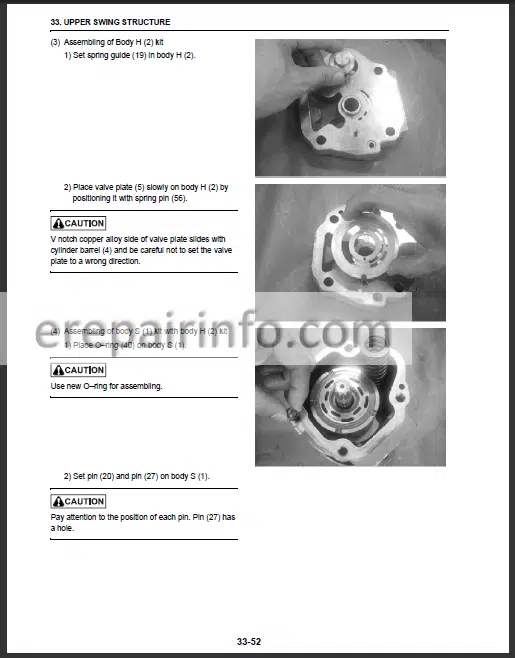

Disassembling And Assembling

Hydraulic Pump

Control Valve

Pilot Valve (Attachment)

Pilot Valve (For Travel)

Swing Motor

Swivel Joint - – Travel System

Removing And Installing

Name Of Travel System Parts

Crawler

Side Plate

Lower Roller

Front Idler

Idler Adjuster

Sprocket

Travel Motor

Swing Bearing

Adjustable Crawler Frame Width

Disassembling And Assembling

Travel Motor - – Troubleshooting (Hydraulic System)

General Precautions

Confirm Actual Troubled Condition At Site

Trouble Diagnosis: Hydraulic

Troubleshooting

Attachment

Travel Operation

Swing Operation

Pump - – Troubleshooting (Electrical System)

Trouble Diagnosis: Electric System

Troubleshooting

General

Attachment Operation

Travel Operation

Troubleshooting (Engine)

Trouble Diagnosis : Engine

Troubleshooting

Starting Trouble

E/G Rotation Trouble

Output Droups Down

Other Trouble - – Engine

Mitsubishi Engine Service Manual

General

Service Data

Basic And Special Tools

Overhaul Determination

Disassembling Engine Main Parts

Inspection And Repairing Engine Main Parts

Reassembling Engine Main Parts

Fuel System

Lubrication System

Cooling System

Inlet And Exhaust System

Electrical System

Engine Adjustment, Break In Operation And Performance Tests

Troubleshooting - – Data

Supporting Data

Hydraulic Circuit Diagram

Standard Specifications

Hydraulic Circuit Operation

Neutral Circuit

Travel Circuit: Travel Forward operation At Nd Speed

Swing Circuit: Swing Left Operation

Bucket Circuit: Bucket Digging Operation

Boom Circuit: Boom Up Operation

Arm Circuit: Arm In Operation

Swing Circuit: Boom Swing Left Operation

Dozer Circuit: Dozer Down Operation

Combined Circuit: Travel (Forward) St Speed/Dozer

Down Operation

Combined Circuit: Travel (Forward) St Speed/Boom Up Operation

Nibbler & Breaker Circuit: Nibbler Close Operation

Schematic Piping For Hydraulic System

Electric Circuit Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet