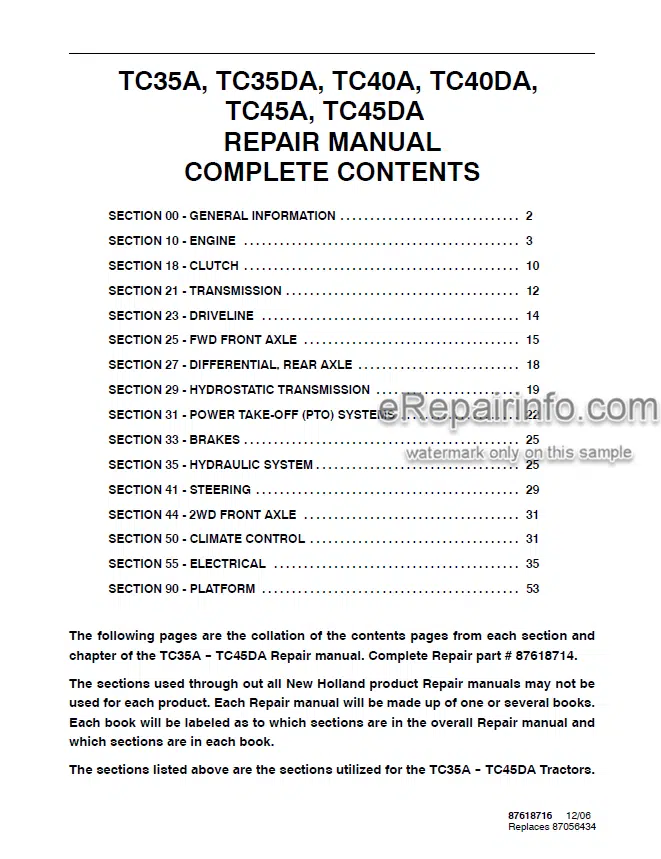

Repair Manual For New Holland TC35A, TC35DA, TC40A, TC40DA, TC45A, TC45DA.

This repair manual provides the technical information needed to properly service and repair the New Holland tractors. Use this manual in conjunction with the operators manual for complete operation, adjustment, and maintenance information.

Format: PDF

Language: English

Pages: 1478

Bookmarks: Yes

Searchable: Yes

Number: 87618716; 86618104

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland TC35A, TC35DA, TC40A, TC40DA, TC45A, TC45DA

Contents

- General information

- Engine N843L, N844, N844L

- Clutch

- Transmission

- Driveline

- FWD front axle

- Differential rear axle

- Hydrostatic transmission

- PTO systems

- Brakes

- Hydraulic system

- Steering

- 2WD front axle

- Climate control

- Electrical Platform

Chapters

- – General Information

Introduction

Safety

Technical Information

Safety Precautions

Safety Decals

Instruction Decals

Specifications

General Dimensions

Minimum Hardware Tightening Torques

Special Tools

Lubricants

Recommended Lubricants

Adjustments

Tire Inflation Pressure

PreSeason And PreDelivery Checklist - – Engine

Specifications

Metric Bolt Torque Specifications

Compression Test And Tools

Description Of Operation

Troubleshooting

Cylinder Head And Valve Train Components

Cylinder Block Assembly

Separating The Tractor At The Clutch Housing/EngineX Transmission

Separating The Tractor At The Hst Housing/EngineHst Transmission

Separating The Tractor At The Hst Engine Frame

Attaching The X Transmission To The Engine

Attaching The Hst To The Engine

Fuel Injector And Glow Plug

Oil Pressure Switch

Temperature Sending Switch And Alternator

Fan, Water Pump And External Oil Tube

Air Inlet Manifold

Rocker Arm Shaft And Support Bracket

Cylinder Head

Valve Tappet

Fuel Shutoff Solenoid

Engine Timing Gear Cover, Timing Gears, And Cam Shaft

Timing Gear Cover Removal

Timing Gears And Cam Shaft

Oil Sump

Oil Suction Pipe And Strainer

Balancer Assembly

Connecting Rods, Bearings, And Pistons, Rings

Flywheel

Backplate And Oil Seal

Crankshaft Main Bearings

Cylinder Head

Inspection And Repair

Valve Seats

Valves

Valve Guides

Valve Springs

Rocker Arms

Push Rods

Cylinder Head

Cylinder Block

Pistons

Piston Rings

Connecting Rods

Connecting Rod Bearing

Clearance Check

Pistons, Rings, And Connecting Rod

Main Bearing And Thrust Washer

Crankshaft

Bearing (Bushing)

Main Bearing

Port Block

Timing Gear

Camshaft

Flywheel

Timing Gear Housing

Front Oil Seal And Steering Pump Seal

Crankshaft And Bearing Holder

Rear Oil Seal And Backplate

Flywheel

Pistons And Connecting Rods

Balancer Assembly

Balancer Shims

Oil Suction Pipe And Suction Strainer

Oil Sump

Camshaft And Camshaft Gear

Idler Gear, Oil Pump, And Injection Timing

Timing Gear Cover

Crankshaft Pulley

Fuel Injection Pump

Hydraulic Oil Pump

Power Steering Pump

Head Gasket Selection

Selection Chart

Cylinder Head

Valve Clearance

Valve Cover

Water Pump And Cooling Fan

External Oil Tube

Glow Plug And Connector

Fuel Injector

Fuel Piping

Alternator And Temperature Sender Switch

Exhaust Manifold

Description Of OperationEngine Lubrication System

Oil Filter

Construction And Function

Oil Pump

Engine Oil Pressure

Check

Oil Pressure Relief Valve

Oil Consumption

Description Of OperationCooling System

Radiator Cap

Thermostat

Water Pump

Cooling Fan

Radiator

Water Pump

Thermostat

Cab Heater

Fuel Variation Mechanism

Delivery Valve Assembly

Ctd (Compact Timing Device)

Pumping Elements

Delivery Valves

Injection Pump

Fuel Pump

SpillTiming Procedure

Fuel Screw/High Idle

Fuel Pump

Auto Bleed

Description Of Operation

Governor

Injectors

Engine Breather Valve

Engine Breather Valve - – Clutch

Bolt Torques

Separating The Tractor At The Clutch Housing/Engine

Attaching The X Transmission To The Engine

Clutch Related Components

Pilot Bearing

Damper Disc

Flywheel Dimensions

Clutch Release Bearing

Clutch Linkage Components

Cross Shaft Bushings

Pedal Bushings

Pedal

Maximum Travel Adjustment - – Transmission

Metric Bolt Torque Specifications

Cross Section

Powerflow

Separating The Tractor At The Clutch Housing/Engine

Clutch Housing

Main Transmission

Retainer Cover

Main Shift Rails And Shift Forks

Main Shaft

Range Shift Rail And Shift Fork

Range Gear Countershaft

Input Shaft

Reverse Idler Shaft

Shuttle Shift Rail And Fork

Main Countershaft

Synchronizers

Main Transmission Components

Synchronizers

Main Countershaft

Shuttle Shift Rail And Fork

Reverse Idler Shaft

Input Shaft

Main Countershaft End Float

Range Gear Countershaft

Range Shift Rail And Fork

Main Shaft

Main Shaft End Float

Main Shaft Gears End Float

Main Shift Rails And Forks

Retainer Cover

Clutch Housing

Attaching TheXTransmission To The Engine

Transmission Shift Levers

Main Shift Control Lever

Main Shift Lever

Shuttle Shift Control Lever - – Driveline

Front Wheel Drive Take Off Gearbox

Sensitrack

Automatic Position

Full Time Front Wheel Drive (Locked Down)

Supersteer™ Front Axle

Troubleshooting

Lubrication

Front Wheel Drive Take Off Gearbox

Sensitrack - – Fwd Front Axle

Front To Rear Axle Ratio

Bolt Torque Specifications

Special Tools

Standard Fwd Axle

Gear Reduction Drop Box

Front Axle And Differential

Drive Pinion

Front Axle

Differential

Gear Reduction Drop Box

Drive Pinion

Differential Gear

Axle And Differential

Differential Case Bearing Preload

Check And Adjustment

Ring GearToPinion Backlash

Check And Adjustment

Gear Reduction Box

Ring GearToPinion Backlash

Bevel GearToPinion Backlash

Supersteert/Sensitrackt

Supersteert

Sensitrackt

Automatic Position (Engaged)

Automatic Position (Disengaged)

Full Time Front Wheel Drive (Locked Down)

Supersteert Front Axle

Supersteert Axle

Gear ReductionDrop Box

Front Axle And Differential

Drive Pinion

Front Axle

Gear ReductionDrop Box

Drive Pinion

Differential Gear

Axle And Differential

Differential Case Bearing Preload

Check And Adjustment

Ring GearToPinion Backlash

Check And Adjustment

Gear Reduction Box

Bevel GearToPinion Backlash

Supersteert Axle - – Differential, Rear Axle

Differential

Differential Lock

Rear Axle

Differential

Drive Pinion

Rear Axle

Final Pinion - – Hydrostatic Transmission

Power Flow

High Range

Low Range

Oil Flow

Neutral Position

Forward Position

Reverse Position

Variable Displacement Pump

Two Position Displacement Motor

Hi/Lo Speed Control/Control Pod

Hi/Lo Speed Control

Foot Control Pedals

Charge Pump Relief Valve

Pressure Testing And Adjustments

High Pressure Relief Valve

Hi/Low Pressure Test

Separating The Tractor

Separating At The Hst Housing/Engine

Separating The Hst Housing At The Gearbox

Attaching The Hst Housing To The Gearbox

Attaching The Hst To The Engine

Hydrostatic Transmission

Charge Pump

Port Block

Cylinder Block Assembly

Motor Swash Plate

Input And Output Shaft

Pump Swash Plate

Port Block

Piston

Charge Pump

Swash Plate

Pump Shaft (Input Shaft)

Charge Pump

Cylinder Block Assembly For Pump

Motor Shaft

Cylinder Block Assembly For Motor

Assembly For Motor

Port Block

Hydrostatic Transmission

Check Valve

Gearbox

Gearbox Identification

Hi/Lo Solenoid Valve

Adapter Block

Cruise Control

Electromagnet Air Gap Adjustment

Hst Pedals

Stop Adjustment

Hst Cruise Control Magnet

Hst Foot Control Pedals

Neutral Adjustment

Hst Pedals Return Spring - – Power TakeOff (Pto) Systems

Pto Hydraulic System

Pto Clutch

Metric Bolt Torque Specifications

Rear Pto

Power Flow Diagram For The X Synchronized Shuttle Shift Transmission

Power Flow Diagram For The Hydrostatic Transmission (Hst)

Power Flow Diagram For Tractors Equipped With A Mid Pto Kit

Hydraulic Fluid Flow

Pto Clutch Assembly

Pressure Testing

Test Procedure

Pto System Diverter Valve Assembly

Pto Clutch Control Valve (Bsn)

Clutch Control Relief Valve

Pto Clutch Control Valve (Asn)

Pto Clutch

Pto System System For X Synchronized Shuttle Shift Transmission

Pto Input Shaft

Pto Countershaft And Rear Pto Shaft

Countershaft

Pto System For Hydrostatic Transmission (Hst)

Pto Input Shaft

Pto Countershaft And Rear Pto Shaft

Disassembly

Mid Pto Countershaft And Drop Box - – Brakes

Specifications

Bolt Torque Specifications

Description of Operation

Brakes

Parking Brake

Overhaul

Brakes

Removal and Disassembly

Inspection

Assembly and Installation

Adjustment - – Hydraulic System

Flow Priority

Hydraulic System

Hydraulic Fluid Filter

Combination System Relief Diverter Valve Manifold Assembly

Control Valve Assembly (Hpl)

Fluid Flow

Neutral Position

Raising Position

Lowering Position

Bypass SpoolFluid Flow

Closed Position

Open Position

Flow Control Valve

Single Lever Position Control

Neutral Position To Raise

Raise Position To Neutral Position

Neutral Position To Lowering Position

Dual Lever Position Control (Draft Control)

Top Link Sensing Raise

Top Link Sensing Lower

Varying Draft Control Settings

Combining Position And Draft Control Settings

Pressure Testing

Main System Relief Valve

Inlet Restriction

Pump Efficiency

Lift Cylinder

Flow Control Valve

Hydraulic Control Valve

Combination System Relief And Diverter Valve Assembly

Pto System Diverter Valve

Hpl Linkage

Control Lever

Description Of OperationHydraulic Pump And Filter

Hydraulic Pump And Filter

Hydraulic Pump

Sump Tube And Screen Filter

Remote Valves

Rear (SingleSpool) Remote Valve

Front (DoubleSpool) Remote Valve

Rear (SingleSpool) Remote System

Fluid Flow

Remote Cylinder Extending

Remote Cylinder Retracting

Front Remote (Two Spool) Loader Control Valve Fluid Flow Diagrams

Bucket Control

Neutral/Lift Control Neutral

Dumping/Lift Control Neutral

Dumping Regen/ Lift ControlNeutral

Roll Back/Lift Control Neutral

Neutral/Lift Control Raising

Neutral/Lift Control Lowering

Neutral/Lift Control Float

Rear (SingleSpool) Remote Valve

Front (Double Spool) Remote Valve - – Steering

Supersteert

Power Steering Control Motor

Spool And Sleeve

Rotor And Fixed Ring

Check Valve

Drive Shaft

Pressure Relief Valve

Power Steering Pump

Steering Cylinders

Wd And Standard Wd

Supersteert

Fluid Flow Neutral Position

Fluid Flow Left Turn

Fluid Flow Right Turn

Manual Operation

Power Steering Operation

Fluid Flow Neutral Position

Fluid Flow Left Turn

Fluid Flow Right Turn

Manual Operation

Troubleshooting

Pressure Testing

Pump, Steering Motor, And Relief Valve

Test Results

Steering Cylinder

Test Results

Lubrication

Lubricate EveryHours

Steering Control Motor

Steering Cylinder

Pump And Reservoir Tank

Pump Installation

Power Steering Tubes - – Front Axle

- – Climate Control

Refrigerant

Refrigerant Oil

Low Pressure Switch

High Pressure Switch

Compressor

Condenser

Evaporator

Expansion Valve

Receiver/Drier

Heater

Heater System

Hvac Control Panel

Cab Air Filter

Cleaning Cab Air Filter

Compressor Protection Switches

HighPressure Cutout Switch

LowPressure Cutout Switch

Component Location

Cab And Engine Bay

Cab Roof

Troubleshooting

Expansion Valve Testing

Temperature/Pressure Chart

Service Precautionary Statements

Leak Testing

Refilling

Contaminants

Preventing Mixing Of Service Equipment

Refrigerant Extraction And Recycling Equipment

Using Extraction Equipment

Using Recycling Equipment

Recycling Vs Reclaiming

Containment Of Air Conditioning Refrigerants

Recovery

Flushing

Recharging/Refilling

Using A Manifold Gauge Set

Checking Refrigerant For Excess Air

Containers For Storing Recycled Refrigerant

Disposal Of Empty Or NearEmpty Disposable Containers

Applicable Sae Standards

Related Sae Standards

Manifold Gauges And Interpretations

Performance Test Examples

Evacuating The Refrigerant

Vacuum Test

Pressure Test

Leakage Test

Charging

Belt Replacement

Hvac Controls

Heater Valve

Condenser

Receiver/Drier

Evaporator/Heater Core Replacement

Expansion Valve

Temperature Sensor

Blower Motor/Blower Motor Resistor

Low Pressure Switch

High Pressure Switch

A/C Compressor

Compressor Assembly Torques

Compressor Breakdown

Clutch Breakdown

Compressor Repaired Internally And Reinstalled In The System

Sanden Compressor Replaced By A New Sanden Compressor

Of The Same Type

Clutch Head Repair

Keyed Shaft Armature Removal

Rotor Assembly Removal

Field Coil Assembly Removal

Field Coil Assembly Installation

Rotor Assembly Installation

Armature Assembly Installation

Replacement Of Shaft Seal

Cylinder Head Removal

Valve Plate Removal

Valve Plate And Cylinder Head Installation - – Electrical

Wiring Harnesses

Grounds

Electrical System Components

Battery

Checking The Electrolyte Level

Main Fuse

Fuse Block

Key Switch

Terminal Identification

Stop Position (Not Shown)

Heat/ Accessory/ Run Position

Start Position

Light Switch (Road Lights)

Terminal Identification And Testing

Work Light Switch

Forward Position On

Headlight

Taillight

Hazard Light Switch

Off Position

On Position

Transmission Range Safety Switch (Hst And Gear)

Extended Position

Retracted Position (Not Shown)

Rear (Main) Pto Safety Switch

Testing

Extended Position

Retracted Position

Mid Pto Safety Switch (Optional For Da, Da, And Da Models Only)

Seat Safety Switch

Parking Brake Safety Switch

Relays

(Da) Series Relay Panel Identification

(A) Series Relay Panel Identification

TestingMicro Relays

Hi, Low, Cruise Control, Fuel Shutoff, Pto Safety, And Glow Plug Lamp Relays

Headlight And Neutral Start Relays

Glow Plug Power Relay

Diodes

Module Testing

Diode Testing

Operator Safety Module

Glow Plug Timer

Testing

Engine Glow Plugs

Hazard Flasher/Turn Signal Control Module

Fuel Level Sending Unit

Fuel Shutoff Solenoid

Engine Oil Pressure Switch

Engine Coolant Temperature Sending Unit

Hi/Low Transmission Range Switch

Optional Testing

Hi/Low Transmission Range Solenoid

Removal

Electric Cruise Control Switch (Hst)

Cruise Control Magnet (Hst)

Cruise Control Brake Release Switch

Extended Position (Not Shown)

Retracted Position

Complete Wiring Schematic

Safety Start Circuit (Operator Present)

Safety Start Circuit (Operator Not Present)

Safe Operation Circuit (Operator Present)

Safe Operation Circuit (Operator Not Present)

Glow Plug Circuit

Road Lights Circuit

Work Lights Circuit

Hazard Flasher Circuit

Right Turn Signal Circuit

Left Turn Signal Circuit

Pto Indicator Light Circuit

Engine Coolant Temperature Circuit

Engine Low Oil Pressure Indicator Light Circuit

Fuel Level Circuit

Parking Brake Indicator Light Circuit

Tachometer Circuit

Auxiliary Power Socket Circuit

Cruise Control Circuit (Hst Transmission)

Hst Range Low Shift Circuit

Hst Range High Shift Circuit

Charging Circuit

Component Operation And Servicing

Instrument Panel

Component Testing And Replacement

Fuel Gauge

Temperature Gauge

Tachometer

Instrument Panel Indicator And Illumination Lights

Bulb Identification Chart

Bulb Replacement

Alternator Specifications

Alternator Troubleshooting

Charging System

Alternator

Description Of Operation

Charging Circuit

Principle Of Ic Regulator

Preliminary Alternator Tests

Alternator Drive Belt

Alternator Output

Alternator Removal

Alternator Disassembly

Alternator Component Testing And Inspection

Stator

Rotor

Rectifier Assembly

Alternator Brushes

Alternator Bearings

Drive Pulley

Alternator Frames

Alternator Bench Check

Starter Motor Specifications

Starter Motor Troubleshooting

Starting System

Description Of Operation

Starter Components

Starter Motor Assembly

Starter Solenoid

Pinion Clutch

Armature

Brush Holder

Field Coil

Starter Solenoid

Assembly

No Load Test

Grounds

Electrical System Components

Battery

Checking The Electrolyte Level

Main Fuse

Fuse Blocks

Key Switch

Terminal Identification

Stop Position (Not Shown)

Heat/ Accessory/ Run Position

Start Position

Multifunction Stalk Switch (Lights, Turn Signals, Horn)

Switch Testing

Work Light Switch

Forward Position On

Installation

Headlight

Taillight/Rear Flasher Light

Front Flasher Warning Light/Turn Signals

Cab Work Lights

Hazard Light Switch

Off Position

On Position

Transmission Range Safety Switch

Extended Position

Retracted Position (Not Shown)

Rear (Main) Pto Safety Switch

Extended Position (Pto On)

Retracted Position (Pto Off)

Mid Pto Safety Switch (Optional)

Extended Position

Retracted Position

Seat Safety Switch

Parking Brake Safety Switch

(Da) Series Relay Panel Identification

TestingMicro Relays

Hi, Low, Cruise Control, Fuel Shutoff, Pto Safety, Glow Plug Lamp,

Flasher Cutoff, Park Brake Interface, Front Work Lights, And Hvac Relays

Headlight, High Beam, Neutral Start, And Cab Power Relays

Replacement

Glow Plug Power Relay

Installation (All Relays)

Diodes

Module Testing

Diode Testing

Operator Safety Module

Park Brake Safety Alarm (Buzzer)

Glow Plug Timer

Engine Glow Plugs

Hazard Flasher/Turn Signal Control Module

Fuel Level Sending Unit

Fuel Shutoff Solenoid

Engine Oil Pressure Switch

Engine Coolant Temperature Sending Unit

Hi/Low Transmission Range Switch (Hst)

Optional Joystick Switch Testing

Hi/Low Transmission Range Solenoid (Hst)

Electric Cruise Control Switch (Hst)

Cruise Control Magnet (Hst)

Cruise Control Brake Release Switch (Hst)

Extended Position

Retracted Position

Cab To Tractor Harness Main Connectors

Electrical Schematic Diagram

Safety Start Circuit (Operator Present Or Not Present)

Safe Operation Operator Present Circuit

Safe Operation Operator Not Present Circuit

Safety Alarm Circuit (Key Off And Park Brake Off)

Safety Alarm Circuit (Key On, Rear Pto On, Operator Not Present And Park Brake On)

Safety Alarm Circuit (Key On, Rear Pto On, Operator Not Present And Park Brake Off)

Glow Plug Circuit

Headlights Circuit (Position, Low And High Beams)

Front Work Lights Circuit

Cab Work Lights Circuit

Interior Cab Lights Circuit

Hazard Flasher Lights Circuit

Right Turn Signal Circuit

Left Turn Signal Circuit

Hvac Circuit

Auxiliary Power Socket Circuit

Front And Rear Wiper Circuit

Horn Circuit

Cruise Control Circuit (Hst Transmission)

Hst Range Low Shift Circuit

Hst Range High Shift Circuit

Charging Circuit

Pto Indicator Light Circuit

Park Brake Indicator Light Circuit

Engine Coolant Temperature Circuit

Engine Low Oil Pressure Indicator Light Circuit

Fuel Level Circuit

Tachometer Circuit

Beacon Circuit

Radio Circuit

Component Operation And Servicing

Component Testing And Replacement

Temperature Gauge

Replacement

Tachometer

Testing

Proof Meter (Hour Meter)

Instrument Panel Indicator And Illumination Lights

Bulb Identification Chart

Bulb Replacement

Alternator Specifications

Alternator Troubleshooting

Charging System

Description Of Operation

Charging Circuit

Principle Of Ic Regulator

Preliminary Alternator Tests

Alternator Drive Belt

Alternator Output

Alternator Removal

Alternator Disassembly

Alternator Component Testing And Inspection

Stator

Rotor

Rectifier Assembly

Alternator Brushes

Alternator Bearings

Drive Pulley

Alternator Frames

Assembly

Alternator Bench Check

Installation

Starter Motor Specifications

Starter Motor Troubleshooting

Starting System

Description Of Operation - – Platform

Hood

Rear Hood Side Panels

Dash Console

Seat

Rops

Fuel Tank

Fenders

Deck

Hood

Rear Hood Panels

Dash Console

Operator Seat

Front Wiper Motor

Washer Tank

Rear Wiper Motor

Door Handle And Latch

Door Striker

Cab Door

Cab Rear Window

Fuel Tank

Fenders

Cab

What you get

You will receive PDF file with high-quality manual immediatly after the payment.

Reviews

There are no reviews yet