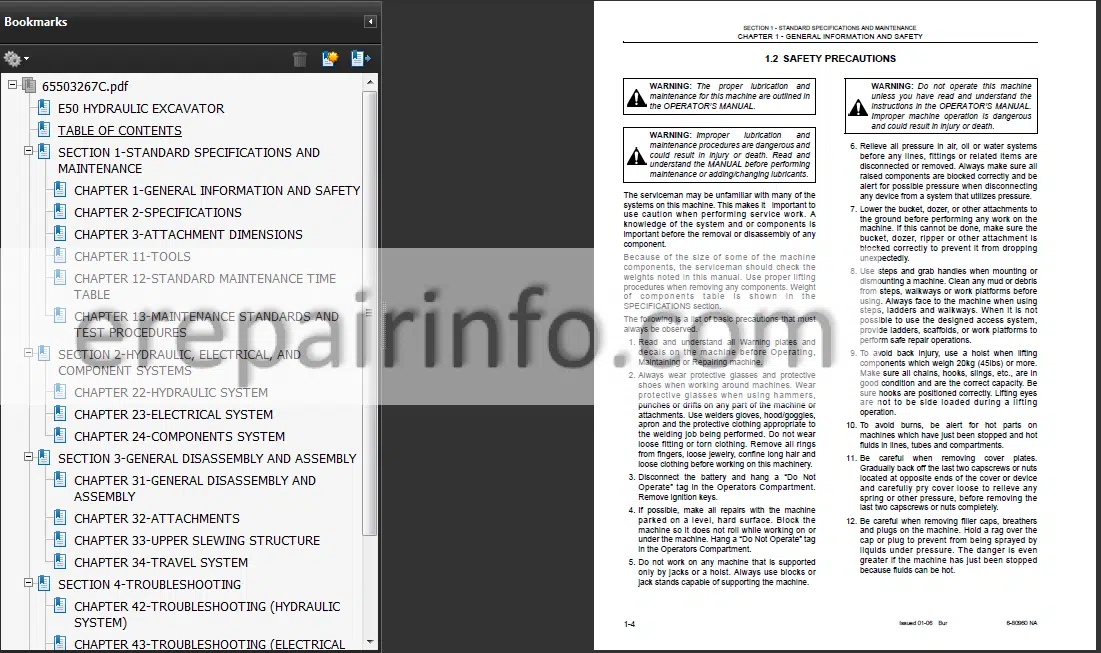

Repair Manual For New Holland E50. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 764

Bookmarks: Yes

Searchable: Yes

Number: 87360588

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

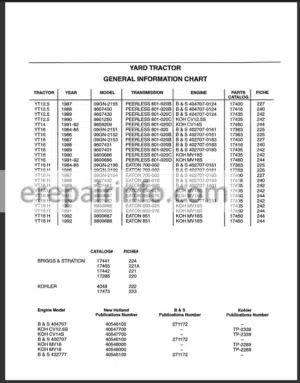

Model

New Holland E50

Contents

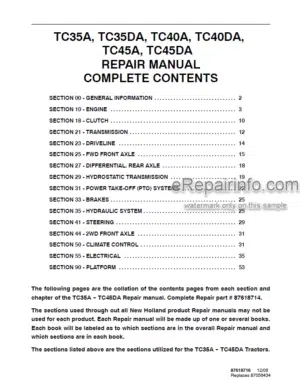

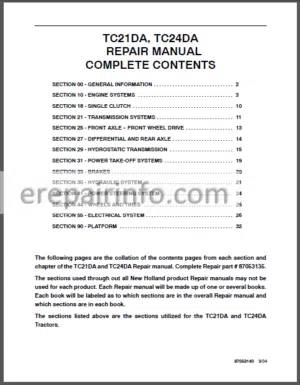

- – Table Of Contents

- – Standard Specifications And Maintenance

General Information And Safety

Preparation Before Disassembling

Safety In Disassembling And Assembling

Disassembling And Assembling Hydraulic Equipment

Electrical Equipment

Hydraulic Parts

Welding Repair

Environmental Protection

Specifications And Performance

Speed And Gradeability

Engine

Hydraulic Components

Side Digging & Dozer

Weight

Loading Machine On A Trailer

Transportation Dimension And Weight Of Attachment

Boom With Arm Cylinder

Arm And Bucket (Standard Bucket)

Arm

Bucket (Standard Bucket)

Dozer (Without Cylinder Weight)

Boom Dimensional Drawings

Boom Maintenance Standards

Clearance Of Pin And Bushing On Boom Section

Clearance In Thrust Direction On Boom And Cylinder Installation Section

Arm

Bucket

Dozer

Swing

Torque Specifications For Capscrews And Nuts

Metric Coarse Thread Standard Tightening Torque Values

Metric Fine Thread Standard Tightening Torque Values

Screw And Tool Sizes

Capscrew

Torque Specifications For Joints And Hoses

Joints For Piping (ORing Sealing Type)

Hydraulic Hose ( Degree Flare Type)

Torque Specifications For Sleeve Type Tube Fittings

Sleeve Type Tube Fittings

Part Number

Plugs

Plug For Hydraulic Pipe Joint

Cap Nut (Joint Plug)

Plug (Tube Plug)

Nut

Plug For Hydraulic Equipment

Pf Screw

Pt Screw

Plug For Flare Hose

Working Conditions

Applicable Range Of Standard Maintenance Time

Excluded Time

Applicable Machine For Estimation Of Standard Maintenance Time

Standard Maintenance Time Table

Classification Of Work Code

Time Tables

Attachment

Canopy And Guard

Upper Structure

Under Carriage

How To Use Maintenance Standards And Precautions

Terminology

Precautions For Judgment

Other Precautions

Performance Inspection Standard Tables

Measuring Engine Speed

Engine Speed Measurement

Measuring Hydraulic Oil Pressure

Standard For Hydraulic Oil Pressure Measurement

Pressure Measurement And Adjustment

Main Circuit Pressure

Pilot Circuit Pressure

Measuring Travel Performances

Test Procedure

Travel

Travel Deviation

Movement Drift Due To Gravity

Drain Rate On Travel Motor

Measuring Slew Performances

Test Procedure

Slew Time

Overrun When Slewing Stops

Slew Drift Due To Gravity

Drain Rate Of Slew Motor

Measuring Attachment Operating Performances

Test Procedure

Cylinder Speed

Gravity Drift Of Cylinders

Measuring Slew Bearing Performances

Test Procedure

Slew BearingBucket Tip Play

Slew Bearing Play

Measuring Track Tension

Track Tension

Specifications

Attachment Dimensions

Tools

Standard Maintenance Time Table

Maintenance Standards And Test Procedures - – Hydraulic, Electrical, And Component Systems

Summary

Hydraulic Circuits And Component Models

Hydraulic Circuit Operation

Electrical System

How To Read Circuit Diagram And Harness Connection

Electrical Equipment And Harness

Components System

Hydraulic Components

Electrical Equipment

Function And Features Of Hydraulic Circuit

Hydraulic Circuits And Component Models

Standard Specifications

Hydraulic Circuit Operation

Color Coding Standard For Hydraulic

Neutral Circuit

Travel Operating Circuit

Nd Speed Operating Circuit (IndependentForward Travel)

Slew Operating Circuit

Slew (Left) Operating Circuit

Bucket Operating Circuit

Bucket Digging Operation Circuit

Bucket Dumping Operating Circuit

Boom Operating Circuit

Boom Raise Operating Circuit

Boom Lower Operating Circuit

Arm Operating Circuit

Arm In Operating Circuit

Operating Circuit For Arm Out

Swing Operating Circuit

Swing (Left) Operating Circuit

Dozer Operating Circuit

Dozer Down Operating Circuit

Nibbler & Breaker Operating Circuit

Nibbler Close Operating Circuit

Nibbler Open Operating Circuit

Breaker Blow Operating Circuit

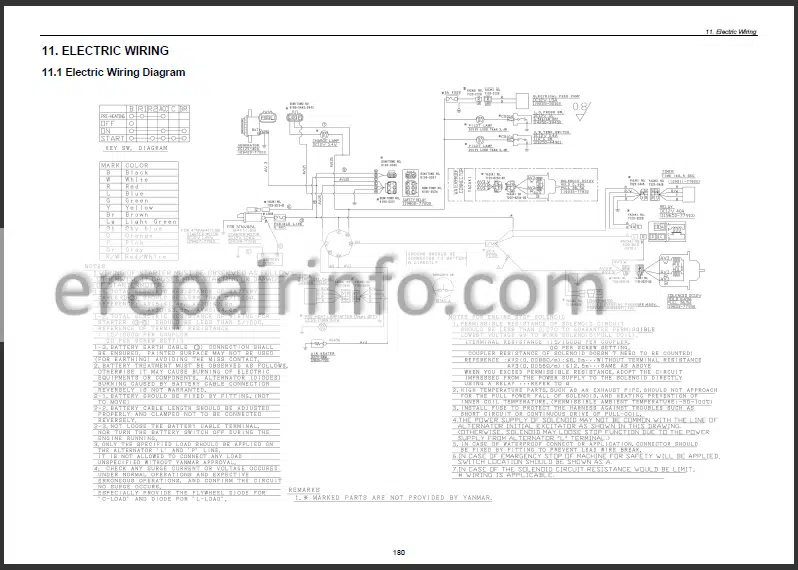

Electric Circuit Diagram

Harness Connection

Electrical Equipment And Harness

Electrical Equipment List

Harness & Cable List

Arrangement Drawing For Components & Harness

Upper Frame Portion

Engine Portion

Relay Unit Portion

Fuel Tank Portion

Work Light Portion

Cab Portion (Opt)

Air Filter Portion (Restriction Switch)

Detail Of Harness & Cable

Inst Main Harness

Engine Harness

Starter Cable

Battery Ground Cable

Engine Ground Cable

Boom Harness

Key Switch Harness

Canopy Working Light Harness

Boom Work Light Extension Harness

Connection Harness With Cab

Air Filter Harness

Hand Control And Slew/Swing Harness

Horn Switch Harness

Instrument Panel Harness (Left)

Hydraulic Components

Electrical Equipment

Hydraulic System

Electrical System

Components System - – General Disassembly And Assembly

General Disassembly And Assembly

Attachments

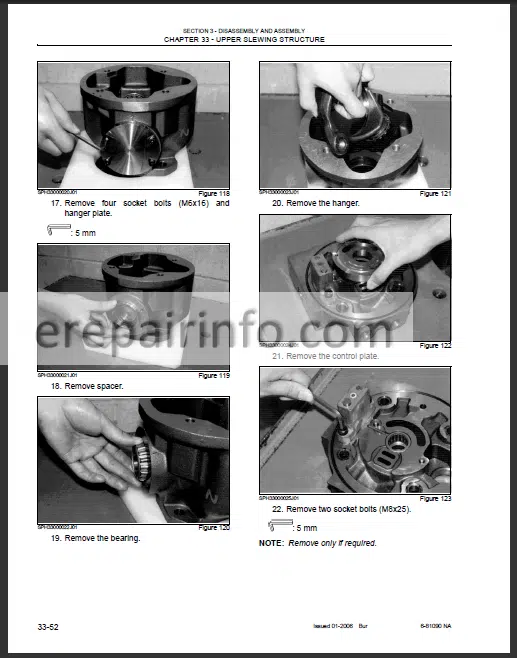

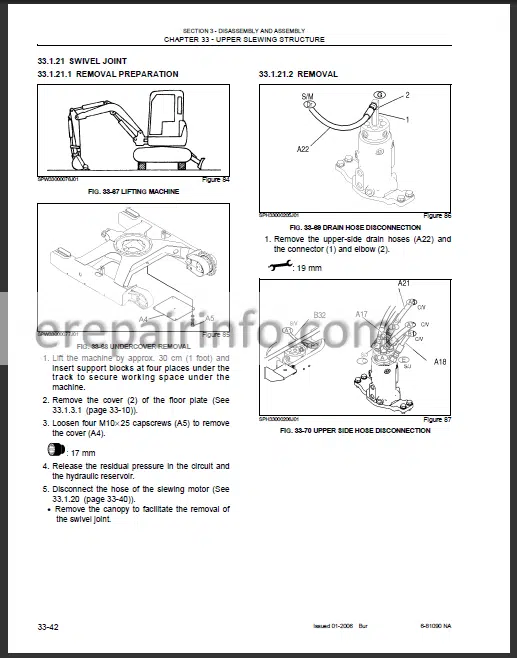

Upper Slewing Structure

Travel System

Removing And Installing

Attachment Assembly And Name

Bucket

Removal Of Bucket

Installation Of Bucket

Arm

Removal Of Arm

Installation Of Arm

Boom

Removal Of Boom

Installation Of Boom

Swing

Preparation For Removal

Removal Of Swing Bracket And Cylinder

Installation Of Swing Bracket And Cylinder

Dozer

Removal

Installation

Disassembling And Assembling

Cylinder

Necessary Tools

General Precautions

Cylinder Construction (Example Of Boom Cylinder)

Maintenance Standards

Jig List

Possible Causes For Trouble And Remedy - – Troubleshooting

Attachment Operational Failure (Excluding Swing Operations)

Attachment Speed Is Slow

Attachment Operating Power Is Low

Malfunction Of Attachment

Travel Operation

Travel Operational Failure

Travel Speed Is Slow

Travel Power Is Low

It Deviates In Travel Independent Operation

Slewing Operation

Slewing Operational Failure

Slewing Speed Is Slow

Slewing Power Is Low

Malfunction Of Slewing Operation

Pump

Engine Speed Is Reduced Due To Pump Load

Malfunction Of Pump

General

Engine Does Not Start

Horn Does Not Work

Working Lights Do Not Work

Hourmeter Does Not Work

Fuel Gauge Does Not Work

Water Temperature Gauge Does Not Work

Attachment Operation

All Controls Do Not Function

Travel Operation

Travel&Speed Change Does Not Work

Deceleration

Optional Decel Motor Does Not Work

Starting Trouble

Starter Does Not Rotate

Starter Rotates But Hard To Start

Engine Runs Rough

Output Power Low

Engine Low Power

Knocking At High Temperature

Other Trouble

Exhaust Trouble

Excessive Oil Consumption

Excessive Fuel Consumption

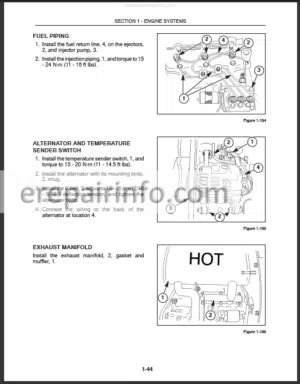

Engine Does Not Stop When Ignition Switch Is Turned Off - – Engine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet