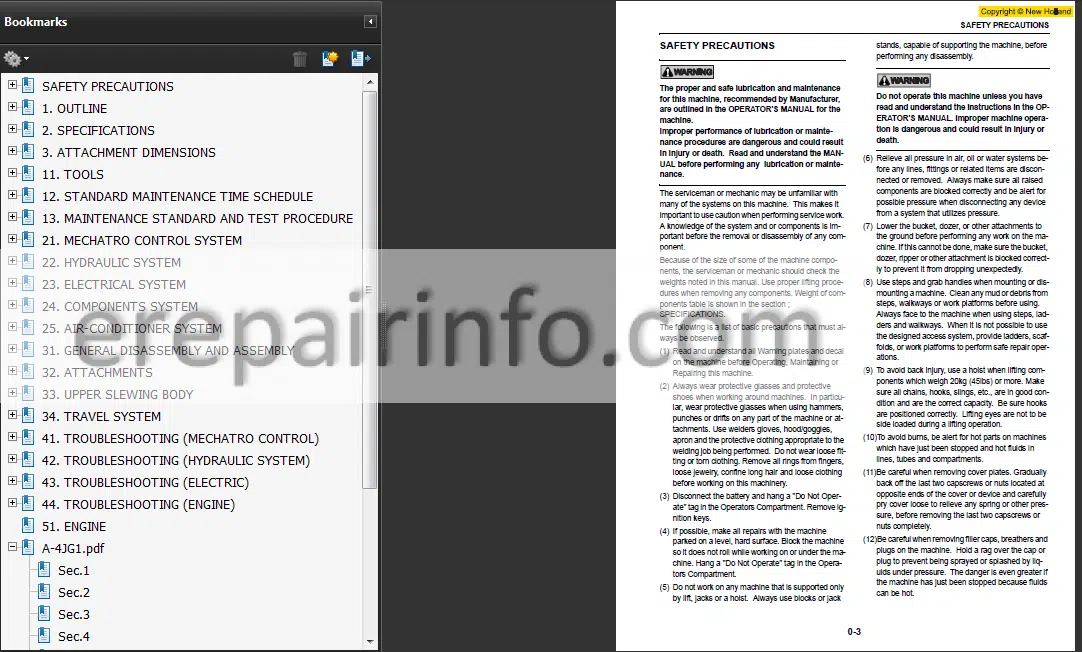

Repair Manual For New Holland E80MSR Excavator. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 940

Bookmarks: Yes

Searchable: Yes

Number: 60413421

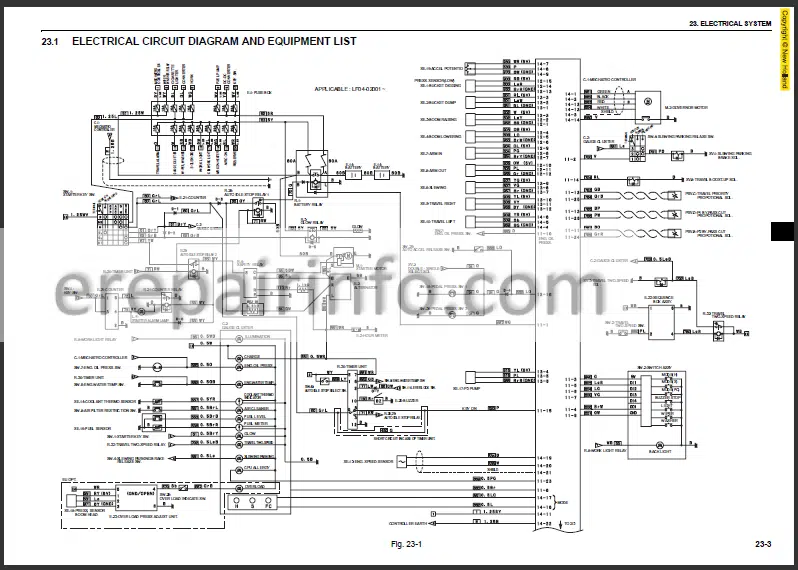

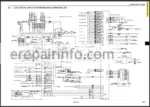

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

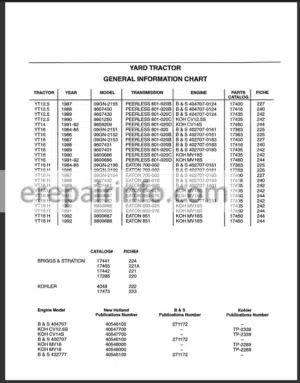

Model

New Holland E80MSR

Contents

- – Safety Precautions

General Safety Information - – Outline

General Precautions For Repairs

Preparation Before Disassembling

Safety In Disassembling And Assembling

Disassembling And Assembling Hydraulic Equipment

Electrical Equipment

Hydraulic Parts

Welding Repair

Environmental Measure

International Unit Conversion System (Based On Marks’ Standard Handbook For Mechanical Engineers) - – Specifications

Name Of Components

Machine Dimensions

Weight Of Components

Transportation Dimension And Weight

Specifications And Performance

Speed And Climbing Capability

Engine

Hydraulic Components

Weight

Type Of Crawler

Type Of Bucket

Combinations Of Attachment

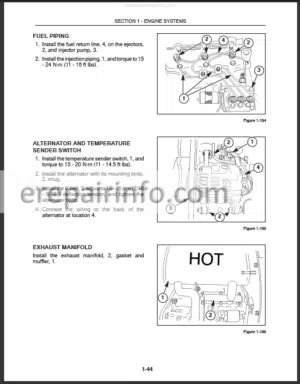

Engine Specification

Engine Characteristic Curve (Isuzu 4Jg1) - – Attachment Dimensions

Boom

Boom Dimensional Drawing

Boom Maintenance Standard

Arm

Arm Dimensional Drawing

Arm Maintenance Standards

Bucket

Bucket Dimensional Drawing

Bucket Dimensional Table

Detail Dimensional Drawing Of Lug Section

Detail Dimensional Drawing Of Boss Section

Dozer

Dozer Dimensional Drawing

Dozer Maintenance Standard

Swing

Swing Bracket Dimension

Swing Maintenance Standard - – Tools

Torque Specifications For Capscrews & Nuts

Metric Coarse Thread Standard Tightening Torque Values. Make Certain To Tighten All Capscrews & Nuts To Proper Torque Values.

Metric Fine Thread Standard Tightening Torque Values. Make Certain To Tighten All Capscrews & Nuts To Proper Torque Values.

Screw And Tool Sizes

Capscrew

Setscrew

Torque Specifications For Joints And Hoses

Joints For Piping (O-Ring Sealing Type)

Hydraulic Hose (30° Flare Type)

Torque Specifications For Sleeve Type Tube Fittings

Sleeve Type Tube Fittings

Plugs

Plug For Hydraulic Pipe Joint

Plug For Hydraulic Equipment

Special Spanners For Tubes

Special Tools

Application Of Screw Locking And Sealing Compounds B B 11-9 Suction Stopper

Components

Dimension

Counterweight Lifting Jig

Upper Frame Lifting Jig

Engine Mounting Pedestal

Track Spring Set Jig - – Standard Maintenance Time Schedule

Standard Maintenance Time Schedule For Excavator

Standard Working Time Table For The Maintenance Of Engine - – Maintenance Standard And Test Procedure

Howto Use Maintenance Standard And Precautions

Performance Inspection Standard Table

Measurement Of Engine Speed

Measurement Of Hydraulic Pressure

Preparing To Measure Hydraulic Pressure

Place To Install Pressure Gauge

Pressure Adjustment Position

Procedure For Adjusting Relief Valve

Measuring Travel Performances

Travel Speed

Deviation Of Travel

Performances Of Parking Brake

Drain Rate Of Travel Motor

Measuring Slewing Performances

Slewing Speed

Performance Of Slewing Brake

Performance Of Slewing Parking Brake

Drain Rate Of Slewing Motor

Measuring Attachment Operating Performances

Operating Time Of Cylinders

Oil Tightness Of Cylinders

Measuring Performances Of Slewing Bearing

Mechatro Controller “A” Adjustment

Engine Control Input / Out

Engine Control Installation

E/G Control Equipment

Adjustment Of Mechatro Control - – Mechatro Control System

Summary Of Mechatro Control System

Boom Raise Conflux Mechatro Control System

Slewing Cut Valve Control Mechatro Control System

Arm In / Out Conflux Mechatro Control System

Travel Straight Mechatro Control System

Travel Boost Control System

Mechatro Control

Troubleshooting

Service Diagnostics

Component Mechatro Control - – Hydraulic System

Summary

Function And Features Of Hydraulic Circuit

Hydraulic Circuits And Component Models

Standard Specification

Boom & Arm Safety Specification

Extra Specification (Opt.)

Neutral Circuit

Safety Lock Lever And Pilot Circuit

Pump Control

Travel Circuit

Forward Pilot Simultaneous Operation Circuit

Travel Main Circuit

Travel Motor Function

Travel Boost-Up

Bucket Circuit

Bucket Digging Pilot Circuit

Auto Accel Operation

E/G Overload Protection With Pump Power Control Operation

Bucket Digging Main Circuit

Boom Circuit

Disassembly And Assembly

Precautions To Be Exercised In Operation

Removal And Installation Of The Unit

Charging Refrigerant

Precautions To Be Exercised In Operation

Operating Procedure

Charging Procedure

Electric Circuit

Wiring Diagram And Connectors

Inspecting Functional Parts

Troubleshooting - – General Disassembly And Assembly

General Disassembly And Assembly

Contents Of General Disassembly And Assembly

Specification Of Tightening Torque - – Attachments

Removing And Installing

Attachment And Component

Bucket

Arm

Boom

Swing

Dozer

Disassembling And Assembling

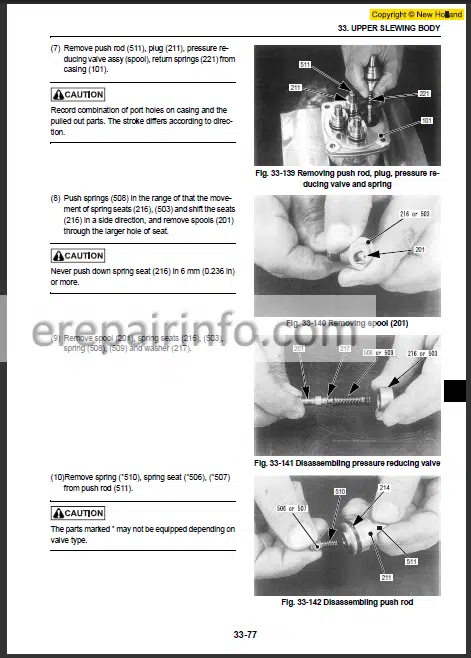

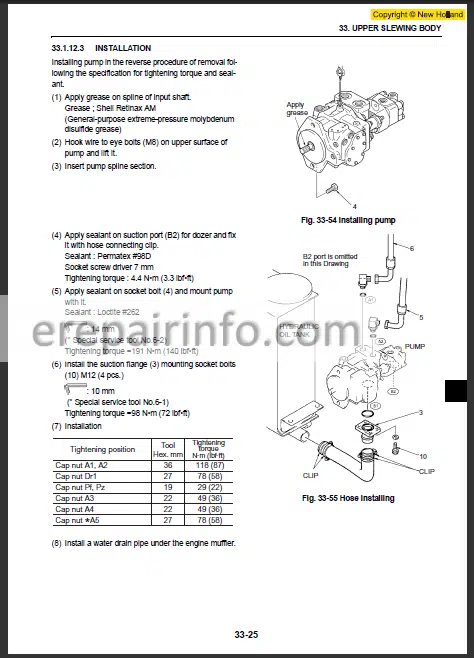

Cylinder - – Upper Slewing Body

Removing And Installing

Cab

Operator Seat

Battery

Instrument Panel

Counterweight

Guard

Under Cover

Air Cleaner - – Travel System

Removing And Installing

Components Of Travel System

Crawler

Upper Roller

Lower Roller (Track Roller)

Front Idler (Idler Adjuster Assy)

Sprocket

Travel Motor

Slewing Bearing

Disassembling And Assembling

Travel Motor - – Troubleshooting (Mechatro Control)

Outline

Judgment Of Actual Thing At Site

Table Of Actuator For Troubleshooting : Mechatro Control

Troubleshooting Summarized : Mechatro Control

Check Point For Mechatro System - – Troubleshooting (Hydraulic System)

Trouble Diagnosis : Hydraulic Troubleshooting - – Troubleshooting (Electric)

Trouble Diagnosis Table : Electric

Controller Error Code Display

Service Diagnosis - – Troubleshooting (Engine)

Trouble Diagnosis : Engine

Troubleshooting

Engine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet