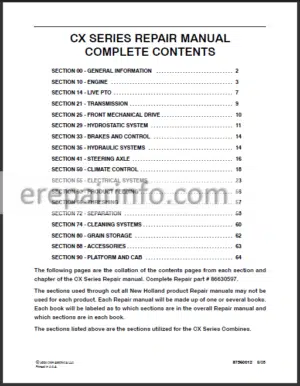

Factory Service Manual For New Holland Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1365

Number: 51500239

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Tractor

T4.90FB

T4.100FB

T4.110FB

Contents

-INTRODUCTION

Reading This Manual

Safety Rules

General

Technical Characteristics

Tightening Torques And Sealants

General Assembly Instructions

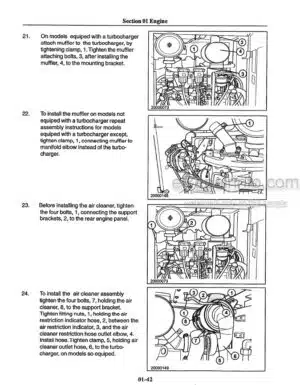

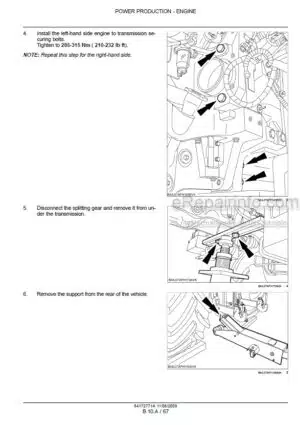

-ENGINE

Safety Rules

General Information

Maintenance

External Views Of Engine

Engine Oil

Coolant

Air Filter

Injection System

Fuel Filter

Alternator Poly-V Belt

Diesel Particulate Filter (DPF)

Diesel Particulate Filter (DPF)

Removal And Installation

Tightening Torques

Wiring Harness Connector Kit

Timing Side

Oil Pump

Crankshaft Gear

Hydraulic Pump Idler Gear (Between Crankshaft And Camshaft Gears) High Pressure Pump Idler Gear (Between Camshaft Gear And Injection Pump Gear)

Hydraulic Pump Gear

Idler Pulley

Crankshaft Hub And Pulley

Water Pump And Pulley

Timing Cover

Front Oil Seal

Turbocharger

EGR Heat Exchanger

Exhaust Gas Temperature And Pressure Sensors

Throttle Valve

Exhaust Manifold

Intake Manifold

Crankshaft Endfloat

Engine Flywheel

Engine Flywheel Ring Gear

Flywheel Housing

Rear Crankshaft Bearing

Shim

Rear Main Bearing Bush

Rear Oil Seal

Tone Wheel

Head Gasket – Piston-To-Head Clearance

Head – Single Head For All Cylinders

Retightening Heads

Valve Guides

Valve Seat

Valves

Valve Spring

Rockers

Hydraulic Tappets

Rocker Rods

Fracture-Split Connecting Rod

Piston

Engine Oil Sump And Transmission Pipe

Oil Suction Pipe

Engine Oil Pressure Relief Valve

Separator Oil Drain Valve

Crankshaft Balancer Weights

Crankcase

Cylinder Sleeve

Camshaft

Camshaft Bushes

Front Camshaft Bush

Piston Cooling Oil Jets

Crankshaft

Front Crankshaft Bush

Injection System

Low Pressure Injection System – Specifications

High Pressure Pump

Injectors

Rail

High Pressure Injection System Components – Tightening Procedure

Oil Filter Housing

Rocker Cover

Thermostat Valve

Alternator

Alternator Pulley

Alternator Regulator

Alternator Bracket

Starter Motor

Electric Sensors

Special Tools

-CLUTCH HOUSING

Safety Rules

General Introduction

Technical Characteristics

Disassembly

Main Inspection, Reassembly And Adjustment Procedures

Tightening Torques

Tools Necessary

-GEARBOX

Safety Rules

General Introduction

Technical Characteristics

Disassembly

Main Inspection, Reassembly And Adjustment Procedures

Tightening Torques

Tools Necessary

-REAR DIFFERENTIAL

Safety Rules

General Introduction

Technical Characteristics

Disassembly

Main Inspection, Reassembly And Adjustment Procedures

Tightening Torques

Tools Necessary

-REAR FINAL DRIVE UNITS

Safety Rules

General Introduction

Disassembly

Main Inspection, Reassembly And Adjustment Procedures

Tightening Torques

Tools Necessary

-FRONT AXLE

Safety Rules

General Introduction

Technical Characteristics

Removal

Main Components

Refitting

Tightening Torques

Tools Necessary

-TRANSFER CASE

Safety Rules

General Introduction

Technical Characteristics

Disassembly

Main Inspection, Reassembly And Adjustment Procedures

Tightening Torques

Tools Necessary

-REAR POWER TAKE OFF

Safety Rules

General Introduction

Technical Characteristics

Disassembly

Main Inspection, Reassembly And Adjustment Procedures

Tightening Torques

Tools Necessary

-BRAKES

Safety Rules

General Introduction

Technical Characteristics

Disassembly

Main Inspection, Reassembly And Adjustment Procedures

-HYDRAULIC SYSTEM

Safety Rules

Main Hydraulic Circuit

Lift Hydraulic System

Lift With Position And Draft Control

Main Components

Checking Operating Pressure Values

Tools Necessary

-PLATFORM

Safety Rules

Removing And Refitting The Platform

Tools Necessary

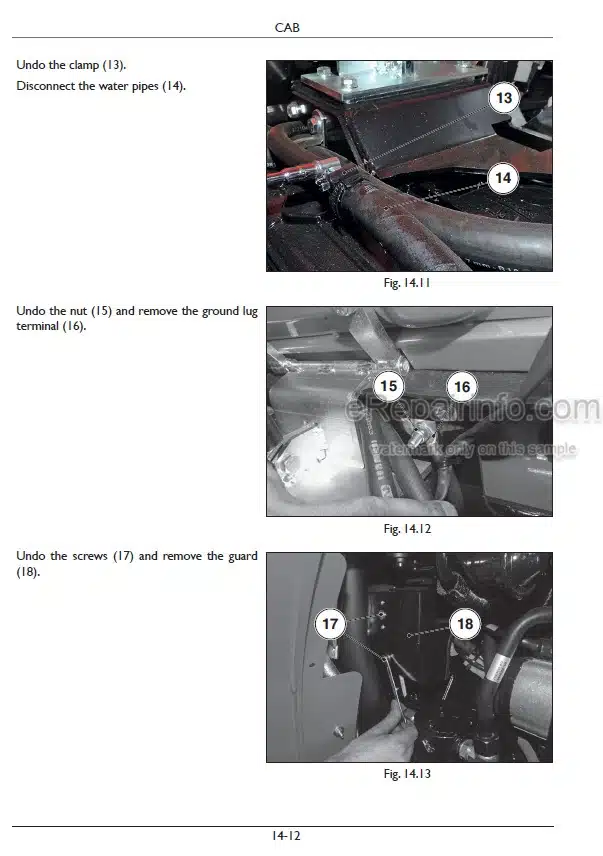

-CAB

Safety Rules

Technical Characteristics

Removing And Refitting

Air Conditioning System

Tools Necessary

-REAR HITCH

Safety Notes

Technical Specifications

Disassembly

Main Inspection, Re-Assembly And Adjustment Operations

Tightening Torques

Tools Required

-ELECTRICAL SYSTEM

Safety Rules

Introduction

Wiring Looms

Systems

Systems For Wiring Harnesses (From Serial No 0000622678 For Roll Bar Versions With SG1/1-Gl11/1 Cabs And Front Lift)

Fuse Box

Error Code List

-TROUBLESHOOTING

Engine Control Unit (ECU)

Vehicle Control Unit (VCU)

Connector List

-SPECIAL TOOLS

Engine Tools List

Vehicle Tools List

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet