Repair Manual For New Holland T1530 Tractor. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 848

Bookmarks: Yes

Searchable: Yes

Number: 84227373

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland T1530

Contents

- – General Information

Introduction

Precautionary Statements

Personal Safety

Machine Safety And Information

Safety

Precautionary Statements

The Tractor

Servicing The Tractor

Operating The Tractor

Driving The Tractor

Operating The Pto

Diesel Fuel

Safety Frame (Rops)

Safety Decals

Instruction Decals

International Symbols

Specifications

General Dimensions

Minimum Hardware Tightening Torques

Metric Bolt Torque Specifications

Lubricants

Recommended Lubricants And Coolants

Adjustments

Rear Tire Liquid - – Engine

Metric Bolt Torque Specifications

Special Tools

Compression Test And Tools

Description Of OperationEngine

Troubleshooting

Cylinder Head And Valve Train Components

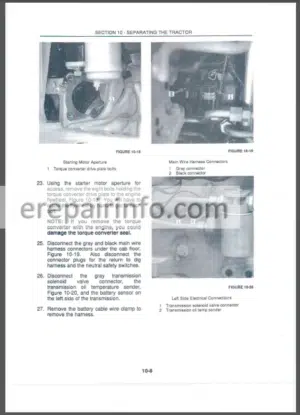

Separating The Tractor At The Clutch Housing/Engine

Attaching The Tractor At The Clutch Housing/Engine

Fuel Injector And Glow Plug

Oil Pressure Switch

Temperature Sending Switch And Alternator

Fan, Water Pump, And External Oil Tube

Air Inlet Manifold

Rocker Arm Shaft And Support Bracket

Cylinder Head

Valve Tappet

Fuel Shutoff Solenoid

Engine Timing Gear Cover, Timing Gears, And Cam Shaft

Timing Gear Cover Removal

Timing Gears And Camshaft

Oil Sump

Oil Suction Pipe And Strainer

Balancer Assembly

Connecting Rods, Bearings, And Pistons, Rings

Flywheel

Backplate And Oil Seal

Crankshaft And Main Bearings

Cylinder Head

Inspection And Repair

Valve Seats

Valves

Valve Guides

Valve Springs

Rocker Arms

Push Rods

Cylinder Head

Cylinder Block

Pistons

Piston Rings

Connecting Rods

Pin To Bushing Clearance

Connecting Rod Bearing

Clearance Check

Pistons, Rings, And Connecting Rod

CrankshaftMain Bearing And Thrust Washer

Bearing (Bushing)

Main Bearing

Port Block

Timing Gear

Camshaft

Flywheel

Timing Gear Housing

Front Oil Seal And Steering Pump Seal

Replacement

Crankshaft And Bearing Holder

Rear Oil Seal And Backplate

Flywheel

Pistons And Connecting Rods

Balancer Assembly

Balancer Shims

Oil Suction Pipe And Suction Strainer

Oil Sump

Description Page

Camshaft And Camshaft Gear

Idler Gear, Oil Pump, And Injection Timing

Timing Gear Cover

Crankshaft Pulley

Fuel Injection Pump

Hydraulic Oil Pump

Power Steering Pump

Head Gasket Selection

Selection Chart

Cylinder Head

Valve Clearance

Valve Cover

Installation

Water Pump And Cooling Fan

External Oil Tube

Glow Plug And Connector

Fuel Injector

Fuel Piping

Alternator And Temperature Sender Switch

Exhaust Manifold

Description Of OperationEngine Lubrication System

Oil Filter

Construction And Function

Oil Pump

Removal

Inspection

Installation And Adjustment

Engine Oil Pressure

Check

Oil Pressure Relief Valve

Oil Consumption

Description Of OperationCooling System

Maintenance

Coolant

Radiator Cap

Thermostat

Water Pump

Cooling Fan

OverhaulCooling System

Radiator

Inspection And Repair

Water Pump

Inspection And Repair

Thermostat

Radiator - – Clutch

Separating The Tractor At The Clutch Housing/Engine

Attaching The Clutch Housing To The Engine

Flywheel Dimensions

Clutch Release Bearing

Clutch Linkage Components

Cross Shaft Bushings

Pedal Bushings

Pedal

Adjustment

Clutch Pedal Safety Switch - – Transmission

Specifications

Sss Gear Transmission

Metric Bolt Torque Specifications

Special Tools

Description Of Operation

Powerflow

Separating The Tractor At Clutch Housing(Transmission Housing

Main Transmission Input Shaft Retainer

Input Shaft

Reverse Idler Shaft And Gear

Shift Rails

Upper Countershaft

Main Shaft

Shuttle Gears

Main Transmission Range Gear Shifter

SynchronizersShuttle Gears

Shuttle Transmission Gears/ Synchronizer

Shuttle Transmission Gears/ Synchronizer

Main Transmission Range Gear Shifter

Shuttle Gears

Main Shaft

Range Gears

Range Gear Shift Fork

Countershaft

Shift Rails

Input Shaft With Retainer

End Play Adjustment (Upper Shaft)

Attaching The Transmission I Differential Housing

Attaching The Clutch Housing/Transmission Housing - – Fwd Front Axle

Front To Rear Axle Ratio

Bolt Torque Specifications

Description Of OperationFwd Front Axle

Fwd Front Axle

Troubleshooting

Lubrication

Lubricate EveryHours

OverhaulFwd Axle

Fwd Axle

Gear Reduction Drop Box

Front Axle And Differential

Pinion Shaft

Ring GearToPinion Backlash

Axle And Differential

Gear Reduction Box

Bevel GearToPinion Backlash

Check - – Differential, Rear Axle

Differential Pinion Gear to Shaft Clearance

Bolt Torque Specifications

Metric Bolt Torque Specifications

Description of Operation

Differential

Differential Lock

Rear Axle

Drive Pinion

Rear Axle

Final Pinion - – Hydrostatic Transmission

Description Of OperationHydrostatic Transmission

Variable Displacement Pump

Operation

Fixed Displacement Motor

Operation

Fluid Flow

Neutral Position

Forward Position

Reverse Position

Hydrostatic Unit

Precautions Before Disassembly

Hydrostatic Pump

Hydrostatic Motor

Hydrostatic Motor Shaft

Swash Plate

Hydrostatic Transmission

Hydrostatic Pump

Hst Piston Pump Cylinder Block

Hst Motor Cylinder Block

Port Block Feed And Check Valves

Feed (Check) Valves Servicing

Charge Pressure Relief Valve

High Pressure Relief Valve

Hydrostatic Pump And Port Block

Hydrostatic Motor And Port Block

Hst Cooler Check Valve

Pressure Tests

High Pressure Relief Valve

Charge Pressure Relief Valve

Troubleshooting

Specifications

Hydrostatic Transmission

Bolt Torques - – Power TakeOff (Pto) Systems

Pto Hydraulic System (Hst Model Only)

Pto Clutch

Metric Bolt Torque Specifications

Special Tools

Description Of Operation

Rear Pto

Power Flow Diagram For TheXSynchronized Shuttle Shift Transmission

Power Flow Diagram For The Hydrostatic Transmission (Hst)

Hydraulic Fluid Flow

Pto Clutch Assembly (Hst)

Troubleshooting

Pressure Testing (Hst)

Test Procedure

Pto System Diverter Valve Assembly (Hst)

Pto Clutch Control Valve (Hst)

Pto Clutch (Hst)

Installation

Power Take Off System ForXSynchronized Shuttle Shift Transmission

OneWay Clutch ( X )

Power Take Off System For Hydrostatic Transmission (Hst)

Pto Input Shaft

Pto Countershaft And Rear Pto Shaft - – Brakes

Specifications

Bolt Torque Specifications

Description of Operation

Brakes

Park Brake

Overhaul

Brakes

Removal and Disassembly

Inspection

Assembly and Installation

Adjustment - – Hydraulic System

Hydraulic System

Hydraulic Fluid Filter

Combination System ReliefDiverter Valve Manifold Assembly

Control Valve Assembly (Hpl)

Fluid Flow

Neutral Position

Raising Position

Lowering Position

Bypass SpoolFluid Flow

Flow Control Valve

Linkage OperationSingle LeverPosition Control

Position Control Operation

Neutral Position To Raise

Raise Position To Neutral Position

Neutral Position To Lowering Position

Dual Lever Position Control (Draft Control)

Top Link Sensing Raise

Top Link Sensing Lower

Varying Draft Control Settings

Combining Position And Draft Control Settings

Pressure Testing

Main System Relief Valve

Inlet Restriction

Pump Efficiency

OverhaulHydraulic System

Lift Cylinder

Inspection And Repair

Flow Control Valve

Hydraulic Control Valve

Combination System Relief Valve And Diverter Valve Assemblies

Hpl Linkage

Adjustment Procedure

Control Lever

Adjustment Procedure

Description Of OperationHydraulic Pump And Filter

Hydraulic Pump And Filter

Hydraulic Pump

Oil Pump Trial Running

Sump Tube And Screen Filter

Description Of OperationRemote Valves

Remote Valves

Rear (SingleSpool) Remote Valve

Front (TwoSpool) Remote Valve

Rear (SingleSpool) Remote System

Fluid Flow

Neutral Position

Remote Cylinder Extending

Remote Cylinder Retracting

Front Remote (Two Spool) Loader Control Valve Fluid Flow Diagrams

Bucket Control

Neutral/Lift ControlNeutral

Dumping/Lift ControlNeutral

Dumping Regen/Lift ControlNeutral

Roll Back/Lift ControlNeutral

Neutral/Lift ControlRaising

Neutral/Lift ControlLowering

Neutral/Lift ControlFloat

OverhaulFront And Rear Remote Valves

Rear (SingleSpool) Remote Valve

Front (TwoSpool) Remote Valve - – Steering

Power Steering System

Special Tools

Description Of Operation

Power Steering System

Power Steering Control Motor Components

Power Steering Control Motor

Spool And Sleeve

Rotor And Fixed Ring

Drive Shaft

Check Valve And System Relief Valve

Check Valve

Pressure Relief Valve

Power Steering Pump

Steering Cylinder

Power Steering Operation

Fluid Flow

Manual Operation

Pressure Testing

Pump, Steering Motor, And Relief Valve

Steering Cylinder

Overhaul

Steering Control Motor

Steering Cylinder

Installation

Pump

Inspection And Repair

Oil Pump Trial Running

Power Steering Tubes - – Wheels And Tires

Wheel Tread Settings

Front Wheel Settings

Rear Wheel Settings

Tractor Weighting

Weighting For Stability

Weighting Limitations

Cast Iron Weights (Optional)

Front Frame Mounted Weights

Optional Front Weight Extension Bracket

Rear Wheel Weights #

Rear Wheel Weight Installation

Rear Counter Weight Bracket (Optional)

Ballasting Box (Optional)

Liquid Ballast (Optional)

Tire Pressure

Rear Tire Liquid

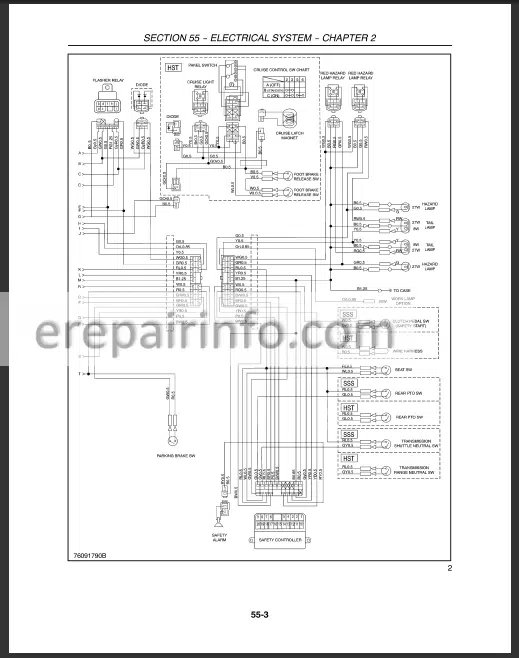

Wheel Nut Torque Specifications - – Electrical System

Component Location And Function

Ground Locations

Description And TestingElectrical System Components

Battery

Electrolyte Level

Main Fuse ( Amp)

Replacement

Fuse Block

Key Switch

Key Switch Terminal Identification

Key Switch TroubleshootingConnector Wiring

Light Switch

Headlights

Taillights

Hazard/Turn Signal Combination Switch

Hazard/Turn Signal Lights

Transmission Range Safety Switch (Hst Only)

Transmission Shuttle Safety Switch (X Only)

Rear Pto Safety Switch (X Only)

Rear Pto Switch (Hst Only)

Seat Safety Switch

Clutch Safety Start Switch (X Only)

Park Brake Switch

Safety Alarm (Buzzer)

Relays

Safety Start Relay

Tail Light Relays

Diodes

Turn Signal!Tail Light Diode Pack

Charging System Diode

Testing Diode Pack

Testing Charging System Diode

Installation (All Diodes)

Safety Controller

Terminal Identification

Testing Safety Start Circuit

Testing Glow Plug Circuit

Testing Pto Indicator Light Circuit

Engine Glow Plugs

Hazard Flasher!Turn Signal Control Module

Fuel Level Sender

Fuel Shutoff Solenoid

Oil Pressure Switch

Coolant Temperature Sending Unit

Positive Battery Cable - – Platform

Description Of Operation

Hood

Screen Guards

Steering Wheel

Instrument Panel

Seat Components

Seat

Roll Over Protection System (Rops)

Fuel Tank

Rear Fenders

Operator Platform

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

You took $149.60 from my bank account for a $89.95 product. WHAT THE FUCK !