Factory Service Manual For New Holland E55BX Compact Hydraulic Excavator; Yanmar 3TNV88C, 3TNV86CT, 4TNV88C, 4TNV86CT, 4TNV98C, 4TNV98CT Industrial Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1337

Number: S5HS0013E01 (april 2014)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Compact Hydraulic EXcavator

E55BX

Tier 4

PIN NETN55001 – PS04-10001 and above

Yanmar Industrial Engines

3TNV88C

3TNV86CT

4TNV88C

4TNV86CT

4TNV98C

4TNV98CT

Contents

1.NEW HOLLAND E55BX SERVICE MANUAL COMPACT HYDRAULIC EXCAVATOR.

2.YANMAR TROUBLESHOOTING MANUAL-INDUSTRIAL ENGINES TNV SERIES.

3.YANMAR 3TNV88C, 3TNV86CT, 4TNV88C, 4TNV86CT, 4TNV98C, 4TNV98CT SERVICE MANUAL INDUSTRIAL ENGINES.

1.NEW HOLLAND E55BX SERVICE MANUAL COMPACT HYDRAULIC EXCAVATOR.

-OUTLINE

General Precautions For Repairs

International Unit Conversion System

-SPECIFICATIONS

Components Name

Machine Dimensions

Specifications And Performance

Machine & Components Mass (Dry)

Transportation

Type Of Crawler Shoes

Type Of Bucket

Engine Specifications

-ATTACHMENT DIMENSIONS

Boom

Arm

Bucket

Dozer

Boom Swing

-TOOLS

Torque Specifications For Capscrews & Nuts

Screw And Tool Sizes

Torque Specifications For Joints And Hoses

Torque Specifications For Sleeve Type Tube Fittings

Plugs

Special Spanners For Tubes

Special Tools

Application Of Screw Locking And Sealing Compounds

Counter Weightlifting Jig

Upper Frame Lifting Jig

-STANDARD MAINTENANCE TIME SCHEDULE

Standard Working Time Table For The Maintenance Of Excavator

-MAINTENANCE STANDARD AND TEST PROCEDURE

How To Use Maintenance Standards And Precautions

Performance Inspection Standard Table

Measuring Engine Speed

Measuring Hydraulic Oil Pressure

Measuring Travel Performances

Measuring Swing Performances

Measuring Attachment Operating Performances

Measuring Swing Bearing Performances

Measuring Crawler Tension

DPF (Diesel Particulate Filter)

-MECHATRO CONTROLLER (OPT.)

Mechatro Controller

-HYDRAULIC SYSTEM

General

Hydraulic Circuit And Device Model Numbers

Function Of Hydraulic Circuit

-ELECTRICAL SYSTEM

Electric Circuit Diagram

Electrical Equipment & Harness

Harness

-COMPONENTS SYSTEM

Hydraulic Equipment

Electrical Equipment

-AIR-CONDITIONER SYSTEM

Basic System Of Air, Heater And Cooler

Component Parts And Structure

General Assembly Of Air Conditioner

Structure And Operation Of Major Parts

Removal/Installation Of Blower Motor And Resistor

Disassembly/Assembly Of Air Conditioning Unit

Electric Circuit

Troubleshooting

-GENERAL DISASSEMBLY AND ASSEMBLY

General Disassembly And Assembly

-ATTACHMENT

Removal/Installation Of Assy

Disassembling And Assembling

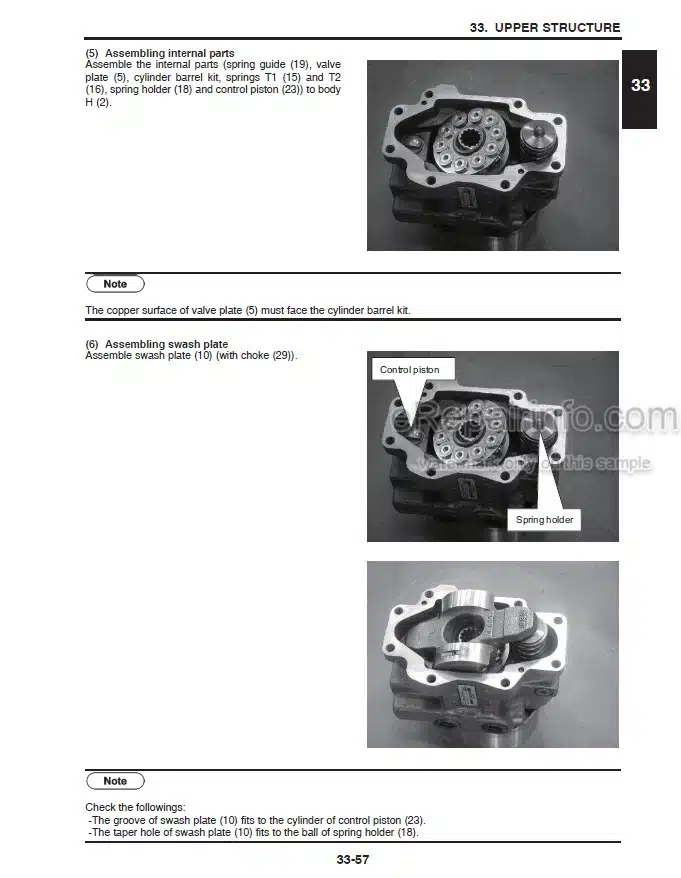

-UPPER STRUCTURE

Removal/Installation Of Assy

Disassembling And Assembling Of Devices

-TRAVEL SYSTEM

Removal/Installation Of Assy

Disassembling And Assembling

-TROUBLESHOOTING (HYDRAULIC SYSTEM)

General Precautions

Trouble Diagnosis : Hydraulic

Troubleshooting

-TROUBLESHOOTING (ELECTRICAL SYSTEM)

Trouble Diagnosis : Electric System

Troubleshooting

-TROUBLESHOOTING (ENGINE)

-TROUBLE SHOOTING (OPT.) (BY ERROR CODES)

Checking The Site And Actual Thing

Failure Classification And Troubleshooting Procedures

Blown Fuse Of Mechatro Controller

Troubleshooting By Error Codes

2.YANMAR TROUBLESHOOTING MANUAL-INDUSTRIAL ENGINES TNV SERIES.

-DTC (DIAGNOSTIC TROUBLE CODES) GENERAL DESCRIPTION

DTC Code List

Description

Sensor Related

Contact Output Related

CRS (Common Rail System) Related

Actuator

Communication Related

ECU Related

Contact Input Related

Post Treatment Control

Others

-METHOD AND PROCEDURE OF FAILURE DIAGNOSIS

Description

Sensor Related

Contact Output Related

Contact Input Related

CRS (Common Rail System) Related

Actuator

Communication Related

ECU Related

Others

3.YANMAR 3TNV88C, 3TNV86CT, 4TNV88C, 4TNV86CT, 4TNV98C, 4TNV98CT SERVICE MANUAL INDUSTRIAL ENGINES.

-INTRODUCTION

-YANMAR WARRANTIES

YANMAR Limited Warranty

Emission System Warranty

YANMAR Co., Ltd Limited Emission Control System Warranty – USA Only

-SAFETY

Safety Statements

Safety Precautions

-GENERAL SERVICE INFORMATION

Component Identification

Location of Labels

Emission Control Regulations

Emission Control Labels

Engine Family

Function of Major Engine Components

Main Electronic Control Components and Features

Function of Cooling System Components

Installation Position of Sensors

Diesel Fuel

Engine Oil

Engine Coolant

Specifications

Principal Engine Specifications

Engine Service Standards

Tightening Torques for Standard Bolts and Nuts Abbreviations and Symbols

Unit Conversions

-PERIODIC MAINTENANCE

Before You Begin Servicing

Introduction

Periodic Maintenance Schedule

Periodic Maintenance Procedures

-ENGINE

Before You Begin Servicing

introduction

Cylinder Head Specifications

Camshaft and Timing Gear Train Specifications

Crankshaft and Piston Specifications

Cylinder Block Specifications

Special Torque Chart

Special Service Tools

Measuring Instruments

Cylinder Head

-FUEL SYSTEM

Before You Begin Servicing

System Structure

Fuel System Specifications

Fuel System Diagram

Fuel System Components

-COOLING SYSTEM

Before You Begin Servicing

Introduction

Cooling System Diagram

Engine Coolant Pump Components

Engine Coolant System Check

Engine Coolant Pump

-LUBRICATION SYSTEM

Before You Begin Servicing introduction

Oil Pump Service Information Lubrication System Diagram

Checking Engine Oil Pressure

Oil Pump Components

-TURBOCHARGER

Before You Begin Servicing

Introduction

Specifications

Troubleshooting

Turbocharger Components

Turbocharger Component Functions

Washing Procedure

Periodic Inspection

-STARTER MOTOR

Before You Begin Servicing

Introduction

Starter Motor Information

Starter Motor Specifications

Starter Motor Troubleshooting

Starter Motor Components

Starter Motor

-ALTERNATOR

Before You Begin Servicing

Introduction

Dynamo and Alternator Information

Alternator Specifications

Dynamo Specifications

Alternator Troubleshooting

Alternator Components

Alternator Wiring Diagram

Alternator Standard Output

Alternator

Dynamo Component Location

Dynamo Wiring Diagram

Operation of Dynamo

Dynamo Standard Output

Testing of Dynamo

Dynamo

-ELECTRONIC CONTROL SYSTEM

Before You Begin Servicing

Introduction

Electronic Control System

Diesel Particulate Filter (DPF)

Electronic Control Harness Connections

-ELECTRIC WIRING

Electric Wiring Precautions

Electrical Wire Resistance

Battery Cable Resistance

Electrical Wire Sizes – Voltage Drop

Conversion of AWG to European Standards

-FAILURE DIAGNOSIS

Special Service Tools

Tier 4 (BOSCH) Compression Inspection Procedures

Measured Value and Troubleshooting

Quick Reference Table for Troubleshooting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet