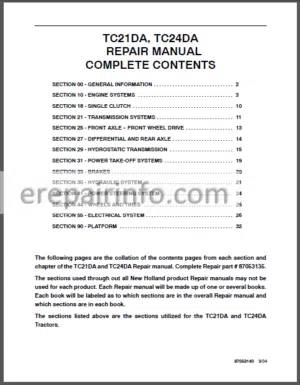

Repair Manual For New Holland T2210 / Boomer 2030 (Hydrostatic/Gear), T2220 / Boomer 2035 Tractors (Hydrostatic).

Manual includes step by step instructions, illustrations, diagrams. Remove, Install, disassemble, assemble, repair procedures, troubleshooting, and other servicing procedures. This repair manual provides the technical information needed to properly service the New Holland tractors.

Format: PDF

Language: English

Pages: 816

Bookmarks: Yes

Searchable: Yes

Number: 84122969; 84122964

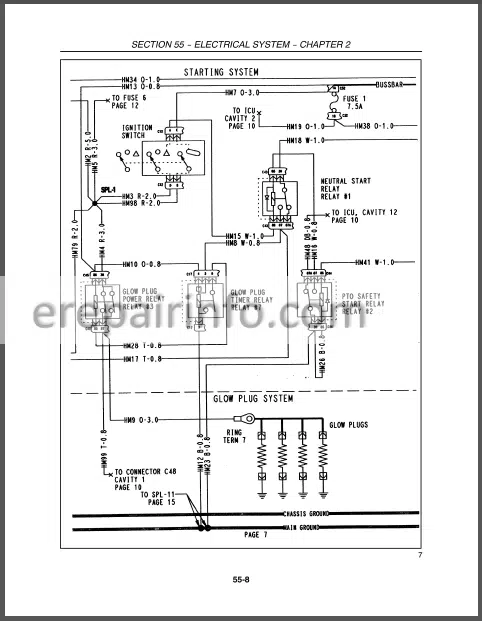

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland T2210, T2220, Boomer 2030, Boomer 2035

Contents

– General Information

Precautionary Statements

Personal Safety

Machine Safety

Information

Safety

Precautionary Statements

The Tractor

Servicing The Tractor

Operating The Tractor

Driving The Tractor

Operating The Pto

Diesel Fuel

Safety Frame (Rops)

Decals

Safety Decals

Instruction Decals

Ecology And The Environment

Helpful Hints

International Symbols

Specifications

General Dimensions

Minimum Hardware Tightening Torques

Lubrication And Maintenance

Lubrication

Liquid Ballast (Optional)

Tire Pressure

Rear Tire Liquid

– Engine

Cooling System All Models

Engine Bolt Torque Specifications

Engine Fuel System Bolt Torque Specifications

Metric Bolt Torque Specifications

Special Tools

Compression Test And Tools

Description Of OperationGeneral Information

Cylinder Head And Valve Train Components

Cylinder Block Assembly

Engine

Preparation

Fuel Injector And Glow Plug

Oil Pressure Switch

Temperature Sending Switch And Alternator

Fan, Water Pump And External Oil Tube

Head Cover

Rocker Arm Shaft And Support Bracket

Cylinder Head

Valve Tappet

Fuel Shutoff Solenoid

Description Page

Timing Gear Cover

Timing Gears And Camshaft

Oil Sump

Oil Suction Pipe And Strainer

Connecting Rods, Bearings, Pistons And Rings

Flywheel

Backplate And Oil Seal

Front Crankshaft Gear

Crankshaft And Main Bearings

Cylinder Head

Inspection And Repair

Valve Seats

Inspection And Repair

Inspection And Replacement

Valve Guides

Inspection And Replacement

Valve Springs

Inspection And Replacement

Rocker Arms

Inspection And Replacement

Push Rods

Inspection And Replacement

Cylinder Block

Inspection

Pistons

Disassembly And Inspection

Piston Rings

Disassembly And Inspection

Connecting Rods

Disassembly And Inspection

Pin To Bushing Clearance

Connecting Rod Bearing Oil Clearance Check

Pistons, Rings And Connecting Rod

Main Bearing And Thrust Washer

Removal And Inspection

Crankshaft

Inspection

Crankshaft Bearing (Bushing)

Replacement

Crankshaft Front Gear, Main Bearings And Thrust Washers

Port Block

Installation

Timing Gear

Inspection

Camshaft

Flywheel

Inspection And Repair

Timing Gear Housing

Front Oil Seal And Steering Pump Seal

Replacement

Crankshaft And Bearing Holder

Installation

Rear Oil Seal And Backplate

Installation

Flywheel

Installation

Pistons And Connecting Rods

Installation

Oil Suction Pipe And Suction Strainer

Oil Sump

Installation

Camshaft And Camshaft Gear

Idler Gear, Oil Pump And Injection Timing

Timing Gear Cover

Installation

Crankshaft Pulley

Fuel Injection Pump

Power Steering Pump

Head Gasket Selection

Cylinder Head

Valve Clearance Adjustment

Head Cover

Water Pump And Cooling Fan

Installation

External Oil Tube

Glow Plug And Connector

Fuel Injector

Fuel Piping

Alternator And Temperature Sender Switch

Exhaust Manifold

Description Of OperationEngine Lubrication System

Oil Filter

Construction And Function

Maintenance

Oil Pump

Installation And Adjustment

Engine Oil Pressure Check

Oil Pressure Relief Valve

Oil Consumption

Description Of OperationCooling System

Maintenance

Coolant

Radiator Cap

Thermostat

Water Pump

Cooling Fan

Radiator

Inspection And Repair

Water Pump

Inspection And Repair

Thermostat

Inspection And Repair

– Clutch

Description Of Operation Single Clutch

Hst Transmission

Adjustments Single Clutch

Free Play

Overhaul Single Clutch

Single Clutch

Description Of OperationDouble Clutch

Gear Transmission

Adjustments Double Clutch

Free Play

Pto Clutch

Transmission Only

Overhaul Double Clutch

Double Clutch

Double Clutch Adjustments

Servicing ClutchRelated Components

Clutch Pilot Bearing ( transmission Only)

Clutch Dimensions

Clutch Release Bearing

Clutch Linkage Components

Clutch Cross Shaft Bushings

Clutch Pedal Bushings

– Gear Transmission

Gear Transmission

General Bolt Torque Specifications

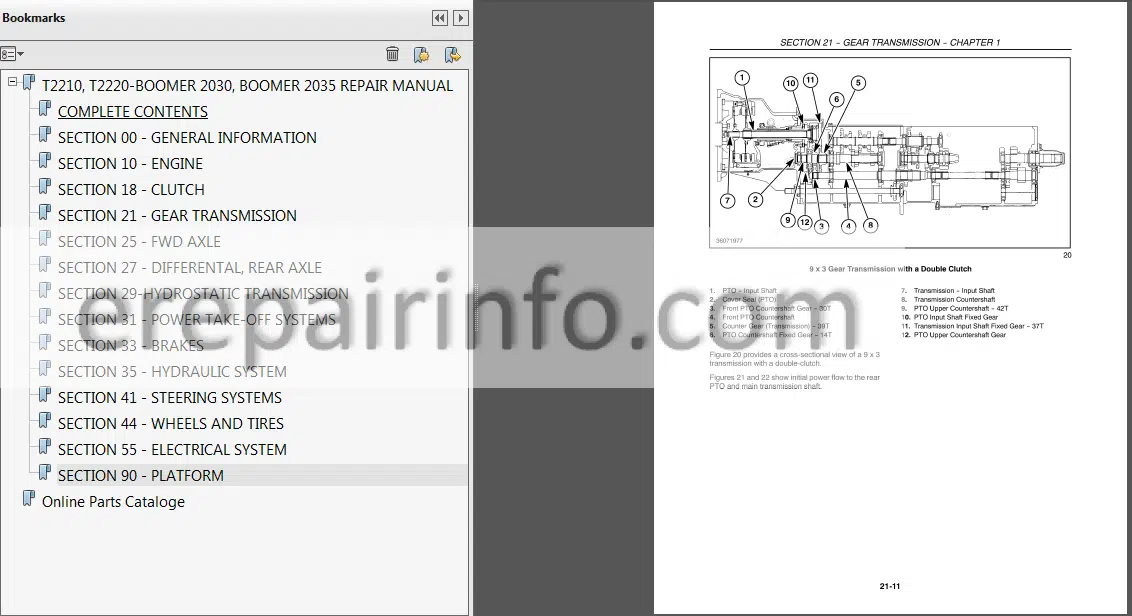

Description of Operation

Gear Transmission

Clutch Housing

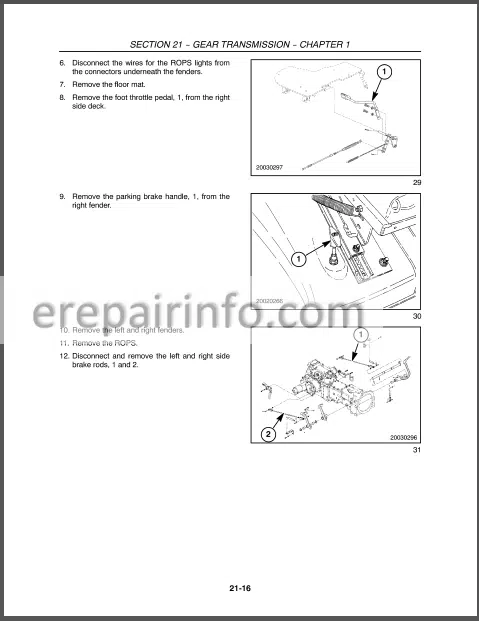

Transmission Preparation

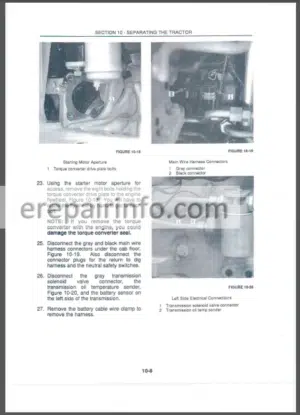

Separating the Tractor at Clutch Housing/Engine

Separating Clutch Housing/Transmission

Separating Transmission/Differential

Transmission Assembly Removal

Double Clutch Input Shaft

Double Clutch

Main Gear Shifter Rod

Main Shaft

Reverse Idler Shaft

Double Clutch Countershaft

Double Clutch PTO Countershaft

Double Clutch FWD Drive Shaft

FWD Shift Rod

Rear Main Shaft

Range Gear Shifter Rod

Drive Pinion

Preinstallation Instructions

Range Gear Shifter Rod

Rear Main Shaft

FWD Drive Shaft

FWD Shift Rod

Double Clutch PTO Countershaft

Double Clutch Countershaft

Reverse Idler

Main Shaft

Main Gear Shifter Rod

Main Transmission Shift Lever

Double Clutch Input Shaft

Transmission/Differential

Clutch Housing/Transmission

Clutch Housing/Engine

Main Shift Lever

– Fwd Axle

Front To Rear Axle Ratio

Description Of OperationSupersteer, Front Axle And Sensitrack

Automatic Position (Engaged)

Automatic Position (Disengaged)

Full Time Front Wheel Drive (Locked Down)

Supersteer Front Axle

Sensitrack

Cable Adjustment

Supersteer Axle

Supersteer Axle Components

Reduction GearDrop Box

Reduction Gear Box Assembly

Seal Installation

Front Axle And Differential

Drive Pinion

Front Axle

Inspection And Repair

Differential

Inspection

Front Axle And Differential

Differential Gear

Axle And Differential

Ring GearToPinion

Backlash Check And Adjustment

Supersteer Axle

Crankshaft Pulley

– Differential Rear Axle

Ring Gear and Pinion Gear Pattern Specification and Adjustment

Bolt Torque Specifications

Description of OperationDifferential Assembly

Differential Lock

OverhaulDifferential Assembly

Drive Pinion

Disassembly (with HST Transmission)

Disassembly (with transmission)

Assembly and Installation

Description of OperationRear Axle

Overhaul Rear Axle

Rear Axle

– Hydrostatic Transmission

Hydrostatic Transmission

Bolt Torques

Minimum Hardware Tightening Torques

Description Of OperationHydrostatic Transmission

Hydrostatic Transmission

Variable Displacement Pump

Operation

Fixed Displacement Motor

Fluid Flow

Neutral Position

Forward Position

Reverse Position

Hst Charge Circuit

Overhaul Hydrostatic Transmission

Separating The Tractor Between The Engine And Clutch Housing

Attaching The Tractor At Engine And Clutch Housing

Separating The Tractor Between The Hydrostatic Transmission And The Rear Axle Center Housing

Hydrostatic Unit

Hydrostatic Gearbox

Hydrostatic Unit And Gearbox

Precautions Before Hst Disassembly

Hydrostatic Pump

Hydrostatic Motor

Hydrostatic Motor Shaft

Charge Pump

Swash Plate

Inspection

Hydrostatic Pump

Hst Piston Pump Cylinder Block

Hst Motor Cylinder Block

Port BlockNeutral And Feed Valves

Disassembly

Neutral Valve

Charge Pump Relief Valve

High Pressure Relief Valve

Hydrostatic Pump And Port Block

Motor And Port Block

Hst Cooler Check Valve

Pressure Tests

High Pressure Relief Valve

High Pressure Relief Valve Access (Alternate Method)

Charge Pump Relief Valve

Description Of OperationGearbox

Hydrostatic Transmission Gearbox

Hst

Gearbox Power Flow

OverhaulGearbox

Gearbox

Gearbox Case

Pto Input Shaft

Transmission Input Shaft

Fwd Shift Rod

Disassembly

Fwd Drive Shaft

Rear Main Shaft

Range Gear Shifter Rod

Disassembly

Drive Pinion Shaft

Pto Countershaft

Gearbox Components

Drive Pinion

Pto Countershaft

Range Gear Shifter Rod

Rear Main Shaft

Fwd Main Shaft

Transmission Input Shaft

Pto Input Shaft

Gearbox

Adjustments

Rear Pto Link

Adjust

MidPto Link

Adjust

Range Gear Link

Hst Neutral Position

Treadle Forward Stop

Treadle Rear Stop Adjustment

Cruise Control Adjustment

Hst Neutralizer

– Power TakeOff Systems

Description Of Operation Live Power TakeOff

Live Power Take Off

Power Take Off Drive Hydrostatic Transmission

Overhaul Power TakeOff

Power Take Off

Output Shaft

Rear Countershaft

Front Countershaft

Shifter

Front Countershaft

Rear Countershaft

Center Countershaft (Hst)

Output Shaft

Description Of OperationMidMount Power TakeOff

MidMount Power TakeOff

OverhaulMidMount Power TakeOff

Countershaft

Shifter Arm

Gear Box

Gear Shifter

Output Shaft

Gear Box

Output Shaft

Gear Shifter

Shifter Arm

Countershaft

Rear Pto Components Assembly

– Brakes

Parking Brake

Brakes

Brake Adjustment

– Hydraulic System

Bolt Torque Specifications

Special Tools

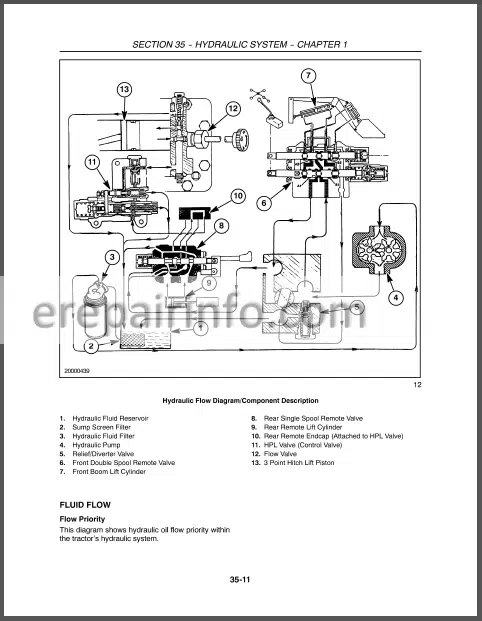

Description Of Operation Hydraulic System

Hydraulic Fluid Filter

Combination System Relief Diverter Valve Manifold

Control Valve (Hpl)

Fluid Flow

Flow Priority

Neutral Position

Raising Position

Lowering Position

Bypass Spool Closed Position

Bypass Spool Open Position

Flow Control Valve

Linkage Operation Single Lever Position Control

Position Control Operation

Neutral Position To Raise Position

Raise Position To Neutral Position

Neutral Position To Lowering Position

Troubleshooting

Pressure Testing

Main System Relief Valve

Inlet Restriction Test

Pump Efficiency Test

Overhaul Lift Cylinder

Lift Cylinder

Flow Control Valve

Hydraulic Control Valve (Hpl)

Combination System Relief Valve And Diverter Valve

Hpl Linkage

Adjustment Procedure

Control Lever

Description Of OperationHydraulic Pump And Filter

Hydraulic Pump And Filter

Overhaul Hydraulic Pump

Hydraulic Pump

Description Of OperationRemote Valves

Remote Valves

Rear (Single Spool) Remote Valve

Front (Double Spool) Remote Valve

Fluid Flow

Neutral Position Rear (Single Spool) Remote System

Remote Cylinder Extending Rear (Single Spool) Remote System

Remote Cylinder Retracting Rear (Single Spool) Remote System

Front (Double Spool) Remote Control System Bucket Control Neutral

And Lift Control Neutral

Bucket Control Dumping And Lift Control Neutral Front (Double Spool)

Remote Control System

Bucket Control Dumping (Regen) And Lift Control Neutral Front (Double Spool) Remote Control System

Bucket Control Rollback And Lift Control Neutral Front (Double Spool)

Remote Control System

Bucket Control Neutral And Lift Control Raising Front (Double Spool)

Remote Control System

Bucket Control Neutral And Lift Control Lowering Front (Double Spool)

Remote Control System

Bucket Control Neutral And Lift Control Float Front (Double Spool)

Remote Control System

Overhaul Remote Valves

Rear (Single Spool) Remote Valve

Front (Double Spool) Remote Control Valve

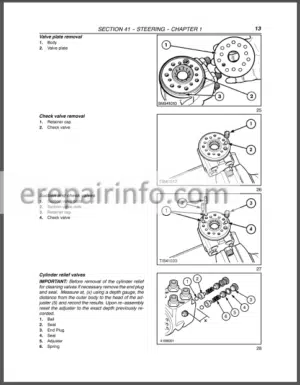

– Steering Systems

Metric Bolt Torque Specifications

Special Tools

Description Of Operation Power Steering System

Description Of Operation Supersteer

PowerSteering Control Motor

Spool And Sleeve

Drive Shaft

Gerotor Pump

Combination Check/Relief Valve Function

Relief Function

Power Steering Pump

Fwd Power Steering Cylinder

Supersteer Steering Cylinders

Fwd Power Steering Operation

Fluid Flow

Neutral Position

Left Turn

Right Turn

Fwd Manual Operation

Supersteer Power Steering Operation

Fluid Flow

Neutral Position

Left Turn

Right Turn

Supersteer Manual Operation

Pressure Testing

Pump, Steering Motor And Relief Valve

Test Results

Steering Cylinder

Test Results

Steering Stops

Troubleshooting

Power Steering Control Motor

Fwd Steering Cylinder

Supersteer Steering Cylinder

Power Steering Pump

Inspection And Repair

Power Steering Tubes

Steering Column

Adjustable Steering Column

– Wheels And Tires

Fwd Tread Setting

Front Wheel Settings

Rear Wheel Settings

Rear Axle Tread Setting

Tractor Weighting

Weighting For Stability

Weighting Limitations

Rear Wheel Weight Installation

Liquid Ballast

Tire Pressure

Rear Tire Liquid

Wheel Nut Torque Specification

– Electrical System

Description of Electrical System

Component Location and Function

Wiring Harnesses

Grounds

Battery and Fuses

Battery

Description

Checking the Battery Electrolyte Level

Fuse Block

Description

Main Fuse

Replacing the Main Fuse

Electrical System ComponentsDescription and Testing

Key Switch

Key Switch Terminal Identification

Stop Position (Not Shown)

Heat I Accessory I Run Position

Start Position

Light Switch

Terminal Identification

Testing

Hazard Light Switch

Testing

“Off’ Position

“On” Position

Installation

Turn Signal Switch

Off Position (Center)

Right Position

Left Position

Transmission Range Safety Switch

Testing

Extended Position

Retracted Position (Not Shown)

Rear PTO Safety Switch

Description

Testing

Mid PTO Safety Switch

Park Brake Safety Switch

Retracted Position (Not Shown)

Extended Position

Cruise Control Brake Release Switch

Seat Safety Switch

Extended Position

Retracted Position

Installation

Diodes

Description

Testing

Relays

Description and Location

Testing Micro Relays

Fuel Shutoff, Glow Plug Lamp, PTO Safety Interlock, Hazard Flasher Cutoff

Hazard Flasher[Turn Signal Control Module

Operator Safety Module

Park Brake Safety Alarm (Buzzer)

Condition

Glow Plug Indicator Light Controller

Cruise Control Magnet

Cruise Control Switch

Glow Plugs

Engine Sensors

Engine Oil Pressure Sender

Engine Coolant Temperature Sender

Fuel Level Sender

Fuel Shutoff Solenoid

Lighting

Head Lamp

Taillight

Flasher Warning Light

Rear Worklight

Auxiliary Electrical Power Socket

– Platform

Hood

Rear Hood Panels

Dash Console

Seat

ROPS

Fenders

Deck

PTO and Range Controls

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet