Factory Service Manual For New Holland Telehandler. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 641

Number: 84559130 (June 2012)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Telehandler

LM5020

Contents

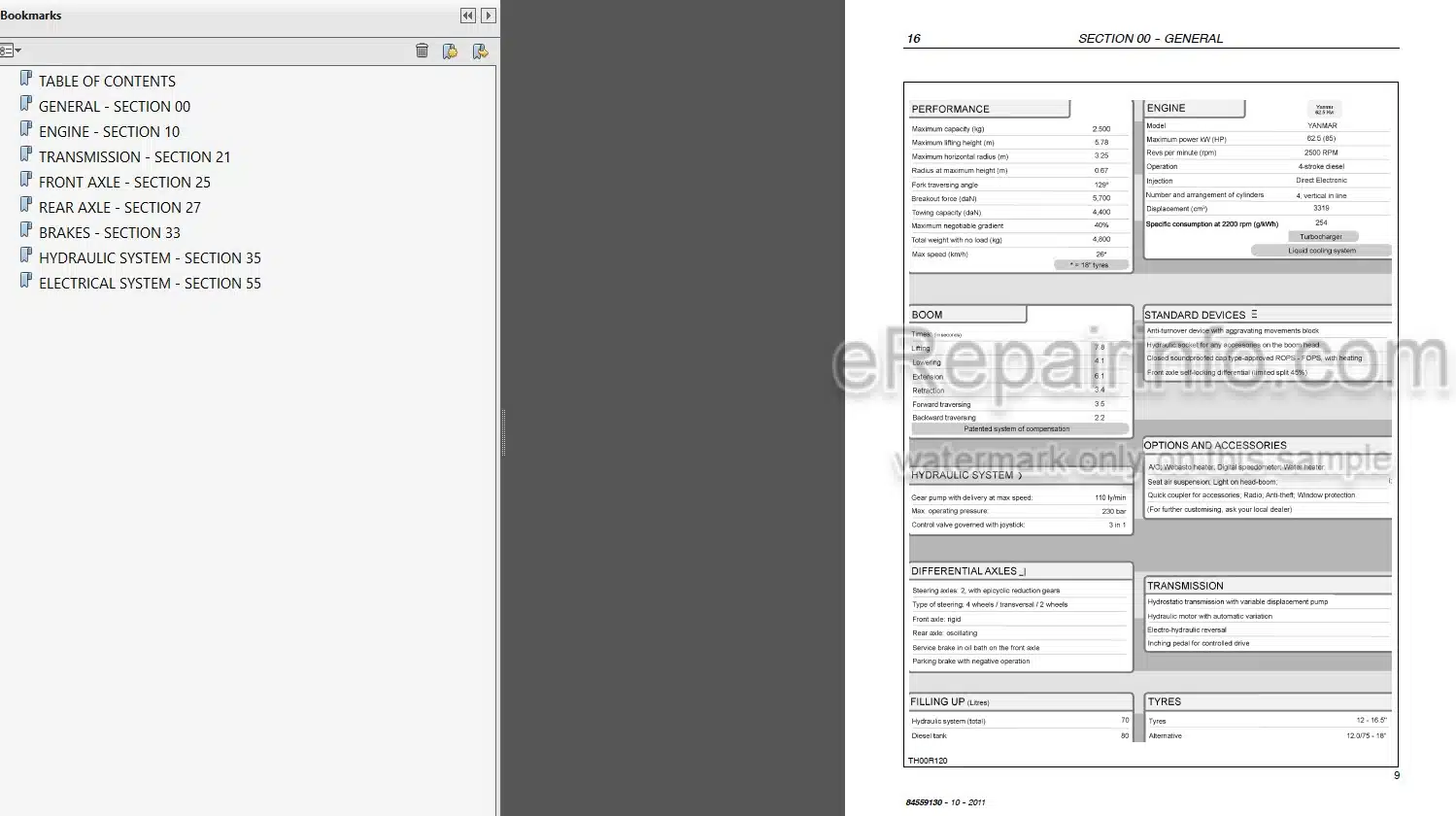

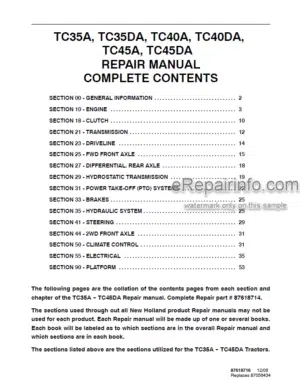

-GENERAL

General Instructions

Safety Rules

Product Identification

Environmental Considerations

Maintenance Techniques

Specific Sealing Compounds

Minimum Tightening Valves For Threaded Fasteners

Minimum Tightening Torques For Fasteners

Load Tables

Table Of Lubrificating Oils

-ENGINE

Main Engine Specifications

Engine Model Views

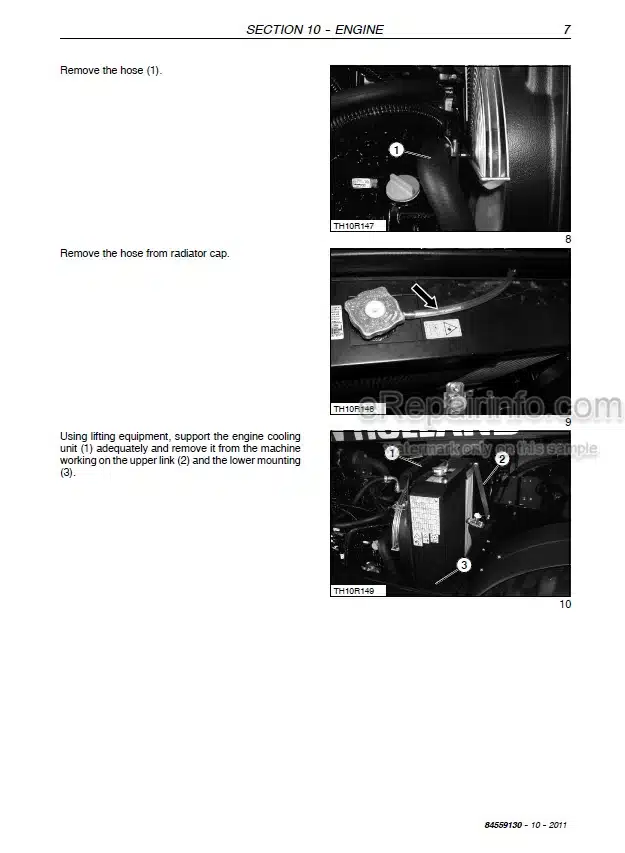

Removal And Installation Of Engine And Radiator

Removal

Installation

Filing The Engine Cooling System

Bleeding Air From The System

Important Warnings

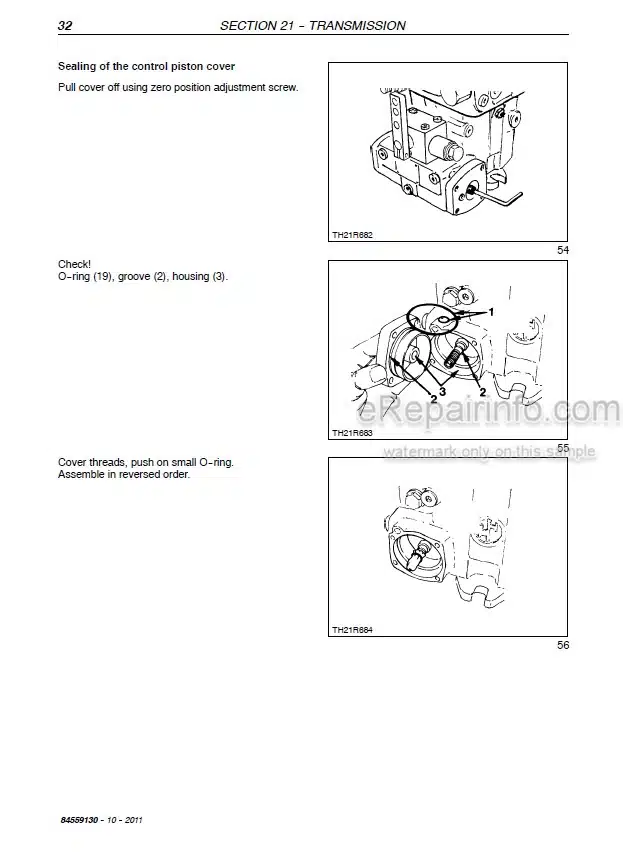

-TRANSMISSION

Variable Displacement Motor

Exchanging Seals

Exchanging The Controller

Sealing The Cover

Checking

Checking Begin Of Regulation Control EP

Checking Begin Of Regulation Control HD

Checking Begin Of Regulation Control HA

Checking Begin Of Regulation Control DA 1/4, DA2,3,4,5,6

Variable Displacement Pump

-FRONT AXLE

Wheel Toe-In Check

Component Overhaul

Front Axle Removal Procedure

Planetary Reduction 1:6 And The Steering Case

Steering Cylinder

Differential: Normal Preloaded Differential Unit

Flanged Reduction Gear Type:603 Integral 603 Input Gear

Bevel Pinion: Version Normal Flange And Nut Revolution Counter Version

Ring And Pinion Adjusting: Step For Preloaded Differential

Swinging Support

Planetary Reduction: 1:4,23

Differential: Preloaded Limited Slip Differential Unit

Differential: With Block To Spheres 100%

Differential: Normal Differential

Differential: Limited Slip Differential Unit (45%)

Update Limited Slip Differential

Update Differential With Service, Negative And % Lock Brake

Bevel Pinion: Flanged To Reductor Gear 603

Ring And Pinion Adjusting: Version Pinion Cover And Single Arm

Ring And Pinion Adjusting: Version Pinion Integral And Double Arm

Drive Shaft Removal

Special Tools

-REAR AXLE

Drive Shaft Removal

Reattachment

Rear Axle Removal Procedure

Overhaul

Installation

-BRAKES

Disassembly The Incoming Disc Brake

Assembly The Incoming Disc Brake

Disassembly Brake: Service Brake And Mechanic Parking Brake

Assembly Brake: Service Brake And Mechanic Parking Brake

Disassembly Brake: Service Brake And Differential Hydraulic Lock 100%

Assembly Brake: Service Brake And Differential Hydraulic Lock 100%

Disassembly Brake: Service Brake, Negative Brake, 100% Locked

Assembly Brake: Service Brake, Negative Brake, 100% Locked

Disassembly Brake: Negative Brake 4 CUP Springs

Assembly Brake: Negative Brake 4 CUP Springs

-HYDRAULIC SYSTEM

Hydraulic System Circuit

Hydraulic Control Valve

Cylinders

Lifting Cylinder

Boom Lifting Phases

Boom Descent Phases

Lifting Cylinders Dismounting Instructions

Boom Overhaul

Replacement Of Internal Boom Tube

Replacement Of Carrier Chain

Tilt Cylinder Replacement

Extension Cylinder Replacement

Boom Extension Replacement

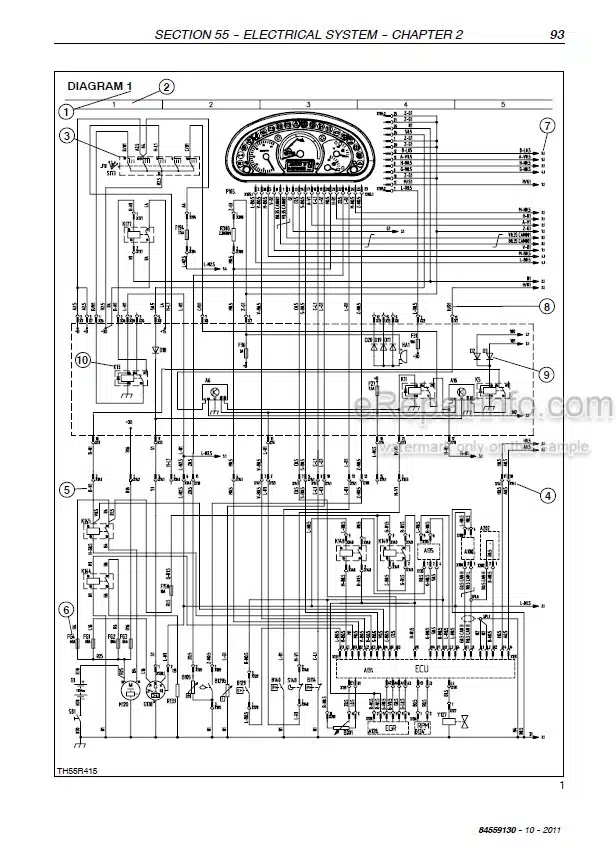

-ELECTRICAL SYSTEM

Hydraulic System Circuit

Hydraulic Control Valve

Cylinders

Lifting Cylinder

Boom Lifting Phases

Boom Descent Phases

Lifting Cylinders Dismounting Instructions

Boom Overhaul

Replacement Of Internal Boom Tube

Replacement Of Carrier Chain

Tilt Cylinder Replacement

Extension Cylinder Replacement

Boom Extension Replacement

Operation

Panel

System Confuguration

Telehandler Layout In Tools Calibration

Calibration Mode

Enter Calibration Mode

Machine Calibration

Tools Calibration

Reset Calibration

Exit Calibration Mode

Test Mode

Panel

Step

Alarms

Panel

Alarm Code

Alarm Code List

Sar-Anti-Tipping System (Lcd Display)

Technical Features

Replacement Of Electrical Cable

Circuit Diagrams

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet